You may wonder how to install ribbon wire connectors for ribbon cables safely and effectively. Careful installation protects you from electric shock, overheating, and damage to your devices. The table below shows key safety risks if you do not follow proper procedures:

| Safety Risk | Description |

|---|---|

| Electric Shock | Mismatched ribbon wire connectors can expose live electrical parts. |

| Electrical Shorts and Fires | Poor contact or exposed wires can cause sparks or fires. |

| Overheating | High resistance points can lead to overheating. |

| Non-Compliance With Standards | Using incompatible ribbon wire connectors can break safety rules. |

| Damage to the Vehicle | Incorrect connectors may harm electrical systems. |

This step-by-step guide helps beginners and DIYers avoid mistakes when learning how to connect a ribbon cable. YLS offers trusted custom ribbon cable solutions for reliable performance.

Key Takeaways

- Always check the connector type before installation to avoid mismatches and ensure a secure fit.

- Use the right tools, like wire cutters and strippers, to prepare your ribbon cable properly for a strong connection.

- Align the ribbon cable correctly with the connector, ensuring Pin 1 matches to prevent signal issues.

- Perform a visual check and continuity test after installation to confirm that all connections are secure and functioning.

- Handle ribbon cables gently during installation to avoid damage and ensure long-lasting performance.

Ribbon Wire Connectors Overview

What Are Ribbon Wire Connectors

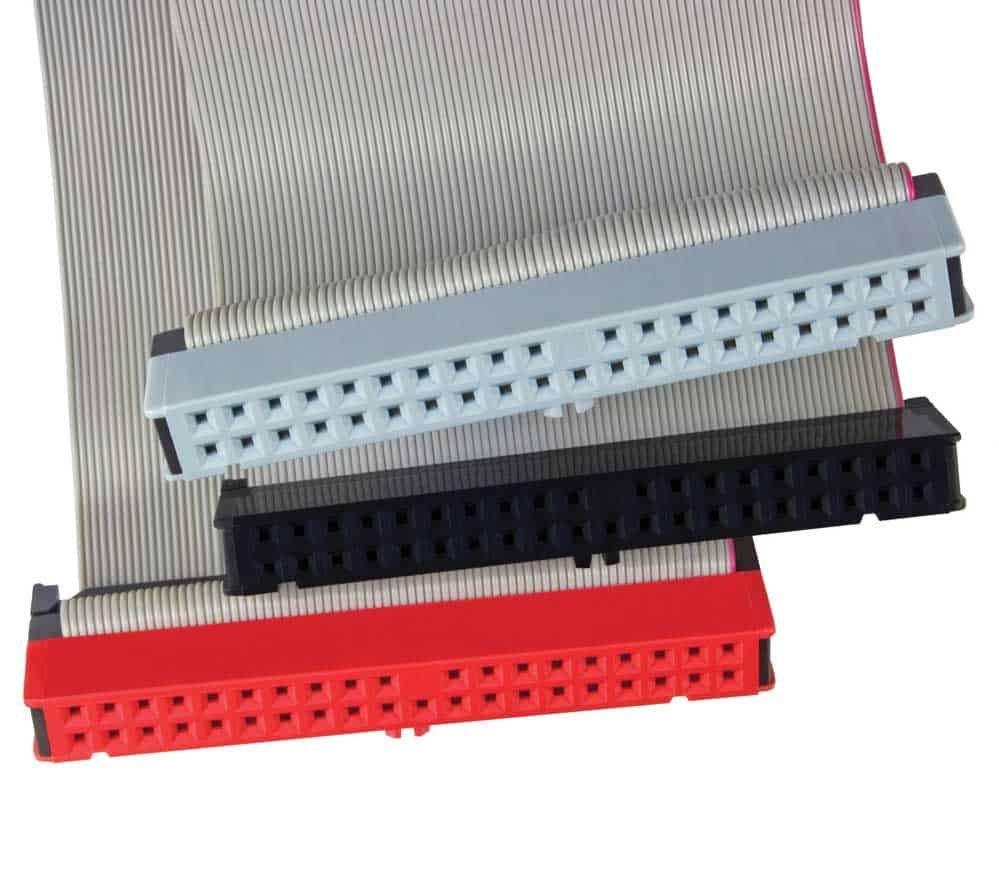

You use ribbon wire connectors to join multiple wires in a flat, organized way. These connectors help you connect a ribbon cable to devices, circuit boards, or other cables. You find several types in the electronics market, each designed for specific tasks.

Here are some common types you may encounter:

- BT224 connectors work well with ATA cables and follow standards like BS9525-F0023, DIN41651, and MIL-C-83503.

- D-subminiature connectors often appear on serial and printer ports.

- Micro ribbon connectors fit 36-pin printer ports and 50-pin SCSI ports.

- DIN 41612 connectors serve Eurocard buses.

- PCB transition headers solder directly onto a printed circuit board.

- DIL headers connect external devices to integrated circuits.

You choose the right connector based on your project’s needs. When you install a connector properly, it can last between 5 to 10 years under normal use. The lifespan depends on the environment and the materials used.

Tip: Always check the connector type before starting your installation. This step helps you avoid mismatches and ensures a secure fit.

Common Uses

You see ribbon wire connectors in many industries and devices. Their flat design makes them ideal for tight spaces and organized wiring.

The table below shows where you might use these connectors:

| Application Area | Description |

|---|---|

| Robotics | Used in automation and pick and place equipment. |

| Computers/Hard Drives | Internal wiring for data storage devices. |

| Electronics | General use in consumer and industrial devices. |

| Test & Measuring Equipment | Utilized in aerospace, medical, and military tech. |

| Connectivity in Limited Space | Ideal for tight spaces due to their design. |

You also find ribbon cable in data transmission, communications, and automated termination equipment. You rely on these connectors for internal wiring in hard drives, CD drives, and other electronics. In robotics and testing equipment, ribbon wire connectors help you achieve reliable connections and organized layouts.

Tools and Materials

Required Tools

You need the right tools and materials needed to install a ribbon cable connector safely. Start with a wire cutter to trim the ribbon cable to the correct length. Use a precision wire stripper to remove insulation from the ends without damaging the conductors. A small flat-head screwdriver helps you open connector housings or adjust locking tabs. You may need a crimping tool if your connector requires crimping for a secure fit. For soldered connections, a soldering iron and solder wire are essential. Tweezers can help you handle small wires and parts. Always keep a multimeter nearby to test your connections after installation.

Tip: Clean your tools before you begin. Dust or oil can affect the quality of your ribbon cable connection.

Materials Checklist

Choosing the right materials ensures your ribbon cable installation lasts and performs well. The table below shows common materials used for ribbon cables and connectors, along with their benefits:

| Material | Description |

|---|---|

| Copper | Highly conductive and flexible; works for everyday uses. |

| Tinned Copper | Tin coating prevents oxidation; ideal for humid areas and easier to solder. |

| Silver-Plated Copper | Superior conductivity and corrosion resistance; best for high-speed data transfer. |

| Polyvinyl Chloride | Flexible and flame-resistant; good for general applications. |

| Teflon (PTFE) | Handles high temperatures and chemicals; used in aerospace and industry. |

| Silicone | Flexible and heat-resistant; perfect for medical and automotive electronics. |

Connector contacts use materials like copper, brass, gold, silver, and tin. Gold contacts offer low resistance and resist corrosion, making them ideal for high-reliability ribbon cable connections. Brass maintains performance in harsh environments. Silver works well for high-current uses.

Environmental conditions also affect your installation. Avoid exposing connectors to chemicals, extreme temperature changes, moisture, or solid debris like dust and metal shavings. These factors can damage your ribbon cable or interfere with connector mating.

Note: Always match your ribbon cable and connector materials to your project’s needs and environment. This step helps you achieve a secure and reliable connection.

Ribbon Cable Preparation

Measuring and Cutting

You start the step-by-step guide by measuring your ribbon cable. Use a ruler or measuring tape to find the exact length needed for your project. Make sure you leave a little extra length for adjustments or future repairs. Cut the ribbon cable with a sharp wire cutter. This tool gives you a clean edge and prevents fraying. Always double-check your measurements before cutting. A mistake here can waste material and cause problems later.

Tip: Measure twice and cut once. This simple habit saves time and avoids errors.

Identifying Pin 1

Correct orientation is key when you learn how to connect a ribbon cable. Pin 1 marks the starting point for your connection. You can find Pin 1 using several methods:

- Look for a small arrow pointing to Pin 1 on the connector.

- Check for a number “1” printed or molded next to the first pin.

- Spot a dot or indentation near Pin 1 on the ribbon cable.

- Find a color-coded stripe or different colored wire at Pin 1.

- Notice if the connector is keyed, which means it only fits one way.

You must match Pin 1 on the ribbon cable to Pin 1 on the connector. This step ensures signals travel correctly and prevents damage to your devices.

Stripping Ends

After you identify Pin 1, prepare the ends of your ribbon cable for connection. Use a precision wire stripper to remove the insulation from each conductor. Strip only enough to expose the metal for a secure fit. Avoid nicking or cutting the wires inside. If you damage a wire, cut the end and start again. Clean, exposed conductors help you achieve a strong electrical connection.

Note: Work slowly and check each wire as you go. Proper preparation makes the step-by-step process of how to connect a ribbon cable much easier.

Connector Attachment

Aligning the Cable

Proper alignment is the foundation for a successful installation. You must pay close attention to the orientation of your ribbon cable and connector before you begin. Start by measuring the required length for your project and cutting the cable accurately. Look for the pink stripe or label on the edge of the ribbon cable. This stripe usually marks Pin 1, which helps you match the cable to the connector correctly.

Next, examine your connector. Notice the position of the tongue or keying feature. When you place the pink stripe and label on the left side facing up, the tongue of the connector should point down. This orientation ensures that signals travel to the correct pins and prevents damage to your devices.

Follow these steps to align your cable:

- Place the ribbon cable flat on your workspace.

- Position the pink stripe and label on the left, facing up.

- Hold the connector so the tongue points down.

- Align the edge of the cable with the connector opening.

- Squeeze the connector gently to hold the cable in place.

Tip: Double-check the alignment before moving to the next step. A small mistake here can cause miscommunication between devices.

If you use YLS Custom Ribbon Cable, you can request custom labeling or color coding for easier identification. This feature helps you avoid confusion and speeds up installation.

Inserting into Connector

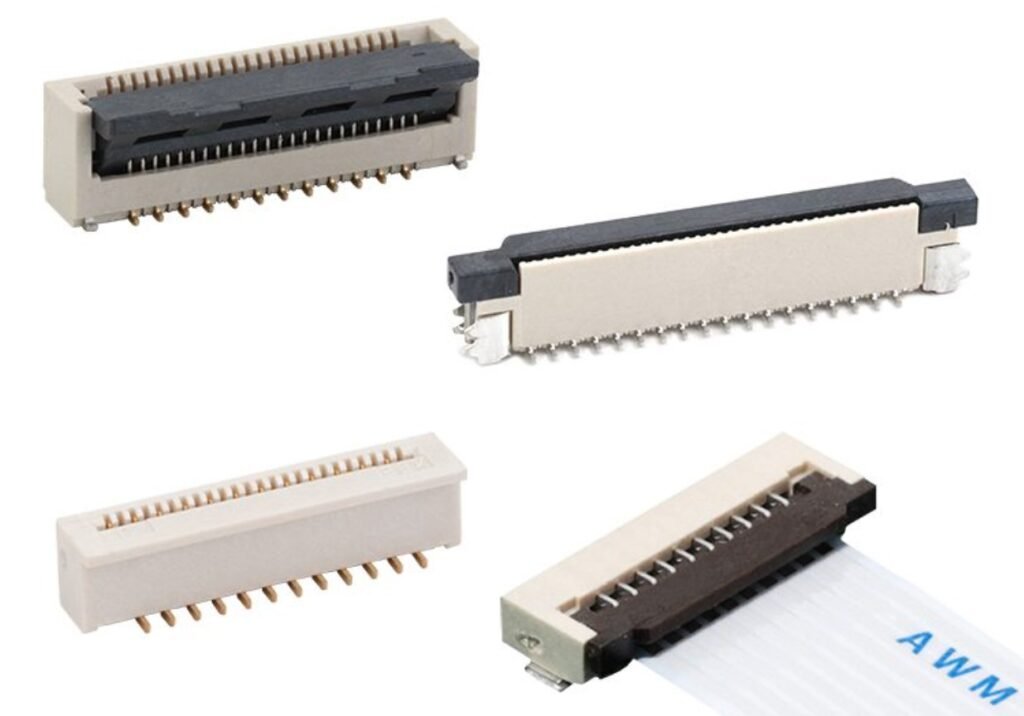

Once you align the ribbon cable, you need to insert it into the connector. You must handle this step with care to avoid damaging the delicate conductors. Most ribbon wire connectors use insulation displacement contacts (IDC) or zero insertion force (ZIF) mechanisms.

For IDC connectors, insert the cable from the top, making sure the edge sits flush with the connector. Use a crimping tool if required. For ZIF connectors, unlock the flap using a spudger or your fingernail. Slide the cable into the socket with minimal force. If you feel resistance, check that the flap is fully unlocked.

Common errors during insertion include leaving loose connectors or ribbons. These mistakes can lead to flickering screens, unresponsive buttons, or no signal. Always double-check that the ribbon cable is fully seated and locked into place. Use a flashlight to inspect the connection and confirm that the cable sits flush with the connector.

- Avoid forcing the cable into the connector.

- Make sure the locking mechanism is open before insertion.

- Confirm that the cable is straight and not twisted.

Note: If you use YLS Custom Ribbon Cable, you benefit from precise conductor spacing and high-quality materials. These features make insertion easier and improve long-term reliability.

Locking or Crimping

Securing the connection is the final step. You must lock or crimp the connector to ensure a stable and reliable attachment. For IDC connectors, use the appropriate crimping tool to close the connector around the cable. This action pushes the contacts through the insulation and creates a solid electrical connection.

After crimping, wrap the cable over the back of the connector and install the cap if your connector design includes one. For ZIF connectors, flip down the locking flap to secure the cable. Repeat the process for the other side if your project requires dual connections.

Check that all connections are secure before powering up your device. Loose connections can cause intermittent problems or complete failure. YLS Custom Ribbon Cable undergoes 100% electrical testing before shipment, so you can trust the quality and reliability of your installation.

Here is a table showing YLS quality assurance measures and customization options:

| Quality Assurance Measure | Description |

|---|---|

| 100% Electrical Testing Before Shipment | Each cable is electrically tested for performance and reliability. |

| UL, RoHS, and REACH Compliance | All materials meet major safety and environmental standards. |

| Customization Option | Description |

|---|---|

| Length | Choose the exact length for your project. |

| Connector Types | Select from various connector styles. |

| Pitch | Customize pitch for different applications. |

| Conductor Materials | Pick materials based on your needs. |

| Additional Shielding | Add shielding for extra protection. |

Tip: If you need special features like extra shielding or unique labeling, YLS can customize your ribbon wire connectors to fit your requirements.

After you finish the locking or crimping step, inspect the connection one last time. Make sure the cable is secure and oriented correctly. You are now ready to connect ribbon cable to your device with confidence.

Testing

Visual Check

Before you power up your device, you need to check your work visually. This step helps you catch mistakes early and avoid problems later. Look closely at the ribbon cable and connector. You want to see clear signs that you installed everything correctly.

- The red stripe on the ribbon cable should line up with pin 1 on both the connector and the device. This stripe helps you confirm the correct orientation.

- Many connectors have a ridge or notch. This feature prevents you from installing the connector the wrong way. Make sure the ridge fits into the matching slot.

- If you made your own cable, double-check that the red stripe matches pin 1 at both ends. This step is important for signal flow and device safety.

Tip: Good lighting makes it easier to spot alignment issues or loose connections. Use a flashlight if needed.

You should also look for any exposed wires, bent pins, or gaps between the cable and connector. These issues can cause poor performance or even damage your equipment.

Continuity Test

After the visual check, you need to test the electrical connection. A continuity test helps you make sure each wire inside the ribbon cable connects properly from one end to the other. You can use a digital multimeter for this task.

- Set your multimeter to continuity mode. Look for a symbol that looks like a diode or a sound wave.

- Place one probe on a pin at one end of the ribbon cable’s connector. Place the other probe on the matching pin at the opposite end.

- Listen for a beep or look for a low resistance reading. This signal means the wire has a good connection.

- Repeat the test for each wire in the ribbon cable. Move the probes to the next pair of matching pins each time.

- Check for shorts by testing between different pins. You should not hear a beep or see a low resistance reading between separate wires.

You now know how to connect a ribbon cable and confirm that your installation works. These tests help you avoid common mistakes and ensure a reliable connection.

Common Mistakes

When you install ribbon wire connectors, you may run into a few common mistakes. Knowing these errors helps you avoid problems and keeps your connections safe and reliable. Here are some of the most frequent mistakes people make during installation:

- Reusing single-use wire connectors. These connectors often do not work well after being opened.

- Stripping wires with a knife or boxcutter. This can damage the wire. Always use a proper wire stripping tool.

- Using the wrong size connectors. If the connector does not fit, the circuit may not work.

- Overtwisting winged connectors. Too much force can break the wires.

- Stripping away too much insulation. Only remove what you need to prevent exposed conductors.

Tip: Always double-check your tools and materials before starting. This step helps you avoid many of these mistakes.

Misalignment

Misalignment is a frequent problem when working with ribbon cables. If you do not line up the cable and connector correctly, you can cause short circuits or signal interference. These issues may lead to intermittent connections. You might notice that signals or power do not reach the right pins. This can cause devices to fail or behave unpredictably. Always check the orientation of the cable and match Pin 1 on both the cable and connector. Many people find that following common ribbon cable connection methods, such as using the colored stripe as a guide, helps prevent misalignment.

Incomplete Insertion

You must insert the ribbon cable fully into the connector. If you stop halfway, the connection will not be secure. This can cause flickering screens, lost signals, or devices that do not turn on. Always push the cable in until it sits flush with the connector. Listen for a click or check for locking tabs to confirm a proper fit. If you feel resistance, stop and check for obstructions.

Skipping Testing

Some people skip the final testing step. This is a big mistake. Without testing, you may not notice a loose wire or a short circuit. Always perform a visual check and a continuity test before using your device. Testing helps you catch problems early and saves time in the long run.

Note: Careful installation and testing ensure your ribbon cable connections last longer and work better.

Troubleshooting

Loose Connections

Loose connections can cause devices to stop working or behave unpredictably. You may notice flickering screens, dropped signals, or intermittent power. Start by checking the alignment of your ribbon cable and connector. Make sure the cable sits flush with the connector and that locking tabs are engaged. If you see any gaps or movement, reseat the cable and press gently until you hear a click or feel resistance.

You can use a multimeter to test for continuity. Place the probes on both ends of the ribbon cable. If you do not get a beep or a low resistance reading, the connection may be loose. Try cleaning the contacts with a soft brush or compressed air. Dust and debris can block the signal. If problems continue, inspect the connector for wear or damage. Sometimes, replacing the connector is the best solution.

YLS offers engineering support if you need help with persistent loose connections. Their custom ribbon cable solutions include quality assurance checks to reduce these issues.

Damaged Wires

Damaged wires in a ribbon cable can lead to signal loss or complete failure. You might see visible cuts, bends, or exposed metal. If you find a damaged wire, you have several options:

- Lightly scratch the insulation and solder the thin cable directly to restore the connection.

- Remove the existing board connector and replace it with a compatible one.

- Use shim techniques by filing down a smaller flex ribbon head to maintain pressure on the connector.

- Consider replacing the connector for a straightforward fix.

Always inspect the ribbon cable for signs of wear before installation. If you use YLS custom ribbon cables, you benefit from strict quality control and electrical testing. This reduces the risk of damaged wires and ensures reliable performance.

Tip: Handle ribbon cables gently during installation. Avoid bending or twisting the cable sharply. Careful handling helps prevent damage and extends the life of your connection.

You can achieve a reliable installation by following each step carefully. Ribbon wire connectors offer a flat, space-efficient design and color-coding for easy alignment. Standardized pitch and conductor counts help you match connectors and cables. To practice safe installation, gather your materials, prepare the wires, select the correct connector, and test each connection. YLS provides custom ribbon cable solutions that support your project needs. Remember, careful preparation and thorough testing help you avoid common mistakes and ensure lasting performance.

- Flat and space-efficient design

- Color-coding for easy alignment

- Simplified termination with IDC connectors

- Gather your materials

- Prepare the wires

- Select the correct connector

- Test each connection

Tip: Practice these steps and reach out for support if you need help with ribbon wire connectors.

FAQ

How do you know which connector fits your ribbon cable?

Check the pitch and number of conductors on your ribbon cable. Match these to the connector specifications. You can find this information on the cable label or datasheet.

Tip: Always use connectors from trusted brands like YLS for best results.

Can you reuse ribbon wire connectors?

Most ribbon wire connectors are single-use. You should not reuse them because the contacts may not grip the wires securely after removal. Always use a new connector for each installation.

What should you do if your ribbon cable is too short?

You need to replace the cable with a longer one. YLS offers custom lengths to fit your project. Never stretch or force a cable to reach, as this can damage the wires.

How do you prevent damage during installation?

Handle the ribbon cable gently. Avoid bending or twisting it sharply. Use proper tools for stripping and crimping. Inspect the cable before and after installation for any signs of wear.

| Step | Action |

|---|---|

| 1 | Use correct tools |

| 2 | Check for damage |

| 3 | Align carefully |

Why choose YLS for custom ribbon cables?

YLS provides engineering support, fast turnaround, and strict quality control. You can customize cable length, pitch, and shielding. Every cable passes electrical testing, so you get reliable performance.

Note: YLS cables meet UL and RoHS standards for safety.