Custom flat flexible cables with fast sampling,

full pitch range, and expert support.

We provide high-quality flat flexible cables with various pitch and conductor options, tailored for your unique application in electronics, robotics, medical, automotive, and more.

Download catalogs andbrochures

Calculate the maximumcurrent your wire can withstand

Request information Now

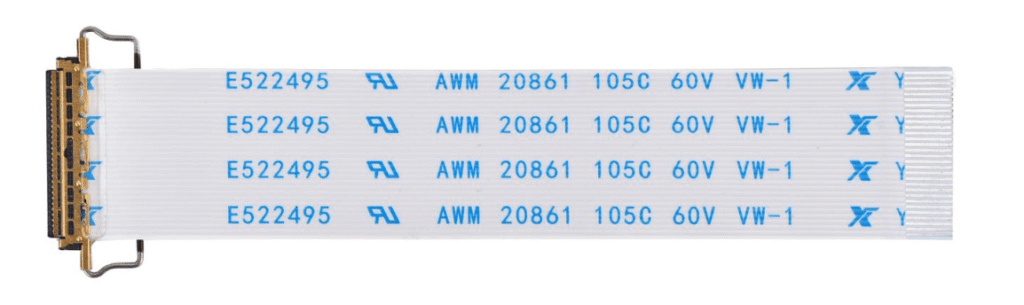

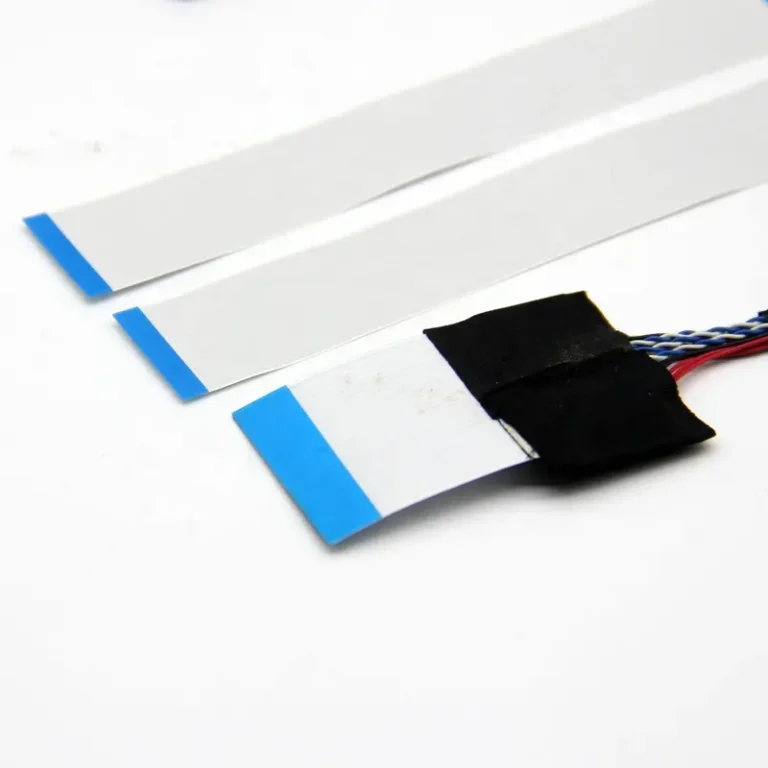

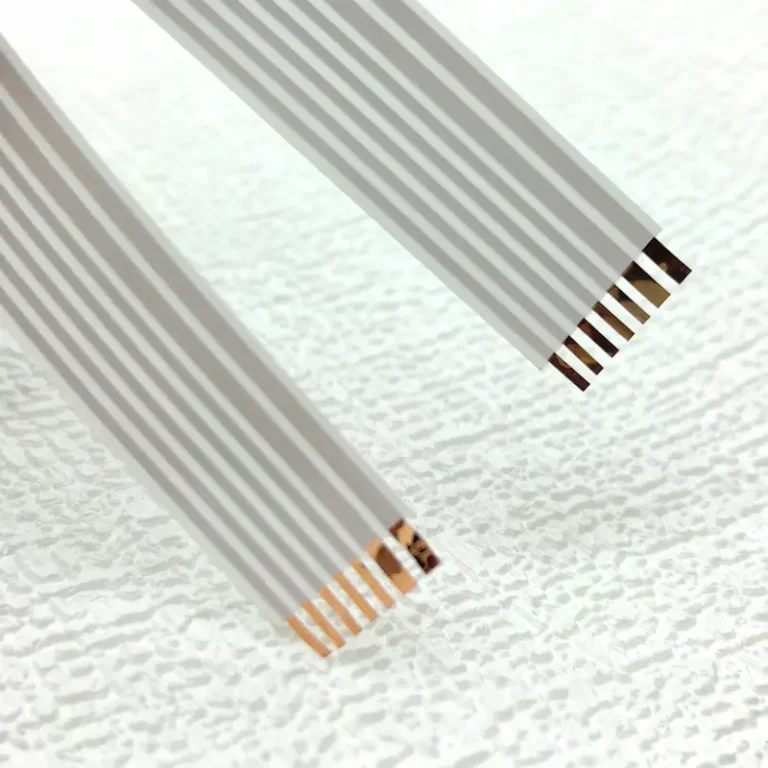

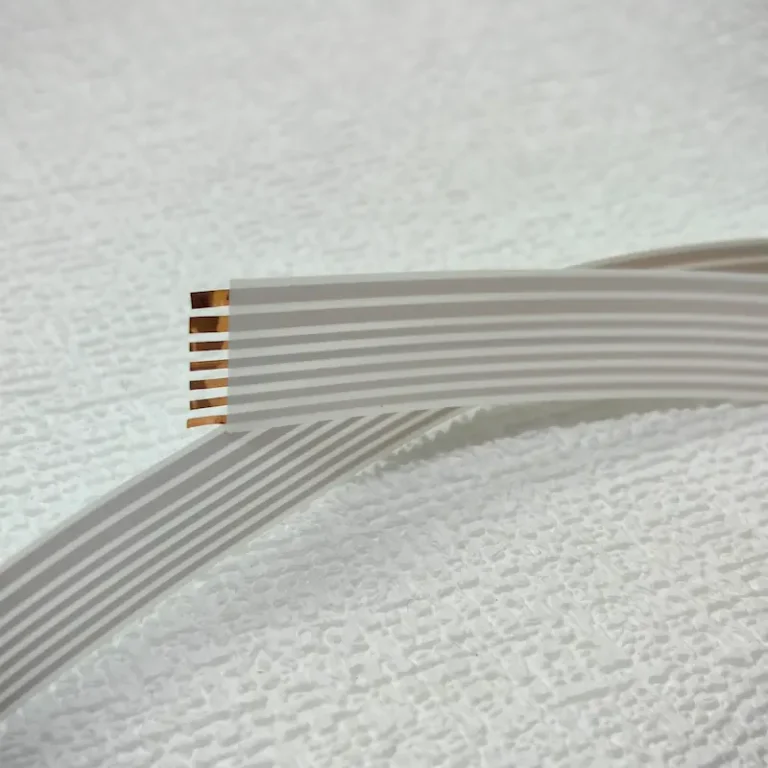

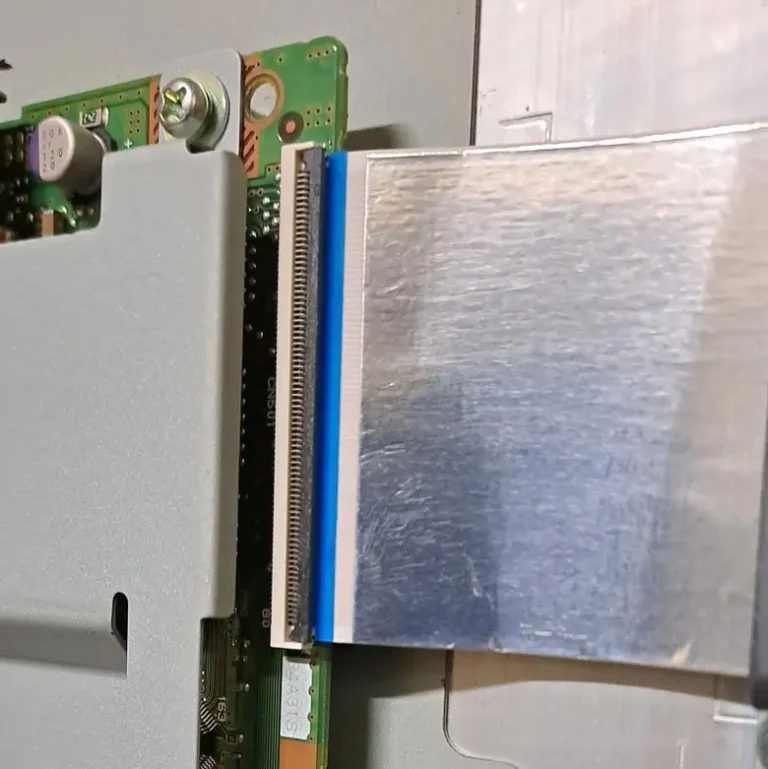

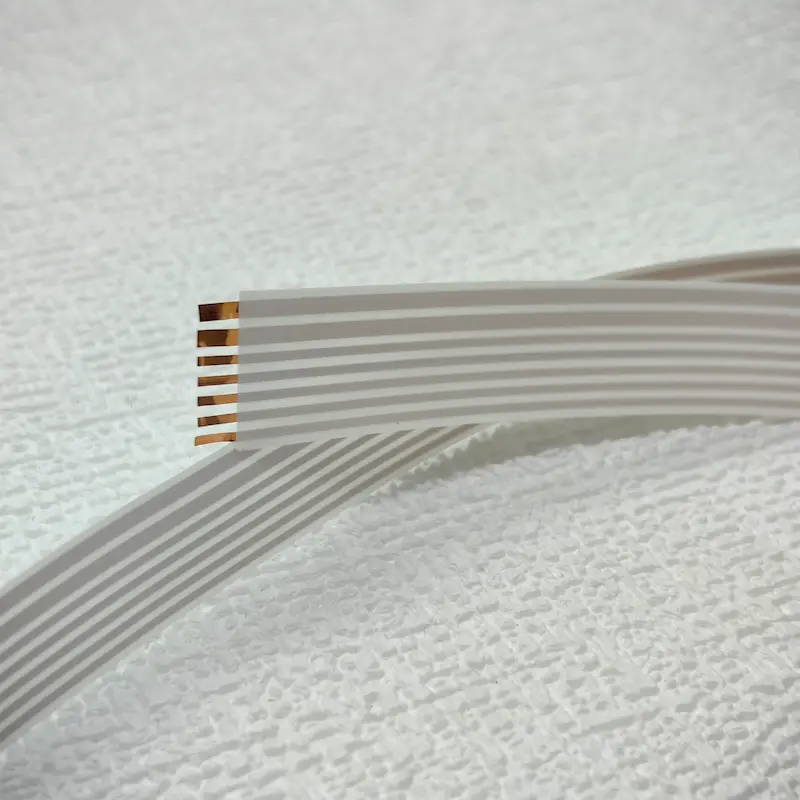

Flat Flexible Cables (FFCs) are thin, flat ribbon-like cables with parallel conductors, designed for compact and flexible electrical connections. It is made from hot-pressed copper wire, copper-tin wire, or copper-nickel wire on a PET film.They are widely used in consumer electronics, industrial systems, automotive devices, robotics, and medical equipment—anywhere space-saving and precision routing are required.

Chat with us now for your Custom needs. Chat on WhatsApp Now

Flexible Flat Cable (FFC) is a solution specifically designed for interconnecting circuit boards in electronic systems. It is made from hot-pressed copper wire, copper-tin wire, or copper-nickel wire on a PET film. YLS offers a wide range of pitch options such as 0.4mm, 0.8mm, 1.0mm, and 1.25mm to meet different application requirements. The cable’s core specifications range from 4 to 96 cores with 0.5mm pitch and 4 to 50 cores with 1.0mm pitch. For 1.0mm pitch cables, users can flexibly choose different thickness options according to their specific needs.

In addition to the standard series, we offer custom-designed flat flexible cables that offer features such as folding, shielding, notching, punching, cutting, labeling, or other special mounting methods to meet your unique requirements.

A reliable all-around FFC cable for everyday board-to-board connections. If you're building consumer electronics or embedded devices, this is the cable that gets the job done without overcomplication.

Designed specifically for modern display assemblies, from tablets to touchscreens. Whether you're routing LVDS or MIPI signals, these FFCs are built for clean, stable video transmission.

Built to handle the heat, vibration, and voltage variations of in-vehicle environments. We work with automotive OEMs and Tier 1s to supply FFCs that meet both electrical and regulatory demands.

When your signal matters and EMI is a concern, our shielded FFCs give you peace of mind. Choose from foil, braid, or double-shielded options for clean data in noisy environments.

Made for compact devices and connectors that don’t tolerate stress. ZIF-compatible FFCs are ideal for tight installs where flexibility and connector life are key.

For designs that move data fast — think cameras, displays, or embedded vision. These FFCs support differential pairs, impedance control, and shielding for up to 10 Gbps signal integrity.

Confidently choose the right FFC cable. This quick reference guide helps engineers and purchasing agents instantly distinguish Type A, Type B, and other configurations by contact orientation and stiffener style.

Overview: This is your most common FFC configuration, with contacts and stiffeners on the same side at both ends.

Key Specs: Same-Side Contact Orientation | Standard Stiffeners on Both Ends.

Use Case: Perfect for standard board-to-board or board-to-display connections

Overview: The contacts are on opposite sides, eliminating the need to twist the cable for reverse connections.

Key Specs: Opposite-Side Contact Orientation | Standard Stiffeners on Both Ends.

Use Case: Connecting reverse-mounted PCBs or components.

Overview: A specialty cable where the stiffener is placed on the same side as the exposed contacts.

Key Specs: Same-Side Contact Orientation | Reverse Stiffeners on Both Ends.

Use Case: For specific ZIF connectors that require pressure directly on the contact side

verview: Combines opposite-side contacts with reverse-side stiffeners for niche applications.

Key Specs: Opposite-Side Contact Orientation | Reverse Stiffeners on Both Ends.

Use Case: Complex, non-standard connections requiring both features.

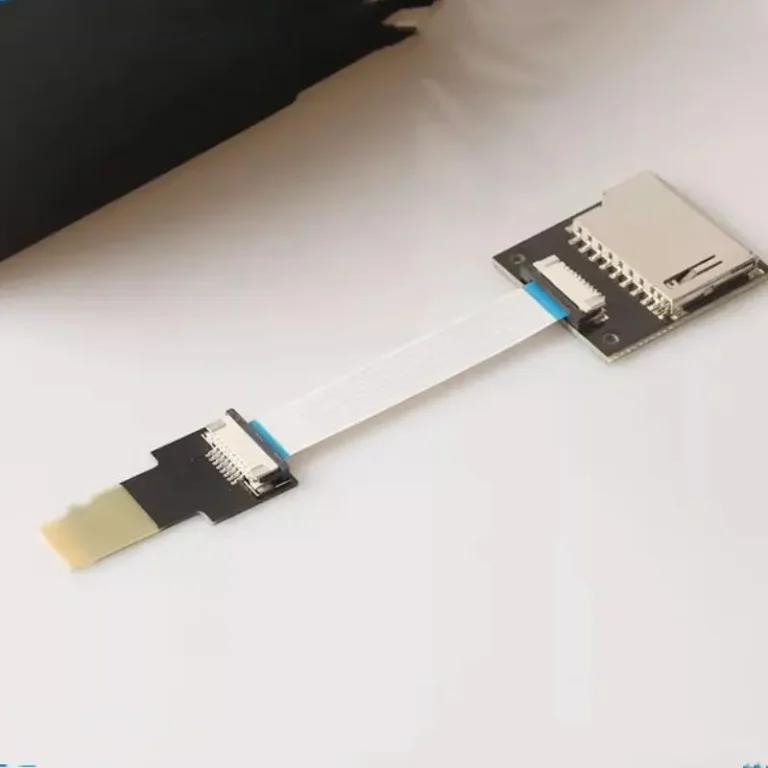

Overview: A hybrid cable with a standard connector termination on one end and exposed leads for soldering on the other.

Key Specs: Mixed Termination | Stiffener on Connector End Only.

Use Case: When one side needs to be permanently hardwired to a PCB.

Overview: A same-side contact cable, but with narrower, “half-width” stiffeners.

Key Specs: Same-Side Contact Orientation | Half-Width Stiffeners on Both Ends.

Use Case: Connectors with side-locking tabs or other mechanisms that require additional clearance.

Overview: Both ends of the cable are stripped for direct, permanent soldering. No stiffeners are used.

Key Specs: Solder Termination on Both Ends | No Stiffeners.

Use Case: Creating a permanent, hardwired link between two boards.

Overview: Features opposite-side contacts but does not have support stiffeners on either end.

Key Specs: Opposite-Side Contact Orientation | No Stiffeners.

Use Case: Reverse-contact connections where the connector provides full mechanical support.

Overview: Combines opposite-side contacts with the narrower, half-width stiffeners.

Key Specs: Opposite-Side Contact Orientation | Half-Width Stiffeners on Both Ends.

Use Case: Reverse connections that also require the clearance provided by side-locking connectors.

Overview: A specialty cable where the stiffener is placed on the same side as the exposed contacts.

Key Specs: Same-Side Contact Orientation | Reverse Stiffeners on Both Ends.

Use Case: For specific ZIF connectors that require pressure directly on the contact side

Overview: A unique hybrid with a reverse-side stiffener on one end and leads for soldering on the other.

Key Specs: Mixed Termination | Reverse Stiffener on Connector End.

Use Case: Custom applications requiring both a hardwired connection and a specialty reverse-contact connector.

Overview: A specialty cable where the stiffener is placed on the same side as the exposed contacts.

Key Specs: Same-Side Contact Orientation | Reverse Stiffeners on Both Ends.

Use Case: For specific ZIF connectors that require pressure directly on the contact side

Overview: An opposite-side contact cable that has a support stiffener on only one of its ends.

Key Specs: Opposite-Side Contacts | Stiffener on One End Only.

Use Case: Asymmetrical reverse-contact designs where only one connector needs support.

Overview: A specialty cable where the stiffener is placed on the same side as the exposed contacts.

Key Specs: Same-Side Contact Orientation | Reverse Stiffeners on Both Ends.

Use Case: For specific ZIF connectors that require pressure directly on the contact side

With over a decade of experience in custom cable engineering and production, Yulian delivers flexible, high-precision, and cost-effective FFC solutions trusted by OEMs and integrators worldwide.

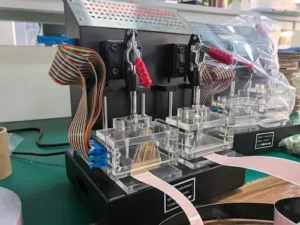

We provide a range of prototyping and manufacturing services to meet our customers’ personalized needs. Fully automated.

From 0.4mm to 1.25mm—fit any design requirement.

Support complex, high-density signal layouts.

Drawings in 24h. Samples ready in 3–5 working days.

Support foldable, shielded, notched, labeled, and special formats.

We help translate your idea or sketch into a working cable.

No middlemen. Competitive pricing from our ISO-certified factory.

Each cable is 100% tested for electrical performance and reliability.

From prototypes to mass production, we adapt to your scale.

Industries We Serve with FFC Cable Solutions

From drones to medical devices, Yulian’s flexible flat cables power critical applications across 8+ industries. We tailor specifications, materials, and structure to your real-world needs—ensuring performance, safety, and reliability.

Custom ultra-light, foldable cables for compact UAV power and signal routing.

Precision cables for diagnostic, monitoring, and imaging devices.

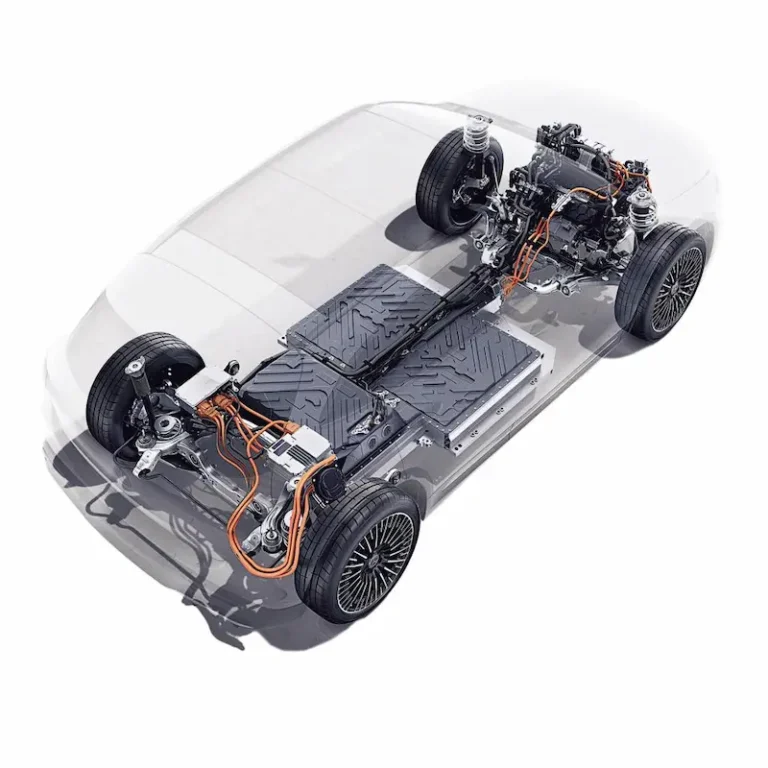

Reliable signal and control wiring for BMS, inverters, and modules.

Custom ultra-light, foldable cables for compact UAV power and signal routing.

Highly flexible and long-life cables for moving joints and arms.

Custom ribbon wiring for in-cabin controls, dashboards, and lighting.

Signal cables for antenna tuning, routers, RF modules, and more.

Versatile internal wiring for screens, power boards, and input devices.

At YLS, we simplify the path from idea to production. Whether you’re upgrading a product or building something new, our six-step process ensures speed, accuracy, and full customization for your flat flexible cable solution.

Tell us about your needs: cable pitch, pin count, length, connectors, UL specs, shielding, fold lines—our team starts with the details that matter.

We translate your specs into manufacturable designs. Expect drawing files and connector matching within 24–48 hours.

Once drawings are approved, we build samples in 3–5 working days, including precision cutting, labeling, and insulation options.

You verify the sample in your device. We assist with adjustments, feedback loops, or connector matching as needed.

Once the prototype is approved, we lock the design, confirm packaging and delivery terms, and prepare for production.

We initiate volume production and ship on time via express, air, or sea—wherever your facility is.

Fold lines or pre-bent shaping

Custom labels or barcodes

Hole punching, notching, peel-tab finishing

Shielding and grounding features

Special packing and reel packaging options

Technical support for connector sourcing

Yulian is a direct manufacturer of flat flexible cables (FFC), delivering precision wiring solutions trusted by global OEMs. With in-house tooling, rapid prototyping, and full customization capabilities, we help you go from concept to cable—fast, reliable, and to your spec.

We offer pitch options from 0.4mm to 1.25mm and core counts up to 96, with full support for folding, shielding, notching, punching, labeling, and custom assembly.

Trusted by Global Brands Across Industries

Increase Values

From consumer electronics startups to industrial automation giants, Yulian has helped 300+ global customers improve reliability, shorten launch time, and lower cable costs with tailored FFC solutions.

A Flexible Flat Cable (FFC) is a type of electrical cable that is flat and flexible, commonly used to connect electronic components where space saving and flexibility are required.

The most common pitch sizes for FFC cables include 0.5mm, 1.0mm, 0.8mm, and 1.25mm, depending on the device’s connector compatibility and signal requirements.

Flat cables are ribbon-like with parallel conductors arranged in a flat plane, ideal for compact spaces and organized wiring. Flexible cables refer to round or flat cables designed to bend easily during use, not always flat in shape.

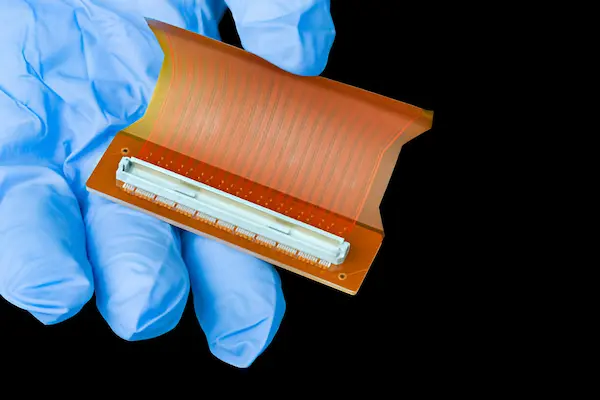

FPC (Flexible Printed Circuit) is made by etching conductive traces onto a flexible plastic substrate, allowing for complex circuits. FFC (Flexible Flat Cable) is a pre-fabricated flat ribbon cable with parallel metal conductors, used primarily for signal transmission between devices.

FFC cable thickness typically ranges from 0.1 mm to 0.5 mm depending on the pitch, number of pins, and insulation. For example, a standard 0.5 mm pitch FFC with 20 pins may be around 0.3 mm thick.

Flat cables are used for their low profile, space efficiency, and easy routing in tight spaces. They also offer consistent electrical characteristics and reduced crosstalk between conductors.

Flat cables may have limitations such as lower current capacity, less durability under constant flexing compared to round cables, and potential electromagnetic interference if not shielded.

FFC stands for Flexible Flat Cable. It is a type of flat ribbon-like electrical cable made with parallel metallic conductors laminated between flexible insulating films.

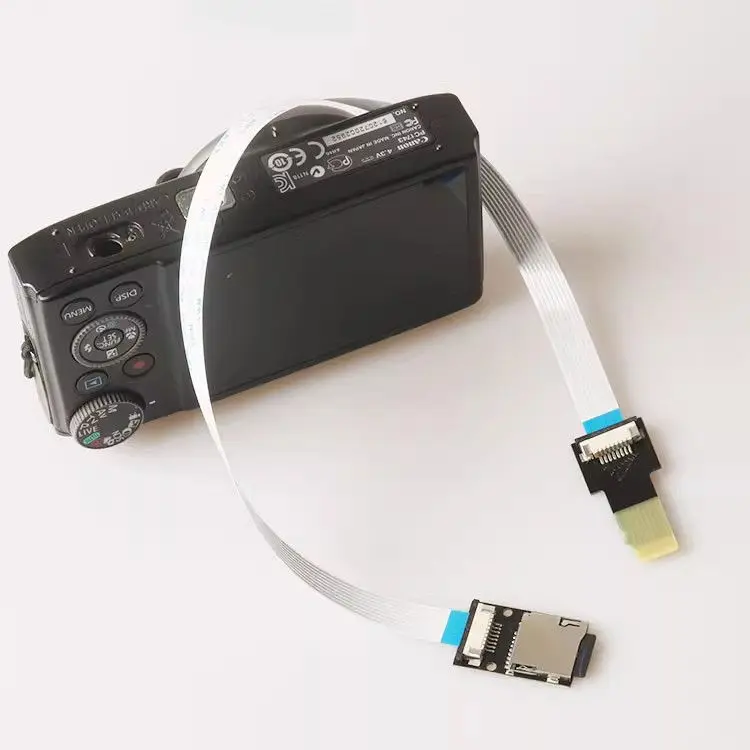

In wiring terminology, FFC refers to a flat, flexible cable assembly used to connect two electronic components or boards, commonly found in laptops, printers, cameras, and LED lighting systems.

The main purpose of FFC cables is to provide reliable, space-saving, and low-profile connections between electronic modules. They simplify internal wiring, especially in tight, compact designs.

Chat with us now for your Custom needs. Chat on WhatsApp Now

Need a quote, sample, or technical consultation? Our team responds within 8 hours. Send us your requirements and we’ll help you build the right cable — no delays, no guesswork.

+86 137 36386818

inquiry@ylscable.com