Flexible Flat Automotive Cable for Modern Vehicles

All uploads are secure and confidential

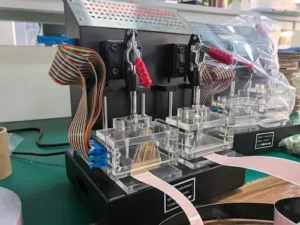

Automotive FFC Cables

Automotive FFC cables are used for displays, sensors, lighting, and battery systems inside vehicles. They save space, reduce weight, and support high-speed signals like LVDS, CAN, and MIPI. With shielded designs and high flex life, they meet the durability and EMI standards required in modern car electronics.

| FFC Flat Cable | Specification |

|---|---|

| Pitch | 0.5mm, 0.8mm, 1.0mm, 1.25mm, 1.27mm, 2.0mm, 2.54mm |

| Conductor | 0.035×0.3, 0.05×0.5, 0.1×0.65, 0.05×0.5 |

| Insulation | 0.043, 0.06, 0.1, 0.08 |

| Reinforcing Tape | 0.16, 0.225, 0.25 |

| Blue Stiffener | 4–8mm & 3–5mm |

| Contact Sides | Same side & opposite side contact |

| Pin Count | 4 to 96 pins (customizable) |

| Cable Length | 20mm – 10,000mm (customizable) |

| Cable Type | Type A, B~H, I (custom options) |

| Service | OEM / ODM available |

| Certification | ISO9001:2008, RoHS compliant |

| MOQ | 50 pcs |

Ask us about sample support.

Product Categories &

Engineering Solutions

Modern vehicles demand more connections in less space — with zero tolerance for failure. Our automotive-grade FFC cables are built for exactly that. Whether you’re wiring a touchscreen, connecting battery cells in an EV, or running data to an ADAS camera, we help you get the right cable for the job — fast.

Automotive Infotainment FFC Cable

- High-speed data: LVDS, eDP, MIPI

- Controlled 100Ω differential impedance

- Heavy EMI shielding for a clear, stable signal

- Vibration-proof connectors for secure linking

Engineered for flawless, high-bandwidth video and data transmission in the vehicle’s demanding electronic environment.

Airbag Rotary FFC Cable (Squib)

- Rated for >15 million rotations

- Gold-plated contacts for max reliability

- Pre-folded for perfect fit & long life

- Meets USCAR-2 safety standards

The vital link ensuring absolute reliability for airbag deployment and steering wheel controls.

EV Battery (BMS) FFC Cable

- High voltage rating (up to 1000V DC)

- Withstands high battery heat (125°C)

- Resists battery chemical exposure

- Optional integrated temperature sensors

Safely monitors voltage and temperature across EV battery cells, crucial for pack safety, longevity, and performance.

ADAS Camera & Sensor FFC

- Ultra-fine 0.3mm pitch for compact cameras

- Supports high-speed HD camera data

- IP67 waterproof option available

- Maintains clear signal over length

Enables high-clarity, low-latency data transmission from critical ADAS sensors and cameras to the central processing unit.

Automotive LED Lighting FFC Cable

- Handles high power for bright LEDs (3A)

- Manages heat to protect LEDs

- Black finish for a clean interior look

- Pre-shaped to fit complex light designs

Designed to reliably power and control complex LED arrays, supporting dynamic lighting effects while managing heat in compact light fixtures.

Steering Wheel & Switch Control FFC Cable

- Durable for >1 million button presses

- Reliably supports LIN/CAN bus systems

- Option for integrated button domes

- Saves space over traditional wires

Provides a reliable, all-in-one connection for Human-Machine Interface (HMI) modules, ensuring long-term performance under constant use.

Contact our engineer for drawing review and sample proposal.

Custom Capabilities — Built to Your Specs

Over 80% of our module FFCs are made to order — whether you’re designing a display panel for a tablet or integrating a touch module into a smart appliance, we help you finalize geometry, connector match, shielding layout, and packaging.

1. Cable Size & Shape

You can tell us how long the cable needs to be, and if it needs to fold — we’ll make it match your space exactly.

2. Number of Pins & Pin Layout

Whether your module needs 6 pins or 60 pins, we’ll arrange them in the correct order and spacing (like 0.5mm or 1.0mm).

3. Ends & Connections

We can leave the ends open, or add gold-plated contacts, or even install the exact connector you use — ready to plug in.

4. Shielding for Sensitive Signals

If your signal is easily affected by noise (like in camera or sensor modules), we can add special shielding to keep it clean.

5. Labels, Tabs & Assembly Help

We can add pull tabs, printed labels, or QR codes — to help your workers install it quickly and correctly.

6. Packaging for Your Production Line

We can pack the cables in trays, bags, or tape & reel — whatever fits your assembly process best.

Faster assembly time

Better fit and fewer errors

Ready for production line

Custom-made to your specs

Send Us your drawing or photo — we’ll make a sample that fits.

Where Our FFC Cables Are Used

Standard Ribbon Cables are ideal for compact, high-performance electronic assemblies across diverse industries. Whether you’re designing wearable tech, medical devices, or automation equipment, our cables provide reliable, space-efficient signal transmission with full customization support.

Drone Interconnect Solutions

Internal wiring in UAVs often faces extremely limited space, vibration, twisting, and weight sensitivity.

We offer lightweight, flexible, and shielded FFC (Flexible Flat Cable) solutions for flight control boards, gimbal control modules, power management modules, and more. We can provide pre-bent and multi-fold designs to improve assembly efficiency and stability.

- Folded ribbon cables optimized for 3D routing

- Low-weight, low-profile design reduces UAV payload

- Tin-plated or EMI-shielded options for signal integrity

Energy Storage Systems

Energy storage battery systems (e.g., lithium batteries, home energy storage) require multi-core cable connections between the BMS (Battery Management System) and battery cells, often encountering EMI and space constraints.

YLS provides custom-length, custom-pitch, and multi-core FFC cables with shielding, flame retardancy, and numbering labels, facilitating efficient integration and long-term stable operation.

- Up to 96 conductors per cable, for dense battery arrays

- Shielded cable variants reduce EMI near switching circuits

- Folded layouts improve space usage in battery trays

Smart Home Devices

Smart home modules, such as LED light strips, access controls, and display controllers, require miniature wiring solutions, along with UL safety certification and long-term stability.

We support small-pitch (0.5mm) and multi-fold designs, suitable for LED strip controllers and touch modules. We offer UL-certifiable materials and support terminal assembly and bulk packaging.

- Flame-retardant materials for in-wall or indoor applications

- Labels & barcodes for easy batch traceability

- Ready-to-connect ends with pre-installed connectors

Robotics & Motion Systems

Internal wiring in robotic arms, linear stages, and collaborative robots often involves continuous movement, bending, and vibration, making it challenging for standard wire harnesses to meet lifespan requirements.

We offer FFC wiring solutions with high flex life (>1 million cycles), multi-fold points, and enhanced flexibility designs, suitable for embedding within mechanical motion areas.

- High-flex life cable construction

- Folded flat cable for articulated joints

- Compact routing inside confined enclosures

Medical Devices

Medical devices (portable diagnostic instruments, surgical robots) demand miniaturization, high signal integrity, and material safety.

We can provide small-sized, high-density flat cables for medical equipment, supporting PI insulation, high-temperature resistance, RoHS/UL materials, and printable traceability markers.

- Medical-grade PET/PI insulation options

- Gold-finished ends for corrosion-free signal transfer

- Serial ID/QR traceability for compliance and QC

Automotive Systems

In-vehicle systems, such as dashboards and in-car display modules, require wiring that can withstand high temperatures and vibration, and integrate with connectors.

YLS offers FFC cables with rigid stiffeners, UL certification, and a temperature range of –40°C to +105°C, compatible with ZIF sockets, crimp terminals, and other connection methods.

- Vibration-resistant reinforced ends

- Temperature range: –40°C to +105°C

- Fully tested & labeled for assembly line traceability

Telecom & RF Devices

Communication terminals and antenna modules are often compact, with extremely demanding cable space requirements, and are prone to RF interference.

We offer shielded, impedance-matched flat cables for MIMO and dual-antenna configurations, with custom lengths and pin assignments to optimize layout and signal integrity.

- EMI-shielded versions with drain wire

- Impedance-tuned for RF or antenna use

- Fits ultra-thin housings & tight routing paths

Consumer Electronics

Consumer electronic devices (printers, cameras, tablets) predominantly use FFCs for inter-module connections, requiring high cost-effectiveness and consistency.

YLS can support FFC deliveries up to millions of units, providing labeling and assembly services to meet the automated production line needs of consumer electronics.

- Competitive pricing with factory-direct supply

- Pre-labeled and reel-packaged for automation

- Available from 50 pcs for pilot production

Not sure which configuration suits your device?

Talk to our technical engineer and get tailored recommendations based on your industry.

Why Choose YLS

More than a cable supplier — we’re your engineering and production partner.

At YLS, every project begins with understanding your technical needs. Whether you require a custom pitch, folded layout, or labeled packaging, we support your project from concept to mass production — with speed, flexibility, and trust.

Over 10 Years of Flat Cable Manufacturing

We specialize in FFC cables and know the industry inside and out.

Factory-Direct Supply with Fast Turnaround

Support complex, high-density signal layouts.

Fully Customizable from Pitch to Packaging

Choose your pitch, pin count, length, termination, folding, and more.

Samples in as Fast as 5–7 Days

Once drawings are confirmed, samples can be ready within a week.

100% Electrical Testing Before Shipment

Each cable is electrically tested to ensure performance and reliability.

Engineering Support at Every Step

Our team helps you match specs, connectors, and optimize routing.

Low Minimum Order Quantity

Start from as few as 50 pieces — perfect for prototyping and pilot runs.

Compliant with UL, RoHS, and REACH

All materials can meet major compliance standards, with full documentation.

Frequently Asked Questions

What type of FFC cable should be used for automotive applications?

For automotive interior modules, FFC cables must withstand vibration, temperature fluctuations, and long-term flexing. Recommended types include shielded or reinforced FFCs with 0.5mm–1.25mm pitch, PET stiffeners, and pre-folded routing. Flame-retardant and high-temp materials (up to 105°C) are commonly required. ISO 6722 and LV214 guidelines are often referenced for automotive signal cables.

What type of cable is used in cars?

Cars use a variety of cable types:

PVC/XLPE insulated wires for general power and control

Coaxial cables for cameras and antennas

Shielded twisted pair for CAN, LIN, and FlexRay networks

FFC (Flat Flexible Cables) for displays, sensors, HVAC, infotainment, and lighting

For space-limited and lightweight designs, FFC is widely preferred inside dashboards and head units.

What is the standard for automotive cable?

The most widely adopted automotive wire standards include:

ISO 6722 (Road vehicle — 60V and 600V cables)

LV 214 (Connector/cable testing in automotive)

USCAR-21 (Wiring assembly performance validation)

While these apply primarily to round cables, automotive FFCs must meet thermal, mechanical, and electrical performance requirements under similar validation protocols.

Can FFC cables handle automotive vibrations and bending?

Yes — automotive-grade FFC cables are tested for high flex life (up to 100,000 cycles) and vibration resistance in 3D mounting environments. Folded FFC with reinforced stiffeners and high-durability adhesive can maintain signal integrity even in hinge areas or rotating displays.

Are shielded FFC cables necessary in car displays or sensors?

In many cases, yes. Shielded FFC cables reduce EMI interference, which is crucial for camera modules, ADAS systems, or high-resolution displays. Aluminum foil or copper braid shielding can be embedded in the cable structure, along with grounding tabs for improved performance.

What’s the typical MOQ and lead time for custom automotive FFC?

Most manufacturers, including YLS, offer MOQ starting from 100–500 pcs. Lead time for samples is typically 5–7 working days; mass production can be completed in 10–15 days depending on complexity. Full support is often provided for drawing confirmation, validation, and packaging.

Chat with us now for your Custom needs. Chat on WhatsApp Now

Let’s Build Your Ideal FFC Cable — Fast Response Guaranteed

Need a quote, sample, or technical consultation? Our team responds within 8 hours. Send us your requirements and we’ll help you build the right cable — no delays, no guesswork.

- 6 specialized cable types for different electronic modules

- Fully customizable specs, connectors, folds, lengths

- Factory-direct pricing & low MOQ starting from 50 pcs

- Fast sample turnaround (5–7 days) and delivery in 2 weeks

- RoHS, UL, and REACH-compliant materials

- Worldwide shipping available (EXW/FOB/CIF terms)

- Engineering support for part matching and customization

- Factory-direct pricing, no middlemen