You see flexible circuitry everywhere, from smartphones to medical devices. This technology powers compact, reliable connections in modern electronics. YLS, a trusted name in flexible flat cable solutions, helps drive these advancements. The global market for flexible circuitry is booming, with an estimated $15 billion value in 2025 and 50 billion units produced yearly:

| Metric | Value |

|---|---|

| Estimated market size (2025) | $15 billion |

| Estimated annual production volume | 50 billion units |

With precise manufacturing and careful assembly at every stage, you get flexible circuitry that adapts to any application.

Key Takeaways

- Choose the right substrate for flexible circuits. Materials like polyimide offer excellent thermal stability and durability.

- Clean and condition substrates before assembly. This step ensures better performance and longevity of flexible circuit boards.

- Follow strict quality control during manufacturing. Regular inspections and testing help maintain high standards and reliability.

- Use rapid prototyping to test designs early. This approach allows for quick adjustments and reduces costs before mass production.

- Package flexible circuits carefully to prevent damage. Use ESD protection and moisture control to ensure safe transport and storage.

Material Preparation

Flexible Circuitry Substrates

When you start making a flexible pcb, you need to choose the right substrate. The substrate acts as the foundation for your flexible printed circuit. YLS Flexible Flat Cable uses high-quality materials to ensure strong performance and reliability. You can select from several substrate types, each with unique properties. The most common materials for flexible pcb substrates include polyimide, polyester, and liquid crystal polymer. These materials affect how your flexible circuit board handles heat, chemicals, and mechanical stress.

Here is a table showing the key properties of popular substrate materials:

| Material | Thermal Stability | Chemical Resistance | Mechanical Properties | Electrical Insulation | Maximum Operating Temperature | Cost |

|---|---|---|---|---|---|---|

| Polyimide (PI) | Excellent | Excellent | Good | Good | ~260°C | Moderate |

| Polyester (PET) | Good | Good | Good | Good | ~150°C | Low |

| Liquid Crystal Polymer | Excellent | Excellent | Excellent | Excellent | ~300°C | High |

Substrate selection impacts the flexibility, thermal stability, and durability of your flexible pcb. Polyimide works best for high-performance flexible printed circuit designs because it resists heat and lasts longer. If you pick the wrong substrate, your flexible circuit board may crack or lose signal quality. YLS offers foldable and shielded cable options to match your specific needs.

After you choose the substrate, you cut large rolls into semi-finished sheets. This step prepares the material for further processing. You must make sure each sheet matches the size and shape needed for your flexible pcb design.

Cleaning and Conditioning

Before you build your flexible printed circuit, you need to clean and condition the substrate. This step removes dust, oils, and other contaminants. Clean surfaces help your fpc perform better and last longer.

You should follow these standard cleaning procedures:

- Use isopropyl alcohol or approved cleaning solutions.

- Wipe the substrate with lint-free cloths or swabs.

- Remove loose debris with an anti-static brush or compressed air.

- Wear gloves and safety glasses to protect yourself.

- Avoid using too much force, which can damage the flexible pcb.

You can also use ultrasonic cleaning for deeper results. This method uses sound waves to shake loose any hidden particles. Clean and conditioned substrates help your flexible circuit board maintain strong electrical insulation and mechanical strength.

Tip: Always work in a well-ventilated area and follow safety guidelines when handling cleaning chemicals.

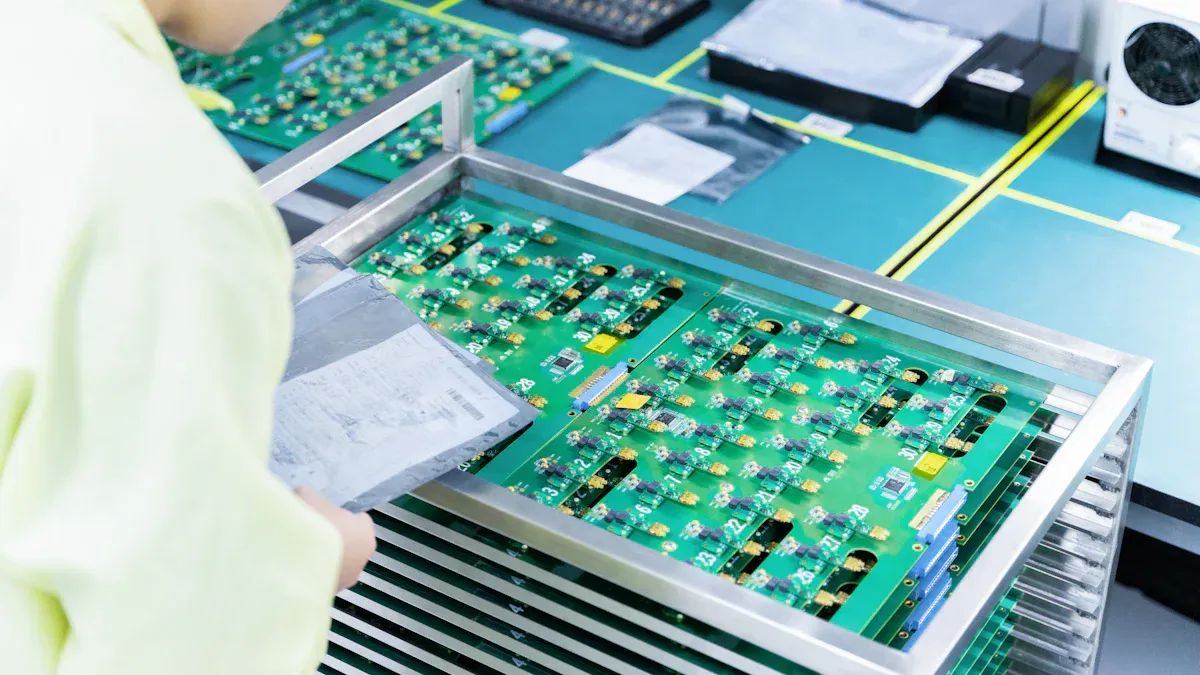

Flexible PCB Manufacturing Process

The flexible PCB manufacturing process involves several precise steps that transform raw materials into high-performance flexible printed circuits. You need to follow strict procedures to ensure every flexible pcb meets industry standards for reliability and quality. YLS uses ISO-certified methods to guarantee that each flexible circuit board delivers consistent results, whether you need a single prototype or a large production run.

Fabricating Flexible PCB Laminates

You start the flexible pcb manufacturing process by fabricating flexible pcb laminates. This step forms the backbone of your flexible pcb. The process requires careful handling of thin materials to prevent damage and maintain dimensional stability. You often use smaller panel sizes and specialized systems to keep accuracy high, since flexible materials can expand or contract with temperature changes.

When fabricating flexible pcb laminates, you can choose from several methods:

- Laser profile cutting lets you create precise and complex shapes. This method reduces the need for expensive tooling and speeds up the process. However, you may notice some carbon residue, which you can remove in later steps.

- Plasma desmear and etch back are essential for multilayer flexible printed circuit designs. These techniques help you achieve reliable plated holes and strong interconnects, which are critical for advanced applications.

- Additive manufacturing offers high customization and reduces waste. You can produce flexible pcb laminates more efficiently compared to traditional methods.

| Aspect | Additive Manufacturing | Traditional Manufacturing |

|---|---|---|

| Customization | High | Limited |

| Waste Reduction | Significant | High |

| Efficiency | Improved | Slower |

You also need to pay attention to selective pad plating. This practice protects the flexibility of your fpc and lowers the risk of mechanical breakage. By focusing on these details, you ensure that your flexible pcb laminates meet the demands of modern electronics.

YLS supports custom fabrication from prototyping to bulky production. You can experiment with different materials, layouts, and components during the prototyping stage. This flexibility helps you find the best solution for your project before moving to full-scale manufacturing.

Circuit Patterning

After you finish fabricating flexible pcb laminates, you move to circuit patterning. This step defines the electrical pathways on your flexible pcb. You need to follow industry standards to ensure safety and performance. For example, UL 796 requires a V-0 rating for flammability, which means the material stops burning within 10 seconds. You also test for maximum operating temperature and comparative tracking index (CTI) to make sure your flexible printed circuit can handle high voltages and heat.

| Key Element | Description |

|---|---|

| V-Rating | Measures material flammability; UL 796 requires a V-0 rating, indicating burning stops within 10 seconds. |

| Maximum Operating Temperature | Defines the highest reliable performance temperature; both standards specify thermal endurance testing. |

| Comparative Tracking Index (CTI) | Assesses electrical breakdown properties; higher values indicate better performance in high-voltage environments. |

You use advanced technology to achieve accurate and consistent circuit patterns. Laser direct imaging (LDI) gives you high precision, with resolutions as fine as 15 micrometers. This method eliminates the need for physical masks and reduces alignment errors. Vacuum tables and roll-to-roll systems keep your flexible pcb flat and stable during imaging, which prevents distortions and ensures consistent tension. You also control the environment by maintaining stable temperature and humidity. This practice minimizes dimensional changes in your flexible circuit board and keeps your patterns accurate.

The flexible pcb manufacturing process at YLS includes rapid prototyping and a wide range of customization options. You can quickly move from concept to prototype, which helps you meet tight deadlines. If you find any design flaws, you can correct them without high costs. Early validation and testing ensure your flexible printed circuit meets all standards before mass production. This approach reduces the risk of defects and supports scalable, customized solutions for any application.

Tip: Rapid prototyping lets you test your flexible pcb design early. You can make changes quickly and avoid costly mistakes during mass production.

The flexible pcb manufacturing process combines advanced technology, strict quality control, and flexible assembly options. You get reliable, high-performance fpc products that fit your exact needs, whether you need a single flexible printed circuit or a full flexible pcb assembly.

Drilling and Plating

Drilling Holes & Vias

When you work with a flexible circuit board, drilling holes and vias is a critical step in the manufacturing process. You need to create precise holes for electrical connections between layers. If you make a single-sided flexible circuit board, you usually drill fewer holes. For a double-sided flexible circuit board, you must add more vias to connect the top and bottom layers.

To keep your flexible circuit board strong and reliable, follow these best practices:

- Place vias away from bend zones and rigid-flex transition areas. This prevents cracks and mechanical stress.

- Use pad plating and rolled annealed copper. These materials help your vias perform better in flexible areas.

- Follow IPC 2223 guidelines. Keep vias at least 20 mils from stiffener edges and 50 mils from rigid-flex interfaces.

Quality control plays a big role during drilling. You should check for burrs, rough edges, and accurate hole placement. Use visual and microscopic inspection to spot defects. Electrical testing helps you verify that all connections work as designed. Automated optical inspection (AOI) can catch misalignment or sizing issues before you move to the next step.

| Quality Control Measure | Description |

|---|---|

| X-ray or Ultrasonic Imaging | Detects internal defects in the PCB. |

| Peel Tests | Checks the strength of the adhesion bond. |

| Visual Inspection | Looks for delamination, bubbles, or misalignment. |

| Automated Optical Inspection | Uses cameras and software to find defects. |

| ISO 9001 | Ensures products meet customer specifications. |

| IPC-6013 | Sets performance requirements for flexible PCBs. |

Electroplating Conductors

After drilling, you move to electroplating. This step adds a thin layer of copper to the inside of each hole and across the circuit traces. The electroplating process creates a continuous electrical path, which boosts signal integrity and lowers the risk of failure in your flexible circuit board. You get better conductivity and reliability, especially in dynamic applications.

You can control the thickness and quality of the copper layer during electroplating. This control is important for both single-sided and double-sided flexible circuit board designs. It helps your flexible circuit board maintain high performance, even when it bends or twists during use.

Quality checks continue during plating. You should use cross-section analysis to confirm the size and placement of plated holes. AOI systems help you spot any misalignment or defects. By following these steps, you ensure your manufacturing process produces flexible circuit boards that meet strict industry standards.

Tip: Careful drilling and plating help your flexible circuit board last longer and perform better in real-world applications.

FPC Layers Alignment and Lamination

Layer Alignment

You need to align multiple layers with precision when you build an FPC. The flexibility of the materials can make this step challenging. Layers may bend or distort, which can cause misalignment. You must use special fixtures and alignment checks to keep each layer in place. Engineers often increase the number of alignment checks during assembly. This helps you avoid errors and ensures that the electrical paths match up perfectly.

YLS offers foldable and shielded cable options. These designs require even greater attention to fpc layers alignment and lamination. Shielded cables need exact placement of the shielding layer to block electromagnetic interference. Foldable cables must keep all layers aligned so they bend without damage.

Tip: Always check your alignment fixtures before starting assembly. Accurate alignment prevents signal loss and mechanical failure.

Lamination Process

You use the lamination process to bond the layers together. High temperatures and pressure help fuse the materials, but you must control these conditions carefully. Too much heat or pressure can damage the flexible materials or cause the layers to separate. You can adjust pre-pressing time and test pressure uniformity with induction paper to avoid glue overflow and other issues.

The lamination process improves the flexibility and durability of your FPC. You also gain protection against electromagnetic interference. Engineers add EMI shielding film after the coverlay. This step prevents signal distortion and keeps your FPC working well in high-frequency systems.

Here are some benefits of lamination in FPC manufacturing:

- You enhance flexibility and durability.

- You protect circuits from electromagnetic interference.

- You maintain consistent performance in demanding environments.

You may face challenges during fpc layers alignment and lamination. The table below shows common problems and solutions:

| Challenge | Solution |

|---|---|

| Glue overflow issues | Use a special freezer for protective film; pre-bake damp CL glue. |

| Alignment inaccuracies | Check fixtures and increase alignment checks. |

| Process-related overflow | Adjust pre-pressing time, pressure, and temperature; test pressure uniformity. |

You can achieve reliable results by following these steps. Your FPC will meet the needs of modern electronics and provide long-lasting performance.

Finishing and Testing

Cutting & Shaping

You reach the final stage of manufacturing when you cut and shape your flexible circuits. This step gives each circuit its exact dimensions and prepares it for assembly or shipment. You can choose from several cutting methods, each with unique advantages and limitations.

| Method | Advantages | Limitations |

|---|---|---|

| Laser Cutting | Ultra-high precision (±0.02mm), no tool wear, design freedom | Heat affected zone, slower speed, higher costs |

| CNC Routing/Milling | Good edge quality, unified rigid-flex forming | Mechanical stress risk, tool maintenance |

| Hard Tooling | Tight tolerances, long lifespan, efficient for large production | Higher initial cost |

You use laser cutting for complex shapes and fine features. CNC routing works well for thicker materials. Hard tooling is best for large-scale production with high precision. During cutting, you separate individual circuits from panels, create subpanels for testing, and make partial cuts or slots for special designs. You also cut stiffeners, coverlays, and EMI shields to fit your finished product.

Tip: Always check your cutting equipment before starting. Precise cutting helps your flexible circuits fit perfectly and perform reliably.

Electrical Testing & Inspection

You must test every finished fpc electrical test to ensure safety and performance. Electrical testing checks for open circuits, shorts, and proper connections. You use several methods to inspect your flexible circuits before shipment.

| Testing Method | Description |

|---|---|

| Electrical Testing | Checks for open and short circuits |

| Continuity Test | Ensures all connections are intact |

| Isolation Test | Verifies no unintended connections between layers |

| Flying Probe Testing | Uses robotic arms for flexible, fixtureless testing |

| In-Circuit Testing | Assesses circuit integrity after assembly |

| 8-Point Electrical Test Checklist | Validates electrical parameters and compliance |

You follow a strict checklist for each finished fpc electrical test. This process confirms that your circuits meet international quality standards. Skilled professionals use the latest equipment to inspect every detail. Quality control happens at every stage, not just at the end. You make sure each flexible circuit meets or exceeds industry specifications.

- You prioritize quality control throughout production.

- You use advanced equipment for precision and care.

- You rely on skilled professionals to maintain strict standards.

Note: Careful inspection and testing guarantee that your flexible circuits work safely and reliably in any application.

Packaging

Final Packaging

You need to protect flexible circuits carefully during transportation and storage. The right packaging keeps your circuits safe from static, moisture, and physical damage. You can use several methods to make sure your flexible PCBs arrive in perfect condition.

- ESD Protection: Place your circuits in ESD (Electrostatic Discharge) bags or ESD foam. These materials prevent static electricity from damaging sensitive components.

- Moisture Control: Use moisture barrier bags and include desiccants. These steps keep humidity low and stop moisture from reaching your circuits.

- Physical Protection: Pack your circuits in high-quality cardboard boxes. This outer layer shields them from bumps and drops during shipping.

- Monitoring: Add humidity indicator cards. These cards help you check if moisture has entered the package.

Tip: Always store flexible circuits in a clean, dry, and well-ventilated area. Avoid places with dust, moisture, or corrosive gases.

Here is a table showing common packaging methods and their benefits:

| Packaging Method | Description |

|---|---|

| Anti-static Packaging | Protects against static discharge, which can harm electronic parts. |

| Moisture-resistant Packaging | Shields circuits from moisture, improving shelf life and reliability. |

| ESD Bags / ESD Shielding Bags | Create a barrier against static electricity. |

| ESD Foam | Cushions and protects while preventing static buildup. |

| Moisture Barrier Bags | Block moisture from entering the package. |

| Desiccants | Absorb any moisture that gets inside. |

| Humidity Indicator Cards | Show if humidity levels are safe during storage and transport. |

You can also use vacuum sealing or fill packages with inert gas. These methods reduce oxygen and moisture, which helps prevent corrosion and oxidation. Keep your storage area between 68°F and 77°F (20°C to 25°C) with 40% to 60% relative humidity. Good packaging and storage help your flexible circuits last longer and work reliably when you need them.

You gain precision and reliability at every stage of flexible circuit manufacturing:

- Coverlay thickness ranges from 0.001 to 0.002 inches, giving insulation and flexibility.

- Laser cutting shapes circuits with tolerances as tight as ±0.002 inches.

- Rigorous electrical and flex cycle testing ensures durability.

Customization lets you match materials and designs to your project, improving performance for robotics, wearables, and more. YLS supports rapid prototyping and strict quality control. If you want to learn more or need help with your flexible circuit project, explore guides and resources or contact YLS for expert support.

FAQ

What makes flexible circuits different from rigid PCBs?

Flexible circuits bend and twist without breaking. You use them in tight spaces or moving parts. Rigid PCBs stay flat and cannot flex. Flexible circuits work well for wearables, robotics, and compact electronics.

How do you customize a flexible flat cable for my project?

You choose the pitch, number of conductors, and shielding options. YLS lets you add notching, punching, or labeling. You get samples fast for testing. Customization helps you match your cable to your device.

Why is ISO certification important in flexible circuit manufacturing?

ISO certification shows you that the manufacturer follows strict quality standards. You get reliable products with consistent performance. You can trust that every flexible circuit meets safety and durability requirements.

How do you test flexible circuits before shipping?

You use electrical testing, visual inspection, and automated systems. Each circuit passes checks for open circuits, shorts, and proper connections. Skilled technicians make sure your flexible circuits work safely in your application.