The pitch of a connector tells you the distance from the center of one pin to the center of the next. This measurement shapes your design choices because it determines how many connections you can fit in a small space. You see smaller pitch sizes in compact devices like smartphones, while larger pitches work well in industrial equipment.

Pitch Size | Applications | Market Trends |

|---|---|---|

0.3mm | High-end smartphones, wearables | Increased demand due to miniaturization |

0.5mm | Consumer electronics, automotive | Balanced solution for various applications |

1.0mm | Automotive, industrial, medical | Preferred for durability and current ratings |

When you select a pitch, you affect compatibility, PCB layout, and how easy it is to manufacture your product. YLS Flexible flat cables offer a range of pitch options to fit your specific needs.

Key Takeaways

Connector pitch is the distance between pin centers. It affects how many connections fit in a device.

Smaller pitch sizes allow for more connections in compact designs, ideal for smartphones and wearables.

Choosing the right pitch ensures compatibility with your PCB layout, reducing the risk of costly redesigns.

Signal integrity can be compromised with tighter pitches due to crosstalk. Select pitch carefully to maintain performance.

Always consider space, electrical needs, and manufacturing costs when selecting connector pitch for your project.

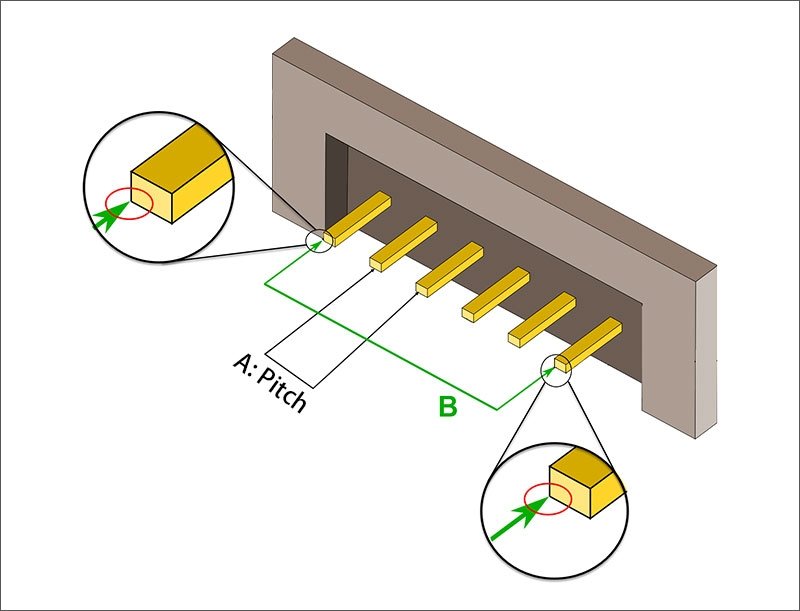

Pitch of a connector explained

Definition and measurement

You need to understand what the pitch of a connector means before you can make smart design choices. The pitch of a connector is the distance from the center of one pin to the center of the next pin. This measurement tells you how close the pins sit next to each other. You measure pitch using precise tools. Calipers help you check the distance between pin centers. A pitch gauge also works well, especially if you want to compare several connectors quickly.

Tool | Description |

|---|---|

Calipers | Used to measure the major diameter and pitch of threads accurately. |

Pitch Gauge | A tool with several leaves that indicates the pitch of a thread, available in metric and imperial. |

When you look at YLS Flexible flat cables, you see pitch options like 0.4mm, 0.5mm, 1.0mm, and 1.25mm. These sizes let you match the cable to your device’s connector and space needs.

Common standards and units

You will find that the electronics industry uses both metric and imperial units for pitch. Some of the most common pitch sizes include 1.27 mm (0.050 in), 2.00 mm, and 2.54 mm (0.1 in). These sizes appear in many devices around the world.

Pitch Size | Measurement |

|---|---|

1.27 mm | 0.050 in |

2.00 mm | N/A |

2.54 mm | 0.1 in |

Many standards guide the use of pitch in connectors:

The DIN standard 2.54 mm pitch was developed in the 1980s for industrial equipment.

IEEE P1386 standard includes 1.0 mm pitch products for consumer electronics.

0.635 mm pitch products are designed for automotive applications.

YLS Flexible flat cables fit well within these standards. You can choose from pitch sizes like 0.4mm, 0.5mm, 1.0mm, and 1.25mm, which cover most modern design needs.

Visualizing connector pitch

You can picture connector pitch by looking at a row of pins or contacts. Imagine measuring from the center of one pin to the center of the next. Smaller pitch sizes mean the pins sit closer together, which lets you fit more connections in a tight space. Larger pitch sizes give you more room between pins, which can help with durability and easier assembly.

Here is a quick look at how YLS Flexible flat cable options compare to industry norms:

Specification | Details |

|---|---|

Pitch Sizes | 0.4mm, 0.5mm, 1.0mm, 1.25mm |

Number of Conductors | Up to 96 conductors for high-density wiring |

Cable Length | Customizable from 30 mm to 1000 mm or longer |

Cable Thickness | Ranges from 0.1 mm to 0.5 mm |

Insulation Material | PET or PI (polyimide) |

Conductor Material | Tin-plated copper |

End Termination | Tinned ends, gold fingers, crimped ends |

Additional Features | Shielding, punching, notching, labeling |

Tip: When you select a pitch, always check the connector type and the space available in your device. This step helps you avoid costly redesigns later.

You now know what the pitch of a connector is, how to measure it, and how to compare different standards. This knowledge will help you make better choices for your next project.

Why connector pitch matters in design

Compatibility and layout

You need to match the pitch of a connector with your device’s requirements. The pitch determines how close each contact sits next to the others. This measurement shapes the density of connections on your printed circuit board. When you select the right pitch, you ensure that your connector fits perfectly with your PCB layout. You avoid mismatches that can lead to costly redesigns or assembly errors.

Connector pitch affects the arrangement of components. Smaller pitch sizes allow you to place more pins in a limited area. This increases connection density and supports compact designs. You see this benefit in devices like smartphones, drones, and medical equipment. YLS Flexible flat cables offer high-density wiring options, which help you maximize space efficiency without sacrificing reliability.

Connector pitch determines the distance between adjacent pins, affecting component placement density.

Smaller pitch increases the number of pins in a limited area, enhancing connection density.

Correct pitch is crucial for compatibility with connectors and maintaining signal integrity.

You must consider the mating process as well. When the pitch matches between cable and connector, you achieve a secure and reliable connection. This step is essential for smooth assembly and long-term performance.

Signal integrity and performance

You want your signals to travel cleanly from one point to another. The pitch of a connector plays a key role in signal quality. When pins sit close together, you risk unwanted interference between signals. This interference, called crosstalk, can degrade performance in high-speed circuits. You must pay attention to pitch selection to protect your data and maintain system reliability.

Aspect | Description |

|---|---|

Crosstalk | Unwanted influence of one signal on another, primarily through capacitive and inductive coupling. |

Near-end Crosstalk (NEXT) | Interference occurring when signals from one pair affect another pair, mainly through induction. |

Far-end Crosstalk (FEXT) | Interference measured at the end of a transmission link, usually lower due to signal attenuation. |

Connector Design | Layouts that separate influencing contact pairs and use ground contacts can reduce crosstalk. |

Coupling Inductance | Affects both interference immunity and emission; varies with signal assignment and connector geometry. |

Shielded Connectors | Reduce interference and act as a barrier against external electromagnetic effects. |

High-speed Signal Integrity | Protection from electromagnetic interference is crucial for maintaining signal integrity in high-speed systems. |

YLS Flexible flat cables support shielded designs and differential pairs. These features help you reduce electromagnetic interference and maintain signal integrity. You can select the pitch that best fits your speed and noise requirements. When you choose the right pitch, you protect your signals and ensure reliable communication between components.

Mechanical and assembly factors

You face mechanical and assembly challenges when working with different connector pitches. Smaller pitches require higher precision during manufacturing and assembly. You must align each contact carefully to avoid misalignment or poor soldering. This step is critical for mechanical stability and long-term reliability.

Challenge Type | Description |

|---|---|

Mechanical Stability | Smaller pitches require higher precision in manufacturing and assembly to ensure reliable connections. |

Manufacturing Precision | Smaller pitches pose challenges in achieving the necessary precision during the manufacturing process. |

Assembly Reliability | Careful management of the assembly process is essential to avoid misalignment or insufficient soldering. |

Manufacturers use advanced assembly techniques to address these challenges. You benefit from careful design practices and component selection. YLS Flexible flat cables offer customizable pitch options, which help you meet your functional and size requirements. You can rely on these cables for easy integration and consistent performance, even in demanding environments.

Tip: Always check the pitch and connector compatibility before starting your design. This step helps you avoid assembly issues and ensures a smooth production process.

Choosing the right pitch for YLS Flexible flat cable

Space and electrical needs

When you select the pitch of a connector, you must look at both space and electrical requirements. The pitch affects how many signals you can fit in a small area. If you design for compact devices, a smaller pitch lets you add more connections without using extra space. You also need to think about electrical needs. The current capacity and signal quality depend on the spacing between each contact. If you use a tighter pitch, you may see more crosstalk, which can affect data quality. You should also check if the cable supports shielding or special dielectric materials for your environment.

Consider conductor pitch and spacing to match device requirements.

Watch for crosstalk risks with tighter pitches.

Choose shielding and dielectric materials based on your application.

Make sure the cable fits your space and electrical needs.

Manufacturing and cost factors

The pitch you choose will influence manufacturing and cost. Smaller pitches allow higher connection density but may increase assembly complexity and cost. Coarser pitches are easier to assemble and often cost less. The table below shows how different pitches affect key factors:

Aspect | Smaller Pitch | Coarser Pitch |

|---|---|---|

Connection Density | Higher, more connections | Lower, fewer connections |

Signal Quality | More interference risk | Better integrity |

Mechanical Strength | Needs precise control | Handles higher loads |

Production Efficiency | More complex assembly | Simpler process |

Cost Implications | May cost more | Usually lower cost |

YLS supports customization for pitch size, conductor count, and features like fold lines or labeling. This flexibility helps you balance performance and cost for your project.

Practical selection tips

You can follow these steps to choose the right pitch for your application:

Identify the devices you want to connect and their spacing needs.

Assess the speed and stability required for data transmission.

Check the cable’s flexibility and how it handles bending or stress.

Match the cable spacing to the connector type for proper mating.

Weigh the cost of smaller pitch cables against their benefits.

Follow industry standards to ensure compatibility and reduce costs.

YLS offers tailored solutions for many industries, from automotive to medical devices. You can select pitch sizes from 0.5mm to 1.25mm and conductor counts from 4 to 96 pins. YLS also recommends checking technical specifications like voltage rating and insulation resistance to meet your industry’s needs.

Tip: Always review your design’s space, electrical, and mechanical requirements before finalizing your pitch choice. This step helps you avoid costly changes later.

Pitfalls and real-world examples

Common mistakes in pitch selection

You may face several challenges when choosing the pitch for a connector. Many engineers overlook real-world factors like electromagnetic interference, vibration, and temperature changes. These issues can affect signal quality and lead to data loss. Testing the connector in the actual device helps you avoid failures. Some designers forget to plan for future upgrades, which can cause compatibility problems later. You should also analyze the materials and installation techniques. Ignoring these details may result in connector failures. Failing to assess load and pressure ratings can lead to mechanical breakdowns.

Overlooking EMI, vibration, and temperature effects

Not planning for future upgrades or changes

Ignoring material compatibility and installation methods

Failing to check load and pressure ratings

Mistakes like these can cause signal interference, mechanical failures, and even short circuits. You risk losing data or damaging your product if you do not address these issues early.

Solutions and best practices

You can avoid most pitfalls by following industry best practices. Experts recommend matching connector pitch to your PCB design to maintain signal integrity. Align the pin count with your board layout for easier assembly. For high-density designs, use fine pitch connectors such as 0.3 mm or 0.5 mm. Be aware that finer pitches may increase soldering risks. Choose a pitch that fits standard assembly equipment to improve manufacturability.

Key Consideration | Recommendation |

|---|---|

Connector Pitch | Match to PCB design for signal integrity |

Pin Count | Align with PCB design for assembly ease |

High-Density Design | Use fine pitch connectors (0.3 mm or 0.5 mm) |

Soldering Risk | Watch for complications with finer pitches |

Manufacturability | Select pitch for standard equipment |

Tip: Always test your connector in the final device and review your design for future compatibility.

Case studies with YLS Flexible flat cable

You can learn from companies that have solved pitch selection challenges using YLS Flexible flat cable. Ford Motor Company needed faster prototyping for new vehicle electronics. They used custom YLS FFCs and reduced prototyping time from months to days. Siemens AG wanted higher production efficiency in automation. By integrating high-density YLS FFCs, they improved assembly speed and cut time-to-market by 30%. Boeing required precision and reliability in aircraft wiring. YLS shielded FFCs helped them increase production efficiency and reduce assembly time by 25%, while maintaining high safety standards.

Company | Challenge | YLS FFC Solution | Results Achieved |

|---|---|---|---|

Ford Motor Co. | Faster prototyping for electronics | Custom YLS FFCs, rapid prototyping | Time reduced from months to days |

Siemens AG | Higher production efficiency | High-density YLS FFCs | 30% faster time-to-market |

Boeing | Precision and reliability in aircraft | Shielded YLS FFCs for critical contact | 25% less assembly time, high safety |

These examples show what happens when you choose the right pitch and follow best practices. You achieve reliable mating, better performance, and faster production.

Understanding connector pitch helps you create reliable and efficient designs. The right pitch supports compatibility, performance, and easy assembly. See how connector choices shape your results:

Connector Type | Pitch (mm) | Key Features |

|---|---|---|

SKEDD Connectors | 2.54 | Tool-free, reliable assembly |

Press-fit Contacts | N/A | Solder-free, stable connections |

SMA Interfaces | N/A | High-frequency, signal integrity |

Early pitch selection ensures your product fits, carries current safely, and integrates smoothly.

YLS Flexible flat cables offer customizable pitches for any application.

You can reach out to YLS for expert advice or custom solutions.

Plan connector pitch early to avoid costly changes and achieve the best results.

FAQ

What does connector pitch mean?

Connector pitch means the distance from the center of one pin to the center of the next pin. You use this measurement to decide how many connections fit in a small space.

What pitch sizes do YLS Flexible flat cables offer?

You can choose from pitch sizes like 0.4mm, 0.5mm, 1.0mm, and 1.25mm. These options help you match your cable to your device’s connector and space needs.

What happens if you select the wrong pitch?

If you select the wrong pitch, your connector may not fit your PCB. You risk signal loss, assembly errors, or costly redesigns. Always check compatibility before you start your design.

What applications need fine pitch connectors?

You need fine pitch connectors for compact devices like smartphones, drones, and medical equipment. These connectors help you save space and increase connection density.

What makes YLS Flexible flat cables suitable for high-density designs?

YLS Flexible flat cables support up to 96 conductors and offer customizable pitch options. You can achieve high-density wiring and reliable performance in tight spaces.