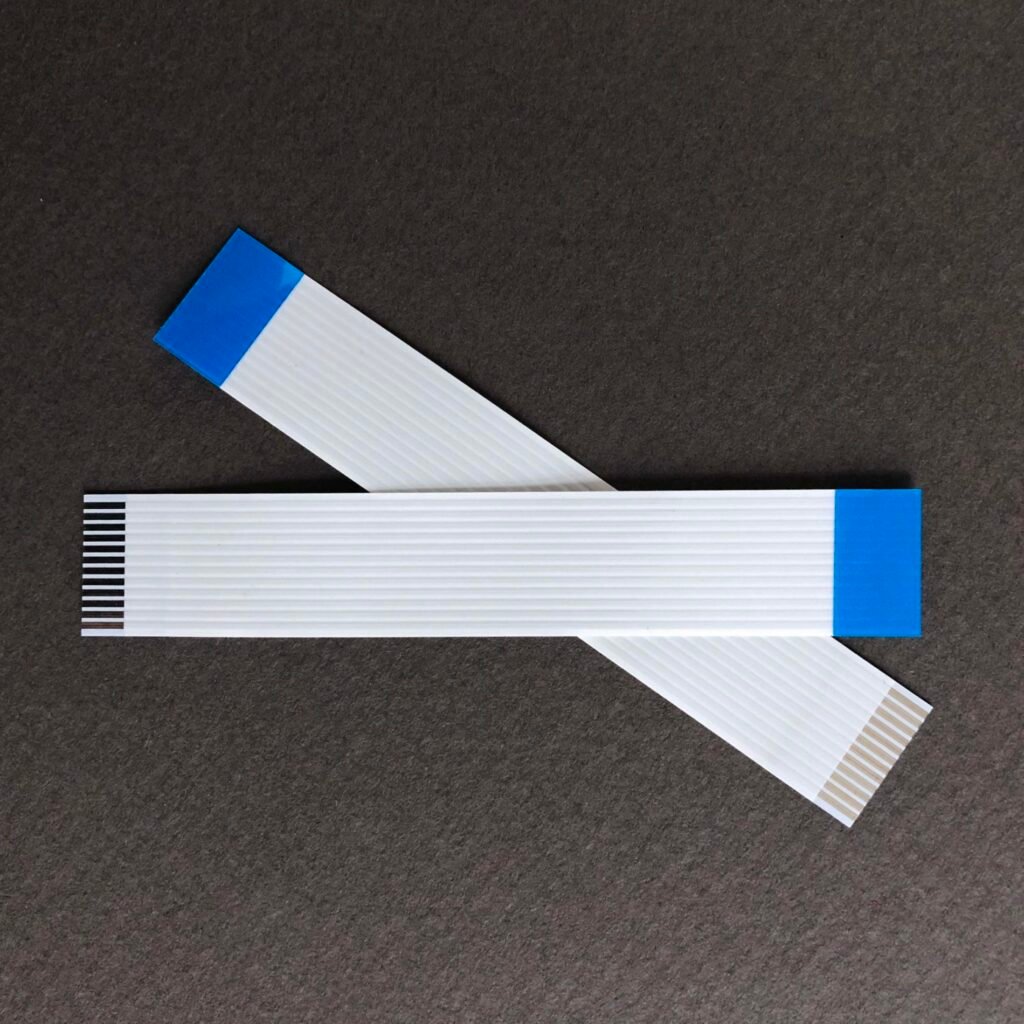

To pick the best cable flat wire for your project, first write down what you need. Think about where you will use the flat cable. Check which features fit your project. Look at things like pitch, conductor count, and insulation material. The table below lists common choices for flexible flat cable in modern devices:

| Specification Type | Details |

|---|---|

| Pitch | 0.025″, 0.050″, 0.100″, 0.156″, 1mm (custom) |

| Number of Conductors | Varies based on connector positions |

| Wire Type | Stranded copper wire (18 AWG to 34 AWG) |

| Insulation Material | PVC, PET, PI, PTFE |

There are many options. Always pick the flexible flat cable that fits your space and meets your quality needs.

Key Takeaways

- Figure out what your project needs before picking a flat cable. Think about things like voltage, current, and how much space you have.

- Pick the right insulation material for where you will use it. PVC works well inside. PTFE or PI is better for heat or chemicals.

- Make sure the cable is flexible and strong. It should bend without breaking. It must handle your project’s conditions.

- Check for trusted certifications like UL and RoHS. These show the cable is safe and high quality. This lowers the chance of electrical problems.

- Ask experts for help if your project is hard. They can give good advice. This helps you avoid expensive mistakes.

Application Analysis

Application Types

Think about where you will use cable flat wire. Every place has different needs. Homes and offices use networking cable for computers. Industrial areas need cables for big machines and lots of movement. Military and aerospace need cables that save space and are light. Flat cable is good for these jobs. It fits in small spaces and keeps things tidy.

Tip: Flat cables take up about half the space of round cables. This makes it easier to organize wires in tight spots.

Remember these things for special uses:

- Flat cables help save space in military and aerospace gear.

- Lighter cables help keep planes and satellites balanced.

- Flexible flat cable can handle quick moves and twisting, so it lasts longer.

Feature Matching

Pick cable features that fit your project. Look for these things:

- Small size helps cables fit in tight places and stops tangling.

- Good design cuts down on interference, so signals stay strong.

- Strong cables last longer and handle tough use.

- You can change some cables for special jobs, like in hospitals or factories.

Category 6 flat cable and cat6 flat cable keep signals strong for fast data. The jacket on flat cables stops rust and protects from chemicals. The design lets heat out, so the cable can carry more power. Even spacing of conductors keeps the cable working well, even when it bends.

Always check if the cable flat wire is flexible, strong, and safe. Picking the right features helps your setup work better and last longer.

Technical Specifications for Flat Cable

Voltage and Current

Before you pick a flexible flat cable, check the voltage and current ratings. The voltage rating shows how much electrical force the cable can safely handle. Most flat cables for electronics have set voltage ratings. You can see the usual ratings in the table below:

| Voltage Rating | Description |

|---|---|

| 300 / 500 V | Domestic and low-power applications |

| 450 / 750 V | Domestic and low-power applications |

| 600 / 1000 V | Domestic and low-power applications |

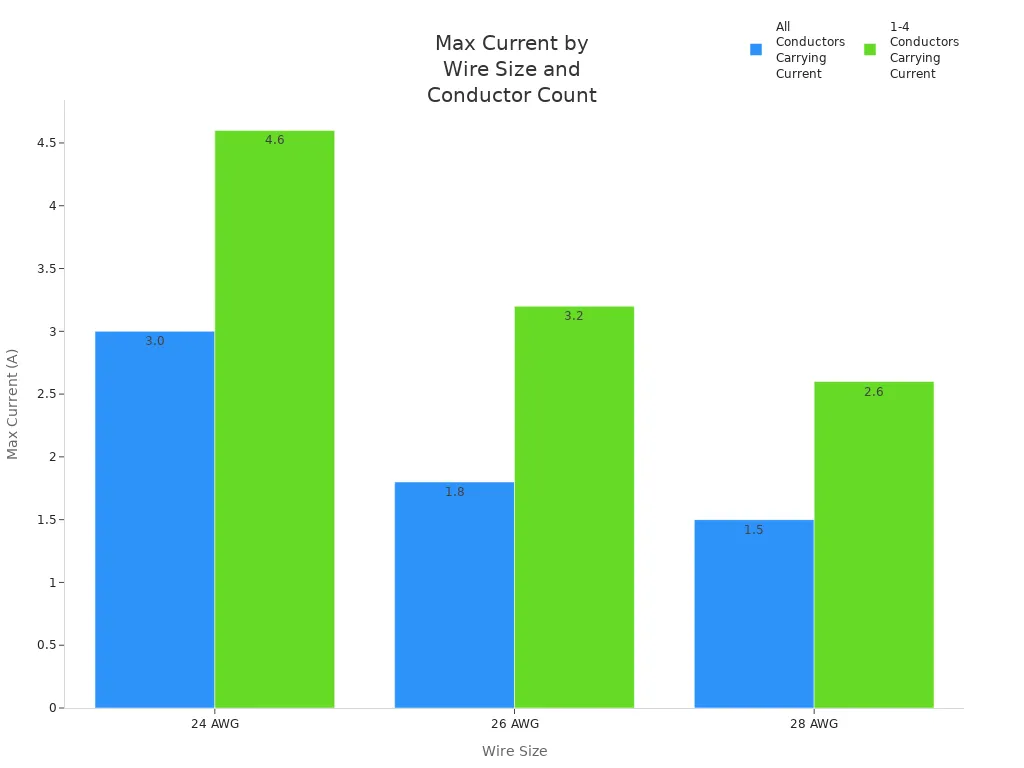

The current-carrying capacity tells you how much electric current the cable can hold safely. This depends on the wire size and how many wires carry current. Look at the tables below to compare current ratings for different wire sizes:

| Wire Size | Current Rating |

|---|---|

| AWG 26 | 1.5 A |

| AWG 28 | 1.0 A |

| Wire Size | All Conductors Carrying Current | 1-4 Conductors Carrying Current |

|---|---|---|

| 24 AWG | 3.0 A | 4.6 A |

| 26 AWG | 1.8 A | 3.2 A |

| 28 AWG | 1.5 A | 2.6 A |

Tip: Make sure your cable flat wire matches your device’s voltage and current needs. This stops overheating and keeps your system safe.

Temperature Range

You should also look at the temperature range for your flexible flat cable. Different wires work in different temperatures. Cars and factories often need cables that can handle hot and cold places. Here is a table with common temperature ranges:

| Wire Type | Temperature Range |

|---|---|

| GPT | -40°C to 85°C |

| TWP | -40°C to 105°C |

| HDT | -40°C to 85°C |

| TXL, GXL, SXL | -40°C to 125°C |

If your project will be in very hot or cold places, pick a cable that can handle it. This helps your cable last longer and work better.

Conductor Material

The material inside your cable affects how well it carries electricity and how long it lasts. Most flexible flat cables use copper wires because copper is a great conductor. Some cables use tinned copper or silver-plated copper for extra protection and flexibility. Aluminium wires are lighter but not used as much. The table below shows the main choices:

| Conductor Material | Description |

|---|---|

| Copper | Most common conductor material due to excellent conductivity. |

| Tinned Copper | Offers improved resistance to corrosion and is suitable for high-flex applications. |

| Silver-Plated Copper | Provides enhanced flexibility and resistance to fatigue under repeated bending. |

Note: Pick the right conductor material for your job. Copper works best for most uses, but tinned or silver-plated copper is good for tough or flexible jobs.

Number of Conductors and Pitch

The number of conductors and the pitch (the space between each wire) affect how well your cable works, especially for data. More conductors let you send more signals at once. A smaller pitch means you can fit more wires in a small space. The tables below show how these features help:

| Feature | Description |

|---|---|

| Conductor Type | 28 AWG stranded wire for optimal flexibility |

| Pitch | .050 in. pitch for efficient mass termination |

| Number of Strands | Total of seven strands |

| Compliance | Nonflammable, RoHS compliant, UL recognized to 200 °C |

| Feature | Description |

|---|---|

| Signal Density | High signal density due to close spacing |

| Insulation Material | TPE insulation for excellent transmission properties |

| Design Flexibility | Exceptional performance and design flexibility |

High signal density and close pitch help your flexible flat cable carry more data in less space. This is important for modern electronics that need fast, reliable connections.

EMI Shielding

Electromagnetic interference (EMI) can cause problems in sensitive devices. Good EMI shielding keeps your signals safe from outside noise. You can pick from several shielding materials:

- Copper: High conductivity and corrosion resistance, good for medical devices.

- Gold: Great conductivity and corrosion resistance, used in sensitive equipment.

- Nickel: Good conductivity and can be mixed for better performance.

- Platinum: Strong and corrosion-resistant, used in important jobs.

- Silver: Best conductor, but not as resistant to corrosion.

To pick the best EMI shielding, follow these steps:

- Decide how much EMI protection you need.

- Check your cable’s size and shape for the right fit.

- Choose a material that matches your needs for conductivity and strength.

EMI shielding is very important for medical, military, and data systems. It keeps your signals clear and your devices safe.

Mechanical and Environmental Factors

Flexibility and Bending

Think about how your cable will bend and move. Flexible flat cable bends easily and fits in small spaces. You can put it around corners without much trouble. This is good for devices where space is tight. Flat cable can run next to other wires and keep things tidy. Its thin shape saves space where round cables cannot fit. But be careful at the connectors. Flat cables can break if you twist or bend them too much.

Tip: Always check how much you can bend your flexible flat cable. If you bend it too much, the wires inside might get damaged.

Durability

You want your cable to last a long time. Round cables have thicker insulation, so they are tougher. Flexible flat cable works well but can be more delicate. Look for cables with strong jackets and good materials. Some jobs, like in cars or planes, need cables that handle heat and shaking. Medical devices need cables that are safe for people. Make sure your cable meets the rules for your job. Rules like FDA and RoHS help you pick safe and strong cables.

| Industry | Durability Needs | Regulation |

|---|---|---|

| Automotive | High temp, vibration resistance | RoHS |

| Medical | Biocompatible, non-toxic | FDA |

| Aerospace | Extreme condition resistance | RoHS, FAA |

Environmental Resistance

You need to protect your cable from tough places. Cables outside need to resist chemicals, oil, and hydrocarbons. Water and moisture can ruin the insulation and cause rust. Pick cables with waterproofing if you expect rain or wet air. Sunlight can hurt cables, so UV resistance is important. Some cables have special stuff to block UV rays. You also need thermal resistance for hot places.

- Chemical, oil, and hydrocarbon resistance keeps the outside safe.

- Water and moisture resistance stops rust and insulation damage.

- UV protection keeps your cable safe from sunlight.

- Thermal resistance helps your cable last in heat or heavy use.

Note: Always match your cable’s environmental resistance to where you use it. This helps your flexible flat cable work well and last longer.

Quality and Reliability in Cable Flat Wire

Certifications

When you pick a cable, look for certifications. These marks show the cable is safe and high quality. Certified cables help stop fires and shocks. They also make your system work better and last longer. Here is a table with important certifications and what they mean:

| Certification | Description |

|---|---|

| UL | Makes sure cables are safe and work well in the U.S. |

| CPR | Focuses on fire safety for buildings in Europe. |

| REACH/RoHS | Limits bad chemicals, so cables are safer. |

| ISO | Follows world rules for safety and quality. |

| IATF 16949 | Sets rules for car parts and systems. |

| ABS/DNV | Checks safety for cables used on ships. |

Certified cables can help you spend less on repairs. They use tested materials and help stop fires from spreading.

International rules also make cables more reliable. They help cables work in tough weather and temperature changes. You get safer cables that last longer and work well.

Manufacturer Selection

Choosing the right company is just as important as choosing the cable. Good companies make cables carefully. They use exact cutting and assembly. Every cable should be tested before leaving the factory. The company should check their suppliers and use good materials.

Look for these signs of a good company:

- They have programs to catch problems early.

- They follow rules like UL, CSA, REACH, and RoHS.

- They keep good records and control their work.

- They check suppliers often and look at their quality.

Buying good cables from trusted companies may cost more at first. But you save money later because you avoid repairs and get better results. For big projects, using better cables like Cat6a or fiber optic is smart.

When you buy flexible flat cable from a trusted company, your system stays safe, works well, and lasts longer.

How to Choose a Flat Cable

Decision Steps

You can find the best flat cable for your project by following a clear process. Start by writing down what you need. Think about your devices, how fast they must send data, and how far the cable must reach. Check the space where you will install the cable flat wire. Make sure it fits and bends the way you want.

Here are the main steps to help you choose a flat cable:

- List Your Needs

Write down what your devices need. Check if you need high-speed data, power, or both. - Check Compatibility

Make sure the cable flat wire matches your devices and connectors. - Review Technical Specs

Look at voltage, current, and temperature ratings. Pick the right flexible flat cable that meets these numbers. - Think About the Environment

Ask yourself if the cable will face heat, cold, moisture, or chemicals. Choose a cable with the right protection. - Compare Quality and Certifications

Pick cables with trusted certifications like UL or RoHS. Read reviews and check if the manufacturer tests their products. - Plan for the Future

Choose cables that support new technology. For example, if you need fast data, look for cables that work with USB4 or Cat6a. - Inspect and Maintain

After installing, check your flexible flat cable often. Store extra cables in a dry, safe place.

⚡ Tip: Avoid common mistakes like bending the cable too much, overstretching, or using the wrong connectors. Always keep the outer layer safe from cuts or damage.

Expert Advice

Experts suggest looking at every part of your setup before selecting a flat cable. You should match the cable’s features to your application. The table below shows what to check for complex systems:

| Factor | Description |

|---|---|

| Environmental Conditions | Check for temperature changes, moisture, and chemicals. Make sure the cable flat wire can handle these. |

| Electrical Specifications | Match voltage, current, and frequency to your system’s needs. |

| Structural Loads | Think about how much weight or movement the cable will face. |

| Insulation and Durability | Pick insulation that fits your job. Some need more heat or chemical resistance. |

You should also look at insulation options:

| Insulation Options | Considerations |

|---|---|

| Temperature Range | Make sure the insulation can handle the heat or cold in your area. |

| Chemical Exposure | Use insulation that resists any chemicals nearby. |

| Flexibility | Choose insulation that lets the cable bend as needed for your setup. |

🛠️ Note: If you pick the wrong cable, you might face overheating, broken wires, or even system failure. Always double-check your choices and ask for help if you are not sure.

When you choose the right flexible flat cable, you protect your devices and make your system last longer. Take your time, compare your options, and always match the cable’s features to your needs. If your project is complex, talk to an expert or the manufacturer. They can help you select the best flat cable for your job.

When picking cable flat wire, use these easy steps for good results:

- Think about how much voltage, current, and heat you need.

- Pick conductor materials that work well and fit your budget.

- Make sure the cable bends enough for your project.

- Check if the cable is strong and works well.

Technical, mechanical, and environmental things affect your choice. You can ask experts if your flat cable project is hard. The table below explains why getting help from experts is smart:

| Benefit | Description |

|---|---|

| Cost savings | Special tools and skills help save money. |

| Faster time to market | Good planning helps you finish faster. |

| Risk mitigation | Experts help avoid problems and make things safer. |

Take your time to look at cable types, how tough they are, and how fast they work. Choose carefully so your cable lasts a long time.

FAQ

What is the main advantage of using flat cable over round cable?

Flat cable helps save space and keeps wires neat. It fits in small places where round cables cannot go. Flat cable is also easier to put in and makes less mess.

Tip: Flat cable works best for tight spaces or tricky wiring.

How do you know which insulation material to choose?

Check where you will use the cable. PVC is good for most indoor uses. PTFE or PI can handle heat and chemicals. Always pick insulation that matches your project.

Can you cut or customize flat cable for special lengths?

You can cut flat cable to the size you need. Use sharp tools and be careful. Some companies make custom cables for special jobs.

- Measure before you cut.

- Get help if you need special features.

What certifications should you look for when buying cable flat wire?

Look for UL, RoHS, and ISO marks. These show the cable is safe and good quality. Certified cables last longer and protect your devices.

Certified cables help stop electrical trouble and keep things safe.