Imagine your automation system suddenly stops working. You discover that a cable failed after only a few months. This mistake leads to costly downtime and lost productivity. When you choose the right high flex cable, you boost system reliability and cut maintenance costs.

- Proper cable selection ensures strong power delivery and reduces signal loss.

- High-quality cables handle tough environments, so you spend less on repairs.

- Smart cable choices keep your operations running without interruption.

The demand for durable cables keeps growing, with high flex cables in industrial automation expected to see a 5.3% annual growth rate over the next decade. Picking the right cable matters more than ever.

Key Takeaways

- Choose high flex cables to enhance system reliability and reduce maintenance costs. They withstand bending and twisting, ensuring consistent performance.

- Select cables based on your specific application requirements. Consider factors like motion profile, environmental exposure, and signal integrity to avoid costly mistakes.

- Prioritize high-quality materials and insulation for durability. Cables with proper shielding protect against electromagnetic interference, ensuring clear signals.

- Document all cable specifications and installation details. Good records help with troubleshooting and future upgrades, keeping your automation system running smoothly.

- Consult with experienced manufacturers for custom solutions. They can provide tailored cables that meet your unique needs and comply with industry standards.

Why High Flex Cables Matter

Role in Industrial Automation

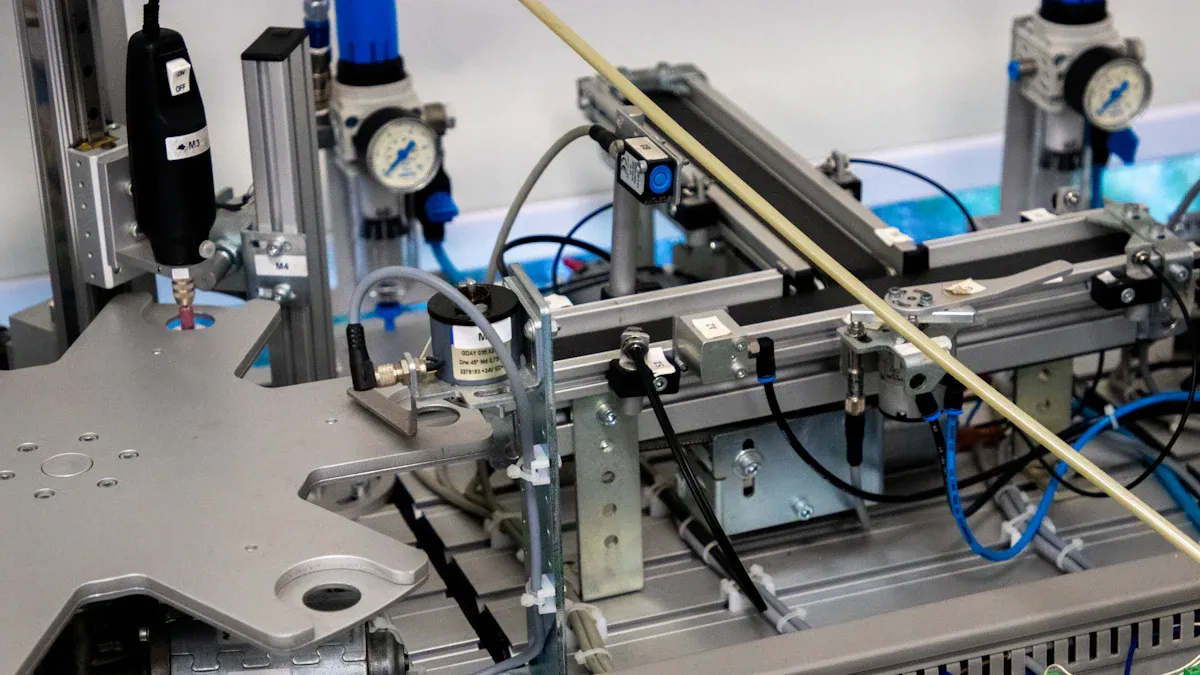

You see high flex cables everywhere in industrial automation. These cables play a key role in keeping machines moving and data flowing. When you use high flex cables, you make sure your equipment works smoothly, even when it bends and twists thousands of times each day.

High flex cables are specifically designed to endure extensive bending, twisting, and continuous movement without compromising performance, making them essential in environments where flexibility and durability are critical.

Here are the main reasons high flex cables are preferred in industrial automation environments:

- High flex cables ensure consistent performance even in challenging conditions.

- They help in reducing downtime and equipment failure.

- Their use contributes to the overall efficiency of industrial automation systems.

You need cables that can handle repetitive motion. Standard cables often fail when exposed to constant movement. High flex cables perform reliably in applications requiring continuous movement. They reduce the risk of downtime and equipment failure due to cable fatigue or breakage. This reliability helps your automation system run longer and more efficiently.

| Attribute | Description |

|---|---|

| Durability | High flex cables are engineered to withstand mechanical stress and harsh environmental conditions. |

| Flexibility | Designed to handle repetitive movement, bending, and twisting without degradation. |

| Suitability | Essential in systems where mobility and durability are paramount. |

Impact on System Reliability

You want your automation system to work without interruptions. High flex cables help you achieve this goal. These cables are designed to endure repetitive motion, which is crucial in automated systems where constant movement occurs. Standard cables fail under continuous bending and twisting, leading to increased maintenance costs and downtime.

- High flex cables are designed to endure repetitive motion, which is crucial in automated systems where constant movement occurs.

- Standard cables fail under continuous bending and twisting, leading to increased maintenance costs and downtime.

- A case study showed that Ninja Van experienced a 35% reduction in cable-related stoppages after switching to high flex cables.

High-performance automation system connectivity cables have demonstrated measurable improvements in various industries, including increased operational efficiency, reduced downtime, and enhanced system performance, all of which contribute to overall system reliability.

| Evidence Description | Key Benefits |

|---|---|

| High flex cables enhance durability and reduce signal interference. | Improved system reliability in high-flex applications. |

| The cable jacket’s material properties increase pull strength and flex life. | Enhanced durability and reduced risk of failure. |

| Ribbon cables outlast standard cables in high-speed applications. | Increased operational efficiency and reduced downtime. |

You can trust high flex cables to keep your automation system running smoothly. Their durability and flexibility make them the best choice for industrial automation projects where reliability matters most.

Choosing the Right Flexible Cable

Application Requirements

When you start choosing the right flexible cable for your automation project, you need to focus on your application requirements. Every system has unique needs. You must consider how the cable will move, what signals it will carry, and the environment it will face. Early cable selection helps you avoid costly redesigns and downtime later.

Tip: Begin cable selection during the initial design phase. This step ensures your system meets performance and reliability goals.

You should look at several factors before making a decision. The table below gives you a guide for your specific application:

| Factor | Description |

|---|---|

| Motion Profile | Think about the type of flexing: linear, continuous rolling, or torsional twist. |

| Cable Diameter and Compatibility | Make sure the cable diameter fits the connector and provides proper strain relief. |

| Environmental Exposure | Check the environmental conditions and choose the right IP rating for connectors. |

| Electrical/Signal Integrity | Select connectors that support the voltage, current, and signal type your system needs. |

You must define the type of signals your system will transmit. For analog signals, shielding is important because interference can cause problems. Digital signals are more robust, but shielding still helps in noisy environments. If you use data communication protocols like USB, Ethernet, or HDMI, you need cables with controlled impedance and differential pair conductors. These features maintain signal integrity and prevent performance loss.

You should also think about the installation environment. If your system operates outdoors or in areas with moisture or chemicals, choose insulation and sheath materials that protect against these hazards. Always check if the cable meets local and international standards for safety and reliability.

Note: Document all cable specifications and wiring diagrams. Good records help you troubleshoot and maintain your system in the future.

Movement and Flex Cycles

Movement and flex cycles play a big role in how long your high flex cables last. You need to match the cable’s design to the motion profile of your application. Flex cycle requirements tell you how many times the cable will bend or twist during its life. If you ignore these numbers, you risk early cable failure.

You should pay close attention to bend radius limitations. The bend radius is the smallest curve the cable can handle without damage. For static applications, use a minimum bend radius of 10 times the thickness of the flex circuit for 1-2 layers. In dynamic applications, increase the minimum bend radius to 100 times the thickness. For example, a double-layer flex PCB with 1 oz copper and a thickness of 0.15 mm should have a minimum bend radius of about 1.5 mm for static use.

- The AS4373 test method checks when conductors and insulation start to separate during flexing. This test helps you know when the cable may lose current carrying capacity.

- The EN3475-512 method evaluates continuity loss during mechanical flex stressing. This method helps you predict when the cable might fail in high-motion environments.

You should select high flex cables that match your system’s movement profile. If your application involves continuous rolling or torsional twist, choose cables designed for millions of flex cycles. Flexible cables with high strand counts and robust insulation last longer in these settings.

Regular inspections and periodic testing help you catch wear or damage early. Use high-quality cable management systems to support and protect your cables. Proper cable management reduces downtime and keeps your automation system running smoothly.

Early cable selection gives you time to balance cost, performance, and maintenance needs. You should consider cable type, voltage rating, voltage drop, insulation material, and mechanical properties. Smart cable management and accurate documentation make future upgrades and repairs easier.

- Select the right cable type for power, data, or control.

- Make sure the cable can handle the maximum operating voltage.

- Consider voltage drop over long distances.

- Choose insulation and sheath materials that fit your environment.

- Evaluate flexibility, bending radius, and abrasion resistance.

- Follow safety and reliability standards.

- Balance initial costs with long-term performance.

Flexible cables are essential for automation projects. You need to match cable features to your system’s needs. By following these steps, you improve reliability and reduce maintenance costs.

High Flex Cable Construction

Conductor and Stranding

When you choose high flex cables, you need to look at the conductor design. High flex cables use stranded conductors made of dozens of fine wires. This design gives you more flexibility than solid conductors. You get cables that bend and twist without breaking.

- Higher strand count increases flexibility and lifespan.

- More strands allow greater movement and reduce the risk of conductor breakage during repetitive flexing.

- Solid core conductors do not offer the same flexibility and often fail in dynamic applications.

Here is a comparison between high flex cables and standard cables:

| Feature | High Flex Cables | Standard Cables |

|---|---|---|

| Conductors | Stranded conductors (dozens of fine wires) | Solid conductors (single strand) |

| Flexibility | High flexibility, withstands repeated bending | Limited flexibility, designed for static use |

| Dynamic Durability | Resists wear, vibration, and mechanical stress | Primarily for fixed installations |

| Weight | Typically lighter and more bendable | Generally heavier and less flexible |

Insulation and Jacket

You need insulation and jacket materials that protect high flex cables in harsh environments. Flexible cables use soft, elastic materials like PVC, silicone, and TPE. These materials resist cold, heat, UV, oils, and chemicals. You get cables that last longer and perform better in tough conditions.

| Material Type | Key Properties | Applications |

|---|---|---|

| TPE/TPR, Santoprene | Halogen-free, Flexible, Cold-resistant, Durable, UV/oil/chemical resistant | Harsh environments, High-movement, Automotive, Health care |

| Fluoropolymer | High heat resistance, Chemical resistant, Durable | Military, Aerospace, Electronics, Automation |

| Thermoset | Heat-resistant, Extra damage-resistant, Long service life | Heat treating, Foundries, Aluminum processing |

Flexible insulation keeps your high flex cables safe from abrasion and mechanical stress. You can use these cables in robotics, automotive, and medical devices where movement happens every day.

Shielding and Signal Integrity

Shielding plays a key role in high flex cables. You need shielding to protect inner conductors from external noise. In automation, electromagnetic interference (EMI) can cause signal loss. Shielding prevents cables from acting as antennas and keeps your signals clear.

- Shielding reflects noise or conducts it to the ground.

- You get uninterrupted signal connections, even in high-power environments.

- The effectiveness of shielding depends on the electrical environment.

YLS High Speed FFC Cable stands out with controlled impedance, low signal skew, and optional shielding. You can customize specifications for your project, including pitch sizes and pin counts. These features give you better flexibility, improved EMI resistance, and reliable performance in compact devices.

| Feature | FFC Ribbon Cable | Traditional Ribbon Cable |

|---|---|---|

| Flexibility | Highly flexible, fits tight spaces | Flexible, but less than FFC |

| EMI/RFI resistance | Improved protection from interference | Good, but not as strong as FFC |

| Space-saving design | Excellent, very compact | Good, but bulkier |

You can tailor high flex cables for unique automation needs. Custom cables adapt to future changes, fit many applications, and include branding or special connectors.

| Specification | Description |

|---|---|

| Adaptability | Custom cables can be modified or scaled to accommodate future changes. |

| Versatility | Suitable for a wide range of industrial applications. |

| Unique Features | Designed with specific connectors, shielding, or coatings for unique needs. |

Flexible high flex cables give you the reliability and flexibility your automation project demands.

Cable Selection for Automation

Environmental Factors

You must consider environmental factors when selecting cables for automation projects. The right choice protects your system from damage and keeps it running smoothly. Temperature, chemicals, and moisture can affect cable performance. Some materials, like nickel-plated copper, withstand high temperatures and resist corrosion. Alloys offer toughness and flexibility, which helps in extreme conditions. Fluoropolymers work well in both hot and cold environments, but lower durometer materials may crack in cold settings. TPE and TPU are recommended for low temperatures because they stay flexible.

Harsh chemicals can cause cable jackets to melt or crack, especially when combined with temperature extremes. Cables with UL approvals, such as PVC and TPE, resist chemical exposure and prevent downtime. You should always check if the cable material matches your environment. Accelerated aging tests help identify weaknesses by simulating long-term exposure.

Tip: A thorough environmental assessment helps you choose the best flexible cable for your automation system.

| Environmental Factor | Description |

|---|---|

| Cable Material | The choice between copper and aluminum affects safety and performance in specific environments. |

| Temperature Resistance | Cables must withstand varying temperatures during operation. |

| Load Capacity | Selection should consider the load the cable will carry. |

| Shielding | Necessary for high voltage cables to prevent damage from electric fields and interference. |

| Environmental Conditions | Cables should be chosen based on the specific conditions they will operate in, such as dampness or contamination. |

Connector Choices

Connector selection plays a big role in cable reliability. You need connectors that match your cable and application. M8 connectors fit tight spaces and work well with sensors and small devices. M12 connectors handle more power and faster data, making them ideal for motors, PLCs, and industrial networks. M12 connectors also provide excellent environmental seals for harsh conditions.

| Feature | M8 Connector | M12 Connector |

|---|---|---|

| Size | Small (8mm thread) | Larger (12mm thread) |

| Power Handling | Low to moderate | Moderate to high |

| Signal Capability | Basic control signals | High-speed data and power signals |

| Environmental Seal | Decent for indoor use | Excellent for industrial use |

| Typical Use Cases | Sensors, small devices | Motors, PLCs, industrial networks |

- Need more power or faster data? Go M12

- Harsh environments? M12 holds up better

- Tight installation space? M8 fits right in

- Need multiple pins? M12 gives you more room to work with

You should secure cables to minimize movement and abrasion. Route cables along walls or ceilings to avoid snagging. Use low-profile ties for bundling and maintain proper spacing to reduce strain. Protective sheathing, like conduit or raceway systems, shields cables from external contact. Avoid overtightening ties to prevent pinching and keep moderate tension for cable longevity.

Compliance and Quality

Standards and Certifications

You need to make sure your cables meet strict standards. These certifications prove that your flexible cables are safe, reliable, and ready for demanding automation projects. When you choose cables with recognized certifications, you protect your system and follow industry rules.

Here is a table showing important standards and certifications for high flex cables:

| Standard/Certification | Description |

|---|---|

| ISO 14644-1 | Cleanroom standard for air cleanliness in controlled environments. |

| ICEA | Insulation and cable standards for electrical applications. |

| UL | Safety and performance standards for electrical devices. |

| CSA | Standards for safety and performance in Canada. |

| MSHA | Standards for mining safety. |

| NEMA | Standards for electrical equipment. |

| USCG | Standards for marine safety. |

| NEC | National Electrical Code standards. |

| ASTM | Standards for materials and testing. |

| IEEE | Standards for electrical and electronic systems. |

You should look for ISO9001:2008 and RoHS certifications. ISO9001:2008 ensures that manufacturers follow strict quality control. This certification means your flexible cables come from a process that values safety, performance, and consistency. RoHS certification shows that your cables do not contain harmful substances, making them safe for people and the environment.

Manufacturer Support

You gain many advantages when you work with experienced manufacturers like YLS. These experts help you design flexible cables that fit your exact needs. You get custom solutions that improve performance and durability.

- Custom engineering support gives you cables built for your specific application.

- You receive help with integration, installation, and troubleshooting.

- Manufacturers can design cables that meet safety standards and reduce risks.

- Custom cables often last longer and save you money on repairs.

- You can choose designs that save space and weight, which is important in medical and aerospace projects.

- Branding options let you add colors or markings for easy identification.

YLS offers engineering support from design to production. You get flexible cables that meet global standards and work well in your automation system. This support helps you avoid problems and keeps your project running smoothly.

Checklist for Choosing High Flex Cables

Key Selection Steps

You want your automation project to run smoothly. Start with a checklist that covers every important step. This approach helps you pick the right cable for dynamic applications and avoid costly mistakes.

Tip: Always match cable features to your system’s movement and environment.

Selection Checklist:

- Identify your application’s motion profile.

- Check the required flex-life rating for your system.

- Choose insulation material based on temperature, chemical, and water exposure.

- Confirm the cable’s bend radius and cycle count.

- Test for tensile, crimp, and torsion force.

- Assess solar and environmental exposure.

- Select cables with proper EMI shielding for signal integrity.

- Verify compatibility with connectors and harnessing needs.

| Cable Type | Flex-Life Rating |

|---|---|

| Normal Flexible Cable | About 50,000 cycles |

| Continuous Flex Cable | About 1 to 3 million cycles |

| High-Flex Cable | Over 10 million cycles |

For dynamic applications, you need cables that last. Materials like PUR and TPE offer durability in harsh environments. Silicone resists sparks and high temperatures. YLS High Speed FFC Cable supports up to 10 million cycles, works from -40°C to +105°C, and provides EMI shielding. You can use it for robotics, factory automation, and other dynamic applications.

| Feature | Description |

|---|---|

| Flex Life | Up to 10M cycles |

| EMI Shielding | Yes, with ground layer |

| Customization | Folding & harnessing available |

| Application | Robotics, factory automation, etc. |

Common Mistakes to Avoid

You can prevent problems by knowing what to watch out for. Many users make mistakes when choosing cables for dynamic applications.

| Mistake | Description | Solution |

|---|---|---|

| Overcrowding in cable tracks | Too many cables cause damage and heat buildup. | Reduce cable count for proper movement. |

| Excessive abrasion | Friction wears down cable jackets. | Use abrasion-resistant jackets. |

| Improper cable selection | Not all cables fit every application. | Match cable design to your system’s needs. |

Note: Always review your cable layout and environment before installation. This step helps you avoid downtime and keeps your automation system reliable.

You improve automation reliability when you plan early and match cable features to your project’s needs. Consider these expert tips:

- Select a high flex cable from manufacturers with strong reputations and strict quality control.

- Review customer feedback and case studies before making your choice.

- Understand installation, operation, and shielding requirements for your application.

Consulting with experts like YLS brings unique advantages:

| Advantage | Description |

|---|---|

| Engineering-Driven Solutions | YLS helps you solve connection challenges with practical designs. |

| Flexible Production for Small Teams | You get low minimum orders and fast pilot runs to support growth. |

| Compliance-Ready | Products meet certifications for global market demands. |

| Reliable Communication | You work directly with English-speaking project managers. |

Use the checklist and expert support to ensure long-term system performance.

FAQ

What makes a cable “high flex”?

High flex cables use many fine wire strands and flexible insulation. You can bend and twist them millions of times without breaking. These cables work best in automation systems that move often.

How do you choose the right cable for harsh environments?

You should check the temperature, chemicals, and moisture in your workspace. Pick cables with jackets like TPE or fluoropolymer for extra protection. Always match the cable material to your environment for longer life.

Why is shielding important in high flex cables?

Shielding blocks electromagnetic interference (EMI). You get better signal quality and fewer errors. In noisy industrial settings, shielding helps your data stay accurate and reliable.

Can you customize high flex cables for your project?

Yes, you can. Many manufacturers, including YLS, offer custom lengths, pin counts, and shielding options. You can request cables that fit your exact needs for size, speed, and flexibility.