When deciding between an ffc vs fpc connector, consider what your project requires most. Here are some key factors to keep in mind:

- Space constraints: An FPC connector is ideal for tight or irregular spaces.

- Electrical performance: FPC connectors excel in complex, multi-layer circuits, while FFC connectors are better suited for simpler designs.

- Cost: FFC connectors generally cost less for basic connections.

- Durability: FPC connectors offer greater flexibility and durability in challenging environments.

Understanding these differences makes it easier to choose the right option when comparing ffc vs fpc connectors.

Key Takeaways

- FFC connectors work well for easy and cheap projects. They use flat cables and do not bend much.

- FPC connectors are good for small spaces. They bend easily and are great for tricky, flexible designs.

- Think about space, price, strength, and power needs before you pick a connector.

- Try out connectors in your device first. Use a checklist to help you not make mistakes and to save time.

- Pick FPC connectors for things that move or fold a lot. Use FFC connectors for things that stay still.

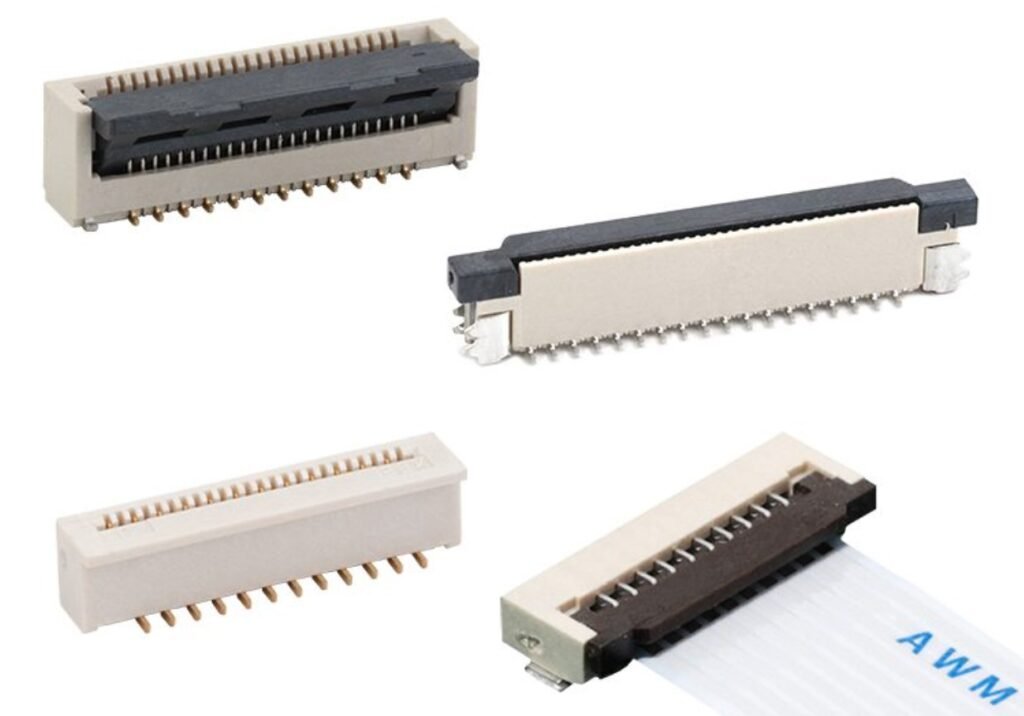

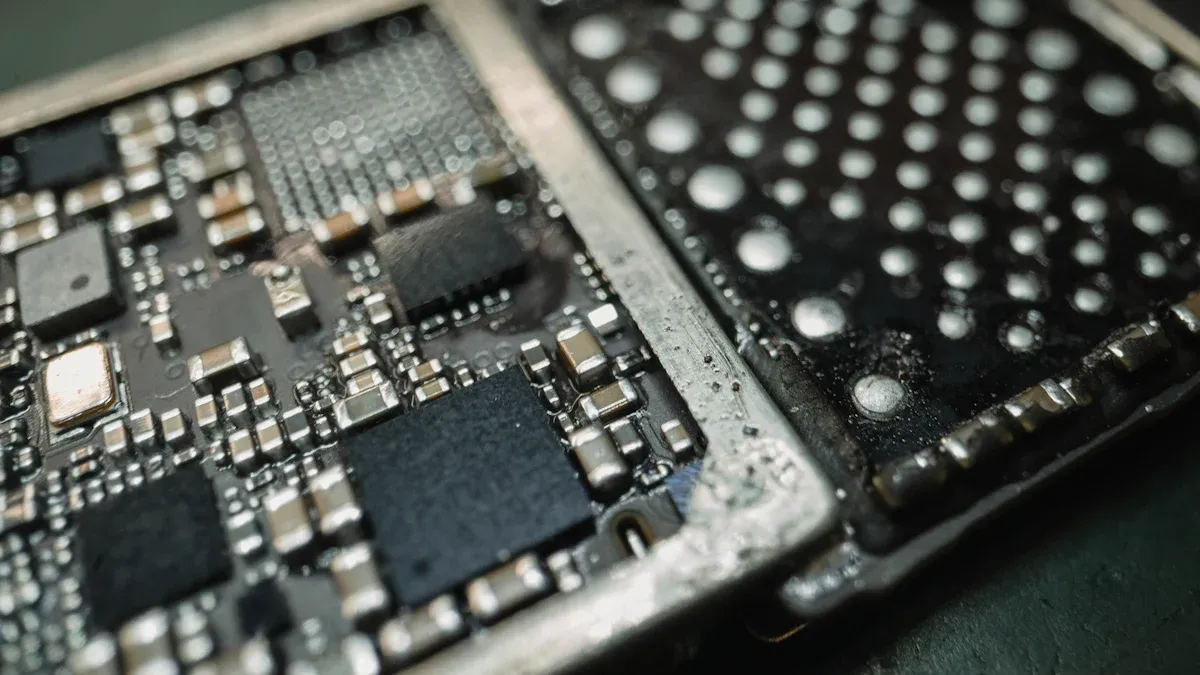

ffc/fpc connectors

What Are FFC Connectors

Ffc connectors are used in devices that need simple connections. They work with a flexible flat cable that looks like a ribbon. This cable has straight lines inside it. You can use ffc connectors for things like displays, printers, or laptops. There are different types of these connectors. Type A has plates on both ends to make it stronger. Type B has a plate on the tape for a small change. Types C and D have plates on the conductor for more strength. Type E is a mix, with one end soldered. Type F lets you peel off part of the plate to connect easier. Type G is good for direct soldering. You can pick different pitches like 0.3mm, 0.5mm, or 1mm. You can also choose how many contacts and the length you need. Ffc connectors help you make cheap and strong connections with flat cables.

What Are FPC Connectors

Fpc connectors work with flexible printed cable or circuit boards. You use them when you need to connect circuits in small or tricky spaces. Fpc connectors can bend or twist and not break. They are found in things like smartphones, cameras, and medical devices. These connectors handle more advanced electrical jobs than ffc connectors. There are many types of fpc connectors for different uses. Fpc connectors are very strong and can fit lots of circuits in a small space. They help you save space and make your project work better.

Key Differences

It is important to know the main differences between ffc and fpc connectors. Ffc connectors use flat cables with straight lines inside. Fpc connectors work with flexible circuit boards and can be shaped in many ways. Ffc connectors cost less and are good for simple jobs. Fpc connectors are better for tough and flexible designs. The choice depends on your project’s space, cost, and how well it needs to work. Use ffc connectors for easy and cheap tasks. Use fpc connectors for projects that need to be strong and flexible.

Tip: Always look at the pitch, number of contacts, and reinforcement before picking a connector.

| Feature | FFC Connectors | FPC Connectors |

|---|---|---|

| Cable Type | Flat flexible cables | Flexible printed cable |

| Structure | Simple, straight lines | Complex, multi-layer |

| Cost | Lower | Higher |

| Flexibility | Moderate | High |

| Durability | Good | Excellent |

| Application | Displays, printers | Phones, cameras |

ffc vs fpc connector

Structure and Thickness

When you look at ffc and fpc connectors, you see they are built differently. Ffc connectors use flat cables. These cables have copper wires and PET plastic. Ffc cables are thick. They measure from 0.5mm to 2.54mm. Fpc connectors are made another way. Makers put copper on a flexible polyimide base. They use layers to make it thin. Fpc cables are much thinner. They are only 0.15mm to 0.2mm thick. Fpc connectors fit in small spaces. Ffc connectors are too thick for tight spots.

| Feature | FFC (Flexible Flat Cable) | FPC (Flexible Printed Circuit) |

|---|---|---|

| Thickness Range | 0.5mm to 2.54mm | 0.15mm to 0.2mm |

| Material Composition | Laminated PET with copper wires | Etched copper on polyimide FCCL, often multilayered |

| Manufacturing Process | Simple lamination | Etching and multilayer lamination |

| Resulting Properties | Thicker, more robust | Thinner, more flexible, fits tighter spaces |

| Connector Compatibility | Only with FFC cables | Works with both FPC and FFC cables |

Pick an ffc connector if you want a strong, thick cable. Choose an fpc connector if you need something thin and bendy.

Cost and Production

Cost and how hard it is to make the connector matter a lot. Ffc connectors are cheaper to make. The process is easy. Makers put copper wires between PET layers. This keeps costs low. You can buy ffc connectors for $0.01 to $0.10 each. Some fancy ones cost more, but most are cheap.

Fpc connectors are harder to make. Makers coat copper on a flexible base. They etch tiny paths for electricity. They add layers to protect the cable. This makes fpc connectors cost more. Fpc connectors usually cost $0.02 to $0.10 each. Special fpc connectors can cost much more.

| Connector Type | Typical Price Range (High-Volume Orders) | Notes |

|---|---|---|

| FFC Connectors | $0.01 – $0.10 per unit | Some premium models up to $0.20+ |

| FPC Connectors | $0.02 – $0.10 per unit | Price depends on pitch, pin count, features |

Note: If you want the lowest price and easy making, pick ffc connectors. If you need special shapes or features, fpc connectors are better but cost more.

Electrical Performance

How well the connector works with electricity is important. Both ffc and fpc connectors can handle similar currents and voltages. You can use them for low or medium power. Most work for less than 1A up to 5A. Some special connectors can handle up to 12A. Both types send signals well at normal speeds.

Fpc connectors do better with high-speed signals. They have features like shielding and impedance control. This helps them work in phones and machines that need fast data.

| Metric | Value | Notes |

|---|---|---|

| Power Contact Rating | 12A total (6A per pos.) | Suitable for power line connection |

| Signal Contact Capacity | 0.5A | For signal transmission |

| Rated Voltage | 50V AC/DC | Maximum voltage rating |

| Contact Pitch | 0.5mm | Standard pitch for FFC/FPC connectors |

| Operating Temperature | -40°C to 85°C | Typical operating range |

- Ffc connectors are good for simple signals.

- Fpc connectors are better for fast and complex signals.

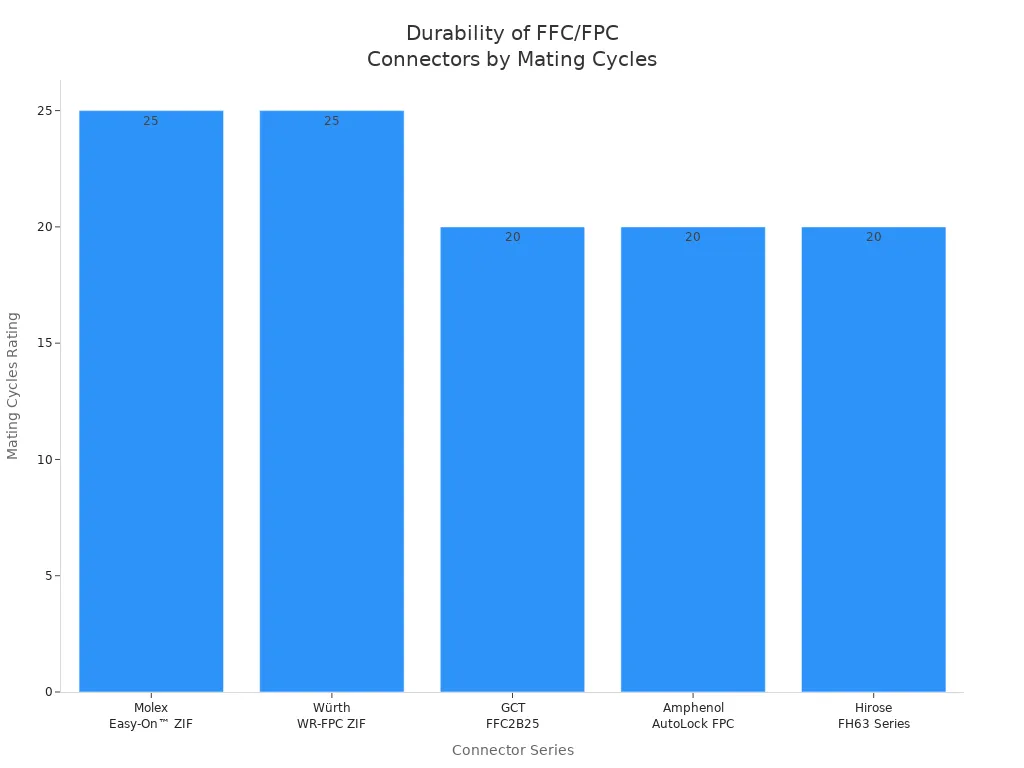

Flexibility and Durability

How much the connector bends and lasts is different for each type. Ffc connectors are thick and not very bendy. You can bend them a little. They do not like tight curves or lots of bending. Fpc connectors bend a lot. You can fold them over 100,000 times. They do not break easily. Fpc connectors are great for things that move or fold.

| Attribute | FFC Connectors | FPC Connectors |

|---|---|---|

| Flexibility | Simple bends; thicker, less flexible | Highly flexible; fits tight spaces, complex bends |

| Bend Cycles | Lower endurance | Over 100,000 bends possible |

| Materials | PET insulation, flat copper wires | Polyimide or polyester with copper traces |

Both connector types last a long time. They can handle heat, cold, and shaking. Fpc connectors last longer in things that move a lot.

Application Suitability

Pick the connector that fits your device. Ffc connectors are best for simple, strong connections. You find them in printers, displays, and laptops. They work well where space is not a problem.

Fpc connectors are good for thin, bendy, and tricky designs. You see them in phones, tablets, and cameras. They are also used in cars, medical tools, and machines. Fpc connectors fit in small spaces and can move a lot.

- Ffc connectors: printers, displays, laptops, home appliances, car screens.

- Fpc connectors: phones, tablets, cameras, smartwatches, car dashboards, medical devices.

Tip: Think about space, movement, and how hard your project is before you pick a connector. The right connector helps your device work better and last longer.

Decision Guide

Assessing Project Needs

Start by thinking about what your project needs. Think about space, cost, how well it works, and how long it will last. Here is a simple guide to help you pick the right connector:

- Count how many circuits you need. Check the pitch and plating so the connector fits your cable.

- Measure the cable length. Look at how far apart the parts are.

- Choose the contact direction. Type A connectors have contacts on the same side. Type D connectors have contacts on different sides.

- Decide how much the cable will bend or move. If your project needs lots of bending, pick a thin cable with a long flex life, like an fpc connector.

- Test some cables. Try them in your device to see if they work well and last.

Tip: Leave some extra cable for easy movement. This helps stop stress and damage. Place cables so they bend the right way. Attach cable ends to strong parts for more strength. Cover copper traces with coatings to stop wear.

Think about where your project will be used. If it faces heat, shaking, or water, pick a connector that can handle these things. Use good strain relief and ways to end the cable to make it last longer.

Here is a table to help you compare space and environment needs:

| Factor | FFC Connectors | FPC Connectors |

|---|---|---|

| Space Constraints | Good for simple routing in tight spaces | Best for compact, irregular, or very tight areas |

| Environmental Factors | Handles moderate heat; polyimide FFCs are better | Works in high temperature, chemicals, and strain |

Matching Connector Features

Match connector features to your project’s needs for the best results. Look at size, strength, and how much electricity it can handle. For cable-to-board jobs, fpc connector types are very flexible and fit in small spaces. Ffc connectors are good for simple, strong connections.

- Header connectors are small and easy to use. You can put them on or take them off fast. They save space and are good if you change parts a lot.

- Terminal blocks are strong and flexible. You can connect wires without solder. These are great for big projects with lots of power.

- Wire-to-board connectors give safe and steady connections for power, data, and sensors. They work for many uses.

- Specialty connectors, like screw-type or modular connectors, help in tough jobs or when you want easy upgrades.

- High-Speed Data connectors move data fast. They can handle shaking, heat, and water. Use them for USB 3.0 or Ethernet.

When you pick a connector, think about these things:

- Size and space: Small connectors fit tight PCBs. Big ones work for large boards.

- Strength and dependability: Pick connectors with locks or strong materials for tough places.

- Electrical standards: Make sure the connector fits your system’s needs.

- Upgradeability: Pick connectors that let you make your project better later.

- Ease of use: Plug-and-play or screw terminals make building and fixing easier.

Look for things like impedance matching and EMI shielding if your project needs fast or clean signals. Waterproof ratings help in outdoor or wet places. For high-power jobs, pick connectors with strong contacts and good heat control.

Note: Testing samples in real life helps you find the best connector. Simulation tools can show how connectors will work before you build your project.

Checklist

A checklist helps you not miss anything when picking connectors. Use this list to make sure you check every detail:

- Make sure all parts and connectors are labeled and listed right.

- Check ESD protection on connector pins and housings.

- Look over your design for problems before making the PCB.

- Use design reviews to find mistakes and make it better.

- Make sure your design matches the first plan.

- Check that the connector footprint matches the datasheet.

- Mark polarity and pin 1 clearly to stop mistakes.

- Check pad sizes and shapes for good connections.

- Check part numbers and maker details in your BOM.

Tip: A checklist helps you find problems early. You can fix them before they cost you. Design reviews with your team make your project stronger and better.

If you follow these steps, you make better choices for your connectors. You save time, money, and avoid common mistakes. Whether you need an fpc connector for a bendy device or an ffc connector for a simple job, this guide helps you pick the right connector for your project.

fpc connectors in Applications

Common Uses

Fpc connectors are found in many things you use every day. They help make small and bendy electronics. You can see fpc connectors in smartphones, tablets, and e-readers. They connect screens, cameras, batteries, and buttons in tight spots. Fpc connectors are also used in cameras and touchscreens. Wearable devices like smartwatches and fitness trackers use them. This is because fpc connectors fit into small and flexible designs.

Fpc connectors are important in cars and factories. In cars, they connect front cameras, LiDAR, radar, navigation, and audio systems. These connectors can handle heat and move data fast. Factories use fpc connectors for strong and steady connections in tough places.

Here is a table that shows where fpc connectors are used:

| Sector | Common Applications |

|---|---|

| Consumer | Smartphones, tablets, cameras, wearables, LCD displays |

| Automotive | Infotainment, dashboards, ADAS, LiDAR, radar, navigation, audio systems |

| Industrial | Machinery, equipment needing durability and reliability |

Fpc connectors save space, work well, and are easy to put in. You can bend or twist them and they will not break. This makes fpc connectors great for new electronics.

How to Use a FPC Connector

You need to be careful when putting in or changing an fpc connector. If you want to know how to use a fpc connector, start by getting the right tools. You need a small soldering iron, solder wire, flux, tweezers, and anti-static gear. Turn off your device before you start.

To put in the connector, clean the PCB and line up the fpc connector with the pads. Hold the connector so it does not move. Solder one corner pin first to keep it still. Then solder the other pins. Look at each solder joint with a magnifier. Test the connection by turning on the device.

If you want to know how to solder a fpc connector, keep your hand steady and watch the heat. Do not let solder touch more than one pin. Always check for mistakes after you finish.

Sometimes you need to take off a broken connector. If you want to know how to remove a fpc connector, use gentle heat from a hot air tool. Use tweezers to lift the connector off. Clean the pads with desoldering wick and alcohol. Put the new fpc connector in place and solder it carefully.

Here is an easy step-by-step guide:

- Turn off and unplug the device.

- Clean the PCB pads.

- Line up the fpc connector with tweezers.

- Solder one pin to hold it.

- Solder the rest of the pins.

- Check and test the connection.

Good habits help you get strong results. Use ZIF connectors if you need to connect and disconnect often. Make sure things line up right. Add strain relief to stop damage from pulling. Pick fpc connectors with the right features for your project.

Tip: Always follow IPC-6013 rules for plating and ratings. This keeps your fpc connector safe and working well.

Examples

FFC Connector Projects

You can find ffc in lots of things you use. These connectors help make flat and strong links. Here are some real projects that use ffc:

- A company made a portable imaging system better by using a custom ffc instead of round cables. This change fixed problems with air flow, EMI, and size. The new ffc design became the main choice for all later models.

- Laptops use ffc to link the keyboard, touchpad, and screen. This gives a thin and bendy connection that fits inside a laptop.

- Cameras often use ffc to join the image sensor to the main board. This keeps the camera small and light.

- Printers use ffc for moving parts and sending signals. You can see these flat cables between the print head and the control board.

- Medical imaging devices use ffc connectors for light and bendy wires. This helps get clear pictures without big cables.

- Home appliances like washers, microwaves, and dishwashers use ffc for control panels and screens.

- Aerospace avionics projects use ffc connectors because they work well in hard places.

Tip: If you need a flat, easy, and strong cable, ffc connectors are a good pick.

FPC Connector Projects

You see fpc in many high-tech electronics. These connectors let you make thin, bendy, and tricky circuits. Here are some projects where fpc connectors are great:

- Smartphones use fpc to link the screen, camera, and battery. This gives you a slim phone that can bend a bit and not break.

- Tablets and e-readers use fpc for touchscreens and buttons. The bendy design lets you add more features in a small space.

- Wearable devices like smartwatches and fitness trackers use fpc connectors. You get a device that wraps around your wrist and still works well.

- Car dashboards use fpc for screens and sensors. The bendy circuits fit into curved spaces and handle shaking.

- Medical devices use fpc for sensors and imaging tools. You get good readings from a small, bendy device.

- Industrial robots use fpc connectors for moving joints and arms. The cables bend and twist many times and do not break.

Note: Fpc connectors help you make devices that are small, light, and bendy. You can trust them in projects that need to move or fit in tight spaces.

Picking between FFC and FPC connectors depends on your project. You need to think about space, cost, and how well it works. Look at the table below to see what matters most:

| Factor | What to Think About |

|---|---|

| Connector Type | ZIF, LIF, Non-ZIF |

| Pitch Size | 0.5mm, 0.8mm, 1.0mm, 2.54mm |

| Number of Contacts | Match how complex your device is |

| Current Rating | How much power you need |

| Durability | What it’s made of and how it locks |

Pick a connector that fits your project goals. This helps your team do a better job and make fewer mistakes.

- Decide what your project needs for power and strength first

- Try out connectors before you choose one

- Use a checklist every time you design

Tip: A simple guide helps you make choices faster and get better results.

FAQ

What is the main difference between FFC and FPC connectors?

FFC connectors use flat, ribbon-like cables. FPC connectors use flexible printed circuits. You choose FFC for simple, flat connections. You pick FPC when you need more flexibility and complex routing.

Can I use FFC and FPC connectors interchangeably?

You cannot always swap them. FFC connectors fit flat cables only. FPC connectors work with flexible circuits. Always check your device’s requirements before you choose.

How do I know which connector pitch to select?

You look at your cable and device. Match the pitch size to your cable’s contacts. Common pitches include 0.5mm, 1.0mm, and 2.54mm. Check your datasheet for the right size.

Are FPC connectors more durable than FFC connectors?

Yes, FPC connectors handle more bending and movement. You use them in devices that fold or flex often. FFC connectors work best in places with little movement.

Do I need special tools to install FPC connectors?

You may need tweezers, a small soldering iron, and a magnifier. Some FPC connectors use ZIF sockets, so you can install them by hand. Always follow the manufacturer’s instructions.