Standard & Custom Ribbon Cable Assembly Solutions

All uploads are secure and confidential

What Is a Ribbon Cable?

Ribbon cables—also known as flat flexible cables (FFC)—are multi-conductor cables arranged in a flat, parallel configuration. Designed for space-saving and flexible routing, they are widely used in notebook computers, LED lighting, printers, and consumer electronics.

| Feature | Ribbon Cable | Round Cable |

|---|---|---|

| Space efficiency | Excellent | Moderate |

| Signal integrity | Parallel wiring | Twisted pairs |

| Flexibility | Good | Good |

| EMI shielding | Optional | Optional |

Need a specific configuration or drawing? → Contact our engineer on WhatsApp Now

Key Specifications of Standard FFC Cable:

Pitch Sizes: Available in 0.4 mm to 2.54 mm. Custom pitch options are also supported upon request.

Number of Conductors: From 4 to 96 conductors, depending on the pitch.

Cable Thickness: Ranges between 0.1 mm and 0.5 mm for flexible applications.

Cable Length: Fully customizable—from 30 mm up to 1000 mm or longer, depending on your needs.

Insulation Material: PET or PI (polyimide), both compliant with RoHS standards.

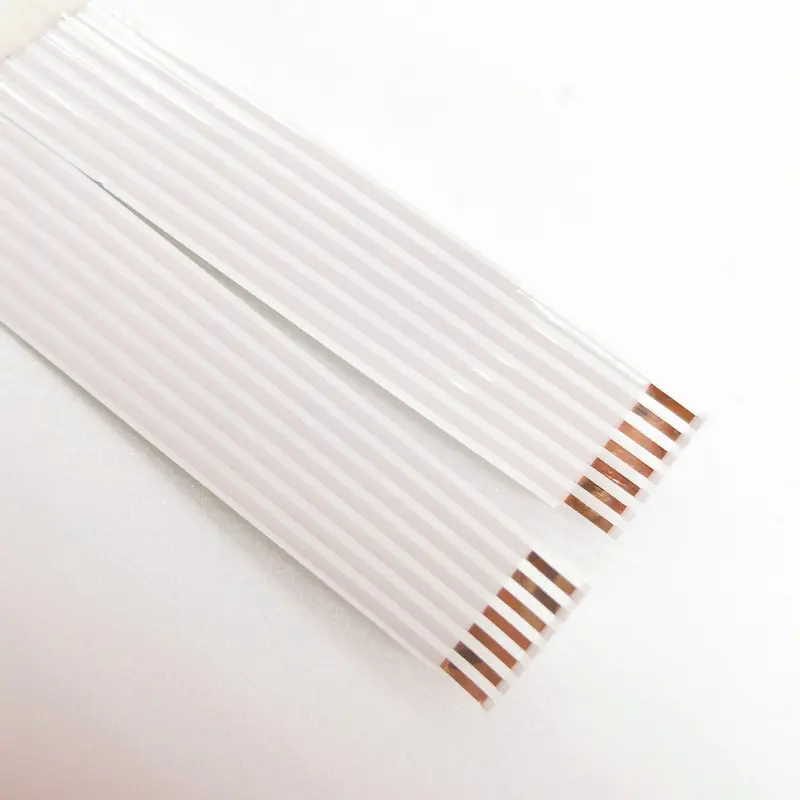

Conductor Material: Tin-plated copper, ensuring excellent conductivity and solderability.

End Termination Options: Choose from tinned ends, gold fingers, crimped ends, or connector-ready configurations.

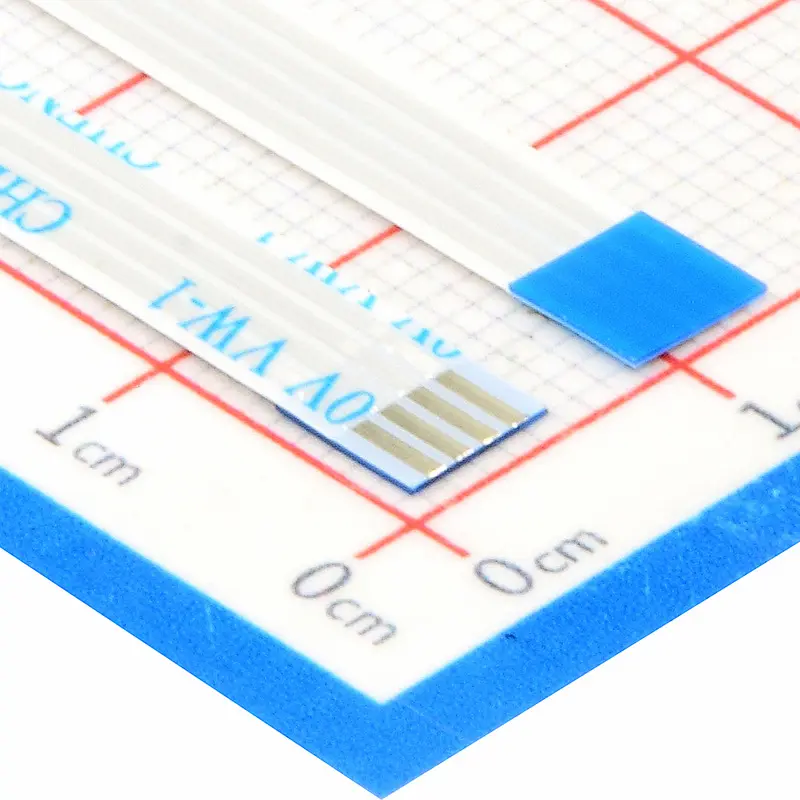

Reinforcement Options: Includes PET stiffeners, Kapton tape, or EMI foil for added durability and shielding.

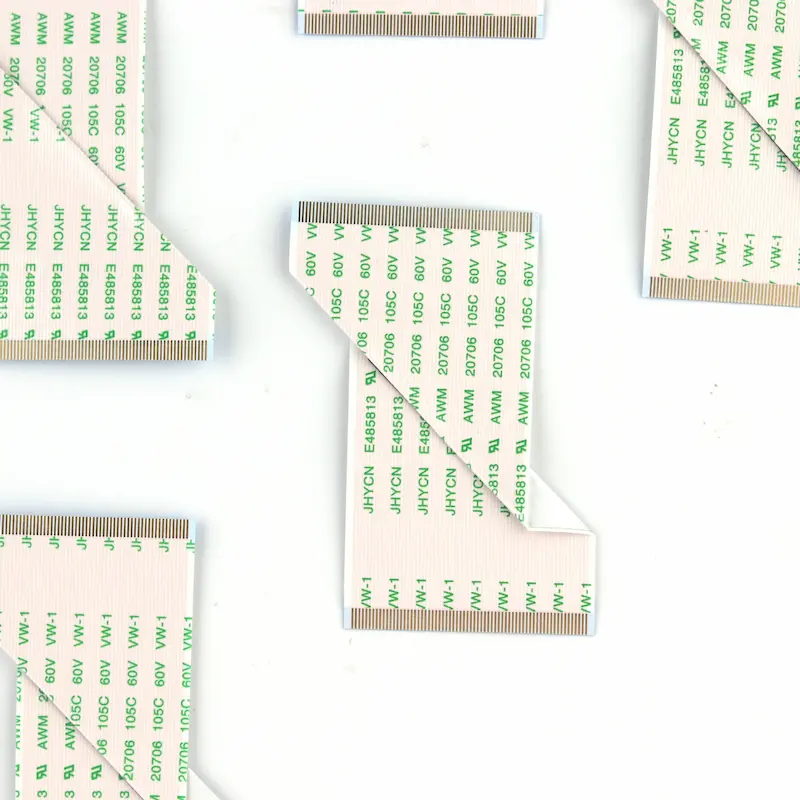

Fold Lines / Creases: Single or multiple fold lines are available for compact installations.

Additional Features: Custom services include shielding, punching, notching, labeling, and overmolding.

Certifications: RoHS compliant, UL certified, and manufactured under ISO9001 standards.

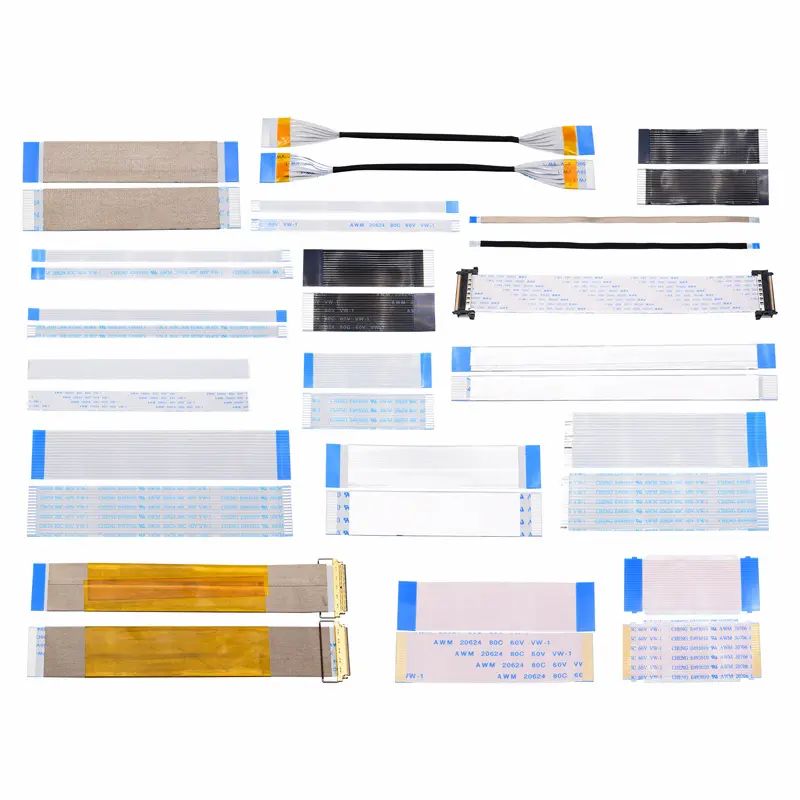

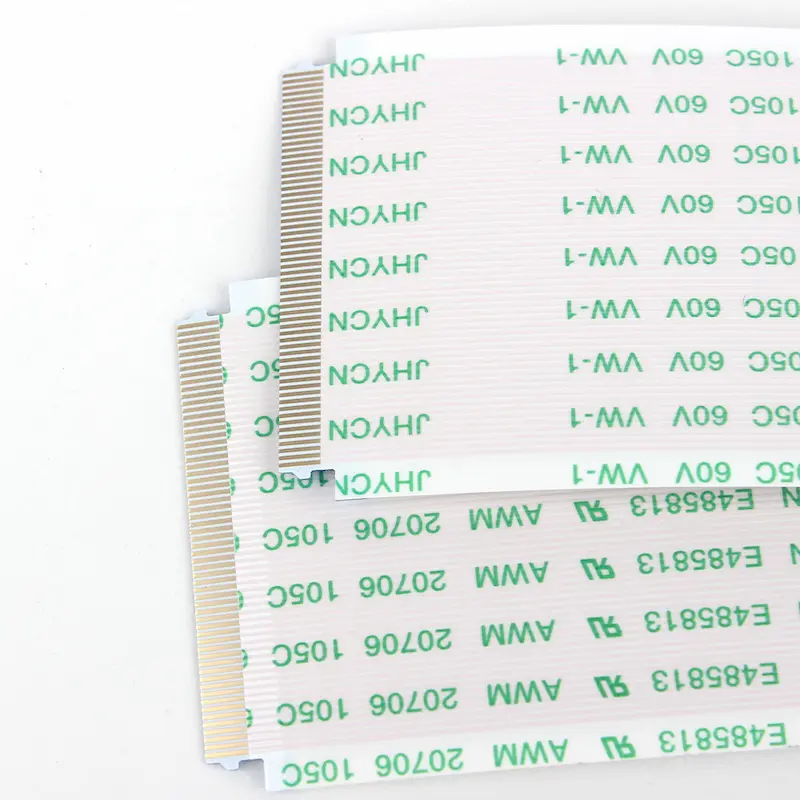

Standard Ribbon Cable Series

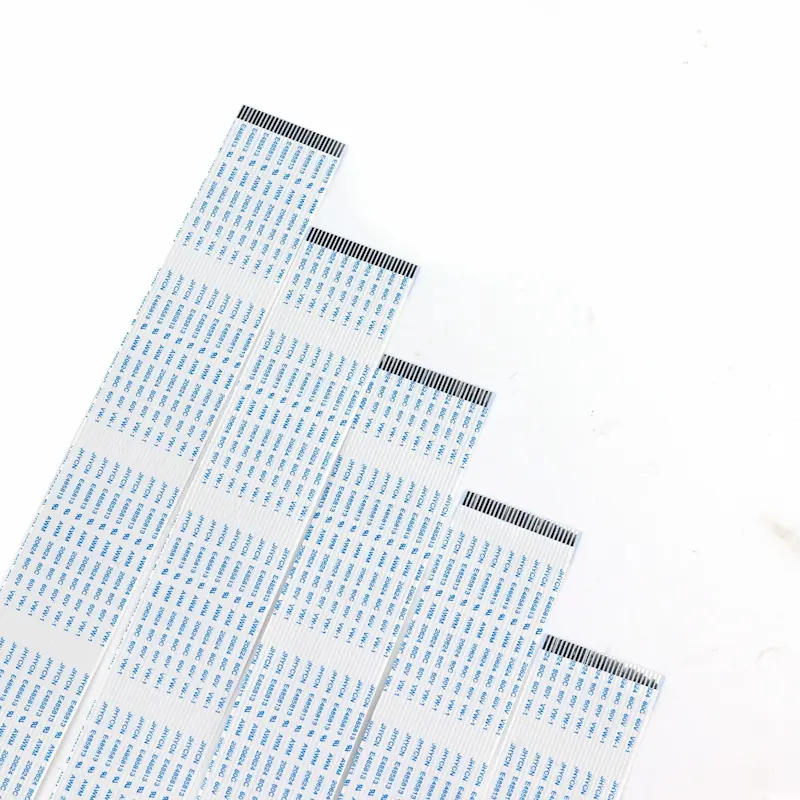

YLS specializes in manufacturing Standard Ribbon Cables (also known as Flat Flexible Cables, or FFCs) with precise conductor alignment, excellent flexibility, and a wide range of pitch and core options. These cables are ideal for compact electronic devices requiring organized, low-profile internal wiring.

We support full customization: pitch size (0.5mm, 1.0mm, 1.25mm, etc.), conductor count (4 to 96 pins), length, fold lines, and labeling. Standard and UL-certified configurations are available for quick delivery.

Chat with us now for your wholesale needs. Chat on WhatsApp Now

Custom Ribbon Cable Capabilities — Built to Your Specs

Your application may require more than just a standard pitch or length. That’s why we offer complete customization on all critical parameters — so your ribbon cable fits perfectly, functions reliably, and installs easily.

Whether you need just 50 pieces for a prototype or 50,000 for production, we can deliver with speed and precision.

1. Pitch & Conductor Configuration

Design the spacing and layout that fit your device’s constraints.

- Available pitches: 0.4mm / 0.5mm / 0.8mm / 1.0mm / 1.25mm

- 4 to 96 conductors

- Symmetrical or custom pin-out

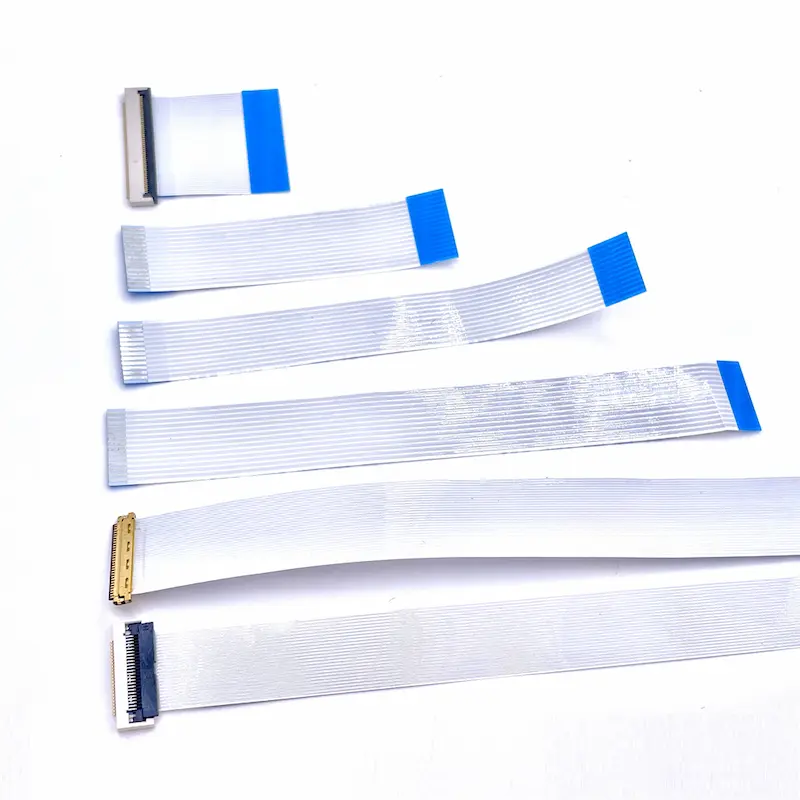

2. Cable Length & Shape

Adapt the cable to your layout without compromising space.

- Lengths from 30mm to 1000mm+

- Straight, L-shape, Z-fold, or multi-branch

- Fold lines pre-creased for easy routing

3. End Termination Options

Seamless integration with your connectors or boards.

- Tinned or gold-flashed bare ends

- PET/PI stiffeners for ZIF sockets

- Solder tail, FPC-style, or custom header connector

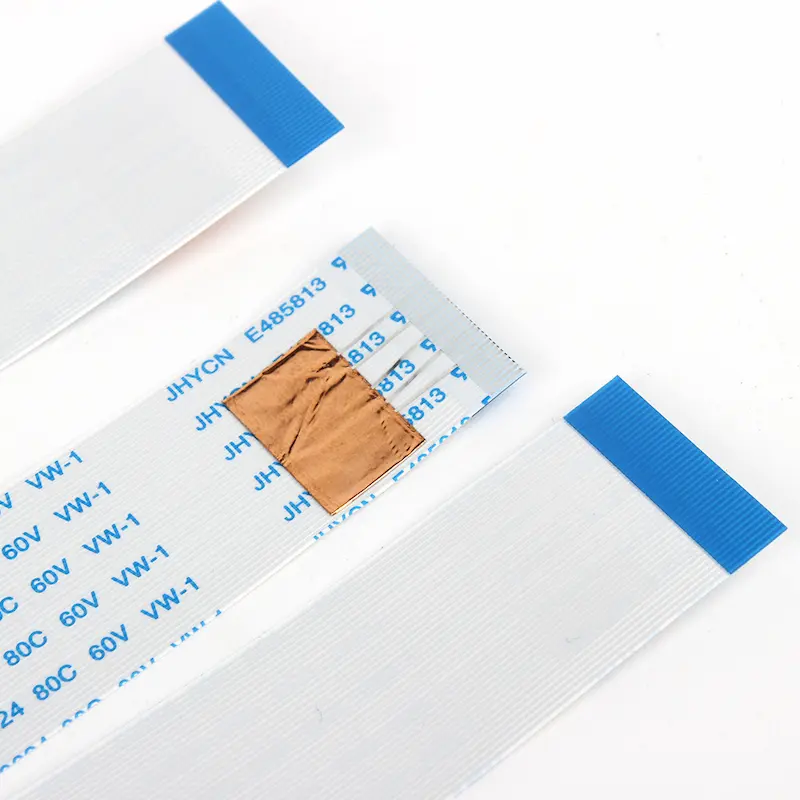

4. Shielding & EMI Control

Protect signal integrity in sensitive environments.

- Aluminum foil or mesh shielding

- Ground tail or drain wire

- Optional double-shielded design

5. Surface & Insulation Customization

Improve durability, appearance, and signal performance.

- PET or PI insulation

- Conductor surface: tin-plated, bare copper, or gold

- Optional heat-resistant or flame-retardant materials

6. Punching & Mechanical Modifications

Built to fit into housings and tight enclosures.

- Punch holes, slots, notches for mounting

- Fold lines for compact 3D routing

- Peel tabs or extended tails

7. Labeling & Traceability

Simplify installation, QC, and inventory tracking.

- QR code / barcode / serial ID

- Printed position marks, logos, or terminal IDs

- Laser or ink marking options

8. Packaging Options

Fit your assembly line or ESD protocol.

- Bulk bag, tray, coil, or tape & reel

- Anti-static or moisture-proof packaging

- Custom labels or part numbers

Not sure which specs to choose? Our engineering team is ready to help. Ask an Engineer

Where Our Ribbon Cables Are Used

Standard Ribbon Cables are ideal for compact, high-performance electronic assemblies across diverse industries. Whether you’re designing wearable tech, medical devices, or automation equipment, our cables provide reliable, space-efficient signal transmission with full customization support.

Drone Interconnect Solutions

Internal wiring in UAVs often faces extremely limited space, vibration, twisting, and weight sensitivity.

We offer lightweight, flexible, and shielded FFC (Flexible Flat Cable) solutions for flight control boards, gimbal control modules, power management modules, and more. We can provide pre-bent and multi-fold designs to improve assembly efficiency and stability.

- Folded ribbon cables optimized for 3D routing

- Low-weight, low-profile design reduces UAV payload

- Tin-plated or EMI-shielded options for signal integrity

Energy Storage Systems

Energy storage battery systems (e.g., lithium batteries, home energy storage) require multi-core cable connections between the BMS (Battery Management System) and battery cells, often encountering EMI and space constraints.

YLS provides custom-length, custom-pitch, and multi-core FFC cables with shielding, flame retardancy, and numbering labels, facilitating efficient integration and long-term stable operation.

- Up to 96 conductors per cable, for dense battery arrays

- Shielded cable variants reduce EMI near switching circuits

- Folded layouts improve space usage in battery trays

Smart Home Devices

Smart home modules, such as LED light strips, access controls, and display controllers, require miniature wiring solutions, along with UL safety certification and long-term stability.

We support small-pitch (0.5mm) and multi-fold designs, suitable for LED strip controllers and touch modules. We offer UL-certifiable materials and support terminal assembly and bulk packaging.

- Flame-retardant materials for in-wall or indoor applications

- Labels & barcodes for easy batch traceability

- Ready-to-connect ends with pre-installed connectors

Robotics & Motion Systems

Internal wiring in robotic arms, linear stages, and collaborative robots often involves continuous movement, bending, and vibration, making it challenging for standard wire harnesses to meet lifespan requirements.

We offer FFC wiring solutions with high flex life (>1 million cycles), multi-fold points, and enhanced flexibility designs, suitable for embedding within mechanical motion areas.

- High-flex life cable construction

- Folded flat cable for articulated joints

- Compact routing inside confined enclosures

Medical Devices

Medical devices (portable diagnostic instruments, surgical robots) demand miniaturization, high signal integrity, and material safety.

We can provide small-sized, high-density flat cables for medical equipment, supporting PI insulation, high-temperature resistance, RoHS/UL materials, and printable traceability markers.

- Medical-grade PET/PI insulation options

- Gold-finished ends for corrosion-free signal transfer

- Serial ID/QR traceability for compliance and QC

Automotive Systems

In-vehicle systems, such as dashboards and in-car display modules, require wiring that can withstand high temperatures and vibration, and integrate with connectors.

YLS offers FFC cables with rigid stiffeners, UL certification, and a temperature range of –40°C to +105°C, compatible with ZIF sockets, crimp terminals, and other connection methods.

- Vibration-resistant reinforced ends

- Temperature range: –40°C to +105°C

- Fully tested & labeled for assembly line traceability

Telecom & RF Devices

Communication terminals and antenna modules are often compact, with extremely demanding cable space requirements, and are prone to RF interference.

We offer shielded, impedance-matched flat cables for MIMO and dual-antenna configurations, with custom lengths and pin assignments to optimize layout and signal integrity.

- EMI-shielded versions with drain wire

- Impedance-tuned for RF or antenna use

- Fits ultra-thin housings & tight routing paths

Consumer Electronics

Consumer electronic devices (printers, cameras, tablets) predominantly use FFCs for inter-module connections, requiring high cost-effectiveness and consistency.

YLS can support FFC deliveries up to millions of units, providing labeling and assembly services to meet the automated production line needs of consumer electronics.

- Competitive pricing with factory-direct supply

- Pre-labeled and reel-packaged for automation

- Available from 50 pcs for pilot production

Not sure which configuration suits your device?

Talk to our technical engineer and get tailored recommendations based on your industry.

Why Choose YLS

More than a cable supplier — we’re your engineering and production partner.

At YLS, every project begins with understanding your technical needs. Whether you require a custom pitch, folded layout, or labeled packaging, we support your project from concept to mass production — with speed, flexibility, and trust.

Over 10 Years of Flat Cable Manufacturing

We specialize in FFC cables and know the industry inside and out.

Factory-Direct Supply with Fast Turnaround

Support complex, high-density signal layouts.

Fully Customizable from Pitch to Packaging

Choose your pitch, pin count, length, termination, folding, and more.

Samples in as Fast as 5–7 Days

Once drawings are confirmed, samples can be ready within a week.

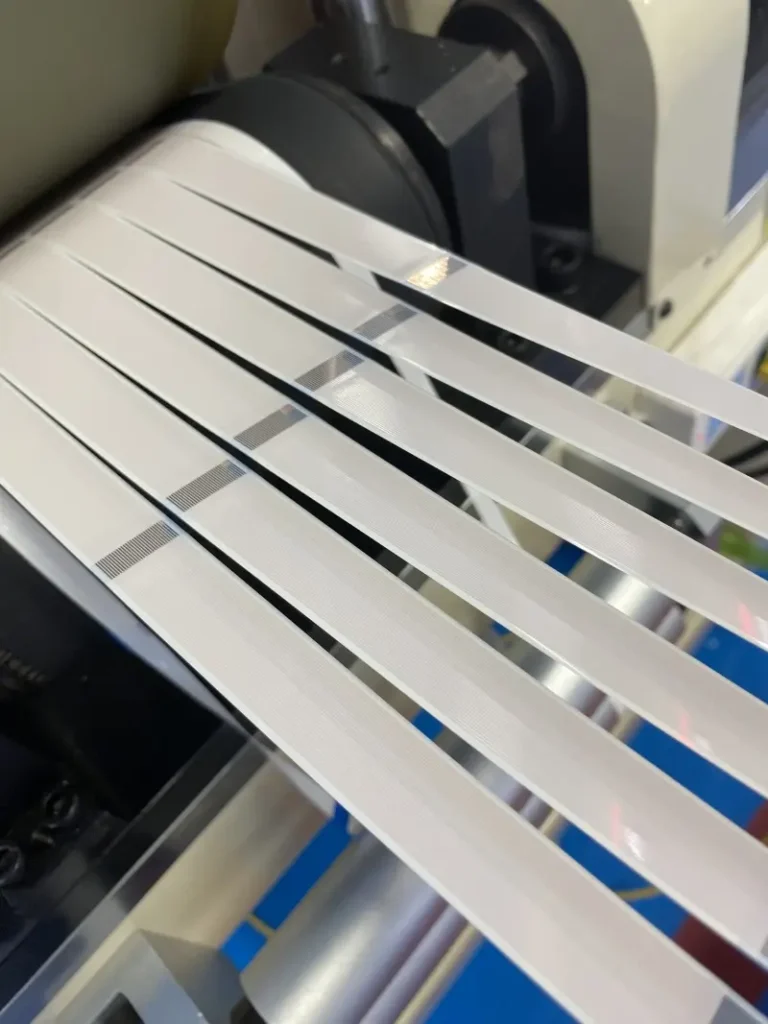

100% Electrical Testing Before Shipment

Each cable is electrically tested to ensure performance and reliability.

Engineering Support at Every Step

Our team helps you match specs, connectors, and optimize routing.

Low Minimum Order Quantity

Start from as few as 50 pieces — perfect for prototyping and pilot runs.

Compliant with UL, RoHS, and REACH

All materials can meet major compliance standards, with full documentation.

Custom FFC Cable Workflow

🧩 Step 1: Project Kick-off

Tell us about your needs: cable pitch, pin count, length, connectors, UL specs, shielding, fold lines—our team starts with the details that matter.

📐 Step 2: Engineering Proposal

We translate your specs into manufacturable designs. Expect drawing files and connector matching within 24–48 hours.

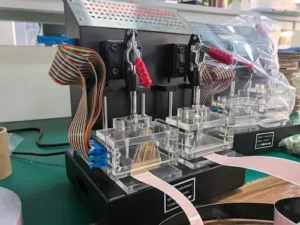

🧪 Step 3: Sample Fabrication

Once drawings are approved, we build samples in 3–5 working days, including precision cutting, labeling, and insulation options.

🧷 Step 4: Testing & Validation

You verify the sample in your device. We assist with adjustments, feedback loops, or connector matching as needed.

🔁 Step 5: Final Sign-off

Once the prototype is approved, we lock the design, confirm packaging and delivery terms, and prepare for production.

🚛 Step 6: Mass Production & Global Delivery

We initiate volume production and ship on time via express, air, or sea—wherever your facility is.

✨ Optional Add-ons:

Fold lines or pre-bent shaping

Custom labels or barcodes

Hole punching, notching, peel-tab finishing

Shielding and grounding features

Special packing and reel packaging options

Technical support for connector sourcing

📦 Need just 50 pieces? Or 500,000?

We support low-MOQ orders with full scalability and consistent quality.

Frequently Asked Questions

What is a ribbon cable used for?

A ribbon cable, also known as a flat ribbon cable or FFC (Flat Flexible Cable), is commonly used to connect internal components in electronic systems where space-saving, organized wiring is critical. Applications include interconnecting PCB boards in printers, scanners, displays, computers, and embedded systems. The parallel conductor layout makes it ideal for signal integrity in short-run, low-profile configurations.

What are the advantages of ribbon cable?

Ribbon cables offer several benefits in both electrical and mechanical design. Their parallel conductor arrangement reduces crosstalk and improves signal clarity for short-distance data transmission. Mechanically, they are lightweight, flexible, and easy to route through tight spaces, enabling compact system design. They also allow mass-termination techniques (e.g., IDC) for cost-effective assembly in high-volume production.

What are the disadvantages of ribbon cable?

While ribbon cables are efficient for many internal connections, they have some limitations. Their flat geometry makes them more prone to EMI (electromagnetic interference) in high-frequency environments if not shielded properly. They are not ideal for long-distance or high-power transmission, and the lack of twisting or shielding in standard types can lead to signal degradation when exposed to external noise. Additionally, their flexibility may reduce mechanical durability under continuous bending without reinforcement.

What types of connectors are commonly used with ribbon cables?

The most common connectors for ribbon cables include IDC (Insulation Displacement Connectors), ZIF (Zero Insertion Force), LIF (Low Insertion Force), and standard board-to-board headers. IDC is widely used in industrial and computing applications due to its ease of assembly and multi-contact termination. For fine-pitch applications like displays or touch panels, ZIF connectors are often preferred because they preserve conductor integrity during frequent mating/unmating cycles.

Are ribbon cables suitable for high-speed data transmission?

Traditional ribbon cables are not ideal for high-speed transmission due to potential impedance mismatches and lack of shielding. However, specialized ribbon cable variants—such as differential pair FFCs or impedance-controlled shielded ribbons—are engineered to support protocols like LVDS, USB 3.0, and HDMI. These types use defined trace spacing, controlled dielectric properties, and ground integration to maintain signal integrity up to several Gbps over short distances.

How is a ribbon cable different from a round cable?

The primary difference lies in the physical layout of the conductors. Ribbon cables consist of multiple parallel wires in a flat arrangement, offering uniform electrical lengths and simplified routing in flat form factors. Round cables bundle conductors in a circular cross-section, often twisted or shielded to enhance EMI resistance and mechanical durability. Ribbon cables are more space-efficient in planar assemblies, while round cables are favored for environments requiring flexibility, durability, and noise immunity.

Chat with us now for your Custom needs. Chat on WhatsApp Now

Let’s Build Your Ideal FFC Cable — Fast Response Guaranteed

Need a quote, sample, or technical consultation? Our team responds within 8 hours. Send us your requirements and we’ll help you build the right cable — no delays, no guesswork.