You use ribbon wire connectors to join multiple wires in a flat, organized way. These connectors help you create clean and reliable links between different parts of an electronic device. You do not need to strip insulation before connecting, which makes assembly faster and easier. In modern electronics, ribbon wire connectors play a key role in keeping your devices working smoothly. Custom solutions from YLS let you match the connector to your project, no matter how unique your needs are.

Key Takeaways

- Ribbon wire connectors simplify the assembly process by allowing quick connections without stripping insulation, saving time and reducing errors.

- Choosing the right materials, like stranded copper and PVC, enhances the performance and durability of ribbon wire connectors in various applications.

- IDC connectors are ideal for high-volume production, enabling mass termination of wires quickly and efficiently, which is cost-effective.

- ZIF connectors provide easy insertion and removal, making them perfect for devices that require frequent maintenance or upgrades.

- Custom solutions from YLS ensure that ribbon cables meet specific project needs, enhancing reliability and performance in electronics.

Ribbon Wire Connectors: Structure

Materials and Design

You will find that the materials used in ribbon wire connectors play a big role in how well they perform. The table below shows some common materials and how each one affects the connector’s performance:

| Material | Impact on Performance |

|---|---|

| Stranded Copper | Provides excellent conductivity and flexibility |

| PVC | Offers good insulation and durability |

| Teflon | Enhances temperature resistance |

| Olefin | Provides flexibility and chemical resistance |

When you choose a ribbon cable for your project, you want materials that match your needs. Stranded copper gives you strong electrical signals and lets the cable bend without breaking. PVC insulation keeps your connections safe and long-lasting. Teflon works well if you need your ribbon cable to handle high temperatures. Olefin helps when you need extra flexibility or protection from chemicals.

Design features also make a difference in how you use ribbon wire connectors. You will notice that these connectors often have:

- Compact shapes that fit into tight spaces in devices like smartphones, tablets, and laptops.

- Secure locking mechanisms that keep connections stable, especially in cars and other vehicles.

- Easy-to-use assembly features that help you connect cables quickly in medical equipment and robotics.

- Strong construction that stands up to tough conditions in factories and aerospace systems.

These design choices help you create reliable and easy-to-maintain connections with your ribbon cable.

Attachment Methods

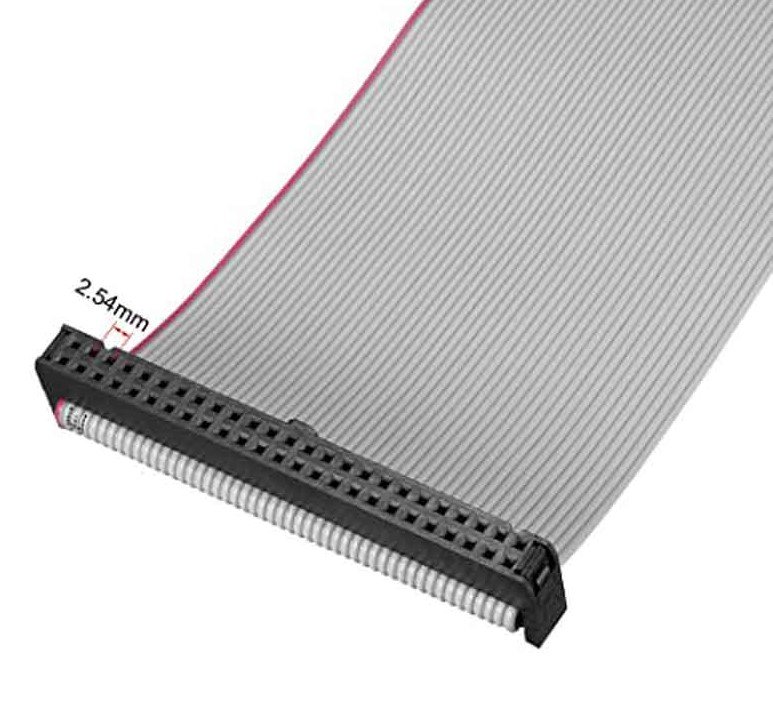

You can attach ribbon wire connectors using several methods, each designed for speed and reliability. The most common method is insulation displacement connection (IDC). With IDC, you do not need to strip the insulation from the ribbon cable. The connector uses sharp contacts to pierce the insulation and make a solid electrical connection.

Here are some steps you might follow when attaching a ribbon wire connector:

- Choose the right crimping tool for your ribbon cable.

- Prepare the cable by aligning it with the connector.

- Use the tool to press the connector onto the cable, ensuring the contacts pierce the insulation.

- Inspect the connection for any defects.

- Insert the assembly into the connector housing.

- Test the finished assembly to make sure it works.

You will find that these methods let you connect multiple wires at once, saving you time and reducing errors. This makes ribbon cable assemblies a popular choice in electronics manufacturing.

Types of Ribbon Cable Connectors

When you work with ribbon wire connectors, you need to choose the right ribbon cable connector for your project. Each type of connector offers unique features and benefits. You will see how these connectors work with ribbon cables and how YLS custom ribbon cable solutions can help you achieve the best results.

IDC Connectors

IDC connectors stand out as one of the most popular choices for ribbon cable assemblies. You use idc connectors to make fast and reliable connections without stripping the insulation from the wires. The connector uses a sharp blade to pierce the insulation, creating a gas-tight metal-to-metal connection. This process removes surface oxides and ensures strong electrical contact.

Tip: IDC connectors let you terminate many wires at once, saving you time and reducing errors in high-volume manufacturing.

You find idc connectors in computers, telecommunication equipment, and industrial controls. Their compact design makes them ideal for tight spaces. You benefit from quick assembly, minimal labor, and cost-effective production. The rugged clips and strain relief features keep your ribbon cable secure and stable.

- Quick and easy assembly due to mass termination

- No need for stripping, crimping, or soldering

- Reliable connections through cold-welding

- Cost-effective and efficient for large-scale projects

YLS custom ribbon cables work seamlessly with idc connectors. You can specify the pitch, conductor count, and end termination to match your connector and application. Whether you need tinned or gold-flashed bare ends, YLS provides options that integrate perfectly with idc connectors.

ZIF Connectors

ZIF connectors offer a different approach for connecting ribbon cables. You use a lever or slider mechanism to insert the cable with zero force. This makes ZIF connectors easy to use and reduces the risk of damaging delicate flat cables. You can quickly connect and disconnect components, which is helpful in devices that require frequent maintenance or upgrades.

| Feature | ZIF Connectors | Other Ribbon Cable Connectors |

|---|---|---|

| Insertion Mechanism | Lever or slider mechanism for zero force insertion | Requires manual pressure for connection |

| Ease of Use | Quick and easy connection/disconnection | More prone to incorrect insertion |

| Application | Ideal for devices needing frequent component changes | Generally used in fixed connections |

You find ZIF connectors in smartphones, tablets, laptops, and medical devices. These connectors work well with flat flexible cables (FFC) and ribbon cables in high-density electronic devices. You also see ZIF connectors in automotive infotainment systems and aerospace applications where reliability and minimal weight matter.

| Industry | Application Description |

|---|---|

| Consumer Electronics | Used in smartphones, tablets, and laptops to connect flexible display cables to the main board. |

| Medical Devices | Found in wearable health monitors and diagnostic equipment for lightweight and flexible construction. |

| Automotive Systems | Utilized in in-car infotainment systems and sensors to manage flexible connections in tight spaces. |

| Aerospace | Employed in satellite and avionics systems for reliability and minimal weight, supporting high-speed data. |

YLS custom ribbon cable solutions include PET or PI stiffeners for ZIF sockets. You can choose the cable length, shape, and reinforcement features to ensure compatibility with your ZIF connector and application.

D-Sub and Card Edge

D-Sub connectors and card edge connectors serve different roles when you connect ribbon cables. D-Sub connectors have a trapezoidal shape and work well in computer and industrial applications. You use them for versatile connections, and they come with accessories like backshells and strain reliefs. These features help you manage cables and reduce electromagnetic interference.

Card edge connectors, such as those found in PCI slots, focus on high signal integrity for printed circuit boards. You use card edge connectors when you need reliable connections in high-density environments. D-Ribbon connectors, with their flat ribbon-like design, are ideal for applications that require many connections in a small space. Accessories like shrouds and cable clamps keep your ribbon cable secure.

Note: D-Sub connectors provide strong cable management, while card edge connectors excel in maintaining signal quality on circuit boards.

YLS custom ribbon cables integrate with D-Sub, card edge, and other connector types. You can select solder tail, FPC-style, or custom header connectors to match your needs. YLS offers tailored solutions, ensuring your ribbon cable connector works perfectly in your specific application.

| Connector Type | Integration Options |

|---|---|

| Tinned or gold-flashed bare ends | Seamless integration with connectors or boards |

| PET/PI stiffeners for ZIF sockets | Ensures compatibility with specific applications |

| Solder tail, FPC-style, or custom header connector | Tailored solutions for diverse needs |

When you choose among the types of ribbon cable connectors, you match your ribbon cable to the right connector for your project. YLS helps you customize ribbon cables for any connector type, making sure your assembly is reliable and efficient.

Flat Cable and Ribbon Wire Cable Applications

Consumer Electronics

You see ribbon wire cable used in many consumer electronics. Laptops rely on ribbon wire cable to connect displays, keyboards, and touchpads. Smartphones use ribbon wire cable for internal connections between screens, cameras, and sensors. Home appliances, such as washing machines and microwaves, depend on ribbon wire cable to link control panels and circuit boards. You also find ribbon wire cable in printers and scanners, where it connects moving parts and transmits data signals. Flat cable helps you save space inside devices, making electronics slimmer and lighter.

Tip: YLS customizes ribbon wire cable for each device, so you get the right length, pitch, and conductor count for your project.

Medical and Automotive

Ribbon wire cable plays a vital role in medical devices. You use ribbon wire cable in patient monitors, imaging systems, and robotic surgical tools. The flexibility of ribbon wire cable allows you to fit it into compact spaces and moving parts. Hygienic materials make ribbon wire cable easy to sterilize, which is important for patient safety. Ribbon wire cable also endures millions of bends, so your equipment stays reliable.

In automotive systems, ribbon wire cable connects infotainment units, sensor arrays, and lighting controls. You benefit from ribbon wire cable that withstands vibration and temperature changes. Electric vehicles use ribbon wire cable to link battery management systems and control units, ensuring smooth data flow. YLS offers ribbon wire cable with custom reinforcement, so your cables last longer in tough environments.

Industrial and Smart Home

You use ribbon wire cable in industrial automation to power sensors, actuators, and machinery. Ribbon wire cable provides flexible and space-efficient wiring, which is essential for compact control panels. Ribbon wire cable enables seamless communication between IoT devices in smart homes. You rely on ribbon wire cable to connect security systems, lighting controls, and smart thermostats. Ribbon cables help you automate processes and improve efficiency.

YLS supports you with custom ribbon wire cable for industrial and smart home projects. You choose the cable shape, length, and termination to match your needs. Ribbon cable applications cover robotics, data equipment, and advanced manufacturing systems. Flat cable and ribbon cables from YLS give you reliable performance and easy installation.

| Application Area | Example Uses | YLS Customization Benefits |

|---|---|---|

| Consumer Electronics | Laptops, smartphones, printers, home appliances | Tailored pitch, length, and conductor count |

| Medical Devices | Patient monitors, imaging, surgical robots | Sterilizable, flexible, durable |

| Automotive | Infotainment, sensors, battery management | Reinforced for vibration and temperature |

| Industrial/Smart Home | Automation, IoT, robotics, security systems | Space-efficient, reliable, easy to install |

Ribbon Wire Connectors vs Other Connectors

Advantages

You gain several benefits when you choose ribbon wire connectors for your electronic projects. These connectors simplify installation and help you manage your inventory more efficiently. IDC connectors, a common type, let you attach cables quickly without stripping or soldering wires. This feature saves you time and reduces labor costs. You can customize these connectors to fit your specific needs, which improves cost efficiency.

Tip: The versatility of ribbon wire connectors means you can use them in many different applications, from computers to industrial controls.

Here is a table showing key advantages for high-density electronic assemblies:

| Advantage | Description |

|---|---|

| Ease of use | Quick attachment without stripping or soldering, ideal for mass production. |

| High density | Flat arrangement allows many connections in a compact space. |

You also benefit from flexibility, customizability, space efficiency, and noise reduction. These features make ribbon wire connectors a smart choice for modern electronics.

Limitations

You should consider some limitations before selecting ribbon wire connectors. These connectors can be affected by electromagnetic interference (EMI), which may impact performance. High-speed data transmission sometimes causes crosstalk between wires. Over long distances, signal strength can decrease, affecting data integrity.

| Limitation | Description |

|---|---|

| Susceptibility to EMI | Performance may suffer due to electromagnetic interference. |

| Crosstalk | Adjacent wires can interfere during high-speed data transmission. |

| Signal Attenuation | Signal strength may weaken over long cable runs. |

Fire resistance is important for safety. Make sure your ribbon cable meets regulations like the EU’s Restriction of Hazardous Substances.

Choosing the Right Connector

You need to evaluate several factors when choosing between ribbon wire connectors and other connector solutions:

- Environmental variables such as exposure to water, dust, and vibration

- Termination finishes, including insertion loss and misalignment

- Maintainability, like repair and cleanability

- Cable limitations, such as bend radius and wavelength range

- Operating environment and signal power budget

- Specific application requirements

- Tools available for connection

- Desired durability of the connection

For best results, follow these practices:

- Use soldering for high-reliability projects.

- Choose crimping for fast, large-scale assembly.

- Select IDC connectors for quick, high-volume production.

- Try wire wrapping for prototypes and low-current uses.

- Pick mechanical connectors for connections you change often.

- Consider heat shrink and solder sleeves for single-use, insulated connections.

Note: Always match your connector choice to your project’s needs and environment to ensure reliable performance.

You have seen how ribbon wire connectors give you flexibility, reliability, and space-saving benefits in modern electronics. Their structure and design support easy integration and strong signal integrity. Custom solutions from YLS let you match your cable to any application.

| Benefit | Description |

|---|---|

| Flexibility | Fits compact and complex devices |

| Enhanced Signal Integrity | Maintains reliable data transmission |

| Cost-Efficiency | Reduces production costs |

| Reliability | Lowers failure rates in critical systems |

You can trust ribbon wire connectors for efficient assembly, durability, and high performance. These features make them a smart choice as electronics continue to advance.

FAQ

What is the main advantage of using ribbon wire connectors?

You get fast, organized connections for multiple wires. Ribbon wire connectors save space and reduce assembly time. You can easily connect or disconnect components in your device.

Tip: Ribbon wire connectors help you keep your projects neat and reliable.

Can you use ribbon wire connectors with custom ribbon cables?

Yes, you can pair ribbon wire connectors with custom ribbon cables from YLS. You choose the pitch, length, and termination style. This ensures your cable fits your exact project requirements.

Are ribbon wire connectors reliable for high-vibration environments?

You can trust ribbon wire connectors in high-vibration settings. Many connectors include locking features and strain relief. These features help prevent accidental disconnection and maintain stable performance.

How do you select the right ribbon wire connector for your application?

You should consider the number of wires, pitch size, and connector type. Think about your device’s space and environment. YLS offers engineering support to help you choose the best option.

| Factor | What to Check |

|---|---|

| Wire Count | Number of connections |

| Pitch Size | Space between wires |

| Connector Type | IDC, ZIF, D-Sub, etc. |