YLS is a leading Flexible Flat Cable (FFC) manufacturer, offering 0.5mm, 1.0mm, 1.25mm pitch FFC solutions with 4–114 pins. Customizable with shielding, folding, cutouts, labels, and more. Fast prototyping in 72h.

Explore our full range of Flexible Flat Cables (FFC) including Standard, LVDS, DF9, Module, NB, and Light Strip types. Pitch options from 0.3mm to 1.25mm. Custom designs available.

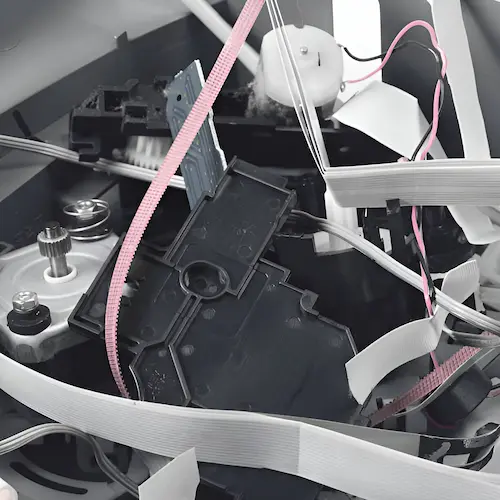

Printers, TVs, washing machines, office devices

Smartphones, tablets, LCD monitors, VR/AR devices

EV batteries, infotainment, camera ADAS, LED lighting

Medical imaging, industrial control, high-speed data lines

Wearables, sensors, compact modules, drones

4K displays, medical devices, test equipment, AI cameras

Discover how YLS Flexible Flat Cables power drones, robots, EVs, medical and smart home devices with reliable, space-saving, and custom interconnect solutions.

Drones demand ultra-lightweight and durable cable systems to support rapid movement, tight spaces, and high EMI environments.

With over 10 years of experience in supplying drone OEMs, YLS understands the importance of ultra-flexible, lightweight FFCs that handle vibration, frequent bending, and compact routing. We support drone manufacturers with pitch options down to 0.4mm and custom folding and shielding.

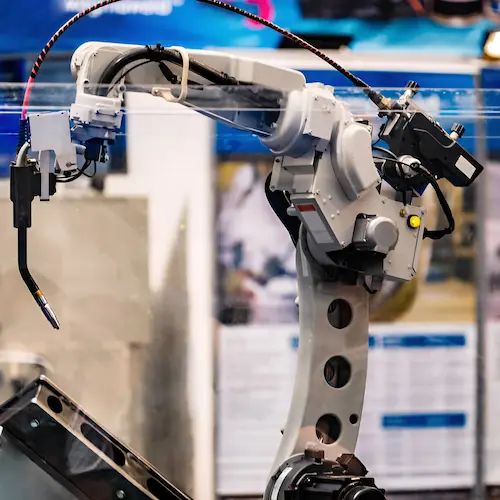

Robotics require high-cycle, bend-resistant cables for arms, joints, and control systems.

Robotic arms and automated platforms demand cables that can flex thousands of times without degradation. We address failure from fatigue and EMI that causes positional errors by engineering FFCs with proven flex‐life testing and robust shielding solutions.

Safe, compact wiring for diagnostic and wearable devices

Medical OEMs rely on precision cabling with zero-failure tolerance. We supply ISO-compliant FFC cables to ultrasound, imaging, and wearable device manufacturers with full traceability.

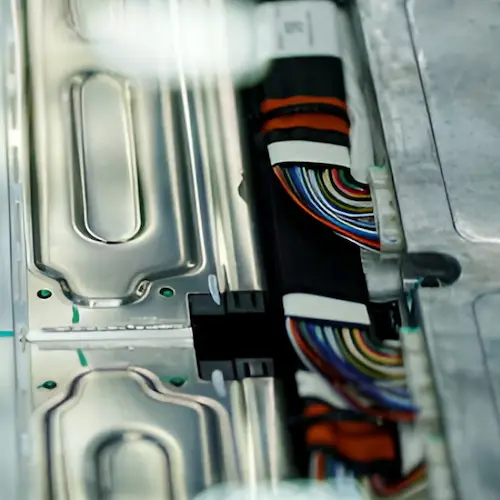

Smart home devices demand space-efficient, low-profile interconnects for displays, sensors, and embedded systems.

Smart home devices demand discreet, thin‐profile cabling behind walls or inside slim modules. We solve clutter and EM interference issues so sensors, controllers, and touchpanels remain reliable over Wi-Fi and Zigbee networks without bulky harnesses or signal dropout.

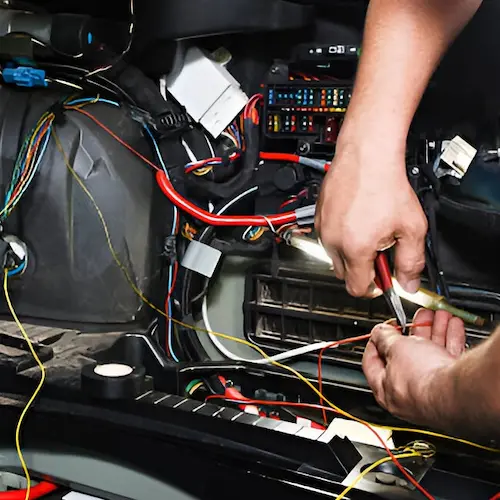

Temperature extremes, vibration resistance, EMI shielding

Automotive harness segments face subzero starts, high underhood heat, and constant vibration. We understand key pain points—cable fatigue and signal noise—by supplying automotive-grade FFCs that resist wide temperature ranges, block EMI from engine electronics, and extend harness life.

Battery packs, BMS, and inverter systems require stable signal/power transmission in high-vibration, high-temperature conditions.

YLS’s FFCs are tailored for energy storage integrators, offering flame-retardant insulation, strong temperature resistance (up to 125°C), and multi-core signal/power lines in one compact form. Used in over 100 ESS projects globally.

Today’s consumer electronics demand compact, lightweight, and high-performance cable solutions.

YLS FFC cables are engineered to fit the slim profiles and dynamic functions of modern devices—like smartphones, smartwatches, earbuds, and wearables.

We offer ultra-thin options as low as 0.5mm thickness, support high-pin count signal routing, and deliver in volumes that scale with your brand.

Base stations, antenna modules, and RF devices need shielded, high-bandwidth cables.

YLS provides custom FFCs with EMI shielding and high signal integrity for telecom applications. Trusted by communication device OEMs in 15+ countries.

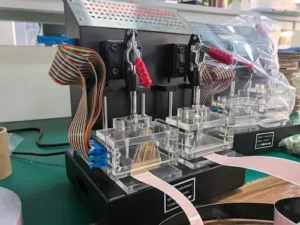

Yulian is a direct manufacturer of flat flexible cables (FFC), delivering precision wiring solutions trusted by global OEMs. With in-house tooling, rapid prototyping, and full customization capabilities, we help you go from concept to cable—fast, reliable, and to your spec.

We offer pitch options from 0.4mm to 1.25mm and core counts up to 96, with full support for folding, shielding, notching, punching, labeling, and custom assembly.

We deliver tailored flat flexible cable and wire harness solutions—from pitch and conductor customization to full engineering support, OEM manufacturing, and industry-specific optimization.

Complete Technical Parameters for High-Quality Flexible Connection Solutions

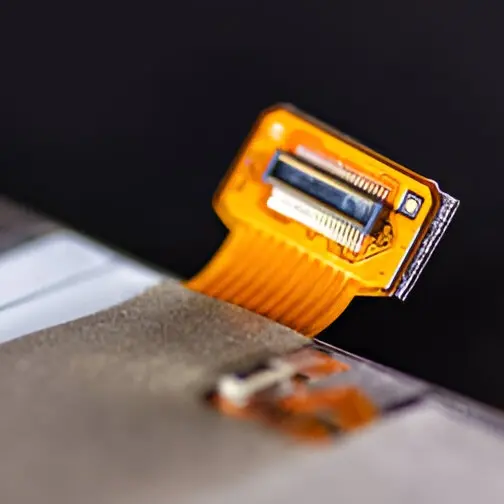

Flat flexible cable (FFC) is a cable with flat and strong conductors primarily used in high-density electronic devices such as Notebooks and TVs. It usually consists of a thin film substrate and multiple metallic conductors, which have a smaller size, better EMI/RFI rejection, and higher flexibility compared to traditional circular cables. FFC cables take up less space than circular cables, providing better protection against electromagnetic interference and eliminating crosstalk problems. In addition, one end of the cable is often reinforced to facilitate insertion and provide strain relief, making FFC cables ideal for high-end applications.

FFC and FPC cables differ in their intended applications and connection methods. FFC (Flexible Flat Cable) is a versatile electrical cable known for its flat and flexible nature. On the other hand, FPC (Flexible Printed Circuit) is a specific type of connector designed to link FPCs and PCBs (Printed Circuit Boards). The primary distinction is that FFCs are flexible, flat cables that excel in space efficiency and flexibility compared to round cables. In contrast, FPCs serve as connectors for the direct insertion of FPCs, although they can also connect with FFCs if necessary.

10+ years in FFCs means we know your needs. Partner with us for profitable, high-quality FFC solutions.

+86 137 36386818

inquiry@ylscable.com