You will see that ffc ribbon cable is best for new electronics. It is very flexible, saves space, and costs less to make. Ffc ribbon cable is flat and thin. It bends easily. This makes it good for devices with little room. Traditional ribbon cable has many wires side by side. It works better for bigger setups. Think about these things before you choose: flexibility, strength, space, signal quality, how to install, and price.

Check the newest usage numbers:

Application Sector FFC Market Share Traditional Ribbon Cables Market Share Consumer Electronics 35% N/A Automotive 30% N/A Industrial Automation 45% N/A

Key Takeaways

- FFC ribbon cables are great for small, new devices. They bend easily and do not take up much space.

- Traditional ribbon cables are better for bigger setups. They are easier to put in when you have lots of room.

- Think about how bendy, big, or costly the cable is before you pick FFC or traditional ribbon cables.

- FFC ribbon cables can handle heat and last longer. They are good for devices that move a lot.

- Always try out your cable in your design first. Make sure it works for your device before making many of them.

FFC Ribbon Cable vs Ribbon Cable

Main Recommendation

When picking cables for electronics, you want them to fit small spaces. They should bend easily and last long. FFC ribbon cable gives these benefits. You see it in smartphones and tablets. It is thin and flexible. This helps it fit into tight designs. Ribbon cable works better in bigger devices. These include desktop computers and control panels. It is thicker and not as flexible. But it is easy to use for simple wiring.

Tip: If you work with small electronics, FFC ribbon cable is usually best. For bigger systems, Ribbon cable may be easier to use.

Key Comparison Factors

You need to think about a few things before picking a cable. The most important are:

- Flexibility

- Size

- Application requirements

- Cost

Engineers pick FFC ribbon cable for its thin and bendable shape. This makes it great for modern electronics. Ribbon cable is bulkier. It fits better in devices that do not move.

Here is a table that shows how these cables compare:

| Factor | FFC Ribbon Cables | Ribbon Cable |

|---|---|---|

| Flexibility | Ultra-flexible, ideal for compact designs | Thicker, less flexible |

| Size | Compact and lightweight | Bulkier, suitable for larger devices |

| Application | Used in smartphones, tablets, wearables | Used in PCs, control systems, legacy hardware |

| Cost | Generally more expensive | Inexpensive, suitable for static wiring |

You should also think about how easy it is to install and fix the cables. The table below shows the differences:

| Aspect | FFC Ribbon Cables | Ribbon Cable |

|---|---|---|

| Installation Complexity | Easier because of flexible design | Harder because of stiff structure |

| Maintenance Requirements | Lower, since they last longer | Higher, connectors break more often |

| Durability | Higher, less likely to wear out | Lower, pins can break |

| Mate/Demate Cycles | Made for more cycles | Fewer cycles, can fail |

| Environmental Sensitivity | Handles different conditions better | Sensitive to heat and moisture |

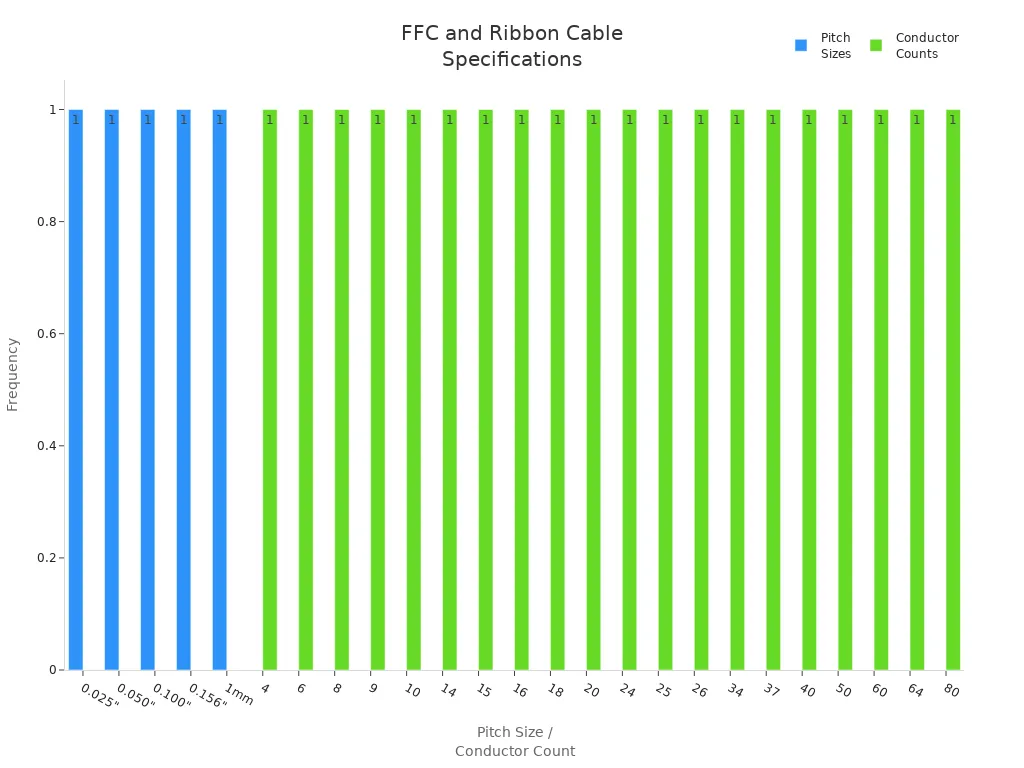

Both cable types follow rules set by the industry. These rules cover pitch sizes, number of conductors, and materials. Here is a quick look:

| Specification Type | Details |

|---|---|

| Common Specifications | Pitch sizes: 0.025″, 0.050″, 0.100″, 0.156″, 1mm; Number of conductors: 4, 6, 8, 9, 10, 14, 15, 16, 18, 20, 24, 25, 26, 34, 37, 40, 50, 60, 64, 80 positions. |

| Common Materials | Conductors: Copper, Aluminum; Insulation: PVC, Polyester (PET), Polyimide (PI), Teflon (PTFE). |

| Common Applications | Used for connecting appliances, instruments, computers, and control equipment. |

When you look at these things, you see why FFC ribbon cable is popular in new electronics. It gives more flexibility, lasts longer, and is easier to install. Ribbon cable still works well for bigger, older systems where space is not a problem.

FFC Ribbon Cable Overview

Structure and Features

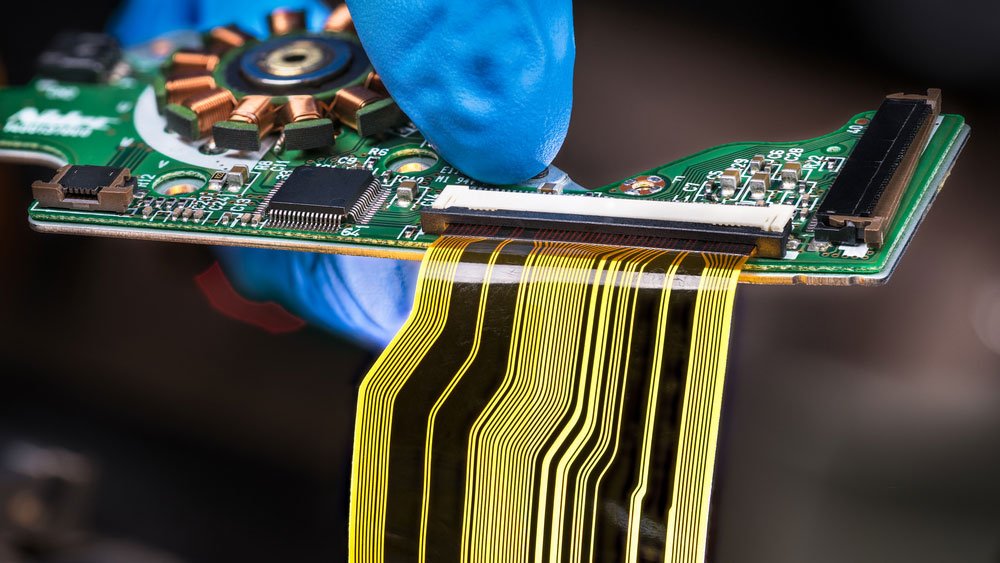

You can see that ffc ribbon cable is flat and bends easily. It has thin copper lines between layers of plastic film. Polyimide is used for the base and cover. This makes the cable strong and keeps it safe from heat. Glue holds the layers together. This lets the cable bend many times without breaking.

Here is a table that lists the main materials in ffc ribbon cable:

| Material | Description |

|---|---|

| Polyimide Substrate | Tough plastic film that keeps heat out and insulates. |

| Copper Traces | Thin copper lines that send signals with little resistance. |

| Polyimide Coverlay | A layer that protects the copper from getting damaged. |

| Adhesives | Special glue that sticks the layers together and lets the cable bend again and again. |

You can use ffc ribbon cable for simple and straight connections. It cannot do tricky routing like some other flexible circuits. This cable can be used again and costs less than custom flexible circuits. Its flat shape helps it fit into small spaces.

Common Uses

You will find ffc ribbon cable in lots of new devices. It connects screens, buttons, and other parts inside electronics. Here are some ways people use it:

- Smartphones and tablets use these cables for screens and touch panels.

- Laptops and notebooks use them for keyboards and screens.

- Printers and cameras use them for moving parts and signals.

- Cars use them in dashboard displays and infotainment systems.

- Medical devices, like portable monitors, use them for good connections.

- Industrial machines use them in robots and automation tools.

Tip: If you need to save space and want flexible connections, ffc ribbon cable is usually the best pick.

Ribbon Cable Overview

Structure and Features

Ribbon cable is flat and can bend easily. The wires sit next to each other in a row. This makes the cable look like a ribbon. Each wire runs straight and does not cross over. This shape keeps the cable thin and simple to use. You can put ribbon cable in small spaces. It works well in crowded electronics. The way it is built helps you install it fast. You do not need much time to connect things. Some ribbon cables have fiber strands in a web shape. This helps save space and keeps wires neat.

Ribbon cable helps you use space well. You can run it through trays or around corners. The wires are easy to see and connect. This gives you a good connection for many devices. Because it bends, you can use it where other cables will not fit.

Tip: If you need to link many parts in a small spot, ribbon cable is a smart choice.

Common Uses

Ribbon cable is used in lots of electronics. It lets you connect things fast and keeps your area tidy. Here are some ways people use it:

- Computer systems: Ribbon cable links hard drives, CD/DVD drives, and old floppy drives.

- Medical devices: It gives strong connections for test tools and monitors.

- Automotive electronics: Ribbon cable is used in dashboards and music systems to save space.

- Industrial automation: It connects PLCs and sensors and fits well in trays.

- Telecommunications: Special ribbon cables help send data and connect equipment.

People still pick ribbon cable for old and new systems. It is good for neat and quick wiring in many jobs.

FFC Ribbon Cable Pros and Cons

Flexibility and Space

FFC ribbon cable is very flexible and saves space. Its flat and thin shape lets it fit in small places inside devices. You can bend and fold it, and the conductors do not break. This makes it great for new gadgets that need every bit of room.

- The cable is flat and bends easily, so it fits in tight spots.

- Many conductors run side by side to send signals well.

- The flat shape lets you put more conductors close together, which helps in small devices.

- Materials like polyimide or polyester make the cable strong and flexible.

FFC ribbon cable helps you make your device smaller and lighter. The conductors are lined up neatly, so signals travel better. You get a tidy layout, which is hard with other flexible cables.

Weight and Cost

FFC ribbon cable makes your device lighter. Its thin shape and bendable design use less material. This lowers the weight, which is good for things you carry.

FFC ribbon cable can cost more than regular ribbon cable. But saving space and weight can make up for the price. It is also easy to install, so you spend less time setting it up.

Note: Lighter cables help devices work better because they are easier to move and put together.

Heat Dissipation

FFC ribbon cable handles heat well. Polyimide and other materials keep it safe from high temperatures. The flat shape spreads heat out, so there are no hot spots. This helps the cable work fast and keeps your device safe for a long time.

Design Limitations

There are some limits to using FFC ribbon cable. The conductors are close together, which can cause signal problems. You might see crosstalk when signals move fast because the traces are near each other.

- Changes in impedance and trace shape can hurt signal quality.

- More capacitance between conductors can cause signal loss.

- You need to match impedance to stop reflections and keep signals strong.

If you need to send fast signals or work in noisy places, you should plan your design carefully. FFC ribbon cable works best when you keep signal paths short and follow good layout rules.

Ribbon Cable Pros and Cons

Durability

Flat ribbon cables are strong for many electronics. The wires sit next to each other. This keeps them neat and safe from damage. If the device does not move, ribbon cables last a long time. But in places with lots of movement, FFC ribbon cables work better. FFC ribbon cables bend more and do not break as fast. They are good for things that move or shake. Ribbon cables are best when you do not need to bend them much.

Complexity

It can be hard to use ribbon cables. They feel stiff and do not bend in every way. You can only bend them along their length. This makes it tricky to fit them in small spaces. If you put them in cabinets or racks, you need to sort each wire. More wires make the job take longer and cost more. Here are some things that make it hard:

- Ribbon cables do not bend much, so routing is tough.

- You have to sort and label each ribbon before you start.

- The stiff feel makes it hard to finish the ends.

- More wires mean more time and money to install.

Installation

You need to plan before you install ribbon cables. They are stiff, so you cannot twist or bend them any way you want. You must measure and lay out each cable to fit right. In small spaces, ribbon cables do not save as much room as flexible cables. You also need to match the connectors to the cable. Good planning helps the signals stay strong and clear. If you want an easier time, you might pick FFC ribbon cable for new devices.

Tip: Always check your space and how you will run cables before you pick ribbon cables.

| Feature | Ribbon Cable | FFC Ribbon Cable |

|---|---|---|

| Durability | Good for static setups | Better for moving parts |

| Complexity | High for large systems | Lower, easier to handle |

| Installation | Time-consuming | Quick and simple |

Comparison Table

When you pick a cable for your project, you want to know how each type works. FFC ribbon cables and traditional ribbon cables have different good points. You can look at their features side by side to help you choose.

FFC ribbon cables bend a lot. They fit into small spaces. These cables save space inside your device. They weigh less, so your device is lighter. FFC cables handle heat well. They protect better from electromagnetic interference. You finish terminations faster with FFC cables. The conductors stay in place, which helps your device work well.

Traditional ribbon cables are flexible too, but not as much as FFC cables. They work best in bigger devices. These cables are heavier and need more room. You may find them easier for simple wiring jobs. Ribbon cables resist heat and interference, but FFC cables do this better.

💡 Tip: If you need a cable for a small, modern device, FFC ribbon cable gives you more benefits. For bigger setups, traditional ribbon cable can be a good choice.

Here is a table that shows the main features:

| Feature | FFC Ribbon Cable | Traditional Ribbon Cable |

|---|---|---|

| Flexibility | Highly flexible, fits tight spaces | Flexible, but less than FFC |

| Space-saving design | Excellent, very compact | Good, but bulkier |

| Weight | Lighter, reduces device weight | Heavier |

| Cost | Often higher, but saves on space and weight | Usually lower, good for simple jobs |

| Heat dissipation | Better performance, spreads heat well | Good, but less effective |

| Durability | Conductors stay isolated, last longer | Conductors can shift, may wear out |

| Installation | Efficient, quick terminations | Can take more time, less efficient |

| EMI/RFI resistance | Improved protection from interference | Good, but not as strong as FFC |

You can use this table to compare the cables and pick the best one for your project. FFC ribbon cables help you make smaller, lighter, and more reliable devices. Traditional ribbon cables work well when you want a simple and strong connection.

Choosing the Right Cable

Application Tips

You want your electronics to last and work well. Picking the right cable helps you do this. First, look at your device size and space. Small gadgets need cables that fit tight spots. Flex cable works best in thin devices like tablets. You get more room for other parts with small cables.

Think about how your device moves. If it bends or folds, flexible cables are better. These cables can handle movement without breaking. You see them in laptops and foldable phones. Robots use them too. They keep signals strong even when the device moves.

Check how many connections you need. FFC ribbon cables let you put more conductors close together. This helps you make smaller connectors and save space. You also get better performance because these cables block interference. Your signals stay clear, which is important for fast data.

Here are some tips to help you choose:

- Write down what your device needs: size, movement, and signals.

- Match the cable type to your space and flexibility needs.

- Use FFC ribbon cables for thin, moving, or fast devices.

- Pick traditional ribbon cables for bigger, still setups.

Tip: Always test your cable choice in your design before you build many devices. This helps you find problems early.

Watch for new trends. In the next five years, more devices will use cables that are smaller and lighter. FFC ribbon cables will get more popular because they block interference and fit more signals. You will need cables that send signals fast and work well as electronics get smaller.

| Trend | Why It Matters |

|---|---|

| Compact Size | Saves space for more features |

| High Density | Packs more signals in less space |

| Enhanced Shielding | Keeps signals clear and reliable |

| Flexibility | Supports moving and folding devices |

Stay updated on cable technology. The cable you pick today affects your device’s future.

You should pick FFC ribbon cables for most new electronics. They bend easily, save space, and work with fast data. Traditional ribbon cables are good for important devices. These need strong EMI protection and last a long time.

Cables with good shielding, like Mylar foil or metal braid, keep signals safe from interference.

When you choose a cable, remember these steps:

- Check your device’s size and how it moves.

- Make sure the cable matches your space and power needs.

- Think about future upgrades as technology gets better.

FFC cables will be used more as devices get smaller and faster.

FAQ

What is the main difference between FFC ribbon cable and traditional ribbon cable?

FFC ribbon cable uses flat, flexible plastic with thin copper traces. Traditional ribbon cable has round wires lined up side by side. You will find FFC cables bend more and fit tight spaces better.

Can you use FFC ribbon cable for high-speed data?

Yes, you can use FFC ribbon cable for high-speed data. The flat design helps reduce interference. You should keep the cable short and follow good layout rules for best results.

How do you connect FFC ribbon cables?

You connect FFC ribbon cables using special connectors called ZIF or LIF. These connectors hold the cable in place without damaging it. You just slide the cable in and lock it.

Are ribbon cables reusable?

You can reuse ribbon cables if they stay in good shape. Check for bent pins or broken wires before using them again. FFC ribbon cables handle more cycles than traditional ribbon cables.