Choosing the right flat electrical wire can feel tricky. You want something that fits your project, whether you’re working with electronics, medical devices, or aerospace tech. Modern options like YLS FFCs offer custom designs and features. Key things to check include wire gauge, insulation, ampacity, and safety standards.

- Consider electromagnetic interference, application type, and space constraints.

- Recent advances bring reduced electronic noise, better heat management, and streamlined designs.

| Benefit | Description |

|---|---|

| Reduced electronic noise | Reliable data transmission |

| Improved heat dissipation | Better reliability in tight spaces |

| Streamlined design | Saves weight and space |

Key Takeaways

- Choose the right wire gauge to prevent overheating and ensure safety. Match the gauge to your device’s current load.

- Check insulation materials based on your environment. Select materials that resist heat, moisture, and chemicals for better durability.

- Look for safety certifications like UL or CE. Compliance with local electrical codes ensures safe and reliable installations.

Flat Electrical Wire Types

Flexible Cable Wire Features

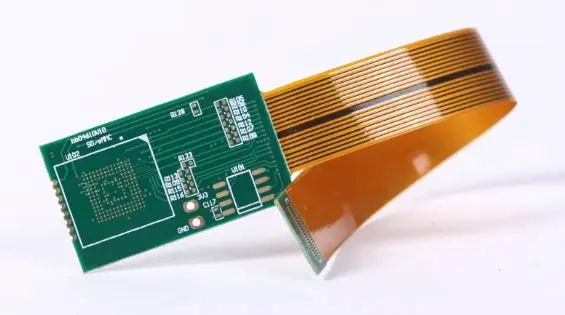

When you look for the best flexible cable wire, you want something that bends easily and lasts a long time. Flexible cable wire uses many fine strands instead of solid metal, which makes it much more flexible. You can twist and fold these wires without worrying about breaking them. Some brands, like YLS, pack in extra strands, so you get a smaller bend radius and longer life. The jacketing material also matters. Special coatings, such as Flexx-Sil™, help the wire stay flexible and resist wear.

Flexible cable wire comes in many sizes and designs. You can choose pitch sizes from 0.4mm to 1.25mm and conductor counts up to 96. YLS lets you customize features like folding, shielding, notching, and labeling. If you need a sample fast, YLS can get one ready in just 48 hours.

Tip: Always match the size and pin count of your flexible cable wire to your device’s connector for the best fit.

| Customization Option | Details |

|---|---|

| Pitch Sizes | 0.4mm to 1.25mm |

| Conductor Counts | Up to 96 |

| Specialized Features | Folding, shielding, notching, punching, labeling, custom assembly |

| Design Options | Shielded & foldable design |

| Sample Availability | 48h sample ready |

Common Applications

You’ll find flexible cable wire in all sorts of electrical applications. In electronics, it connects parts inside smartphones, tablets, and wearables. The auto industry uses it for sensors, actuators, and heating elements because it’s lightweight and easy to route. Medical devices rely on flexible cable wire for diagnostic equipment and sensor connections. Aerospace engineers pick it for weight-sensitive projects. Robotics and drones need flexible cable wire for moving parts that bend and twist thousands of times.

Here are some common uses:

- Computers and printers use flexible cable wire for internal wiring.

- Cars use it in lighting and battery systems.

- Telecommunication setups rely on it for signal transmission in tight spaces.

- Medical devices need flexible cable wire for compact, reliable connections.

Flat electrical wire stands out from round wire. It saves space, bends in one direction, and offers predictable electrical performance. You get easier routing and cleaner installations, especially in tight spots. In smartphones, flat wire makes devices thinner and more flexible. In cars, it boosts durability. In medical gear, it delivers precision and reliability.

How to Choose the Right Wire

Picking flat electrical wire for your project can feel overwhelming. You want to make sure you get the right wire gauge, insulation, and ampacity for your needs. Let’s break down how to choose the right wire step by step so you can avoid common mistakes and keep your project safe.

Right Wire Gauge Selection

Wire gauge is one of the most important things to check when you choose flat electrical wire. The wire gauge tells you how thick the wire is and how much current it can handle. If you pick a wire that’s too thin, it can overheat and cause a fire. If it’s too thick, you might waste money and space.

Here’s a simple process to help you pick the right wire gauge:

- Check the current load. Figure out how much current your device or circuit will use. Higher current needs a thicker wire.

- Measure the wire length. Longer wires can lose voltage, so you may need a thicker wire gauge for longer runs.

- Think about the application type. For heating, motors, or sensitive electronics, always check the recommended gauge for each use.

- Pick the wire material. Copper is the most efficient, but you might see aluminum or stainless steel in some cases.

- Look at wire thickness and width. Make sure the wire fits your connectors and space.

Tip: Thicker wires (lower AWG numbers) carry more current and stay cooler. Always match the wire gauge to your current load and application.

If you use an undersized wire, it can overheat and damage your equipment. Too-small wires also cause voltage drops, which can mess up motors and electronics. For home projects, always check the recommended gauge for outlets, lights, and appliances.

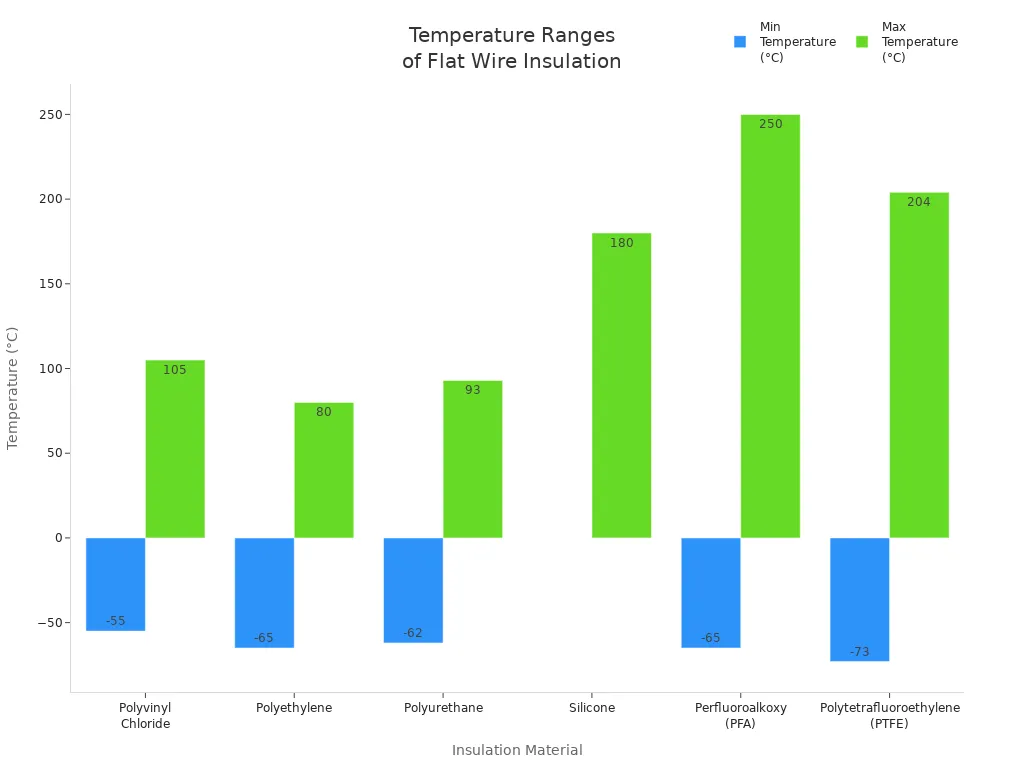

Insulation and Material Considerations

Insulation keeps your flat electrical wire safe from heat, moisture, and chemicals. The right insulation material depends on your environment. If you work in high temperatures, you need insulation that won’t melt or crack. If you deal with chemicals or water, pick a material that resists corrosion.

Here’s a quick look at common insulation materials:

| Material Type | Key Properties | Temperature Range (°C) |

|---|---|---|

| Polyvinyl Chloride | Cost-effective, high durability, fire and chemical resistance | -55 to 105 |

| Polyethylene | High electrical insulation, resistant to cracking | -65 to 80 |

| Polyurethane | Flexible, high water and chemical resistance | -62 to 93 |

| Neoprene | Superior abrasion and cut resistance, resistant to oils and solvents | N/A |

| Silicone | High flexibility, exceptional flame retardance | Up to 180 |

| Perfluoroalkoxy (PFA) | Excellent electrical efficiency, withstands high temperatures | -65 to 250 |

| PTFE | Exceptional resistance to oil, chemicals, heat, and moisture | -73 to 204 |

- Silicone insulation is flexible but can get brittle in extreme heat.

- Teflon (PTFE) is great for high temperatures and stays flexible.

- FEP jackets offer flexibility and high-temperature resistance.

Environmental factors matter too:

- High temperatures can break down insulation and cause shorts.

- Low temperatures make some materials brittle.

- Humidity can lead to corrosion and insulation failure.

- Dry air can crack insulation and cause static.

Ampacity and Voltage Ratings

Ampacity means the maximum current your flat electrical wire can safely carry. If you push more current than the ampacity allows, the wire overheats and the insulation can fail. That’s a fire risk you don’t want.

| Temperature Rating | Common Applications | Voltage Rating |

|---|---|---|

| 60°C | Residential wiring | Up to 2000V |

| 75°C | Most modern installations | Up to 2000V |

| 90°C | High-heat insulation types | Up to 2000V |

- The ampacity of a wire depends on the current load and the wire gauge.

- Higher temperature-rated wires can handle more current.

- Always match the electrical load to the wire’s ampacity to prevent overheating.

If you go over the recommended ampacity or voltage rating, you risk insulation failure and fire. Stick to the ratings for safe and reliable performance.

Safety and Compliance

Safety comes first when you install flat electrical wire. You need to follow local electrical codes and use certified products. Here are some key certifications:

| Certification | Description |

|---|---|

| UL | Underwriters Laboratories, tests and certifies products for safety. |

| CE | European standards compliance mark. |

| CSA | Canadian Standards Association, certifies products for safety. |

To stay compliant, follow these steps:

| Compliance Step | Description |

|---|---|

| Understand Applicable Electrical Codes | Learn your local codes and the National Electrical Code (NEC). |

| Hire a Licensed Electrician | Get professional help to meet safety codes. |

| Obtain Necessary Permits | Make sure you have permits for inspections. |

| Undergo Regular Inspections | Check for code violations during and after installation. |

| Invest in Quality Equipment | Use certified wires and connectors. |

| Stay Informed | Keep up with code changes. |

| Ensure Proper Documentation | Keep records for future reference. |

Common mistakes include using wires that are too short or long, loose connectors, improper grounding, overloaded circuits, and incorrect reconnections. Measure wire length carefully, match connectors to wire size, and label wires before disconnecting.

Practical Examples and Expert Support

Let’s look at some real-world examples:

| Application | Recommended Cable Type |

|---|---|

| House & building Wiring | Single-core wire E-BEAM treated LS0H as per IS 17048. |

| Industrial Control Systems, Appliance | Shielded instrumentation cables, multi-core & control cables |

| Automotive Wiring | Low-voltage flexible automotive cables with heat-resistant sheaths |

If you need a custom solution, manufacturers like YLS can help. YLS offers tailored flat electrical wire and wire harness solutions, fast prototyping in 72 hours, and full customization with shielding, folding, cutouts, and labels. Here’s how the process works:

| Step | Description |

|---|---|

| 1 | Submit Requirements: Send terminal model, drawings, specs, UL code & pin count. |

| 2 | Get Drawings & Samples: Receive drawings and samples in 5–7 days. |

| 3 | Validate Samples: Test and confirm specs, make adjustments if needed. |

| 4 | Approve & Production: Start mass production and arrange shipment. |

Note: Consulting with experts gives you access to years of experience, helps you meet safety standards, and lets you get a solution that fits your project perfectly.

If you’re working on home projects, industrial controls, automotive wiring, or data transmission, always check the wire gauge, insulation, ampacity, and compliance. When in doubt, reach out to professionals or trusted brands like YLS for advice and rapid prototyping.

You want your project to run smoothly, so start by matching wire features to your application requirements. Always use the right wire gauge and check voltage ratings. Look for certifications like UL or CE. Plan your cable routes and keep connections tight. If you need help, reach out to trusted brands like YLS for expert advice and custom solutions.

- Use the correct wire gauge to prevent overheating.

- Check voltage ratings for safe electrical loads.

- Look for certifications to meet safety standards.

- Plan cable routes to avoid interference.

- Consult experts for reliable, tailored solutions.

Ready to tackle your next project? Apply these tips and make safety your top priority! 🚀

FAQ

What is the main advantage of flat electrical wire over round wire?

Flat wire saves space and bends easily in one direction. You get cleaner installations and better performance in tight spots.

How do you know which wire gauge to pick?

Check your device’s current load and wire length. Use a wire gauge chart or ask your supplier for help.

Can you get custom flat cables for unique projects?

Absolutely! Brands like YLS offer custom lengths, pin counts, and features. You can request samples and get expert advice for your specific needs.