You should know the big differences between flat flex cables and ribbon cables before you pick one for your electronics project. Flat flex cables are very thin and bend easily. This makes them great for small devices. But if you bend them too much, they can break. Ribbon cables are harder to bend and usually cost less. You often find them in computers and printers.

- Flat flex cables fit in small spaces and can move a lot.

- Ribbon cables are good for things that do not move.

| Feature | Ribbon Cables | Flex Cables |

|---|---|---|

| Flexibility | Hard to bend | Very easy to bend |

| Cost | Costs less for big projects | Costs more |

| Applications | Used in computers, printers | Used in phones, laptops |

Key Takeaways

- Flat flex cables work well in small devices that move. They bend easily and are small in size.

- Ribbon cables are best for things that do not move. This makes them good for computers and printers.

- Think about how much movement and space your project needs. This helps you pick flex or ribbon cables.

- Flex cables bend more and are good for wearables. Ribbon cables are easy to keep neat because of their colored wires.

- Price matters; ribbon cables usually cost less. Flex cables work better when space is tight.

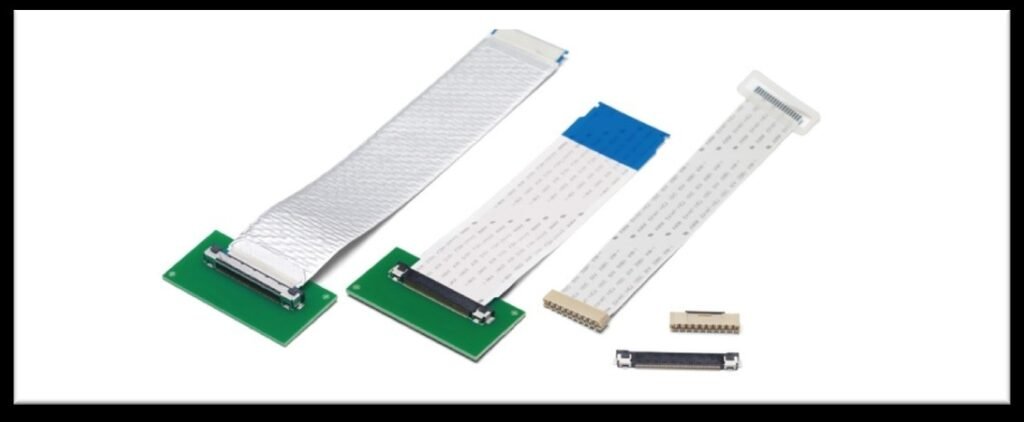

Flat Flex Cables

Structure

Flat flex cables look different from other cables. They use a thin polyimide plastic film for the base. This film makes the cable strong and bendable. Copper traces run on top and carry signals or power. A polyimide coverlay keeps the copper safe from harm. Special glue holds all the layers together. The glue works even when you bend the cable a lot.

Flex cables bend well because of their smart design. Polyimide plastic film lasts a long time. Copper traces are thin so they work better. The polyimide coverlay keeps the copper safe. Glue sticks the layers together so they do not come apart.

When you use flat flex cables, leave some extra length. This helps stop the cable from tearing. Do not bend the cable too much or too sharply. Make sure the cable bends the right way. Reinforce the ends to keep them from ripping. Keep the copper traces away from sharp things.

Applications

Flat flex cables are used in many places. They save space and can move easily. You see them in:

- Cell phones and laptops to connect screens and parts

- Folding devices where boards need to move

- Cars for important wiring

- Medical tools like endoscopes

- Machines in factories for tight connections

| Industry | Applications |

|---|---|

| Consumer Electronics | Cell phones, laptops, wiring inside devices |

| Telecommunications | Connections in communication devices |

| Medical | Medical tools and endoscopes |

| Automotive | Important wiring in cars |

| Industrial | Connections in factory machines |

| Commercial | Many commercial devices and systems |

Pros and Cons

Flat flex cables have good points and bad points.

| Advantages | Disadvantages |

|---|---|

| Small and light | Easier to damage by bending or twisting |

| Very flexible | Can carry less current than other cables |

| Fast data transfer with less signal loss | Harder to fix or connect again |

These cables fit in small spaces and bend easily. They are great for things that move or fold. But they can break if bent too much or too sharply. They carry less current than some other cables. Fixing them is not easy.

Ribbon Cables

Structure

Ribbon cables are flat and simple. They have many wires next to each other. The wires run side by side like a ribbon. This lets you connect many things at once. Most ribbon cables have wires spaced 1.27mm apart. This size fits lots of connectors. Makers add color stripes to help match wires. The colors help you avoid mistakes when you set them up. The flat shape helps you keep cables neat inside devices.

- These cables are wide and flat with many wires.

- The wires are next to each other for easy setup.

- The spacing is 1.27mm between each wire.

- Colors help you find the right wire fast.

Tip: Look at the color stripes before you connect ribbon cables. This helps you not mix up the wires.

Applications

Ribbon cables are used in lots of places. You see them in computers and printers. They are also in scanners and medical machines. Ribbon cables connect parts inside hard drives and CD drives. Some old computers used ribbon cables too. Factories and cars use them for wiring inside machines.

- Used in computers and phones

- Found in medical machines and labs

- Used in printers and scanners

- Good for cars and factory machines

- Connects hard drives and CD drives

Pros and Cons

Ribbon cables have good and bad sides. The flat shape saves space and keeps wires tidy. Color stripes make wires easy to spot. The wires run side by side so signals do not mix. You can connect many things at once. But ribbon cables do not bend well. If you twist or fold them, they can break. They do not block outside signals as well as round cables. Connectors can wear out if used a lot. Ribbon cables work best for short distances because signals get weak if the cable is too long.

| Advantage | Description |

|---|---|

| Flat shape saves space | Fits easily inside devices |

| Easy to organize | Color stripes help you find wires |

| Signals stay clear | Wires side by side stop mixing |

| Connects many things | Lets you hook up lots of parts |

| Disadvantage | Description |

|---|---|

| Not very bendy | Can break if twisted or folded |

| Can get damaged | Wires may snap if pulled hard |

| Weak against outside signals | Outside signals can mess with it |

| Not good for long cables | Signals get weak if cable is long |

Note: Be gentle with ribbon cables. Do not bend them sharply. Keep them away from things that can mess with signals.

Key Differences

Flexibility

When you look at flexibility, flex cables stand out. You can bend them in many directions without breaking them. In laboratory tests, flex cables show better flexibility and durability than ribbon cables. If your project needs cables that move a lot or fit into tight spaces, flex cables work best. Ribbon cables do not bend as easily. They can break if you twist or fold them too much. You should use ribbon cables in places where the cable stays still.

If you need a cable that bends and moves, choose flex cables. For cables that stay in one place, ribbon cables are a good choice.

Size

Flex cables and ribbon cables both save space, but flex cables are usually thinner. You can fit flex cables into very small devices. Ribbon cables are flat and wide, so they take up more room. Here is a side-by-side comparison of thickness:

| Type | Thickness (mm) |

|---|---|

| Terminal Thickness | 0.30±0.05 |

| Insertion Thickness | 0.121 ±0.02 |

| Conductor Thickness | 0.035±0.005 |

- Insulation thickness average: 9mil

- Minimum insulation thickness: 7mil

The pitch range for Temp-Flex Flat-Ribbon Cables goes from 0.32mm to 2.54mm. This means you can find both types in different sizes, but flex cables fit better in very tight spots.

Durability

You want your cables to last, especially in tough places. Flex cables are made to handle lots of bending and movement. Some flex cables, like GORE High Flex Flat Cables, work well in harsh environments. They keep working even when you bend them many times. Ribbon cables can also last a long time. Some, like IDC Ribbon Cables, can handle up to 100 million flex cycles. They are light and resist vibration, but they do not bend as much as flex cables. If you need cables for high-vibration or moving parts, flex cables give you more reliability.

Cost

Cost matters when you pick cables for your project. Ribbon cables usually cost less, especially if you need a lot of them. Flex cables cost more because they use special materials and designs. If you have a big project and need to save money, ribbon cables might be the better choice. If your project needs cables that bend and fit in small spaces, you may need to spend more for flex cables.

Signal Quality

Signal quality is important for fast and clear data. Flex cables can transfer data quickly with less signal loss. However, they do not have built-in shielding against electromagnetic interference (EMI). This means outside signals can sometimes affect them. Ribbon cables also do not have strong EMI protection. Round cables do better in noisy environments because they have more shielding. If you use cables near strong electrical signals, you may see some signal loss with both flex cables and ribbon cables.

- Flex cables are compact and easy to route but do not have shielding.

- Ribbon cables keep wires side by side, which helps reduce crosstalk, but they still lack strong EMI protection.

- Round cables work best for high-speed and high-noise areas.

Tip: For most consumer electronics, flex cables and ribbon cables work well. For high-speed or noisy environments, round cables with shielding are better.

Flex Cable vs Ribbon Cable in Modern Electronics

Consumer Devices

Flex cables are found in many new devices. Phones and tablets use them for thin shapes. USB-C is now the main way to charge and send data. It is fast and easy to plug in. Flex cables bend and twist, so they fit in foldable phones and smartwatches. Ribbon cables are still used in printers and old computers. Most new gadgets pick flex cables because they save space and bend easily.

Tip: Devices that are thin and light often have flex cables inside.

| Advantage | Description |

|---|---|

| Space-saving design | Good for small spaces in wearables because they are compact. |

| Flexibility | Easy to fit in places that move, which is important for wearables. |

| Durability | Makes wearable tech last longer and work well. |

| Ease of installation | Makes it simple to put together small devices like wearables. |

Industrial Uses

Factories need cables that last and work under stress. Flex cables can move a lot and fit in tight spots. You see them in robots, lifts, and aerospace machines. Ribbon cables stay in place and do not shake much. They are light, so machines move faster. Both types are made to be safe and reliable. Some cables resist fire, oil, and chemicals for tough jobs.

- Flex cables can bend millions of times and still work.

- Ribbon cables are lighter than round cables, so they wear less and shake less.

Robotics and Automation

Robots need cables that bend many times. Flex cables are lighter and bend better. They also get rid of heat faster. This helps robots move quickly and fit in small places. Flat cables help signals stay strong, which is good for control. Ribbon cables have many wires for easy setup, but they do not bend as well. Flex cables are best for robots that move a lot.

Note: Flex cables help robots last longer and work better in small spaces.

Emerging Tech

New tech in 2025 needs better cables. Devices are getting smaller and smarter. Thin and bendy cables are needed more. Small devices use flat cables because they fit well. Fast data needs new materials and designs. Cars use special cables for control and entertainment. Smart factories and IoT need strong cables for data. Foldable phones and wearables use rigid-flex PCBs to connect parts that move. New coatings and materials make flex cables stronger and able to bend more times.

| Trend | Description |

|---|---|

| Miniaturization | More need for small, thin, and bendy ribbon cables in portable devices. |

| High-speed data transmission | New materials and designs help signals move faster. |

| Automotive electronics | More control units and safety systems mean more special cables. |

| Sustainability | Cable makers use eco-friendly materials and better ways to make cables. |

| Industry 4.0 and IoT | Smart devices need strong cables for smooth data transfer. |

Choosing the Right Cable

Project Needs

When you start a new electronics project, you need to think about what your cables must do. You should look at how much movement your cables will face and how much space you have. If your project needs high flexibility, you should choose flex cable. Flex cable bends easily and fits into tight spots. This makes it perfect for devices that move or fold, like wearables and foldable phones. Ribbon cables work well when you need to connect many parts at once and the cables will not move much. You often see ribbon cables in computers and printers.

Here is a table to help you compare key traits of flex cables and ribbon cables for your project:

| Factor | Flex Cable (FFC) | Ribbon Cable |

|---|---|---|

| Flexibility | Very flexible, bends many ways | Flexible, but less than flex cable |

| Space Efficiency | Saves space, fits tight designs | Bulkier, good for many connections |

| Electrical Properties | Stable, keeps signal strong | Can lose signal, may heat up |

| Application Suitability | Great for moving parts | Best for fixed, multi-connection setups |

| Termination Techniques | Handles ends well | Harder to finish ends |

| Temperature Tolerance | Works well under heat | Needs jackets for high heat |

| Fire Resistance | Check specs for safety | Must meet fire safety rules |

Tip: If your project needs cables that bend and move, choose flex cable. For projects with many connections that stay still, ribbon cables are a good choice.

Space and Movement

Space and movement matter a lot when you pick cables. Flex cable is thin and light, so you can fit it into very small places. Flexible flat cable works best in devices where parts move or fold. Flat cables save space and keep your design neat. Ribbon cables are flat and wide, which helps you organize many wires. They fit into narrow spaces, but they do not bend as much as flex cable.

- Flex cable is best for moving parts and tight spaces.

- Ribbon cables work well for connecting many things in a fixed spot.

- Flat cables help you keep your device small and tidy.

You should always check how much your cables will move and how much space you have. If you need cables that bend often, choose flex cable. If you need to connect many parts and space is not tight, ribbon cables may work better.

Note: Always match your cable choice to your project’s needs for movement and space. This helps your device last longer and work better.

It is important to think about what ribbon cables and flex cables can do. Flex cables are good for small devices that move. Ribbon cables are better for places where wires do not move. If you want your project to last, look for new things like fast data, smart connectors, and green materials.

Tip: Check the cable size, how much it will move, and if you can get it easily before you pick ribbon cable or flex cable.

- Fast data and smaller devices change which cables people use.

- Smart factories keep track of cables so they do not run out.

FAQ

What is the main difference between flat flex cables and ribbon cables?

Flat flex cables bend easily and fit in small spaces. Ribbon cables stay flat and connect many parts at once. You use flex cables for moving parts. You use ribbon cables for fixed connections.

Can you use flat flex cables in computers?

You can use flat flex cables in laptops and tablets. They connect screens and small parts. Most desktop computers use ribbon cables for hard drives and older devices.

How do you protect cables from damage?

You should avoid sharp bends and keep cables away from heat. Reinforce the ends with tape or clips. Use covers to shield cables from dust and moisture.

Which cable works best for robots?

Flex cables work best for robots. They bend many times and fit in tight spaces. Robots need cables that move without breaking.