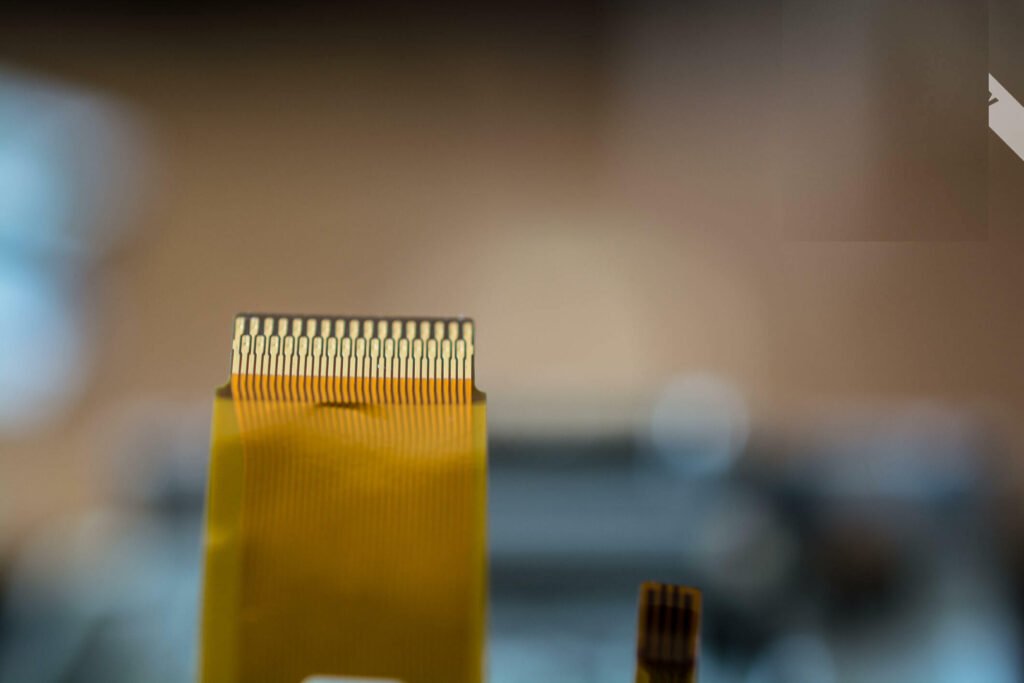

Picture a medical monitor in a hospital room. You want it to work all the time. Custom ribbon cable assemblies help make this happen. These ribbon assemblies link important parts inside electronic devices. They use flat and bendy ribbon shapes. You get high reliability and great performance, even in hard places. Custom design, careful building, and strong testing give you dependable electronic systems. Ribbon assemblies help electronics in planes, data centers, and factories. With custom ribbon assemblies, you get connections that save space and work well. These keep your devices working their best.

Key Takeaways

- Custom ribbon cable assemblies help devices work better. They keep signals strong. They protect against interference. They work well in tough places.

- Special designs and color coding make them easy to install. This helps people make fewer mistakes. They fit into complex electronics in many fields.

- Their flat and bendable shape saves space. It helps build smaller devices. It keeps devices cool and neat.

- Modular and flexible assemblies are easy to upgrade. They are simple to fix. This helps systems work well as needs change.

- These assemblies follow strict safety rules. They help move data fast. They are ready for new technology in the future.

Enhanced Reliability

Signal Integrity

Ribbon cable assemblies help your devices work well. Their flat, bendy shape keeps signals strong. This design stops signals from getting weak. Custom ribbon cable assemblies are flexible and conduct electricity well. This means signals do not drop as much. Your electronics can work better. Some ribbon assemblies have metal layers. These layers block outside interference. They keep your data safe and your signal clear. This is important for high-frequency uses.

You can pick how many conductors you need. You also choose the insulation and cable length. This lets you get exactly what you want. Customizing helps your cables work better and last longer. Bad cable choices can cause breaks or signal mistakes. Good ribbon assemblies stop these problems. You get fewer errors and better performance.

Tip: Work with engineers early. This helps you set up the right spacing and grounding. Your ribbon cable assembly will meet tough signal rules.

Environmental Protection

Ribbon cable assemblies must handle tough places. They need to survive heat, chemicals, and stress. Custom ribbon assemblies use strong materials. Some use stainless steel jackets or Teflon insulation. These materials stop crushing, rust, and heat damage. You may also see O-rings, lock-nuts, and overmolded connectors. These parts keep out water and dust. They help protect your cable assembly.

Here is a table that shows some materials used in ribbon cable assemblies and how they help:

| Material | Use in Ribbon Cable Assembly | Reliability Benefit |

|---|---|---|

| Stranded Copper | Main conductor | High conductivity, flexible, durable |

| Teflon (PTFE) | Insulation | Heat and chemical resistance |

| Stainless Steel | Jacketing, connectors | Corrosion and crush resistance |

| Silicone | Insulation | High temperature tolerance, flexibility |

| Gold Plating | Connector contacts | Corrosion resistance, strong connections |

Picking the right ribbon cable assembly helps you avoid problems. You can stop insulation cracks, bad crimps, and signal loss. These assemblies give you the strong performance you need, even in hard places.

Tailored Custom Ribbon Cable Assemblies

Complex Designs

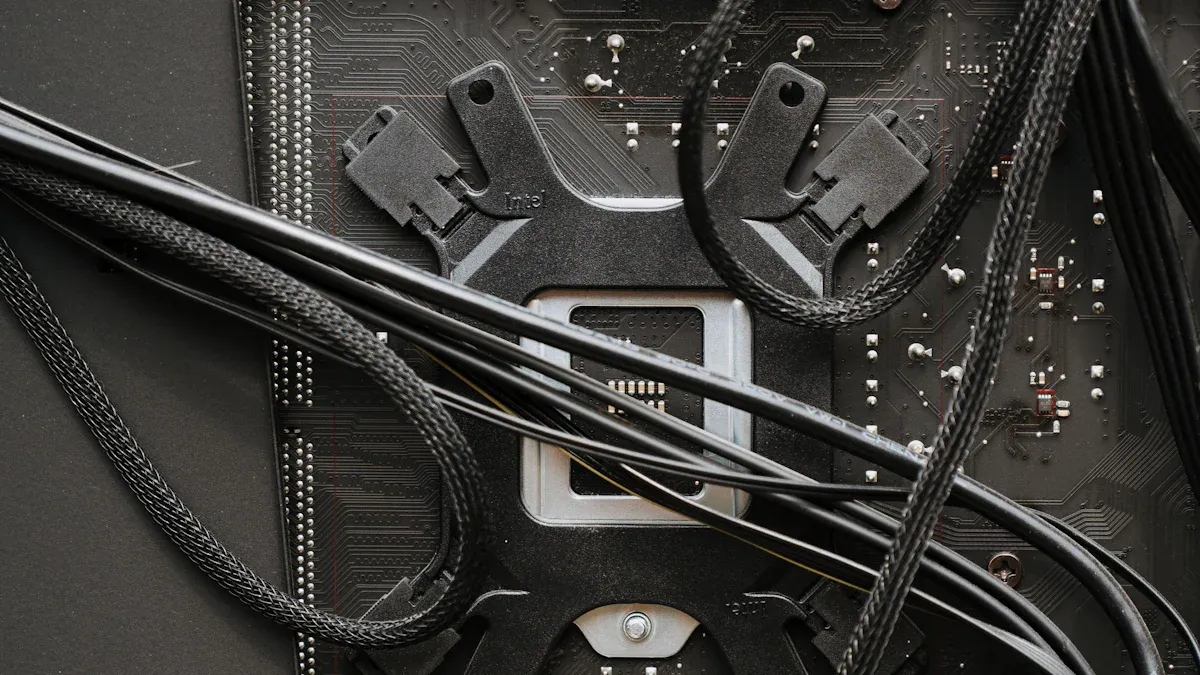

Working with complex electronics can be hard. Custom ribbon cable assemblies help you fix these problems. You need cables that fit your needs. In factories, you want cables that last and work in tough places. These cables can handle heat, shaking, and chemicals. You use them in machines and factory robots. In the military, you need cables that follow strict rules. These cables block electromagnetic and radio frequency interference. Materials like aluminized mylar and Kevlar® fillers keep your signal safe. They also protect your system. You also find these cables in cars, medical tools, and communication gear. Data centers need ribbon assemblies to move data fast. They help keep everything working. You count on custom cable assemblies for uptime and good work.

Custom ribbon cable assemblies use special design tools. You use CAD software to make the right cable. Prototyping lets you test different parts and connectors. You check if the cable works and fits right. You also test if it lasts in tough places. This helps you avoid mistakes and save money. You get cables that fit your needs and work well.

Tip: Rapid prototyping with custom ribbon cable assemblies helps you find problems early. You can change designs fast and make sure everything fits before you build the final system.

Color Coding

Color coding makes it easier to install ribbon cable assemblies. You see clear marks on each wire. The first wire often has a red stripe. This helps you put the cable in the right way. You count wires and match colors to diagrams. This stops mistakes and makes installation faster. You use color coding in many places, like data centers and the military.

Here are some ways color coding helps you:

- You find each wire fast and connect it right.

- You save time when you install or fix cables.

- You make fewer mistakes and keep cables safe.

- You follow safety rules and stop errors.

- You work faster when there are lots of wires.

Color coding also helps in big projects. IDC connectors with color coding let you connect wires fast. You do not need to strip wires or use many tools. Kits with labels make your job even easier. You spend less time learning and make fewer mistakes. In the military and government, color coding saves lots of time and money every year.

| Benefit | How Color Coding Helps You |

|---|---|

| Fast Installation | You connect wires quickly and correctly |

| Fewer Errors | You avoid wrong connections |

| Easy Maintenance | You find and fix problems faster |

| Safety | You follow safety standards |

| Cost Savings | You reduce labor and training costs |

You see color coding in all kinds of ribbon cable assemblies. This feature helps you in many jobs and keeps your systems working well.

Space Optimization

Compact Devices

You want your devices to be small and light. Custom ribbon cable assemblies help you do this. Their flat and bendy shape lets you fit many wires in tight spots. You can lay them flat or bend them around corners. This makes them great for tablets, medical monitors, and handheld tools. You save space because these cables cut down on extra wires and mess.

Custom ribbon cable assemblies also work for wire-to-board jobs. You can connect many places with just one cable. This keeps your device neat. The flat shape helps move heat away. Your device stays cooler, even when it works hard. These cables last a long time, so your small devices work longer.

Here are some ways ribbon cable assemblies help in small devices: 1. Flat, side-by-side wires use less space inside. 2. You can move cables easily in tight or tricky spots. 3. Custom choices let you pick the right length, color, and connector. 4. Color coding helps you put cables in right, even in small spaces. 5. The thin shape helps make tiny cable assemblies.

Tip: Use custom ribbon cable assemblies to make your products smaller and stronger.

High-Density Applications

Modern electronics often need lots of connections in one spot. Custom ribbon cable assemblies make this easy. Their flat, rectangle shape lets you group many wires together. You can fit up to 100 wires in one ribbon cable. This is good for computers, data centers, and factory machines.

Ribbon cable assemblies help you handle space and wiring problems. You get neat cable paths and easy setup. Mass termination with IDC connectors saves time and cuts mistakes. These cables carry both data and power in high-density spots. Your systems run well and stay neat.

Custom ribbon cable assemblies work well in high-density jobs because: – They let you route cables in a tidy way. – The flat shape keeps things slim and saves space. – You can change the cables for your special needs. – They help spread heat out to keep things cool.

You can count on ribbon cable assemblies to work well in all your high-density jobs.

System Integration

Cable Assembly Flexibility

You want your electronic systems to work well together. Modular ribbon cable assemblies help with this. These assemblies have smart designs. You can add, remove, or change cables as you need. Clips, clamps, tubing, and trays keep cables neat and easy to find. This makes it faster to install or fix things.

If you talk to engineers early, you get cables that fit your system. You can pick fast-latching or tool-less connectors. These choices save time and help stop injuries from doing the same job over and over. Modular ribbon cable assemblies work in tough places. They handle heat, shaking, and even radiation. You can fix or upgrade one cable assembly without changing everything. This helps you keep up with new technology.

Here are some flexibility features you might see in custom ribbon cable assemblies:

| Flexibility Feature Type | Description and Flexibility Aspect | Application/Benefit |

|---|---|---|

| Hybrid Ribbon Cable | Mixes coaxial, power, and data cables; fits different spaces and places | Good for complex systems in medical, aviation, and automation |

| Intermittent Bonding Ribbon Cable | Only bonds some parts for more bend and 180° turns | Cuts mistakes and saves time when making things |

| Twisted Flat Ribbon Cable | Switches between straight and twisted wires to lower crosstalk | Makes signals better in sensitive spots |

| Rainbow Ribbon Cable | Uses color-coded wires so you can find them easily | Helps with setups that have many connectors |

| Round-to-Flat Ribbon Cable | Changes from round to flat shape for tight spots | Useful when you need to route cables in tricky ways |

| Customization Options | Pick pitch, number of conductors, shielding, and connectors | Lets you get cable assemblies that match what you need |

Tip: Modular ribbon cable assemblies make it easy to upgrade or fix things. You can keep your system working as your needs change.

Compliance

You want your custom ribbon cable assemblies to follow strict rules. These rules keep your products safe and legal. Many industries need cable assemblies to pass tests and get certifications. For example, UL certification checks for safety. RoHS compliance means your assemblies do not use bad materials. ISO 9001 and IATF 16949 show your manufacturer has good quality.

Testing for compliance checks many things:

| Test Category | Purpose/Focus | Description/Examples |

|---|---|---|

| Electrical Testing | Checks wiring and insulation | Continuity, high voltage, and resistance tests |

| Mechanical Testing | Measures strength and durability | Pull, flex, and abrasion tests |

| Environmental Testing | Tests performance in harsh conditions | Heat, humidity, salt spray, UV, and chemical resistance |

| Certification | Proves industry standard compliance | UL, CSA, MSHA, RoHS, CE |

You can trust custom ribbon cable assemblies with these certifications. They will work well and last a long time. These tests help you stop failures and keep your systems safe.

Note: Always make sure your cable assembly supplier follows the latest industry standards. This keeps your business and your customers safe.

Future-Ready Assemblies

Emerging Technologies

New technology is changing electronics every day. Custom ribbon cable assemblies help you keep up. You need assemblies for smart devices, IoT systems, and AI hardware. These assemblies use new design tools and 3D printing. This makes cable assemblies smaller and smarter. They also use less energy.

- IoT and smart home systems need small, strong assemblies.

- AI tools help you design better cable assemblies faster.

- Robotics and automation make building more exact and quick.

- Smart sensors check temperature and tension for better quality.

- Digital twins let you test cable assemblies before making them.

- You can pick assemblies for factories, data centers, or electric vehicles.

You want assemblies that last and work well in tough places. These assemblies support Industry 4.0, IIoT, and smart robotics. They give you strong connections for sensors and actuators. You also see more eco-friendly cable designs. These help you meet new rules.

Tip: Pick assemblies with smart features and flexible designs. This helps your electronic systems stay ready for the future.

High-Speed Data

You need assemblies that move data fast for your devices. Modern uses like data centers and 5G networks need fast, strong signal transfer. Custom ribbon cable assemblies use new connectors and materials for this.

| Advancement Area | Description |

|---|---|

| High-Frequency & High-Speed | Assemblies support higher data rates and frequencies, reducing signal loss and electromagnetic interference. |

| Miniaturization & Flexibility | Smaller, lighter, and more flexible assemblies fit compact devices and automotive applications. |

| Advanced Materials & Durability | High-temperature polymers and improved shielding keep assemblies working in harsh environments. |

| Smart Manufacturing & Automation | Robotics and automation improve quality and speed of assembly production. |

Assemblies have changed from CAT-5 to CAT-6 and more. These can reach speeds up to 10 Gbps or higher. Some assemblies now go up to 800 Gbps for data centers. You get options like programmable EEPROM and custom setups. These features help you use assemblies for your needs.

Flat, side-by-side wires save space and keep things neat. You can make a few assemblies or thousands. You get strong signals and fewer mistakes. This means your devices work better.

Note: Choose assemblies made for high-speed data. This keeps your systems ready for what comes next.

You can see that custom ribbon cable assemblies help electronics work better. These assemblies keep wires neat and save space. They fit many different uses. You get strong connections for fast data and hard places. More people want these assemblies as new uses show up in cars, home gadgets, and smart devices.

- Small and packed assemblies help make tiny devices.

- You can change assemblies to fit what you need.

- Green materials and smart parts help future electronics.

You can pick custom ribbon cable assemblies for your project. This helps you keep up with new uses and changes.

FAQ

What makes custom ribbon cable assemblies better than standard cables?

Custom ribbon cable assemblies are made just for your device. You can pick the length, color, and connector you need. This helps you avoid mistakes. Your electronics work better with the right cables.

Can you use ribbon cable assemblies in outdoor or harsh environments?

Yes, you can use ribbon cable assemblies outside. You can choose strong materials like Teflon or stainless steel. These materials protect your cables from heat, water, and chemicals.

How does color coding help during installation?

Color coding helps you match wires fast. You can see where each wire goes. This saves time and helps you avoid mistakes. You finish your work faster.

Are custom ribbon cable assemblies safe for medical devices?

Custom ribbon cable assemblies follow strict safety rules. These cables pass tests for medical use. This keeps your devices safe and working well.

How do you know if your ribbon cable assembly meets industry standards?

Always ask your supplier for certifications like UL or RoHS. These show your cable assembly meets safety and quality rules. You can trust your cables to work well.