Choosing the right ffc flat flex cable is important. You need to match things like pitch, pin count, and connector type. The correct cable helps your device stay safe. It also makes sure your device works well. FFC cables link electronic parts with thin, bendable strips. You see them in smartphones and tablets a lot. They save space and make devices stronger.

| Aspect | Impact |

|---|---|

| Device Performance | It makes devices flexible and tough. It helps devices work in hard places. |

| Safety and Reliability | FFCs that resist heat are very important for safety. They help cars work in tough conditions. |

Key Takeaways

- Pick the right FFC cable by matching pitch, pin count, and connector type. This helps the cable fit well and work best in your device.

- FFC cables bend easily, so they work well in small spaces. You can use them in things like smartphones, laptops, and medical tools.

- Always look at the current rating and temperature limits for FFC cables. This stops the cable from getting too hot and keeps it safe to use.

- Measure FFC cables with a ruler or caliper to be sure. Good measurements help you avoid problems and keep your device working.

- Think about what you need when picking FFC or FPC cables. FFC cables cost less and are good for easy jobs. FPC cables work better for important or hard tasks.

FFC Flat Flex Cable Basics

What Is an FFC Cable?

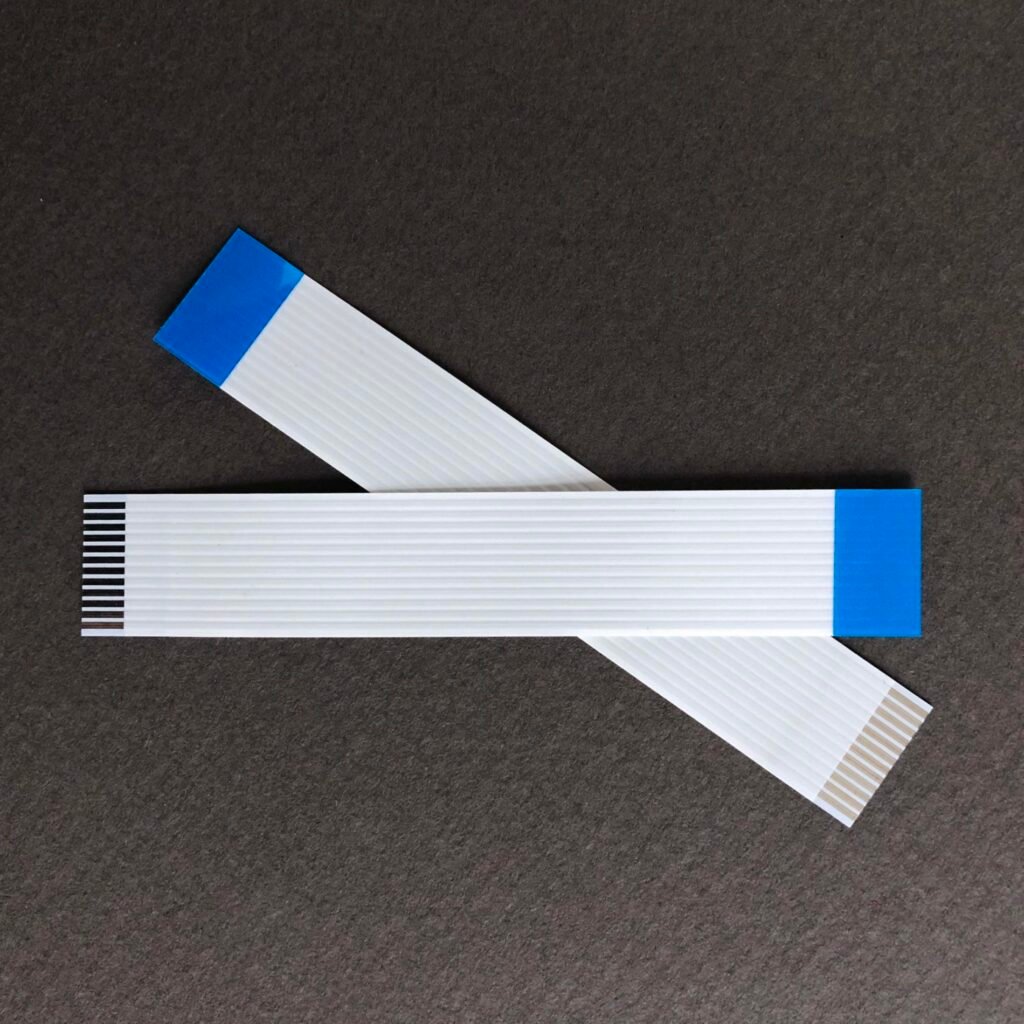

You see ffc cables in lots of electronics. These cables have thin, flat strips. They bend and fold without breaking. You use ffc cables to connect parts in small spaces. Their design saves space and keeps devices light. Ffc cables come in many shapes and sizes. They have different pin counts, usually from 20 to 100. You can pick from spacing standards like 0.3mm, 0.5mm, and 1.0mm. The table below lists important features of ffc cables:

| Characteristic/Standard | Details |

|---|---|

| Flexibility | Ffc cables bend and fold easily. |

| PIN Index Range | 20-100 |

| Spacing Standards | 0.3mm, 0.5mm, 0.8mm, 1.0mm, 1.25mm, 1.27mm, 2.54mm |

| Conductor Size Standards | 0.0350.3mm, 0.050.5mm, 0.1*1.6mm, and more |

| Length of Reinforcing Plate | 3.5mm to 20mm |

| User-Friendliness | Easy to wire and operate |

| Applications | Many uses in different devices |

You can look at the chart to see spacing standards:

Common Uses for FFC Cables

Ffc cables are found in many places. They work well in electronics like smartphones and laptops. You use them in industrial devices to connect data and power. Ffc cables also fit in cars, robots, and medical tools. Their small size and flexibility help in tight spaces. Here is a table showing where ffc cables are used:

| Application Area | Description |

|---|---|

| Consumer Electronics | Used in devices where compact and flexible cable design is essential. |

| Industrial Devices | Connects data and power points in a lightweight, flexible package. |

| Automotive | Suitable for various automotive applications due to their compact size. |

| Aerospace & Defense | Utilized in specialized equipment requiring flexible connections. |

| Robotics | Employed in robotic systems for efficient space management. |

| Medical Equipment | Ideal for medical devices needing compact wiring solutions. |

| Home Appliances | Commonly found in appliances that require flexible connections. |

Ffc cables have lots of uses. Their design helps solve wiring problems in many areas.

Flat Flexible Cables vs. Other Types

You may wonder how ffc cables are different from other cables. Flat flexible cables bend much more than ribbon or round cables. You can use them in small, moving devices. Ribbon cables are stiff and do not bend much. You use them in places that do not move. Round cables take up more space and do not fit well in tight spots. The table below shows the differences:

| Cable Type | Flexibility | Space-saving |

|---|---|---|

| Flat Flexible Cable | High flexibility, bends easily | Ideal for small, moving devices |

| Ribbon Cable | Stiff, does not bend easily | Good for static applications |

| Round Cable | Less space-efficient | Not specified in detail |

Tip: If your device moves or has little space, ffc cables are usually the best pick.

Key Specifications for FFC Cables

Pitch and Pin Count

When picking an ffc flat flex cable, check pitch and pin count first. Pitch is the space from one conductor’s center to the next. Pin count means how many conductors are inside the cable. These features help you match the cable to your device and connectors.

You can measure pitch with a ruler or caliper. Put the tool over several pins. Count the gaps between pins. Divide the total length by the number of gaps. For example, if you measure 4.5mm over 10 pins, the pitch is 0.5mm. Make sure the pitch is the same everywhere on the cable. This helps your ffc cables work well in your device.

| Pitch (mm) | Pin Count | Connector Type |

|---|---|---|

| 0.50 | Customizable | Standard, ZIF |

| 1.00 | Customizable | Standard, ZIF |

| N/A | 40 | Standard |

- Common pitches are 0.50 mm and 1.00 mm.

- Pin counts and lengths can be changed.

- You can find standard pin counts in stores.

If pitch and pin count do not match, your ffc cables will not fit. This is a big problem with ffcs.

Connector Type

You also need to pick the right connector type for your ffc flat flex cable. The connector joins the cable to your device. There are different types of ffcs connectors. Each type has good and bad points.

| Connector Type | Activation Mechanism | Compatibility Considerations |

|---|---|---|

| ZIF | Sliding or flipping actuator | Good for frequent use or delicate cables |

| LIF | Small force, latch/friction | Easier to use, less secure than ZIF |

| Non-ZIF | Direct insertion with force | Cheaper, but can damage the cable during use |

ZIF connectors are great if you connect and disconnect a lot. LIF connectors are easy but may not hold tight. Non-ZIF connectors cost less, but they can hurt the ffc cables. Always check which connector your device needs before buying.

Current Rating and Voltage Drop

Current rating shows how much electricity each pin in your ffc flat flex cable can carry. Most ffc cables can handle up to 2A per pin. If you use more current, the cable can get too hot and break your device. This is a problem with ffcs.

Voltage drop means losing voltage as electricity moves through the cable. Longer cables lose more voltage. If you use a long ffc, you might lose signal quality. This can make your device work badly.

| Specification | Details |

|---|---|

| Pitch | 0.5mm – 2.54mm |

| Number of Conductors | 4 – 80PIN |

| Length | 50mm – 500mm |

| Current Rating | Max 2A/PIN |

| High-Current Design | Thickened conductor design |

Tip: Always check the current rating and cable length before you pick an ffc flat flex cable. This helps keep your signal strong and avoids problems with ffcs.

Temperature and Durability

FFC cables must work in many places. You need to check the temperature range for your ffc flat flex cable. Most ffcs work best between -20°C and 80°C. If you use them below -20°C, the insulation can crack. If you use them above 80°C, the cable can get too hot or break. Some special ffcs can take more heat, but they cost more.

| Temperature Range | Implications |

|---|---|

| Below -20°C | Less flexible, insulation may crack |

| -20°C to 80°C | Best range for most ffc cables |

| Above 80°C | Insulation breaks down, more resistance, needs special high-temp cables |

The material of your ffc flat flex cable also affects how long it lasts. Polyimide and copper are used a lot. Polyimide is strong and handles heat well. Copper carries electricity and lasts a long time.

| Material | Properties | Impact on Durability |

|---|---|---|

| Polyimide | Strong, insulates, handles high heat | Bends many times without breaking |

| Copper | Carries electricity, can be made very thin | Lasts longer if high purity is used |

- Flex cables work well in places that bend a lot, like hinges.

- The flexible base lets you bend the cable many times without breaking the copper inside.

If you use the wrong material, you might see problems with ffcs, like breaking early or losing signal.

Mounting Style and Cost

You can mount ffc cables in different ways. The most common styles are:

- Surface mount

- Through-hole

- Board-to-board

Each style fits different uses. Surface mount and board-to-board are good for small devices. Through-hole is strong for tough connections. Ffc cables usually cost less than other wire-to-board options. This is a big advantage of ffcs.

Note: Ffc flat flex cables help you save space and money in your device. They fit well in small designs and have many advantages over other cable types.

When you pick an ffc flat flex cable, always match all the key features. This helps you avoid problems with ffcs and keeps your device safe. You also get the good things about ffcs, like flexibility, low cost, and strong signals. Ffc cables work in many devices, but you must check every detail for the best results.

Measuring and Identifying FFC Flat Flex Cable

Tools Needed

You need some tools to measure flexible flat cables. First, get a ruler or caliper. These help you check the cable’s width and pitch. You also need a test fixture for electrical tests. A simple test jig with ZIF sockets and a microcontroller helps you check signals. You can use a multimeter to test if the cable works. These tools help you avoid mistakes and make sure your ffc cables fit.

| Tool | Purpose |

|---|---|

| Ruler/Caliper | Measures cable width and pitch |

| Multimeter | Checks if the cable works |

| Test Fixture | Runs electrical tests on ffc cables |

| Test Jig | Checks signal quality and compatibility |

Tip: Clean your tools before you measure. Dirt can change your results.

Measurement Steps

You need to follow steps to measure flexible flat cables. This helps you pick the right ffc for your devices.

- Prepare the Cable

Put the ffc cable flat on a clean table. Make sure it is not twisted or bent. - Measure the Width

Use a ruler or caliper to check the cable’s width. Write down the number. - Count the Conductors

Look at the end of the cable. Count each conductor or pin you see. This gives you the pin count. - Calculate the Pitch

Use this formula:Pitch = Cable Width / (Number of Conductors + 1)For example, if your cable is 5mm wide and has 9 conductors, the pitch is 5mm / (9 + 1) = 0.5mm. - Check Consistency

Measure the pitch at different spots on the cable. The pitch should be the same everywhere. - Electrical Testing

Connect the cable to your test fixture. Use a multimeter to check if every conductor works. Do high-pot tests to check insulation. Measure contact resistance to find weak spots. - Review Results

Look for pass or fail signals from your test equipment. If you see a fail, check the cable for damage or wrong measurements.

Note: Always double-check your measurements. Small mistakes can cause big problems.

Verifying Cable Compatibility

You need to make sure your flexible flat cables match your devices before you use them. Use a test jig with ZIF sockets and a microcontroller. Run test patterns to check every line in the cable. System tests help you see if all conductors work. Check the power draw and current rating to avoid overheating.

- Test signal quality with a test jig.

- Run system tests to check all lines.

- Make sure the current rating matches your device.

- Check that the cable fits the connector type.

The 1:1 connection principle is important. Each pin on one end of the ffc cable matches the same pin on the other end. This keeps signals strong and reliable. The flat, parallel design of flexible flat cables helps keep signals clear. The insulation lets the cable bend without breaking the connection.

| Compatibility Check | Why It Matters |

|---|---|

| 1:1 Pin Connection | Makes sure signals go to the right place |

| Signal Integrity | Stops data loss or errors |

| Current Verification | Prevents overheating and device failure |

| Connector Match | Makes sure the cable fits and works |

Alert: Always check for voltage drop in long flexible flat cables. Too much drop can weaken signals and hurt your devices.

Flexible flat cables work best when you measure and test them carefully. You keep your devices safe and working well when you follow these steps.

Common Mistakes with FFC Cables

Measurement Errors

Measuring ffc cables can be tricky. Small mistakes can cause big trouble. If you get the pitch or pin count wrong, the cable will not fit. Many people forget to check the width in more than one place. This can make the cable not match the connector. Some users think ffc cables are tough. Pulling or twisting the cable can hurt the thin wires inside. Too many cables in one spot can bend or twist them. This makes the cables break early. Always measure with care and handle ffc cables gently.

Tip: Use a caliper to get better results. Double-check your numbers before you buy or use ffc cables.

Overlooking Current or Temperature Limits

You must watch the current and temperature ratings for ffc cables. If you use too much current, the copper can get hot and break. High heat can make the insulation crack or fall apart. Bending the cable too much puts stress on the copper. This can make it fail after a while. This is very important for devices that move or get hot. If you ignore these limits, your device may stop working or become unsafe.

Note: Insulation problems start when you push ffc cables too far. This can make the cable work badly or stop working at all.

Ignoring Connector Orientation

Always check how the connector lines up before you install ffc cables. If you skip this step, you might put the cable in wrong. This can make your device not work or act weird. Follow the design rules for connector orientation to keep things working right.

- Bad connections happen if you do not check the orientation.

- Your device may stop working or act strange.

- Always match the cable to the connector as shown in the manual.

Alert: Never force an ffc cable into a connector. If it does not fit, check the orientation and try again.

Choosing Between an FFC and FPC

Differences in Structure

FFC cables and FPC cables are built in different ways. FFC cables have flat wires that run next to each other. These wires are covered with a protective tape. FFC cables are thicker than FPC cables. Their thickness is usually between 0.5mm and 2.54mm. Making FFC cables is easy for manufacturers. They stick PET and copper wires together. FFC cables are used for jobs that are not very critical. They are good when you want to save money and need flexibility.

FPC cables are made differently. They use copper paths that are etched onto a thin base. FPC cables are much thinner than FFC cables. Their thickness is often just 0.15mm to 0.2mm. Making FPC cables needs strict steps and careful checks. FPC cables go into devices that must work perfectly. You see FPC cables in military, medical, and aerospace equipment. FPC cables work well and can handle tricky wiring. But they cost more and are harder to make.

| Feature | FFC Cables | FPC Cables |

|---|---|---|

| Structure | Flat parallel wires wrapped in protective tape | Flexible circuits with etched copper paths |

| Thickness | Typically thicker (0.5mm to 2.54mm) | Much thinner (0.15mm to 0.2mm) |

| Manufacturing Process | Simple lamination of PET and copper wires | Strict manufacturing and quality control |

| Applications | Less critical applications | Mission-critical devices |

| Quality Control | More relaxed standards | Rigorous testing |

Tip: Pick FFC cables if you want simple and cheap cables. Choose FPC cables if you need strong and reliable cables.

Application Scenarios

You should know when to use FFC cables or FPC cables. Each type works best for certain jobs. FFC cables are great for tight spaces and simple connections. They are used in electronics, robots, and cars. FFC cables help devices that need to bend and connect easily. You find FFC cables in laptops, printers, and car dashboards.

FPC cables are better for tough jobs. They can handle hard wiring and lots of movement. FPC cables are found in smartphones, medical tools, and aerospace devices. FPC cables last long and work very well. But they cost more and need careful checks.

| Cable Type | Preferred Scenarios | Key Features |

|---|---|---|

| FFC | High-density connections, consumer electronics, robotics, automotive systems | Flexibility, cost-effectiveness, simple connections |

| FPC | Advanced applications like smartphones, medical devices | Complex routing, high performance, withstands movement |

- Consumer electronics

- Robotics

- Automotive systems

Note: Think about what your device needs before you choose. Use FFC cables for flexible and cheap wiring. Use FPC cables for hard jobs and strong connections.

Choosing the right FFC flat flex cable keeps your device safe and working well. You should always match pitch, pin count, and connector type. Before you buy, use a checklist:

- Leave slack for movement.

- Do not bend cables too sharply.

- Watch cable orientation and avoid twists.

- Reinforce cable ends and protect traces.

You also need to check for safety standards like UL 94 and IEC 60332. Flame-retardant insulation helps prevent fire hazards. Careful selection and good installation give your device long life and strong performance.

FAQ

What does “pitch” mean in FFC cables?

Pitch means the distance from the center of one conductor to the center of the next. You measure it in millimeters. You need to match the pitch to your device’s connector for a proper fit.

How do you know if an FFC cable is compatible with your device?

Check the pitch, pin count, and connector type. Make sure the cable matches your device’s connector. You can use a caliper or ruler to measure. Always test the cable before final installation.

Can you bend FFC cables in any direction?

You can bend FFC cables, but only along the flat direction. Do not twist or fold them sharply. Sharp bends or twists can damage the internal wires and cause the cable to fail.

What happens if you use the wrong current rating?

If you use a cable with a low current rating, it can overheat. Overheating may damage your device or cause the cable to break. Always check the current rating before use.

Are FFC and FPC cables interchangeable?

FFC and FPC cables look similar, but they have different structures. You should not swap them unless your device supports both. Always check your device’s manual for the correct cable type.