Reliable FFC Cable Solutions for Medical Devices

Customized flat flexible cables engineered for medical devices — ensuring biocompatibility, ultra-flexibility, and signal integrity under critical conditions.

What is Medical FFC Cable?

YLS medical FFCs are ultra-thin, biocompatible cables for diagnostic, wearable and surgical devices. They survive sterilization, repeated flex, EMI-shielded for real-time data, and integrate IPX-sealed connectors, meeting ISO 10993 to guarantee safety in life-critical applications.

Where Are Medical FFC Cables Used?

Explore our specialized Medical FFC Cable solutions designed for diagnostic imaging, patient monitoring, endoscopy, infusion systems, lab analyzers, and wearable devices. Built for reliability, compactness, and high signal integrity across critical healthcare applications.

Diagnostic Imaging Device FFC Cable

For ultrasound, CT, X-ray, and MRI—delivers low-noise, high-speed signals between sensors, displays, and control boards.

Patient Monitoring FFC Cable

Used in ECG, SPO2, and vital sign monitors. Compact, flexible, and built for continuous, reliable signal transmission.

Endoscope & Surgical Tool FFC Cable

Ultra-slim, bendable FFCs for endoscopes and surgical cameras—supporting video signals and sterilization requirements.

Infusion & Drug Delivery FFC Cable

Ideal for insulin pumps and infusion devices. Ensures precise control of motors, sensors, and UI in small spaces.

Lab Analyzer & PCR Equipment FFC Cable

Supports sample analyzers and PCR machines with durable, high-cycle FFCs for stable connection in moving parts.

Wearable & Portable Medical FFC Cable

Lightweight, skin-safe FFCs for ECG patches, health monitors, and portable diagnostics—built for mobility and flexibility.

Common Wiring Challenges in Medical —Solved with FFC

At YLS, we not only supply high-reliability FFCs but also collaborate with your design team to optimize cable routing, folding patterns, and connector mating for your specific Medical architecture.

Struggling to fit wiring in a sleek product enclosure?

Our ultra-thin, pre-folded FFCs route cleanly around tight corners and compact housings where round wires can't.

Getting signal noise in a dense Wi-Fi/Bluetooth environment?

We offer shielded, impedance-controlled FFCs to protect sensitive data lines—ideal for monitors, cameras, and diagnostics.

Concerned about FFC reliability after repeated sterilization?

Our medical-grade materials withstand ETO, autoclave, and gamma sterilization without delamination or cracking.

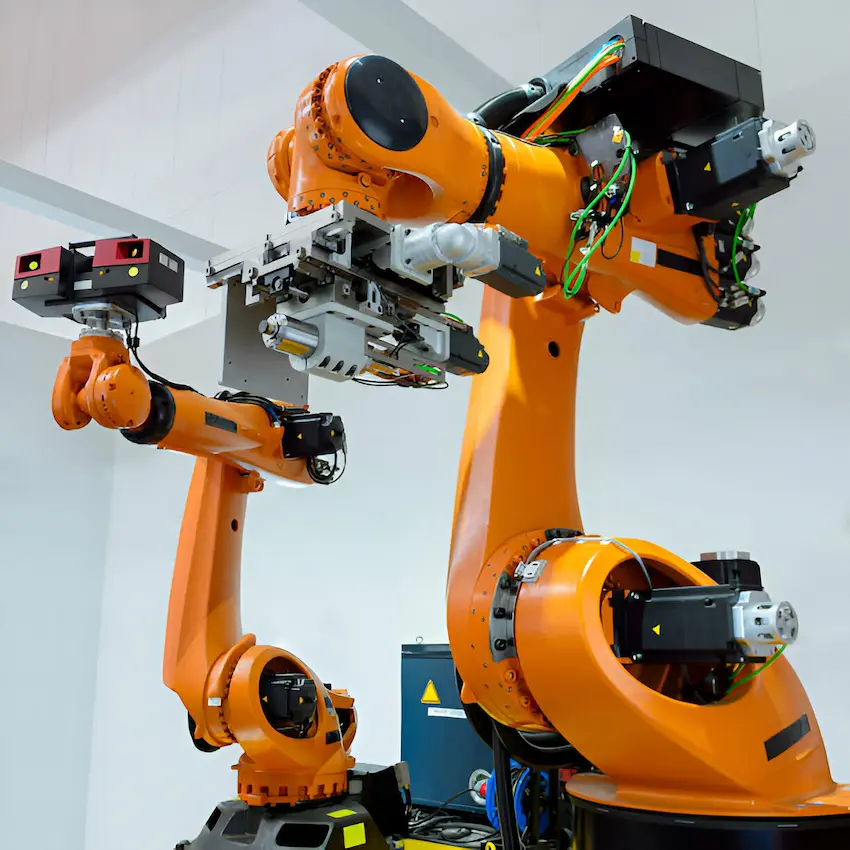

Flex cables failing in high-movement applications like robotic arms or wearables?

YLS FFCs are tested to endure 100,000+ bend cycles, ensuring reliable performance in dynamic medical equipment.

Let’s solve your cable bottlenecks → Contact our engineering team

Technical Capabilities

FFC Cable Specs for Medical

- Our FFC cables support ultra-low bending radii and tight U-turns, ideal for compact surgical and diagnostic equipment.

- All cable materials can be sourced with ISO 10993 or USP Class VI certification for biocompatibility and patient safety.

- Proven flex endurance over 10 million cycles in robotic arms, imaging gantries, and infusion systems.

- Fully tailored to your device layout with variable pitch sizes and conductor counts.

- Foil and mesh shielding options reduce EMI interference in sensitive medical signals.

- Manufactured in clean environments, sealed edges reduce fiber fraying and particulate generation.

Quick Spec Summary:

| Specification | Value / Range |

|---|---|

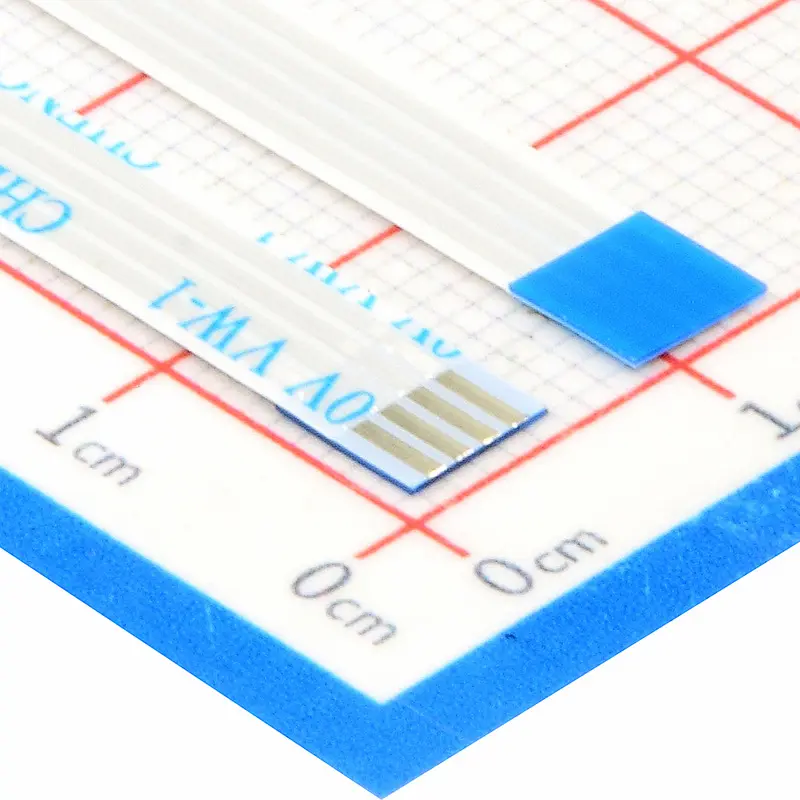

| Pitch Size | 0.3mm / 0.5mm / 0.8mm / 1.0mm / Custom |

| Conductor Material | Tin-plated Copper / Bare Copper / Custom |

| Cable Thickness | 0.08mm – 0.18mm |

| Cable Width | 3mm – 50mm (customizable to device size) |

| Number of Conductors | 2–80+ (configurable based on channel needs) |

| Insulation Material | PET / PI / TPE / Medical-grade materials |

| Operating Temperature | -20°C to +105°C (up to 125°C for surgical tools) |

| Voltage Rating | Up to 60V (Higher on request) |

| Bending Radius | ≥ 0.5mm (ideal for tight routing paths) |

| Life Cycle (Flex Durability) | 3–10 million+ cycles (based on test profile) |

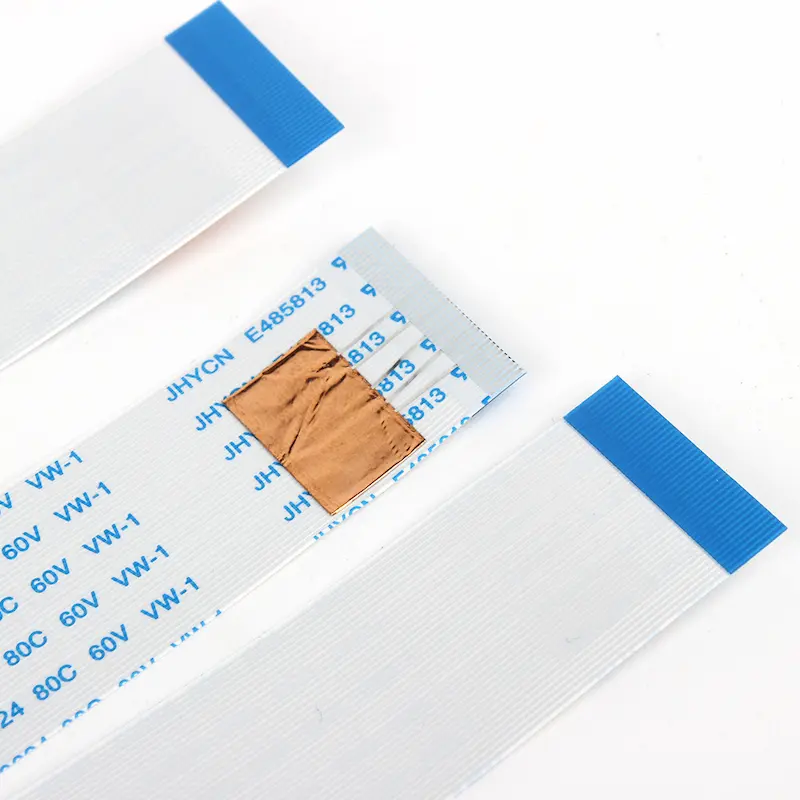

| EMI Shielding | Optional Aluminum Foil / Copper Mesh |

| Biocompatibility | USP Class VI / ISO 10993 certifiable |

| Surface Treatment | Heat-sealed edges / Anti-bacterial coating |

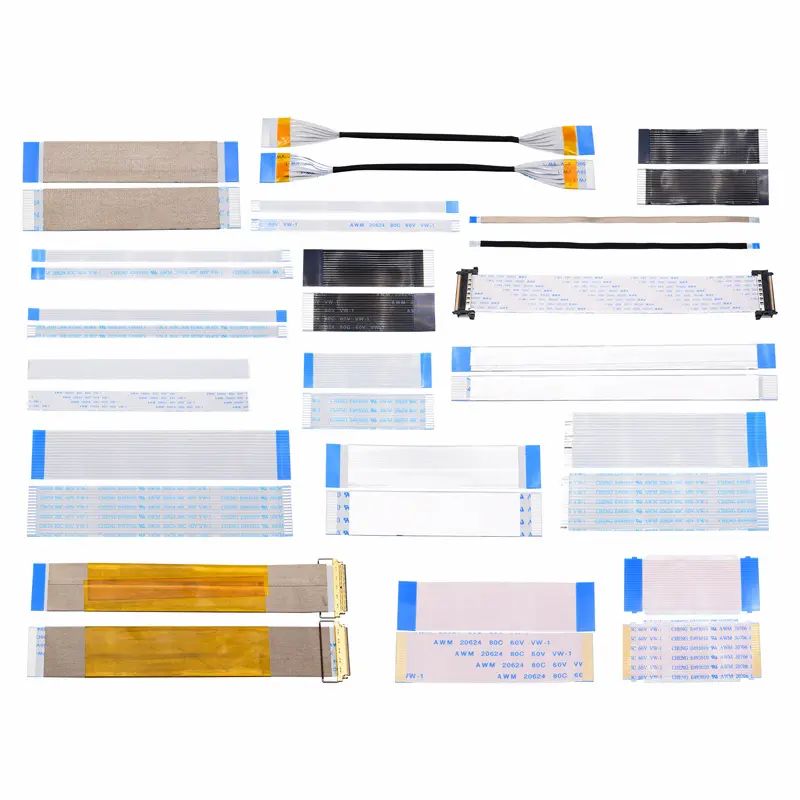

Custom Ribbon Cable Capabilities — Built to Your Specs

Your application may require more than just a standard pitch or length. That’s why we offer complete customization on all critical parameters — so your ribbon cable fits perfectly, functions reliably, and installs easily.

Whether you need just 50 pieces for a prototype or 50,000 for production, we can deliver with speed and precision.

1. Pitch & Conductor Configuration

Design the spacing and layout that fit your device’s constraints.

- Available pitches: 0.4mm / 0.5mm / 0.8mm / 1.0mm / 1.25mm

- 4 to 96 conductors

- Symmetrical or custom pin-out

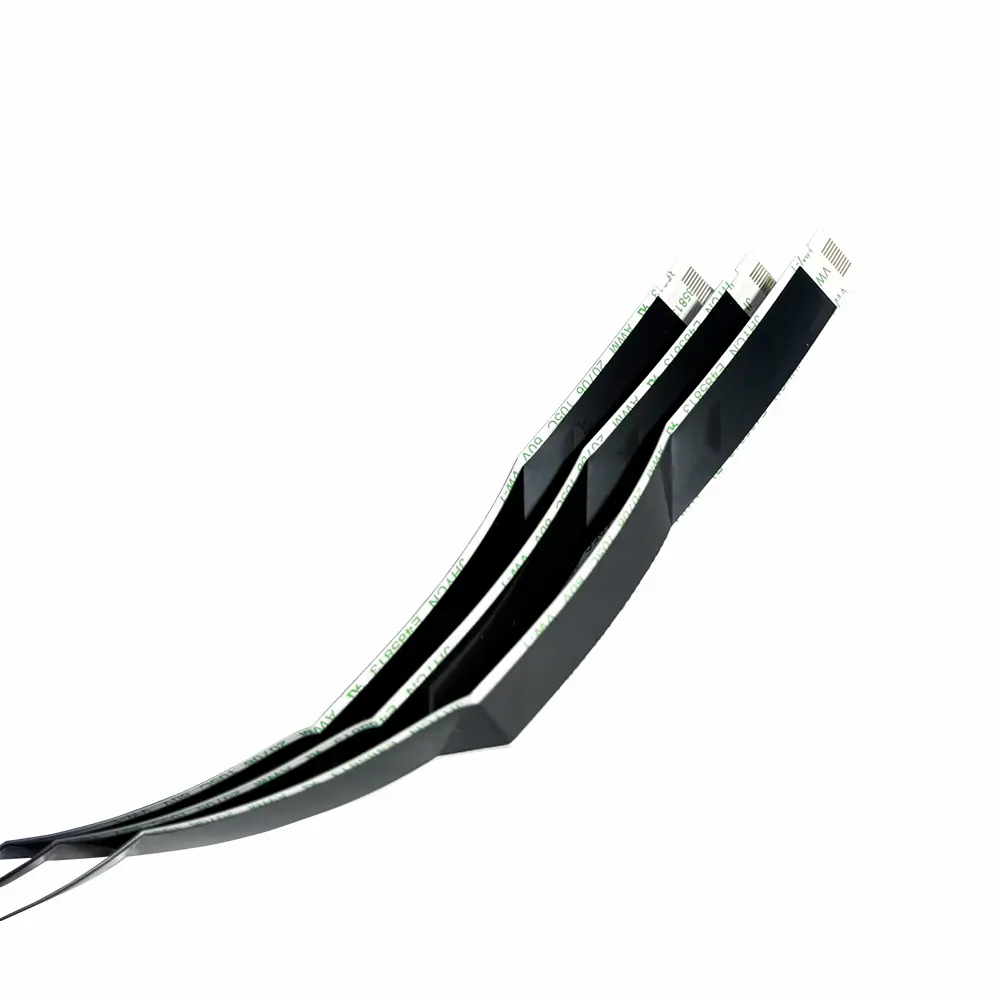

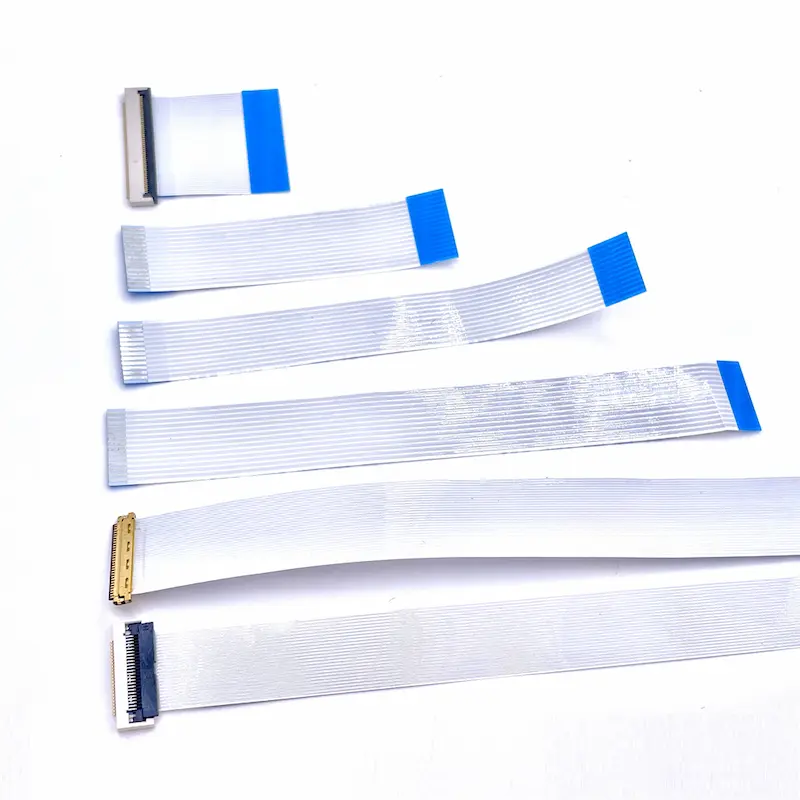

2. Cable Length & Shape

Adapt the cable to your layout without compromising space.

- Lengths from 30mm to 1000mm+

- Straight, L-shape, Z-fold, or multi-branch

- Fold lines pre-creased for easy routing

3. End Termination Options

Seamless integration with your connectors or boards.

- Tinned or gold-flashed bare ends

- PET/PI stiffeners for ZIF sockets

- Solder tail, FPC-style, or custom header connector

4. Shielding & EMI Control

Protect signal integrity in sensitive environments.

- Aluminum foil or mesh shielding

- Ground tail or drain wire

- Optional double-shielded design

5. Surface & Insulation Customization

Improve durability, appearance, and signal performance.

- PET or PI insulation

- Conductor surface: tin-plated, bare copper, or gold

- Optional heat-resistant or flame-retardant materials

6. Punching & Mechanical Modifications

Built to fit into housings and tight enclosures.

- Punch holes, slots, notches for mounting

- Fold lines for compact 3D routing

- Peel tabs or extended tails

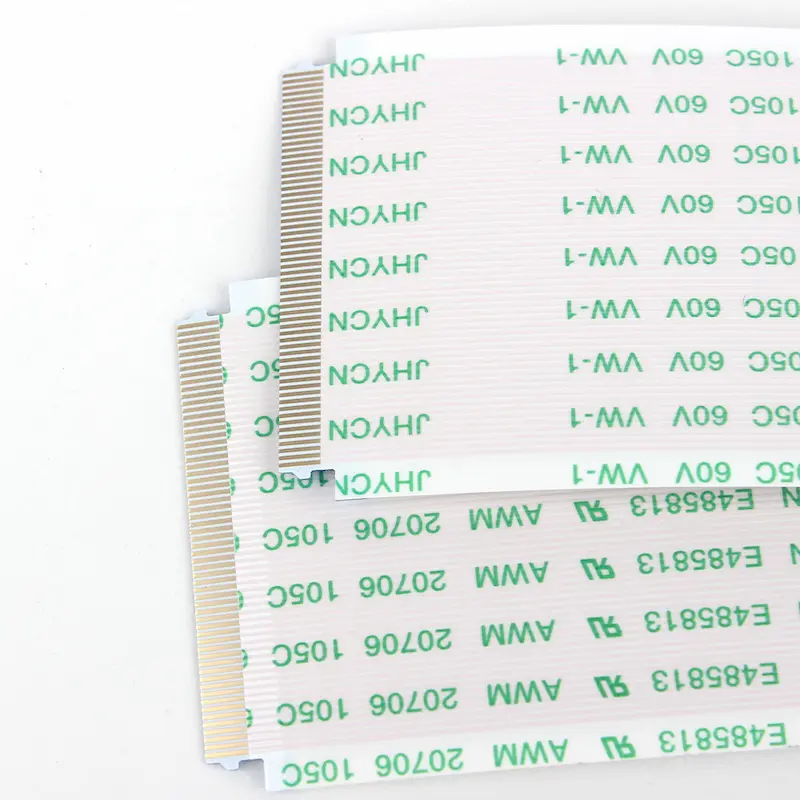

7. Labeling & Traceability

Simplify installation, QC, and inventory tracking.

- QR code / barcode / serial ID

- Printed position marks, logos, or terminal IDs

- Laser or ink marking options

8. Packaging Options

Fit your assembly line or ESD protocol.

- Bulk bag, tray, coil, or tape & reel

- Anti-static or moisture-proof packaging

- Custom labels or part numbers

Not sure which specs to choose? Our engineering team is ready to help. Ask an Engineer

Custom FFC Cable Workflow

At YLS, we simplify the path from idea to production. Whether you’re upgrading a product or building something new, our six-step process ensures speed, accuracy, and full customization for your flat flexible cable solution.

🧩 Step 1: Project Kick-off

Tell us about your needs: cable pitch, pin count, length, connectors, UL specs, shielding, fold lines—our team starts with the details that matter.

📐 Step 2: Engineering Proposal

We translate your specs into manufacturable designs. Expect drawing files and connector matching within 24–48 hours.

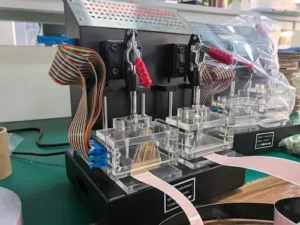

🧪 Step 3: Sample Fabrication

Once drawings are approved, we build samples in 3–5 working days, including precision cutting, labeling, and insulation options.

🧷 Step 4: Testing & Validation

You verify the sample in your device. We assist with adjustments, feedback loops, or connector matching as needed.

🔁 Step 5: Final Sign-off

Once the prototype is approved, we lock the design, confirm packaging and delivery terms, and prepare for production.

🚛 Step 6: Mass Production & Global Delivery

We initiate volume production and ship on time via express, air, or sea—wherever your facility is.

✨ Optional Add-ons:

Fold lines or pre-bent shaping

Custom labels or barcodes

Hole punching, notching, peel-tab finishing

Shielding and grounding features

Special packing and reel packaging options

Technical support for connector sourcing

ABOUT YLS

Reliable FFC cables factory integrated services

Yulian is a direct manufacturer of flat flexible cables (FFC), delivering precision wiring solutions trusted by global OEMs. With in-house tooling, rapid prototyping, and full customization capabilities, we help you go from concept to cable—fast, reliable, and to your spec.

We offer pitch options from 0.4mm to 1.25mm and core counts up to 96, with full support for folding, shielding, notching, punching, labeling, and custom assembly.

- Ultra-Fine Pitch, High Pin Count

- 48-Hour Custom Sample Delivery

- Foldable & Shielded Cable Options

- Expert Support for Complex Wiring

- ISO/IATF Certified Manufacturing

- 100% Electrical QC Before Shipment

- Low MOQ, Fast Turnaround

- 10+ Years Across Key Industries

Frequently Asked Questions

What sterilization methods can your FFC cables withstand?

Our medical-grade FFCs are compatible with ETO, gamma, and autoclave sterilization, with no degradation in insulation or adhesion.

Do you offer biocompatible or ISO 10993-compliant materials?

Yes, we can manufacture FFCs using ISO 10993-tested materials upon request, suitable for contact or near-contact medical devices.

What is your typical lead time for custom medical FFCs?

For standard configurations, lead time is 7–10 days. Custom solutions with tooling or special materials take 2–4 weeks depending on complexity.

Can you provide traceability and compliance documentation?

Absolutely. We provide full material traceability, RoHS/REACH compliance, and optional batch-level reports for regulated markets.

Are your FFCs suitable for wearable or mobile medical devices?

Yes. We offer ultra-flexible, lightweight FFCs ideal for compact devices like portable monitors, glucose meters, and health wearables.

Do you support rapid prototyping for new medical designs?

Yes, we offer low-MOQ prototyping services with flexible tooling options to accelerate development cycles for startups and OEMs.

Chat with us now for your Custom needs. Chat on WhatsApp Now

More Solutions

Let’s Build Your Ideal FFC Cable — Fast Response Guaranteed

Whether it’s for foldable drones, camera gimbals, or onboard computing—our FFC solutions are designed to fly. Tell us what you need—we’ll build it.