Custom Consumer Electronics FFC Cable for Modern Devices

YLS specializes in high-reliability FFC cables for consumer electronics, supporting compact layouts, EMI protection, and multi-signal routing. Our cables are engineered for devices like smartwatches, headphones, cameras, and VR modules. We offer fast prototyping, OEM customization, and volume production for R&D and procurement teams.

What is Consumer Electronics FFC Cable?

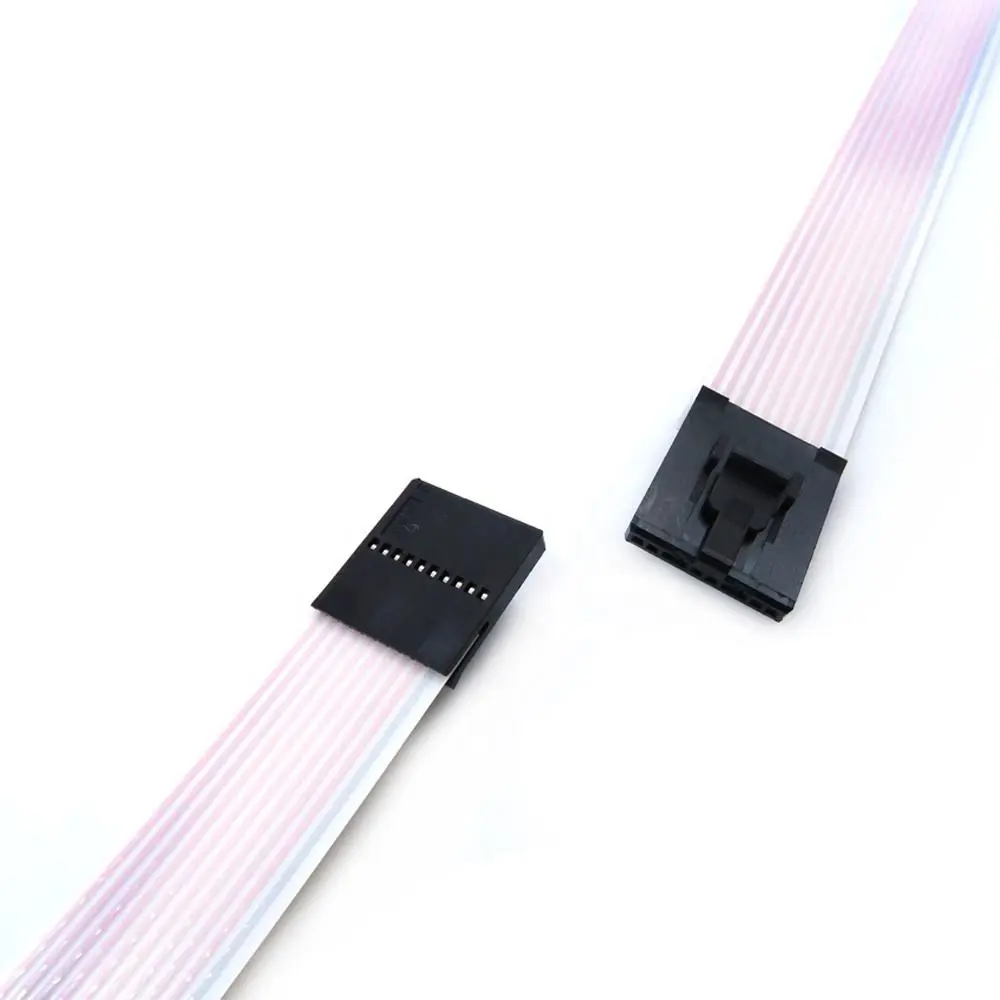

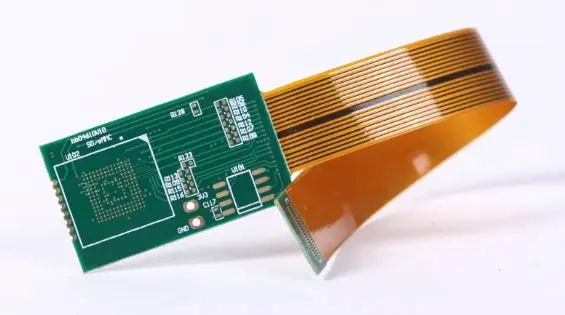

Consumer Electronics FFC (Flexible Flat Cable) is a type of flat, flexible ribbon cable used to connect internal components in compact electronic devices like smartphones, tablets, laptops, cameras, and wearables. It offers high signal integrity, flexibility, and space efficiency—ideal for slim, high-performance designs.

Where Are Consumer Electronics FFC Cables Used?

Explore how our Consumer Electronics FFC Cables power the connections inside popular devices—from foldable phones and gaming consoles to smart cameras and wearable tech. Each cable type is tailored to meet space, speed, and flexibility needs in today’s compact electronic systems.

Smartphone & Tablet FFC Cables

Ultra-thin, high-flex FFC cables for connecting displays, touch panels, cameras, and PCBs in modern smartphones and tablets.

Laptop & Notebook FFC Cables

Reliable FFC assemblies for keyboards, displays, cameras, and I/O interfaces in slim laptop and notebook designs.

Wearable Device FFC Cables

Miniature and dynamic-flex cables designed for smartwatches, fitness bands, and other compact wearables with space and flexing constraints.

Gaming Console & Controller FFC Cables

Durable, high-cycle cables supporting display, input, and battery connections in gaming consoles, handhelds, and controllers.

AR/VR Headset FFC Cables

Flexible, EMI-shielded cables for high-speed signal transmission in compact AR and VR headsets, supporting motion sensors and high-res displays.

Audio & Headphone FFC Cables

Lightweight, compact FFC cables designed for wireless earbuds, headphones, and portable speakers—supporting battery, mic, and control modules.

Common Wiring Challenges in Consumer Electronics —Solved with FFC

At YLS, we not only supply high-reliability FFCs but also collaborate with your design team to optimize cable routing, folding patterns, and connector mating for your specific robot architecture.

Compact housing with multiple components?

Our ultra-thin, pre-folded FFC cables bend around components and hinges, enabling space-efficient layout in phones, wearables, and earbuds.

Intermittent signal loss in high-speed data interfaces?

We offer impedance-controlled and shielded FFCs to maintain signal integrity in USB, HDMI, and camera module connections.

Frequent flexing at hinge points or folding mechanisms?

Our dynamic-flex FFCs are tested for tens of thousands of bending cycles—ideal for foldable phones, gaming consoles, and AR/VR gear.

Struggling with complex multi-connector assemblies?

We provide multi-branch FFCs with custom pinouts to simplify internal wiring in smart devices and reduce assembly steps.

Let’s solve your cable bottlenecks → Contact our engineering team

Technical Capabilities

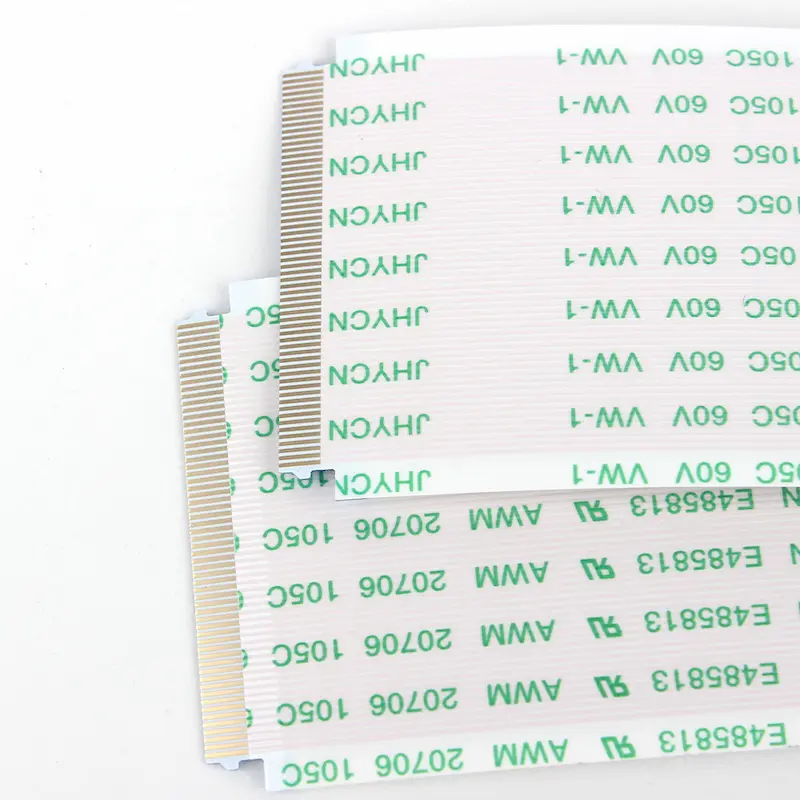

FFC Cable Specs for Consumer Electronics

- Enables efficient routing inside compact housings like earbuds, fitness trackers, and handheld consoles.

- Multi-layer shielding options to maintain stable signal transmission in dense electronic environments.

- Supports up to 80 conductors in ultra-compact layouts for camera, display, or button integration.

- ±10% impedance matching available for high-speed signal lines like USB, HDMI, or touch interfaces.

- Improved assembly efficiency and error reduction during mass production.

- Ensures long-term reliability in devices with internal heat build-up, such as gaming devices or tablets.

Quick Spec Summary:

| Specification | Details |

|---|---|

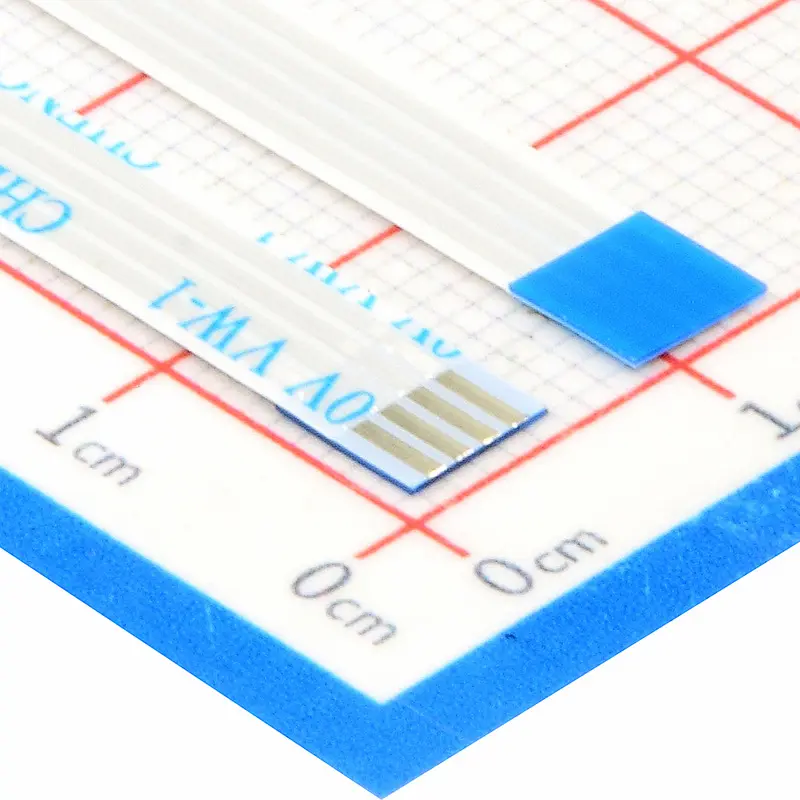

| Pitch Options | 0.3mm / 0.5mm / 1.0mm / 1.25mm / 2.0mm |

| Number of Conductors | 4–80 pins (customizable based on device needs) |

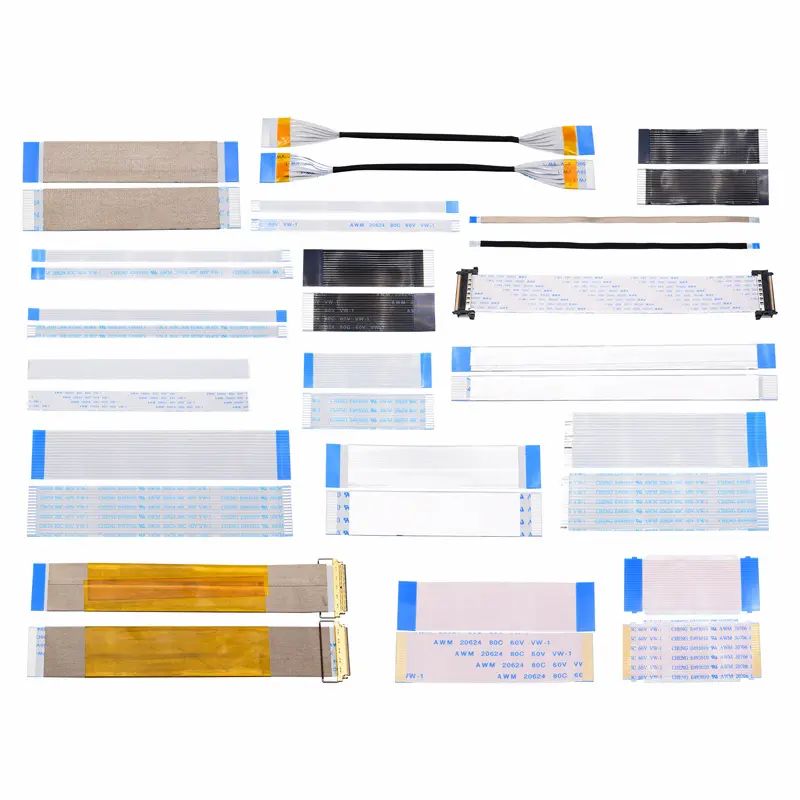

| Cable Type | Type A, Type B, Type D, Shielded, ZIF |

| Rated Voltage | 30V |

| Rated Current | Up to 1A per conductor |

| Operating Temperature | -40°C to +105°C |

| Bending Radius | Min. 1mm |

| Surface Treatment | Tin/Gold-plated contacts |

| Connector Compatibility | Compatible with standard FFC/FPC connectors |

| RoHS/REACH Compliance | Yes |

Custom Ribbon Cable Capabilities — Built to Your Specs

Your application may require more than just a standard pitch or length. That’s why we offer complete customization on all critical parameters — so your ribbon cable fits perfectly, functions reliably, and installs easily.

Whether you need just 50 pieces for a prototype or 50,000 for production, we can deliver with speed and precision.

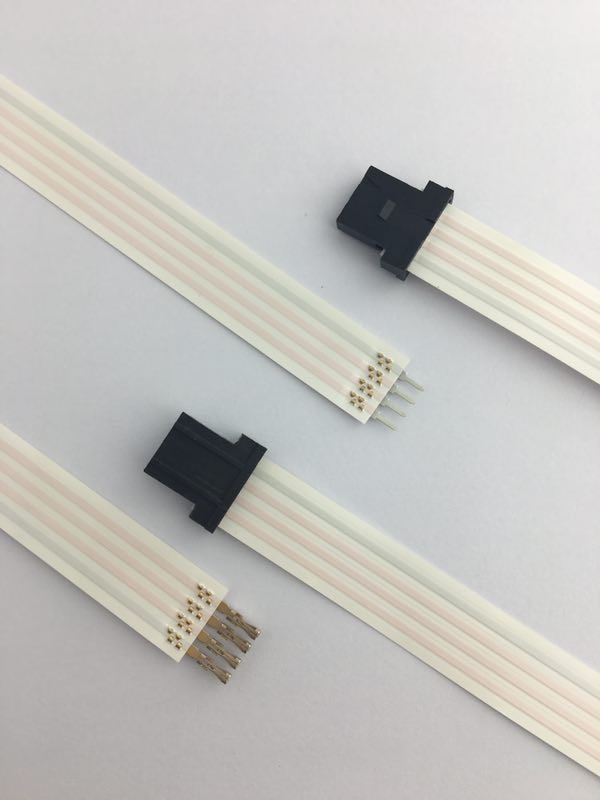

1. Pitch & Conductor Configuration

Design the spacing and layout that fit your device’s constraints.

- Available pitches: 0.4mm / 0.5mm / 0.8mm / 1.0mm / 1.25mm

- 4 to 96 conductors

- Symmetrical or custom pin-out

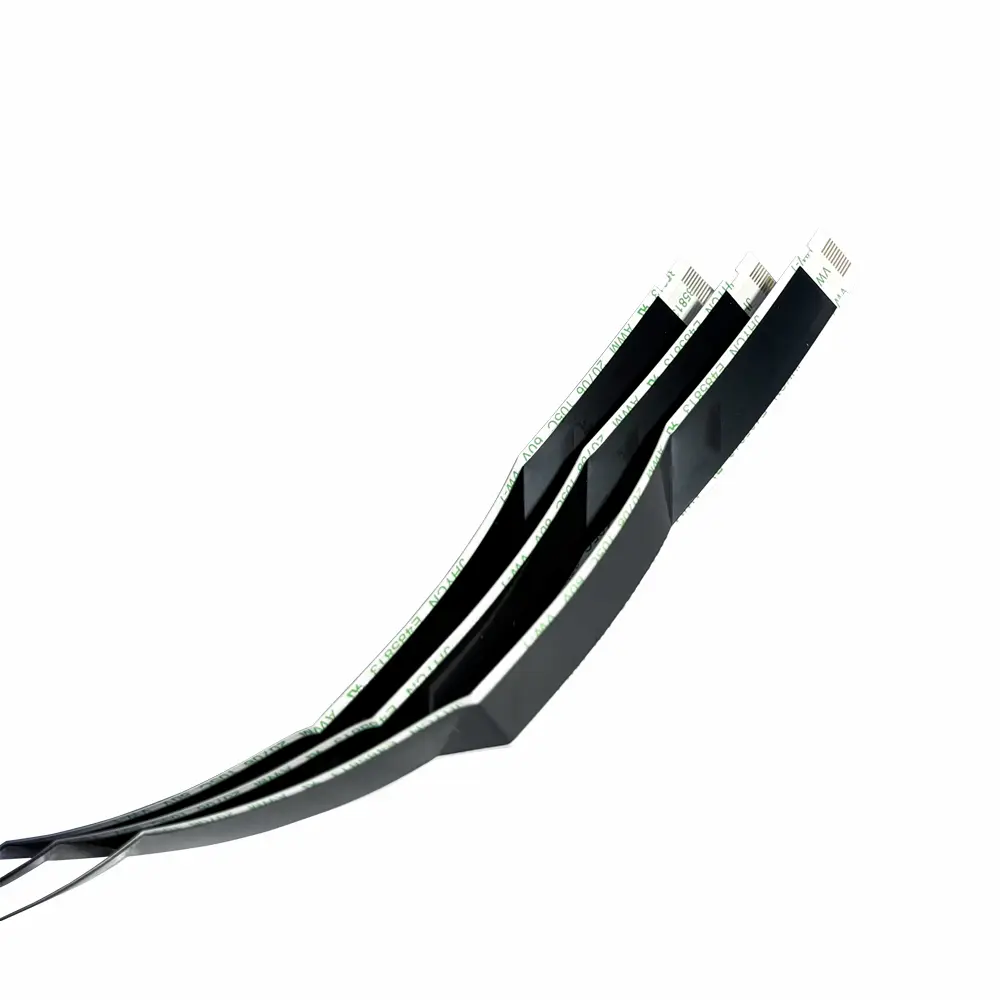

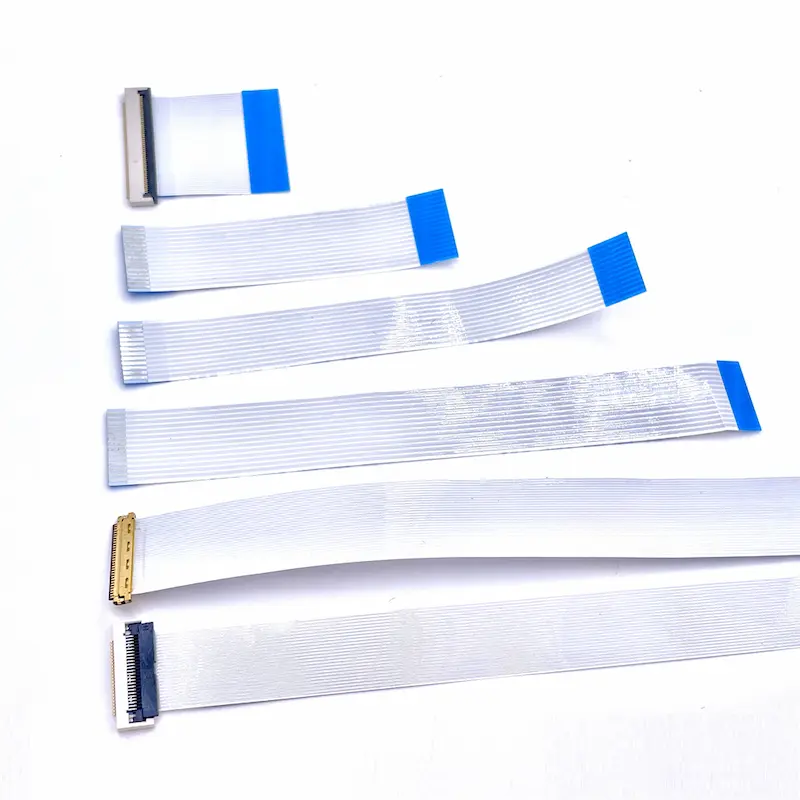

2. Cable Length & Shape

Adapt the cable to your layout without compromising space.

- Lengths from 30mm to 1000mm+

- Straight, L-shape, Z-fold, or multi-branch

- Fold lines pre-creased for easy routing

3. End Termination Options

Seamless integration with your connectors or boards.

- Tinned or gold-flashed bare ends

- PET/PI stiffeners for ZIF sockets

- Solder tail, FPC-style, or custom header connector

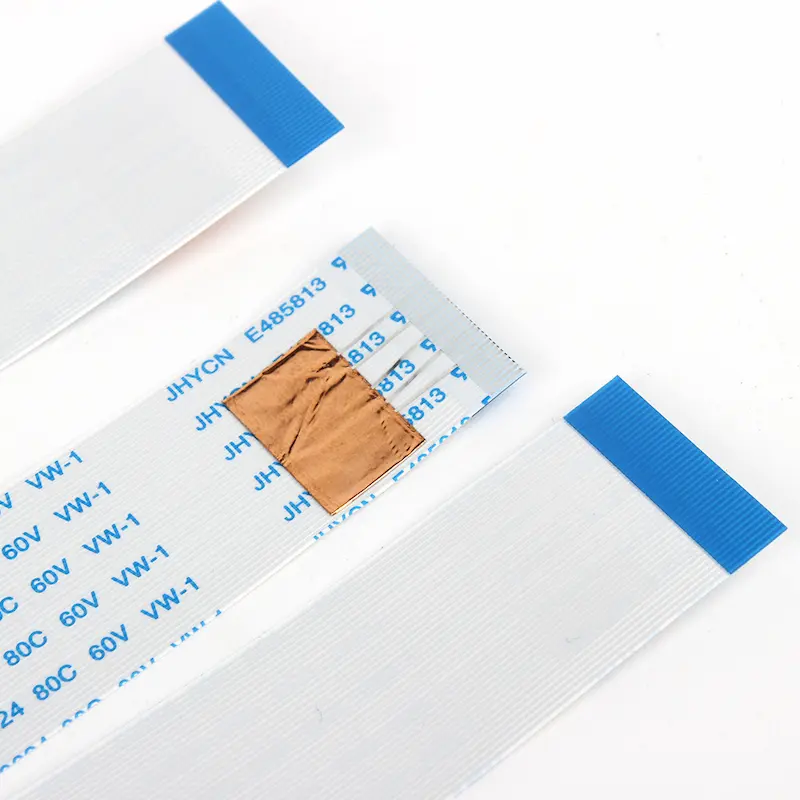

4. Shielding & EMI Control

Protect signal integrity in sensitive environments.

- Aluminum foil or mesh shielding

- Ground tail or drain wire

- Optional double-shielded design

5. Surface & Insulation Customization

Improve durability, appearance, and signal performance.

- PET or PI insulation

- Conductor surface: tin-plated, bare copper, or gold

- Optional heat-resistant or flame-retardant materials

6. Punching & Mechanical Modifications

Built to fit into housings and tight enclosures.

- Punch holes, slots, notches for mounting

- Fold lines for compact 3D routing

- Peel tabs or extended tails

7. Labeling & Traceability

Simplify installation, QC, and inventory tracking.

- QR code / barcode / serial ID

- Printed position marks, logos, or terminal IDs

- Laser or ink marking options

8. Packaging Options

Fit your assembly line or ESD protocol.

- Bulk bag, tray, coil, or tape & reel

- Anti-static or moisture-proof packaging

- Custom labels or part numbers

Not sure which specs to choose? Our engineering team is ready to help. Ask an Engineer

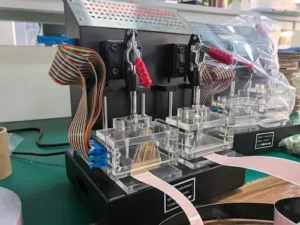

Custom FFC Cable Workflow

At YLS, we simplify the path from idea to production. Whether you’re upgrading a product or building something new, our six-step process ensures speed, accuracy, and full customization for your flat flexible cable solution.

🧩 Step 1: Project Kick-off

Tell us about your needs: cable pitch, pin count, length, connectors, UL specs, shielding, fold lines—our team starts with the details that matter.

📐 Step 2: Engineering Proposal

We translate your specs into manufacturable designs. Expect drawing files and connector matching within 24–48 hours.

🧪 Step 3: Sample Fabrication

Once drawings are approved, we build samples in 3–5 working days, including precision cutting, labeling, and insulation options.

🧷 Step 4: Testing & Validation

You verify the sample in your device. We assist with adjustments, feedback loops, or connector matching as needed.

🔁 Step 5: Final Sign-off

Once the prototype is approved, we lock the design, confirm packaging and delivery terms, and prepare for production.

🚛 Step 6: Mass Production & Global Delivery

We initiate volume production and ship on time via express, air, or sea—wherever your facility is.

✨ Optional Add-ons:

Fold lines or pre-bent shaping

Custom labels or barcodes

Hole punching, notching, peel-tab finishing

Shielding and grounding features

Special packing and reel packaging options

Technical support for connector sourcing

ABOUT YLS

Reliable FFC cables factory integrated services

Yulian is a direct manufacturer of flat flexible cables (FFC), delivering precision wiring solutions trusted by global OEMs. With in-house tooling, rapid prototyping, and full customization capabilities, we help you go from concept to cable—fast, reliable, and to your spec.

We offer pitch options from 0.4mm to 1.25mm and core counts up to 96, with full support for folding, shielding, notching, punching, labeling, and custom assembly.

- Ultra-Fine Pitch, High Pin Count

- 48-Hour Custom Sample Delivery

- Foldable & Shielded Cable Options

- Expert Support for Complex Wiring

- ISO/IATF Certified Manufacturing

- 100% Electrical QC Before Shipment

- Low MOQ, Fast Turnaround

- 10+ Years Across Key Industries

Frequently Asked Questions

What types of consumer electronics use FFC cables?

FFC cables are widely used in smartphones, tablets, laptops, gaming devices, smartwatches, and AR/VR headsets to connect displays, cameras, sensors, and boards.

How do FFC cables benefit compact consumer designs?

Their ultra-thin, flexible form allows tight routing inside slim housings, ideal for space-constrained layouts like foldable phones and earbuds.

Can FFC cables handle high-speed signal transmission?

Yes. We offer impedance-controlled and shielded FFCs optimized for USB, HDMI, and MIPI/eDP interfaces, ensuring stable, high-speed performance.

Are your FFC cables tested for repeated flexing?

Absolutely. Our dynamic-flex rated FFCs undergo 10,000+ bending cycles, making them reliable for wearables and devices with hinges or moving parts.

Do you offer custom FFC designs for unique device layouts?

Yes. We support full customization—including length, pitch, folding, pinout, EMI shielding, and connectors—to match your exact product design.

What is the typical lead time for production and delivery?

For standard or repeat orders, production starts within 72 hours and ships within 10–14 days. Custom projects vary based on complexity.

Chat with us now for your Custom needs. Chat on WhatsApp Now

More Solutions

Let’s Build Your Ideal FFC Cable — Fast Response Guaranteed

Whether it’s for foldable drones, camera gimbals, or onboard computing—our FFC solutions are designed to fly. Tell us what you need—we’ll build it.