You might ask about the good and bad sides of a flexible printed circuit board. Many companies now pick flexible PCBs because they can bend and fit in tight spots. You can find these boards in smart watches, health tools, and car electronics. Flexible materials help you make products that weigh less. The world market for flexible printed circuit boards is growing quickly. It was $21.01 billion in 2023 and could reach $76.49 billion by 2033.

| Metric | Value / Description |

|---|---|

| Market Size 2023 | USD 21.01 billion |

| Projected 2033 | USD 76.49 billion |

| CAGR (2023-2033) | 13.79% |

| Largest Market | Asia Pacific |

Knowing the good and bad points of flexible PCBs helps you pick the best one for your next project.

Key Takeaways

- Flexible PCBs can bend to fit small spaces. This helps save space and weight. Devices become lighter and easier to carry.

- These boards last a long time. They work well in tough places. They do not break from heat, shaking, or bending.

- Flexible PCBs make assembly easier. They need fewer parts and connectors. This makes building faster and cheaper over time.

- They cost more to make. They are harder to fix. Careful design and handling help stop damage.

- Pick flexible PCBs if your product must bend or fit small spaces. Use rigid PCBs for stronger and cheaper boards.

Flexible Printed Circuit Board Benefits

Space and Weight Savings

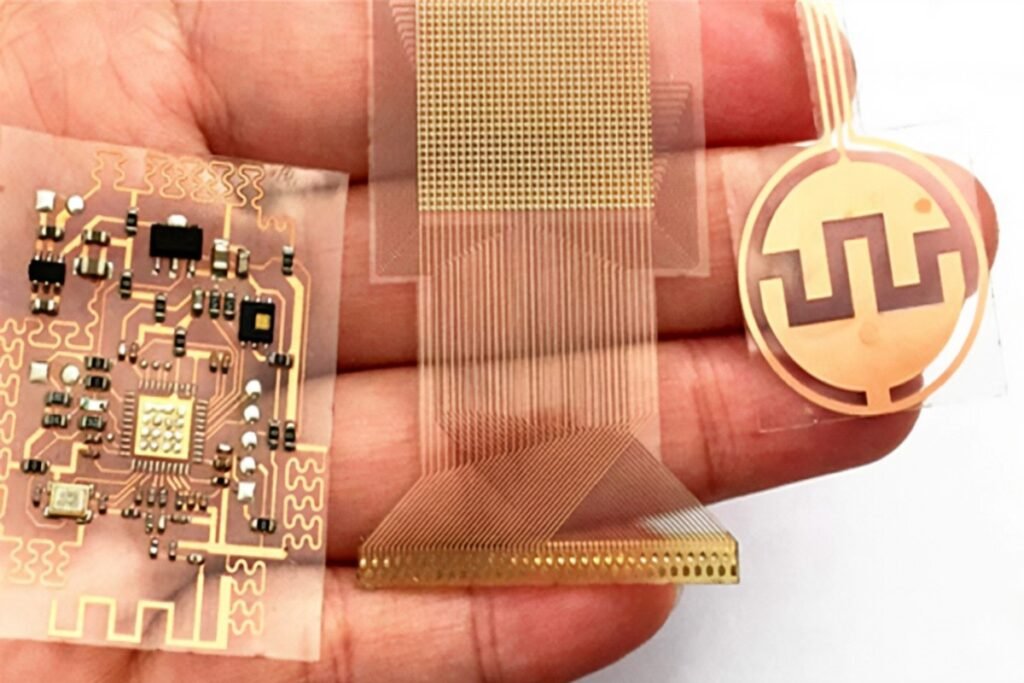

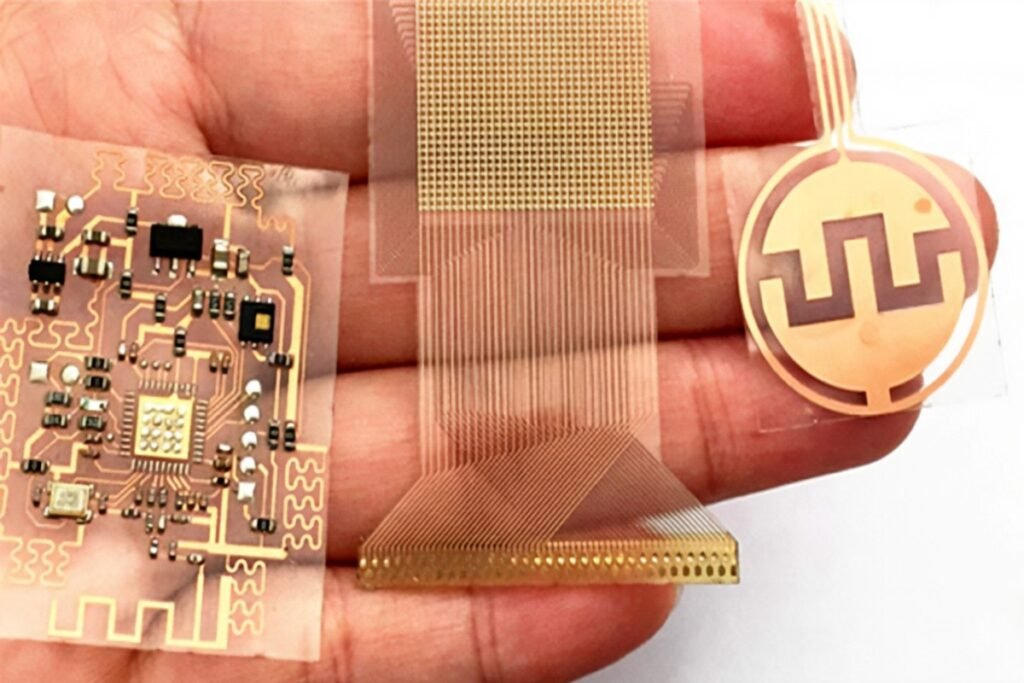

Flexible printed circuit boards help save space and weight. They use thin materials like polyimide. This lets you bend and fold them into small spaces. You can make products smaller and lighter with this.

- One flexible PCB can take the place of many rigid boards and cables. This makes things weigh less.

- Their thin design uses less space than thick rigid boards.

- You can fold or bend them to fit in empty spots. This is very helpful in satellites and spacecraft.

- Lighter designs help portable devices and wearables. These are easier and more comfortable to use.

Some real examples are medical patches that check your health, foldable phones, and sensors in fitness trackers. In space, flexible PCBs help satellites and CubeSats weigh less, so they use less fuel.

Flexibility in Design

Flexible PCBs let you be creative with your designs. You can bend, twist, and shape them to fit almost anywhere.

- They use materials like polyimide or polyester. These let you bend and fold the circuits.

- You can make three-dimensional shapes. This helps make products smaller and easier to use.

- Flexible PCBs do not need extra connectors or cables. This makes them stronger and last longer.

Medical, aerospace, and electronics companies use this flexibility to make new products.

Enhanced Reliability

Flexible PCBs are strong and last a long time, even in tough places.

- Special materials like polyimide and liquid crystal polymers can handle heat, shaking, and chemicals.

- Flexible circuits can bend and twist without breaking. This means they work longer in moving parts.

- Not needing connectors and solder joints in flexible spots means fewer things can go wrong.

You find flexible PCBs in medical tools, car sensors, and space electronics. These need to work well all the time.

Thermal Management

Flexible PCBs help control heat in small devices.

- Polyimide can handle high heat and helps move heat away.

- Copper and thermal vias help carry heat away from parts.

- Thin materials let heat escape faster because of their shape.

Flexible circuits fit in small spaces. This helps make better layouts that lower heat problems.

Simplified Assembly

Flexible PCBs make building things faster and cheaper.

- They mix rigid and flexible parts, so you need fewer pieces.

- You do not need extra connectors or cables. This makes building easier.

- You only have to test one board, so testing is quicker.

One medical company made their devices better and cheaper with flexible PCBs. A tool company saved 40% on costs by using flexible circuits in batteries. These stories show how flexible PCBs make building things easier and save money.

Flexible Circuit Boards Pros and Cons

Pros of Flexible PCBs

There are many good things about flexible circuit boards. Companies pick them because they save space and make products lighter. You can put them in small or weird-shaped places. This is great for wearables, medical tools, and things used in planes.

- Flexible PCBs let you change the shape to fit your needs. You can bend, twist, or fold them easily.

- These boards help make tiny and packed circuits. You can build small and complex designs.

- Flexible printed circuit boards need fewer connectors and solder joints. This means fewer things can break and they last longer.

- They help get rid of heat better. Materials like polyimide stop parts from getting too hot.

- Flexible PCBs can handle shaking and stress. This makes them strong for cars, planes, and machines.

- You can make things faster. Fewer parts and easy assembly mean quicker building and less work.

- Flexible circuit boards help save money over time. They work well and lower the number of repairs needed.

- You can use flexible PCBs in smart devices, phones, and health monitors. These need to be light and fit in small spaces.

Tip: Flexible PCBs cost more at first, but they help save money later. They are best for products where space and reliability are important.

Cons of Flexible PCBs

You should also think about the problems with flexible PCBs. Some issues can change how much you spend, how long things take, and how easy it is to fix them.

| Disadvantage / Limitation | Explanation |

|---|---|

| High Manufacturing Cost | Flexible PCBs cost more because of special materials and hard steps to make them. |

| Low Durability | Too much bending can break the circuit. You need to be careful with them. |

| Complexity in Repairs | It is harder to fix flexible circuit boards than regular ones. Getting to broken parts is tough. |

| Limitation in Heavy Component Installation | You cannot put heavy parts on flexible circuit boards. Stress can make them fail. |

| Limited Layer Count | Flexible PCBs have fewer layers than regular ones. This means you cannot add as many features. |

| Testing Challenges | Testing flexible PCBs takes longer and needs special tools. This makes them cost more to make. |

- Flexible PCBs cost a lot to make. You pay more at the start for materials and building.

- Fixing and keeping them working is harder. Bending can break them, and fixing needs special skills.

- You cannot add big or heavy parts. Flexible circuit boards cannot hold much weight.

- Making flexible PCBs needs careful planning. You must think about how much you can bend them and pick the right materials.

- Checking and testing takes more time. Their shape means you need special tools.

Note: Flexible electronics with only one layer have less room for parts. This means they cannot do as much or sense as well. You might also have trouble where hard and soft parts meet, which can hurt how well the device works.

When you look at the good and bad sides, flexible PCBs give many benefits for new electronics. But you need to plan for higher costs, harder repairs, and limits before you use them.

Flexible PCBs vs Rigid PCBs

Key Differences

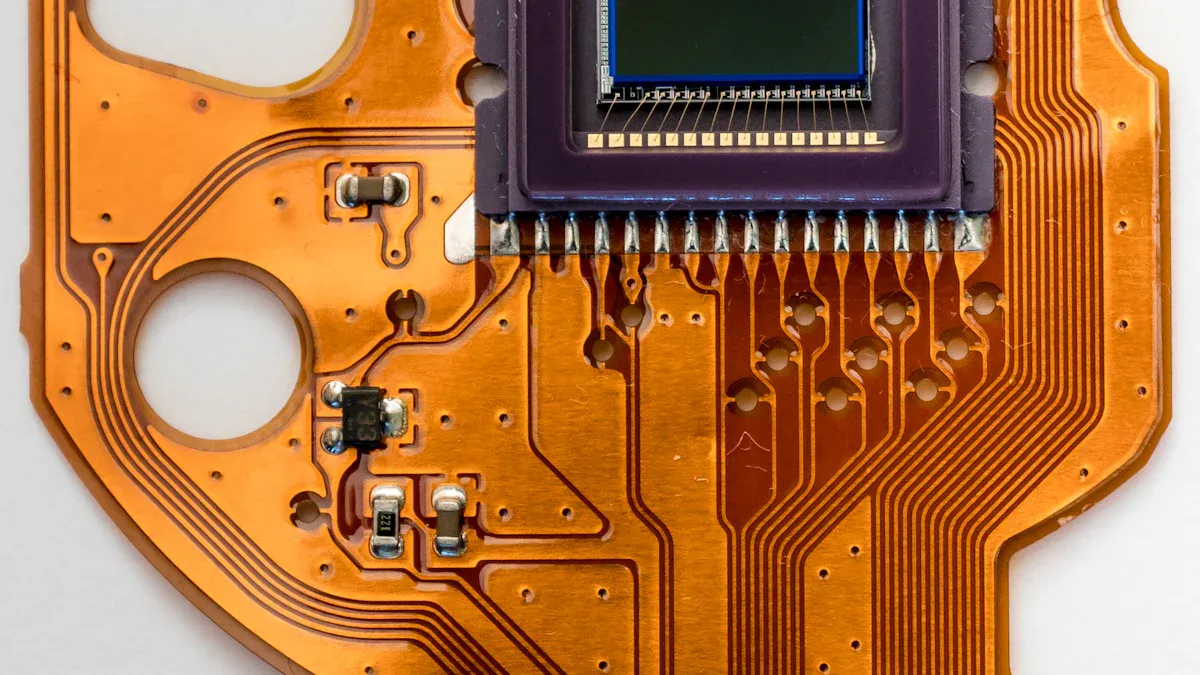

Flexible PCBs and rigid PCBs are not the same. They use different materials and have different structures. Flexible PCBs use polyimide films like Kapton. These films are thin and can handle heat. You can bend them many times and they will not break. The copper in flexible PCBs is soft and can move. This helps the board bend and twist. Rigid PCBs use glass-reinforced materials like FR-4. These materials are strong but cannot bend. Their copper layers are hard and do not move. The insulation is thick and does not bend easily.

Here is a table to help you compare:

| Aspect | Rigid PCBs | Flexible PCBs |

|---|---|---|

| Substrate Material | FR-4 epoxy laminate, Rogers laminates | Polyimide films (Kapton, Apical) |

| Conductive Layer | Electrodeposited copper (rigid) | Annealed copper (flexible) |

| Flexibility | Inflexible, stable | High flexibility, endures bending |

| Thermal Stability | Up to ~260°C | Up to ~400°C |

| Design Needs | Simple, no bending radius | Needs careful bend radius, via layout |

Flexible PCBs need special design steps. You must plan how much to bend them. You also need to think about where to put holes and lines. Rigid PCBs are easier to design. They do not need as many rules.

Tip: Use flexible PCBs if you need to bend the board or fit it in a small space. Pick rigid PCBs if you want a strong board that costs less.

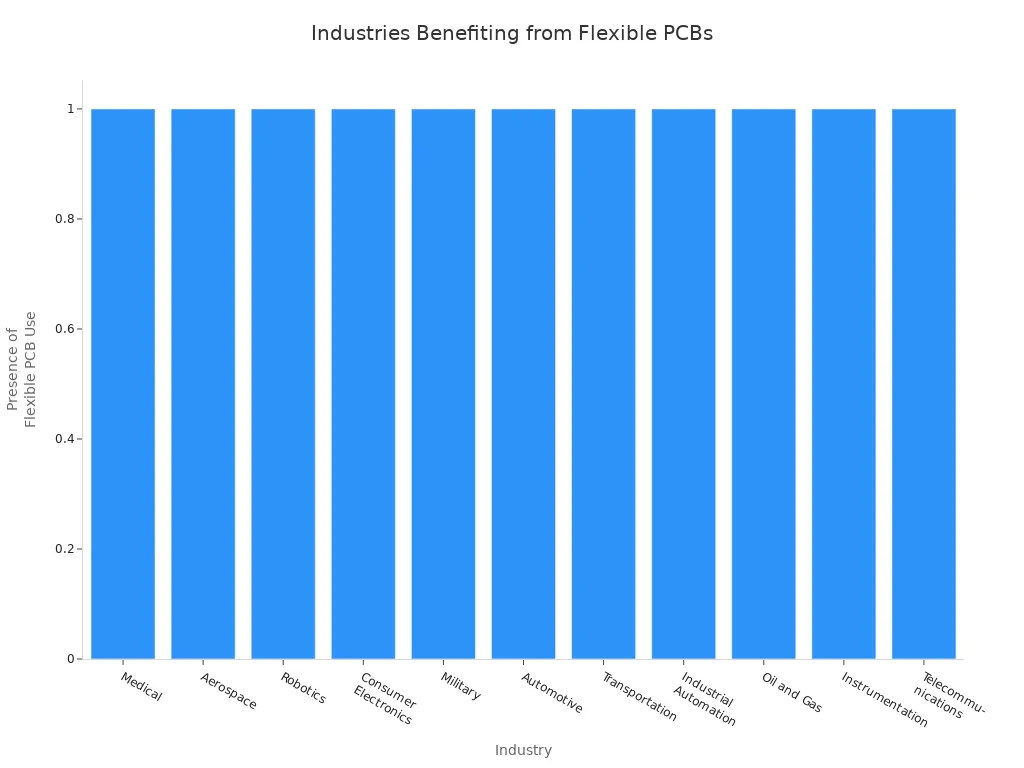

Application Suitability

Pick the right PCB for your project’s needs. Flexible PCBs are best for things that bend or twist. They fit well in small or tight spaces. You see them in wearables, medical tools, and cars. They are light and can fold. This makes them good for small gadgets and sensors.

- Flexible PCBs are used in electronics, cars, planes, health tools, and wearables.

- They can take the place of big cables. This saves space and means fewer parts can break.

- These boards keep working even if you bend them many times.

Rigid PCBs are better for things that do not move. You find them in computers, TVs, and big machines. They give strong support and steady power. They also cost less when you make a lot of them.

Note: If you need both strength and bending, use a hybrid rigid-flex PCB. This type mixes the good parts of both boards.

Choosing between flexible and rigid PCBs depends on space, movement, price, and how tough your product must be. Always test your design to make sure it works well.

Choosing Flexible PCBs

Decision Factors

When you pick flexible PCBs, you must think about a few things. First, ask how much your device will bend or move. If it bends a lot, use a bend radius that is six times the board’s thickness. If it only bends once, three times the thickness is enough. Keep important parts and traces away from places that bend often. This helps stop damage and keeps your device working longer.

Pick the right materials for your board. Polyimide is a good choice because it can handle heat and stays bendy. Thinner polyimide films and boards without glue make the board more flexible and lower stress. Rolled annealed copper foil is better than electrodeposited copper. It lets your board bend many times without breaking.

Add strain relief to help your board last longer. Use wider traces or extra copper near places that bend. Stiffeners made from FR4 or polyimide give support near heavy parts. Do not put tall or heavy parts in areas that bend. Put them on stiffeners or rigid sections instead.

Think about where your device will be used. If it faces heat, water, or shaking, match the thermal expansion of the board and parts. This lowers stress from heat and makes your device last longer.

Here is a quick checklist to help you:

| Factor | What to Check |

|---|---|

| Bend Radius | 6x thickness for dynamic, 3x for static |

| Material Choice | Polyimide, rolled annealed copper |

| Component Placement | Away from bend zones |

| Strain Relief | Wider traces, copper pours |

| Stiffeners | Use near heavy components |

| Environment | Match thermal expansion, resist moisture |

Tip: Try making a paper model of your design before you build it. This helps you find problems early and saves time.

Common Use Cases

Flexible PCBs are in many things you use every day. You find them in smartphones, cameras, laptops, and wearables like smartwatches. These boards help make devices smaller and lighter. They also take the place of wires and connectors, so there are fewer parts to break.

Flexible PCBs are important in medical devices. You see them in health monitors you wear, sensors inside the body, hearing aids, and surgery tools. Their bendy shape lets them fit in small spaces and match the shape of the body. This makes them more comfortable and helps them work better. Flexible PCBs also stand up to shaking and changes in temperature, which is important for medical tools.

In cars and airplanes, flexible PCBs help save space and weight. They can handle shaking and bumps, so they are good for sensors and control systems. You also find them in robots and factory machines, where they let things move and fit into tricky shapes.

Here are some common uses:

- Smartphones and tablets

- Wearable electronics (smartwatches, fitness trackers)

- Hearing aids and medical patches

- Cameras and laptops

- Automotive sensors and controls

- Aerospace systems and satellites

- Surgical instruments and implantable devices

Note: Flexible PCBs help make building devices faster and easier. They also make devices work better and cost less to fix over time.

Flexible printed circuit boards have lots of good points for new devices.

- You can bend and twist these boards to fit small spaces.

- They are light, so products are easier to carry and use.

- These boards are great for wearables, medical tools, and things used in space.

| Benefits | Drawbacks |

|---|---|

| Very flexible | Cost more at the start |

| Thin and light | Harder to design |

| Save space | Must handle with care |

Think about what your project needs before picking flexible PCBs. Also, think about where you will use them. Talk to PCB makers to pick the best materials and make sure the boards are good quality. You can find more information on websites like HemeixinPCB.com and Wevolver.com. Look up new ideas and ask suppliers for test boards to try out flexible choices.

FAQ

What makes flexible PCBs different from rigid PCBs?

Flexible PCBs bend and twist. Rigid PCBs stay flat and strong. You use flexible PCBs in small spaces or moving parts. Rigid PCBs work best in devices that do not move.

Can you repair a flexible PCB if it breaks?

You can fix some flexible PCBs, but repairs are hard. The thin material can tear or crack. You often need special tools and skills. Many people choose to replace the board instead.

Where do you see flexible PCBs used most?

You find flexible PCBs in smartwatches, medical patches, and car sensors. They fit in small spaces and move with the device. Many wearable and portable gadgets use them.

Do flexible PCBs cost more than regular PCBs?

Flexible PCBs usually cost more to make. You pay extra for special materials and careful design. Over time, you may save money because they last longer and need fewer repairs.

How do you choose the right material for a flexible PCB?

Tip: Pick polyimide for heat resistance and durability. Use rolled annealed copper for better bending. Ask your PCB maker for advice on the best materials for your project.