Choosing between FFC vs FPC depends on your project’s specific needs. If your design is straightforward and budget-friendly, FFC connectors are a solid option. FFC connectors work well when you only require basic flexible connections. However, if your project involves tight spaces or frequent bending, FPC connectors are the better choice. FPC connectors also accommodate more complex shapes. When deciding between FFC vs FPC, consider factors like structure, flexibility requirements, manufacturing difficulty, cost, and the intended application.

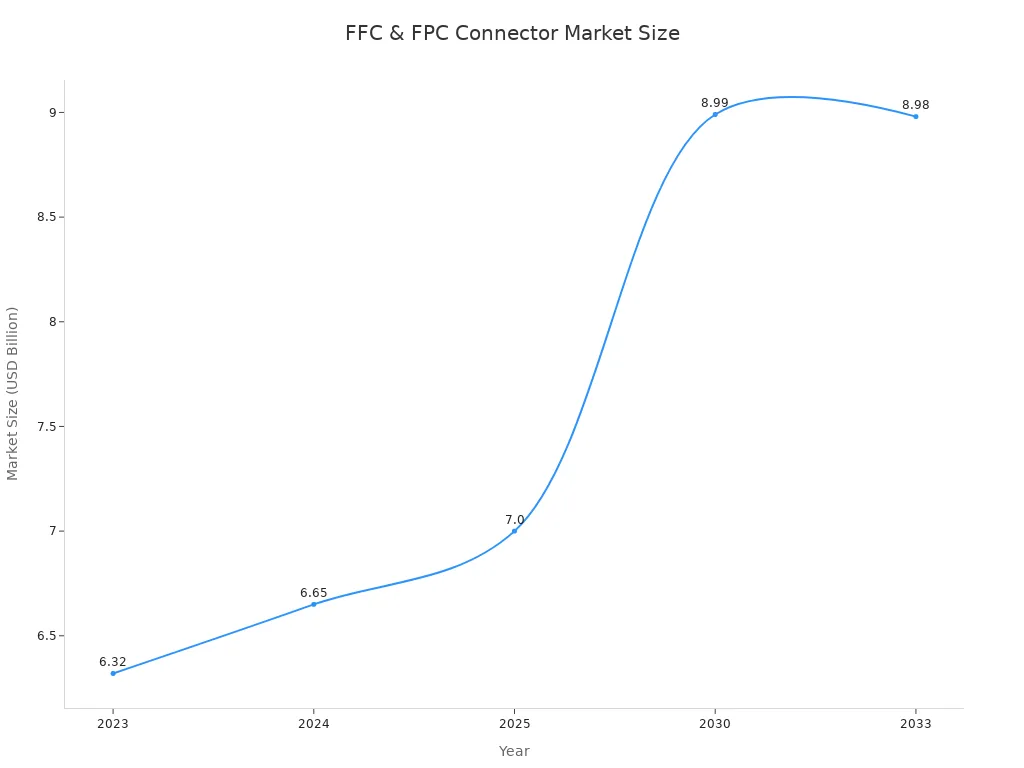

The global market for flexible connectors is expanding rapidly, especially in electronics and automotive industries. Choosing the right connector—FFC vs FPC—based on your project’s needs will help ensure optimal performance.

Key Takeaways

- FFC connectors are easy to use and not expensive. They work well for simple bends and straight lines. You can find them in things like printers and laptops.

- FPC connectors can bend more and fit into tight spots. They are good for tricky circuits. This makes them great for small spaces like in smartphones and medical tools.

- FFC is simpler and costs less to make. FPC takes more time, skill, and money to build. But FPC lasts longer and can handle heat better.

- Pick FFC if your project is simple, cheap, and in a safe place. Choose FPC if you need tight bends, small spaces, or tough places.

- Use the guide to help you pick the right connector. Think about how much movement, space, money, and what kind of place your project needs. This will help your project work best.

ffc vs fpc Overview

flexible flat cable

A flexible flat cable, or FFC, is a simple way to connect electronics. It is not expensive. FFC has thin, flat wires lined up next to each other. These wires are stuck onto a plastic sheet. This makes FFC good for easy connections that need to bend a little. You can find FFC in printers, laptops, and cameras. These devices have small spaces and need straight connections.

To make a flexible flat cable, metal wires are glued to plastic. Then, a cover is put on top for protection. This lets the cable bend and twist without snapping. But FFC cannot handle tricky circuit paths. FFC works well for some bending and normal heat, up to 150°C. It also helps stop unwanted signals from causing problems. This is good for crowded electronics. New FFCs are smaller and have easy-lock connectors. This makes putting them together faster and safer.

Tip: Pick a flexible flat cable if you want a simple, bendy, and cheap way to connect two things.

flexible printed circuit

A flexible printed circuit, or FPC, is more advanced than FFC. FPCs look like tiny circuit boards that can bend. They are made from a bendy material called polyimide film. FPCs have copper lines that can be shaped into hard patterns. This lets FPCs handle tricky circuits and add more parts.

FPCs are strong, safe from chemicals, and keep electricity inside well. Polyimide helps FPCs bend a lot and work in high heat. FPCs can send fast signals and data. This is why they are used in phones, smart watches, and cars. Making an FPC is like making a regular circuit board. It uses cutting and layering steps. New FPCs have better connectors for machines, faster data, and last longer in tough places.

| Feature | Flexible Flat Cable (FFC) | Flexible Printed Circuit (FPC) |

|---|---|---|

| Structure | Parallel wires on plastic film | Copper traces on flexible substrate |

| Complexity | Simple | Complex, multi-layer |

| Flexibility | Good for basic bends | Excellent, supports tight spaces |

| Customization | Limited | High, supports advanced designs |

Choosing between ffc and fpc depends on what your project needs. If you need more bending, tricky shapes, or strength, FPC is best. If you want something simple, FFC is a good pick.

key differences

Structure

FFC and FPC connectors are built in different ways. FFC has flat copper wires next to each other. These wires sit between plastic layers. This makes a ribbon-like cable. It bends, but only in simple ways. FFC cannot hold parts on its surface. It is best for straight connections.

FPC is like a bendy circuit board. It has copper lines on a soft base called polyimide. FPC can have many layers and tricky shapes. You can put parts right on the FPC. This helps when devices need to fold or twist.

- Main structure points:

- FFC: Flat copper wires between PET, simple and straight.

- FPC: Copper lines on polyimide, can be multi-layered.

- FFC: No parts can be added.

- FPC: Can hold parts and complex circuits.

- Both: Have similar pitch sizes, but inside they are different.

Note: FPC is more flexible and complex. FFC is simple and cheaper.

Materials

FFC and FPC use different materials that change how they work. FFC uses PET for insulation. Inside, flat copper wires send signals. This makes FFC thicker and less bendy than FPC. FFC does not usually have extra shielding or gold on it.

FPC uses polyimide or polyester as its base. Polyimide lets FPC bend a lot and stand up to heat. The copper lines in FPC are glued and covered with polyimide. Some FPCs have stiffeners or shields for more support. Gold on FPC connectors helps them last longer.

| Material Component | FFC | FPC | Effect on Performance |

|---|---|---|---|

| Substrate | PET | Polyimide or polyester | FPC bends more and lasts longer |

| Conductors | Flat copper wires | Etched copper lines | Both send signals, but FPC can be complex |

| Insulation | PET film | Polyimide cover | FPC stands up to heat and chemicals better |

| Shielding | Little or none | Can have aluminum or copper | FPC blocks unwanted signals better |

| Surface Finish | None | Gold (optional) | FPC connectors last longer |

Tip: Pick FPC for hot or tough places. FFC is good for simple, cheap jobs.

Manufacturing

FFC and FPC are made in different ways. FFC is made by putting copper wires between PET sheets. Then, the cable is cut to the right size. This is fast and cheap. It is good for making lots of cables. FFC cables are thicker, from 0.5mm to 2.54mm.

FPC is harder to make. It starts with a bendy copper sheet. The process uses etching, drilling, and layering. This makes detailed circuits. FPC can be as thin as 0.15mm. This is good for small devices. FPC can have many layers and shapes. But it takes more time and costs more.

| Aspect | FFC | FPC |

|---|---|---|

| Manufacturing | Copper wires in PET | Etching, drilling, many layers |

| Thickness | 0.5mm–2.54mm | 0.15mm–0.2mm |

| Customization | Not much | A lot |

| Lead Time | Short (days to weeks) | Longer (weeks to months) |

| Cost | Low | Medium to high |

Note: FFC is quick and cheap for easy jobs. FPC is better for tricky designs but takes more time and money.

Applications

ffc Uses

FFC connectors are found in many things we use daily. They are simple and can bend, so they are good for easy connections. Many electronics use FFC for inside wiring. Printers, laptops, and cameras use FFC to link moving parts or small boards. You can also find FFC in DVD players, Blu-ray players, plasma TVs, and set-top boxes. Appliances and keyboards use FFC because the cables fit in small spaces and can move a little.

Factories use FFC in their machines too. Automation tools and measuring devices use these connectors because they are cheap and work well. Car makers use FFC in driving tools, safety gear, music systems, and dashboards. Power supplies and LED lights also use FFC for steady work.

Here are some places where ffcs are used:

- Portable electronics: smartphones, tablets, laptops, cameras

- Car music and safety systems

- Factory robots and machines

- Home appliances and LED lights

Tip: FFC is best for jobs that need simple, bendy, and cheap connections.

fpc Uses

FPC connectors are used for harder and more packed jobs. They are thin and bendy, so they fit in tiny or weird spaces. Many phones, tablets, and laptops use FPC to link screens, cameras, touch pads, and keyboards to the main board. This helps make devices slim and light.

Doctors’ tools also use FPC connectors. Hearing aids and small test machines need bendy circuits that can move a lot. Cars use FPC in music systems, smart driving tools, and inside lights. These connectors work well in small spaces and can handle tricky circuit paths.

Here are some places where fpcs are used:

- Electronics: linking screens, cameras, and touchpads

- Medical tools: hearing aids, small monitors

- Cars: music systems, smart driving, inside lights

Note: FPC is good for jobs that need lots of bending, small size, and tricky circuits.

The ways FFC and FPC are used help engineers pick the right one. FFC is good for easy, bendy jobs. FPC is better for hard, space-saving designs.

Pros and Cons

ffc Advantages

FFC connectors have many good points for projects.

- They cost less because they use fewer materials. The way they are made is simple.

- Their flat shape helps machines put them in faster and more correctly.

- FFC connectors keep signals strong. The wires are spaced evenly, so signals do not get lost.

- Many FFC cables have shielding. This stops unwanted signals from getting in.

- These connectors work well in things that need steady data.

- Their shape makes them easy to use in small spaces.

- FFC connectors help people make fewer mistakes when putting them together.

- They are good for making lots of products quickly.

Tip: FFC connectors are great for projects that need cheap, simple, and steady connections.

ffc Disadvantages

FFC connectors also have some bad points.

- They cannot be used for hard or layered circuits.

- FFC connectors are not very strong. They can break if used in tough places.

- Most FFCs made from polyester can only take some heat. They do not stand up to chemicals.

- Even with polyimide, ffc connectors are not as strong as fpc connectors.

- They do not work well where it is very hot or where there are strong chemicals.

- These problems make ffc connectors not good for hard or special jobs.

fpc Advantages

FPC connectors have special good points for tricky and small designs.

- They bend a lot and fit in tiny or odd spaces.

- Their thin and light build saves room in small gadgets.

- FPC connectors can have very small pitch sizes. This helps in tiny products.

- They give great electrical work, with fast and steady signals.

- Their design makes fixing easier and keeps them in place.

- FPC connectors are good for folding gadgets and things you wear.

- They work for hard layouts and packed circuits.

- These good points make fpc connectors perfect for new electronics.

fpc Disadvantages

FPC connectors have some bad points that designers must think about.

- They cost more because they use special stuff and are hard to make.

- Making fpc connectors needs careful tools and skilled people.

- Fixing or changing them is hard after they are made.

- You must be careful when touching fpc connectors so they do not break.

- Mistakes can happen more when making or putting them together.

- Only trained people should solder or fix these connectors.

Note: FPC connectors are best for projects where space, bending, and how well they work matter more than price or easy fixing.

Comparison Table

When picking connectors, it helps to look at their features side by side. The table below shows the biggest differences between FFC and FPC connectors. This helps you see which one is better for your device or circuit.

| Attribute | FFC (Flexible Flat Cable) | FPC (Flexible Printed Circuit) |

|---|---|---|

| Structure | Flat copper wires on plastic film | Etched copper traces on flexible polyimide substrate |

| Materials | PET insulation, flat copper wires | Polyimide or polyester, copper, optional gold finish |

| Thickness | 0.5mm to 2.54mm | 0.15mm to 0.3mm |

| Flexibility | Thicker, less flexible; best for simple bends | Thinner, highly flexible; fits tight spaces |

| Cost | Low; ideal for mass production and cost savings | Higher; complex manufacturing increases price |

| Typical Uses | Printers, laptops, cameras, appliances, automotive | Smartphones, wearables, medical devices, compact electronics |

| Customization | Basic: pitch, locking style, length | Advanced: ultra-fine pitch, stacking, rugged designs, integrated circuit components |

Note: FFC connectors are good for easy and cheap connections in big projects. Their design is simple and keeps costs down. FPC connectors can bend more and be changed in many ways. They work well for hard circuits and packed spaces.

Customization Options at a Glance

- FFC connectors let you change pitch and locking style. They are best for projects that need simple and steady connections.

- FPC connectors can have many special features. These include very tiny pitches, stacking, and putting sensors or chips right on the circuit. Some FPC connectors can bend over 100,000 times, so they are great for things that move or fold a lot.

Manufacturers pick FFC connectors when they want to save money and finish fast. FPC connectors are chosen when the circuit must fit in a small spot or bend many times.

Decision Guide

Picking the right connector can seem hard. This checklist and these tips will help you choose between FFC and FPC.

Quick Checklist: Which Connector Should You Choose?

- Movement Needs

- Does your project bend or fold a lot?

- If yes, FPC is best for lots of bending.

- If no, FFC is good for simple bends.

- Does your project bend or fold a lot?

- Space Constraints

- Is your device thin or full of parts?

- FPC fits in tight and tricky spaces.

- FFC works in simple layouts with more room.

- Is your device thin or full of parts?

- Budget

- Is saving money important?

- FFC is cheaper for basic connections.

- FPC costs more but is good for advanced designs.

- Is saving money important?

- Environment

- Will it face heat, chemicals, or shaking?

- FPC is better for tough places.

- FFC is fine for normal use.

- Will it face heat, chemicals, or shaking?

- Circuit Complexity

- Does your design need many layers or extra parts?

- FPC can handle complex circuits and hold parts.

- FFC is best for simple cable-to-board jobs.

- Does your design need many layers or extra parts?

💡 Tip: Always pick the connector that matches your project’s movement, space, and strength needs.

Simple Decision Flow

- Does it need to bend or fold a lot?

- Yes → Pick FPC

- No → Go to next question

- Is space very small or shaped oddly?

- Yes → Pick FPC

- No → Go to next question

- Is your budget small and design easy?

- Yes → Pick FFC

- No → Go to next question

- Will it face heat, chemicals, or shaking?

- Yes → Pick FPC

- No → FFC might work

Practical Tips for Matching Connector Type to Application

Experts suggest these steps when picking connectors for your project:

- Learn which connector types fit your job, like car, PCB, or cable-to-board.

- Look at the shape, size, pin layout, lock, and how tough it is.

- Check voltage, current, and signal type.

- Make sure connectors fit together.

- Use tools like calipers and magnifiers to check closely.

- Find part numbers or brands to know who made it.

- Compare what you find to datasheets and rules.

- Test-fit connectors before putting everything together.

- Ask for help if you are not sure.

- Do not think all connectors fit the same. Some look alike but have different pins.

- Always check keying and polarity so you do not break anything.

- Think about how tough it needs to be, like IP66 for wet or dusty places.

🛠️ Note: Pick cable types for your signal and where you use them. Twisted pair cables cut down noise in factories. FPC is great for fast, bendy links in small gadgets.

Standards and Certifications Table

For important jobs, always check for standards and certifications. This table shows common rules for FFC and FPC connectors:

| Standard Category | FFC Connector Standard | FPC Connector Standard |

|---|---|---|

| Flex Cycle Testing | IPC-TM-650 2.4.3 | IPC-TM-650 2.4.3.1 |

| Impedance Control | N/A | IPC-2141A |

| Material Certification | UL 94V-0 | IPC-4101/102 Slash Sheets |

Jobs in medicine, cars, or planes may need more rules. For example, IPC/WHMA-A-620 checks quality for different jobs. IATF 16949 is needed for car parts.

📋 Tip: Always read datasheets and rules before picking a connector.

Final Thoughts

Choosing FFC or FPC depends on how much it moves, space, money, where it is used, and how tricky it is. Use this guide to pick the right connector. If you are not sure, ask a supplier or engineer for help.

Picking FFC or FPC connectors depends on what your project needs. Think about how much it must bend, how much space you have, and how hard the design is. The table below shows the main things to look at:

| Factor | FPC Connector | FFC Connector |

|---|---|---|

| Flexibility | High, can bend a lot | Low, bends just a little |

| Custom Circuits | Yes, can be made special | No, not for custom circuits |

| Typical Use | Touchscreens, sensors | Printers, LCD modules |

Make sure the connector fits what your device needs. Use the decision guide to help you pick. If your design is special or tricky, ask an engineer or supplier for help.

FAQ

What is the main difference between FFC and FPC connectors?

FFC connectors have flat wires on plastic. FPC connectors have copper lines on a bendy board. FPC connectors can fit in smaller and trickier spaces.

Can FFC and FPC connectors be used in the same device?

Yes, some devices use both types together. FFC connectors are good for straight and easy links. FPC connectors work in tight or odd spots.

Which connector lasts longer in high temperatures?

FPC connectors last longer when it is hot. Polyimide in FPC stands up to heat better than PET in FFC. FPC works well in tough places.

Are FFC connectors easier to install than FPC connectors?

Yes, FFC connectors are simple and quick to put in. FPC connectors need more care and sometimes special tools.

How can someone choose the right connector for a project?

Tip: Look at space, movement, cost, and where it will be used. FFC is good for easy and cheap jobs. FPC is better for tricky, bendy, or hot places. Always check datasheets before you pick.