You encounter ribbon wiring in almost every modern electronic device. Ribbon wiring refers to a flat arrangement of multiple wires running parallel to each other, forming a single, flexible strip. This design makes ribbon cable ideal for compact spaces. The global ribbon cable market continues to grow rapidly:

- Projected to reach USD 4.22 billion by 2032

- Estimated at USD 2.92 billion in 2025

- CAGR of 5.4% from 2025 to 2032

Choosing the right ribbon wiring depends on the materials used, which impact performance and reliability:

| Material | Type | Key Features |

|---|---|---|

| Copper | Conductor | Highly conductive, flexible, affordable |

| Tinned Copper | Conductor | Prevents oxidation, boosts durability |

| Silver-Plated Copper | Conductor | Best for high-speed data transfer |

| Polyvinyl Chloride | Insulation | Flexible, flame-resistant, low cost |

| Teflon (PTFE) | Insulation | High temperature and chemical resistance |

| Silicone | Insulation | Flexible, heat-resistant |

You should always consider customization and quality when selecting ribbon wiring for your project.

Key Takeaways

- Ribbon wiring is essential for modern electronics, offering a compact and flexible solution for organizing multiple connections.

- Choose the right materials for ribbon cables to enhance performance; options include copper for conductivity and Teflon for heat resistance.

- Customization is key; tailor ribbon cables to your project needs by selecting pitch sizes, conductor counts, and insulation types.

- Consider environmental factors like temperature and moisture when selecting ribbon wiring to ensure durability and reliability.

- Work with reliable suppliers like YLS for expert support and tailored solutions to meet your specific ribbon cable requirements.

What Is Ribbon Wiring?

Structure and Design

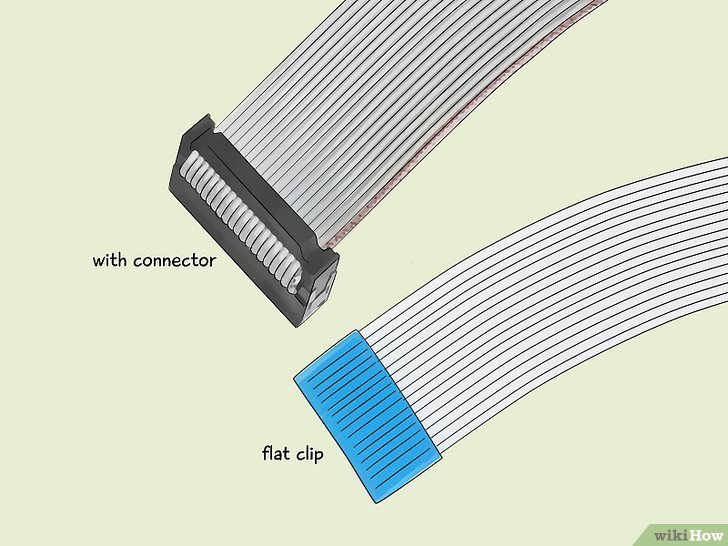

You see ribbon wiring as a flat cable with many wires running side by side. This design gives the cable a wide and flat look. Each wire sits parallel to the others on a plastic film, which makes the cable flexible and easy to fit into tight spaces. Ribbon cables stand out because you can connect them quickly to IDC connectors. These connectors use sharp forked contacts to make mass termination simple and reliable.

Ribbon wiring helps you organize multiple connections in a neat and compact way. You avoid tangled wires and bulky bundles, which makes your device easier to assemble and maintain.

Take a look at how ribbon cables compare to other flexible wiring options:

| Component | FFC Ribbon Cable | FPC Flexible Circuit |

|---|---|---|

| Structure | Flat, flexible cable with parallel conductors on plastic film | Complex assembly with etched copper circuitry on polyimide |

| Flexibility | Flexible in one direction | Flexible in multiple directions |

| Application | Point-to-point signal/power transmission | Supports complex circuit designs |

| Manufacturing | Simple lamination and stamping process | Involves photolithography and chemical etching |

You use FFC ribbon cables for simple, compact connections in devices like printers and laptops. FPC flexible circuits work best when you need complex routing, such as in smartphones and tablets.

Common Uses

You find ribbon wiring in many industries because it fits well in compact designs and supports reliable connections. Here are some common uses:

- Consumer Electronics: You see ribbon cables inside laptops, tablets, and printers for internal wiring.

- Automotive Systems: You rely on ribbon wiring in infotainment systems and sensor arrays.

- Medical Devices: Ribbon cables help connect imaging systems and robotic surgical tools.

- Industrial Automation: You use them in robotics and manufacturing machinery for precise control.

- Aerospace & Defense: Ribbon wiring connects avionics and navigation systems in aircraft.

You also find ribbon cables in robotics, computers, hard drives, and test equipment. Their flat shape makes them ideal for limited spaces, helping you build devices that are both compact and efficient.

Types of Ribbon Cable

You can choose from several types of ribbon cables to fit your project needs. Each type offers unique features for different environments and applications. Here is a quick overview of the main categories you will find:

| Category | Description |

|---|---|

| Flat Ribbon Cable | Flat conductors arranged side by side |

| Round Ribbon Cable | Round conductors bundled together |

| Molded Ribbon Cable | Molded connectors for easy installation |

| Hybrid Ribbon Cable | Mix of different cable types |

| Others | Special variations for unique requirements |

Standard Ribbon Cable

You often use standard ribbon cable in computers, printers, and other electronics. Flat ribbon cables have a pitch of 0.050 inches and usually feature 24 wires in two rows. You will see wire gauges like AWG 26 or AWG 28. These cables make it easy to organize connections and save space inside devices.

- Common conductor counts: 24 wires

- Typical pitch: 0.050 inches

- Wire gauges: AWG 26, AWG 28

High-Temperature Ribbon Cable

You need high-temperature ribbon cable for harsh environments. These flat ribbon cables can handle extreme temperatures from -104°C to +260°C. You will find certifications such as LSZH, UL-94V-0, and FAA Vertical Burn standards. Use these cables in aerospace, automotive, or industrial settings.

| Temperature Range | Certification Details |

|---|---|

| -104°C to +260°C | LSZH, UL-94V-0, FAA Vertical Burn |

Waterproof Ribbon Cable

You rely on waterproof ribbon cable when moisture or dust is a concern. Flat ribbon cables with waterproof features protect sensitive electronics in outdoor or medical devices. You can use these cables in equipment exposed to water, humidity, or chemicals.

- Sealed insulation for moisture resistance

- Ideal for medical and outdoor electronics

Custom Ribbon Cable

You can order custom ribbon cables from YLS to match your exact requirements. Custom options include pitch sizes from 0.4 mm to 2.54 mm, conductor counts from 4 to 96, and cable lengths from 30 mm to over 1000 mm. You select connector types, conductor materials, and additional shielding. Custom ribbon cables work well in consumer electronics, medical devices, automotive systems, and industrial equipment.

| Customization Aspect | Details |

|---|---|

| Length | Custom lengths available |

| Connector Types | Multiple connector options |

| Pitch | Customizable pitch sizes |

| Conductor Materials | Tin-plated copper, other materials |

| Additional Shielding | EMI protection, PET stiffeners |

Tip: Custom ribbon cables let you tailor pin configurations, cable pitches, and lengths for your specific application. You get the flexibility to design flat ribbon cables that fit your device perfectly.

You see that flat ribbon cables come in many forms. Custom ribbon cables from YLS give you the freedom to choose every detail, so your project gets the best fit and performance.

Features of Ribbon Cable Assemblies

Flexibility

You benefit from the flexibility of ribbon cable assemblies during installation and operation. These assemblies bend and twist easily, which lets you fit them into tight spaces or around obstacles. You can manipulate a flat ribbon cable assembly without damaging the conductors. This flexibility reduces the risk of breakage and improves reliability. You find that custom ribbon cord assemblies adapt to many configurations, making them ideal for devices with limited space. Flexible flat cable assemblies also help you avoid tangled wires, which keeps your workspace organized.

- You position ribbon cable assemblies in compact devices.

- You reduce installation time because the cables move easily.

- You improve reliability since flexible assemblies resist damage.

Space-Saving Design

You notice the space-saving design of flat ribbon cable assembly in many modern electronics. The flat shape allows you to route cables in confined areas. You see that planar cable assemblies use pre-defined fold lines, which guide folding and prevent uneven stress. Conductor spacing and alignment keep the assembly safe and efficient, even in high-density designs. The benefits and features of flat ribbon cable assembly include compact storage and easy routing. You use custom ribbon cable assemblies to maximize space in your project.

| Design Element | Contribution to Space-Saving |

|---|---|

| Pre-Defined Fold Lines | Guides folding, reduces stress, allows compact storage |

| Conductor Spacing and Alignment | Prevents short circuits, ensures safe use in high-density designs |

Signal Integrity

You rely on ribbon cable assemblies for strong signal integrity, especially in high-frequency applications. Flat ribbon cable assemblies support high speeds when you use careful design. Shielding techniques, such as EMI protection, prevent cross-talk between conductors. You maintain signal fidelity by choosing assemblies with proper reinforcement. YLS engineers custom ribbon cord assemblies with options like PET stiffeners and EMI shielding, which protect your signals. You find that ribbon cables features like shielding and conductor quality help your devices run smoothly.

- You support high-speed data transfer with flat ribbon cable assemblies.

- You prevent interference using shielding.

- You maintain reliable connections in demanding environments.

Ease of Termination

You experience ease of termination with ribbon cable assemblies. The standardized pitch and conductor counts match IDC connector sizes, which simplifies installation. You use mass termination to connect many wires at once, reducing labor and error risk. Color-coding helps you align pins correctly, which prevents reversed connections. Custom ribbon cord assemblies from YLS offer connector-ready configurations, making integration seamless. You save time and effort during assembly, which improves productivity.

| Feature | Description |

|---|---|

| Flat and Space-Efficient Design | Ideal for routing in confined spaces with limited sideways flexing. |

| Standardized Pitch and Conductor Counts | Specified by conductor spacing and number of conductors, matching IDC connector sizes. |

| Simplified Termination with IDC | Quick, mass termination reduces labor and error risk. |

| Color-Coding for Easy Alignment | Simplifies pin alignment, ensuring proper orientation and reducing reversed connections. |

| Wide Range of Applications | Used in various devices like computers, robotics, and medical equipment for reliable connections. |

You see the advantages of ribbon cables in compact assemblies and flexible routing. Flat ribbon cable advantages include easy installation and reliable performance. You choose custom ribbon cable assemblies to match your exact needs. While disadvantages of flat ribbon cable assembly may exist in some cases, you find that the benefits far outweigh them for most projects.

Specifications of Ribbon Cable

When you select a ribbon cable for your project, you need to understand the key specifications that affect performance, compatibility, and reliability. These specifications help you match the cable to your application and ensure long-lasting results. Let’s break down the most important factors you should consider.

Pitch and Conductor Count

Pitch refers to the distance between the centers of two adjacent conductors in a ribbon cable. This measurement determines the physical size of the cable and its compatibility with connectors of flat ribbon cables. You often see pitch sizes ranging from 0.4 mm to 2.54 mm, which allows you to fit cables into tight spaces or match them with specific insulation displacement connector types.

The number of conductors describes how many individual wires run side by side in the cable. You choose the number of conductors based on the complexity of your device and the number of signals you need to transmit. YLS offers ribbon cable options with conductor counts from 4 to 96, giving you flexibility for both simple and advanced designs.

Here’s a table showing common ribbon cable specifications for pitch and conductor count:

| Pitch Size (mm) | Number of Conductors |

|---|---|

| 0.4 | 4 to 96 |

| 2.54 | 4 to 96 |

Tip: Always check the pitch and number of conductors to ensure your ribbon cable fits your connectors and meets your signal requirements.

Wire Gauge and Materials

Wire gauge measures the thickness of each conductor in a ribbon cable. You often see gauges like 30 AWG or 32 AWG in compact electronics. Thinner wires save space, while thicker wires handle more current. The choice of conductor material also affects durability and signal quality. Most ribbon cable designs use copper or tinned copper for excellent conductivity and corrosion resistance.

Material selection for cable jackets and conductors is crucial for durability. You want cables with high tensile strength and resistance to environmental factors. Flat ribbon cables have a greater surface-to-volume ratio, which means they dissipate heat more efficiently than round cables. This design allows your ribbon cable to handle higher current levels without overheating.

| Aspect | Ribbon Cable | Round Cable |

|---|---|---|

| Flex Life | 100 times longer | Standard flex life |

| Weight | One-fourth the weight | Standard weight |

| Heat Dissipation | Better heat dissipation | Less efficient heat dissipation |

| Mass of Moving Bundles | Reduced mass allows greater acceleration | Higher mass leads to more vibration |

You benefit from lighter cables, longer flex life, and improved heat management when you choose the right wire gauge and materials.

Insulation and Compliance

Insulation protects the conductors inside your ribbon cable from damage and interference. You find insulation materials like polyester (PET), polyimide (PI), and fluoropolymer in high-quality cables. These materials offer flexibility, chemical resistance, and flame retardance.

Compliance standards ensure your ribbon cable meets safety and environmental requirements. YLS manufactures cables that comply with ISO9001, UL, and RoHS standards. You can trust that your cables are safe, reliable, and environmentally friendly.

| Insulation Material | Compliance Standard |

|---|---|

| Polyester (PET) | UL 94 V-0 |

| Polyimide (PI) | UL 94 V-0 |

| Fluoropolymer | UL 94 V-0, IEC 60332 |

Note: Always verify that your ribbon cable insulation meets shared standard specifications for your industry.

End Termination Options

End termination refers to how the ends of your ribbon cable connect to other components. You have several options, each with unique benefits for installation and reliability. The most common ribbon cable connectors include insulation displacement connector (IDC) and crimp connectors.

IDC connectors pierce the insulation and make gas-tight, vibration-proof connections. You can terminate multiple wires at once, saving time and reducing errors. Crimp connectors use metal-to-metal contact and work well for individual wires. You may need special tools for crimping, but you get reliable connections for different wire diameters.

| Feature | IDC Connectors | Crimp Connectors |

|---|---|---|

| Connection Method | Insulation-piercing, no need to strip insulation | Metal-to-metal contact through crimping |

| Reliability | Gas-tight and vibration-proof connections | Reliable for various wire diameters |

| Manufacturing Efficiency | Allows for multiple terminations at once, saving time and cost | Suitable for distinct wires but may require more time for individual terminations |

| User-Friendliness | Can be terminated with basic tools, low force required | Requires specific crimping tools and techniques |

| Versatility | Available in various pitches and configurations | Effective for different wire diameters in a single unit |

YLS offers a wide range of ribbon cable connectors, including tinned ends, gold fingers, and connector-ready configurations. You can customize your cable to fit your assembly process and device requirements.

When you choose ribbon cable specifications, consider pitch, number of conductors, wire gauge, insulation, compliance, and termination options. These shared standard specifications help you build reliable and efficient electronic systems.

Applications of Ribbon Cables

You see applications of ribbon cables in many industries. Their flat and flexible design helps you create compact assemblies and organize wiring in tight spaces. The following sections show how you use ribbon cables in different fields.

Consumer Electronics

You rely on ribbon cables to connect internal components in devices like computers, printers, and tablets. Their flat shape fits easily inside slim cases. You use them for high-speed data and signal transmission, which supports real-time performance. Ribbon cables help you reduce clutter and keep wiring organized. You can customize them for different connector types and lengths, making assembly simple.

- Connects internal parts in computers and printers

- Supports high-density connections in small devices

- Provides organized and customizable wiring

- Enables fast data transfer for responsive systems

Medical Devices

You use ribbon cables in medical devices where space and reliability matter. Their slim, multi-wire layout saves room on circuit boards. You benefit from extreme flex life, which means cables last longer in devices with moving parts. Chemical-resistant jackets allow easy cleaning and sterilization. Fixed conductor spacing gives you stable signal transmission, which is important for accurate readings.

| Feature | Importance in Medical Devices |

|---|---|

| Slim, multi-wire layout | Saves space in compact equipment |

| Extreme flex life | Withstands constant motion |

| Chemical-resistant jacket | Ensures safety and hygiene |

| Fixed conductor spacing | Maintains clean signal transmission |

| Standard IDC connectors | Simplifies assembly and maintenance |

Automotive Systems

You find ribbon cables in vehicles connecting sensors, infotainment systems, and control modules. Their flexible design handles vibrations and temperature changes. You use them for both data and power transmission. Ribbon cables help you build reliable connections in harsh environments.

- Connects electronic components in vehicles

- Provides durability and flexibility for moving parts

- Supports stable performance in changing temperatures

Industrial Equipment

You use ribbon cables in control boxes and machinery. Their flat shape saves space and makes wiring easy to organize. Flexible cables move with equipment and handle impacts well. You choose ribbon cables for robust designs that need to withstand vibration.

- Saves space in control panels

- Allows easy movement and organization of wires

- Handles vibration and impact in industrial settings

Tip: You improve device reliability and simplify assembly when you choose flat ribbon cable applications for compact and flexible routing.

You see that applications of ribbon cables cover many industries. YLS offers custom solutions to help you integrate ribbon cables into your projects for better performance and space management.

Choosing Ribbon Wiring

Matching Specifications to Needs

You need to match ribbon wiring specifications to your project’s requirements. Start by looking at the key criteria that affect performance and compatibility. The table below helps you compare important factors:

| Criteria | Description |

|---|---|

| Pitch | Spacing of conductors within the ribbon cable; choose based on connector and space needs. |

| Extreme temperatures | Select cables with jackets like silicone for harsh environments. |

| Flexibility | Essential for tight spaces; custom cables can offer more flexibility. |

| Long life | Pick cables with proven durability and reliability. |

| Fire resistant | Important for safety and meeting fire safety standards. |

You should always check the pitch and conductor count to ensure the cable fits your connectors. If your design needs frequent bending, select a cable with high flexibility. For projects in demanding environments, choose cables rated for extreme temperatures and fire resistance.

Environmental Considerations

Environmental factors play a big role in ribbon wiring selection. You must consider temperature, moisture, and mechanical stress. The table below shows how these factors impact your choice:

| Environmental Factor | Impact on Ribbon Wiring Selection |

|---|---|

| Temperature extremes | Insulation and coatings must handle the expected temperature range. |

| Moisture and chemicals | Materials should resist corrosion from water, oil, or chemicals. |

| Mechanical stress | Vibration or movement requires strain relief and protective coatings for durability. |

- Ambient Temperature: High heat can damage insulation and reduce resistance.

- Humidity: Moisture can cause electrical breakdown and degrade materials.

- Vibration: Movement may require extra reinforcement to prevent wear.

You protect your devices by choosing ribbon cables with the right insulation and protective features for your environment.

Cost and Support

Cost and support matter when you select ribbon wiring. You should look beyond the initial price and consider the total cost of ownership. Think about warranty coverage, installation, and maintenance. A good warranty can lower long-term costs by covering repairs or replacements.

- Technical Support: Reliable manufacturers like YLS offer expert guidance and fast responses.

- After-Sale Services: Training resources and maintenance programs help you integrate cables smoothly.

- Fast Turnaround: YLS provides quick production and delivery, so you meet tight deadlines.

- Low Minimum Order Quantities: You can order only what you need, which helps control costs.

You gain peace of mind when you work with a supplier that supports you from design to delivery. YLS stands out by offering flexible ordering, strong technical support, and dependable service.

You now understand ribbon wiring and ribbon cables. You see many types, including standard, high-temperature, and waterproof options. You notice features like flexibility, space-saving design, and strong signal integrity. You select cables by pitch, conductor count, and insulation. You use ribbon cables in electronics, medical devices, and automotive systems.

- Custom solutions help you meet unique project needs.

- Reliable suppliers follow strict quality standards.

- Early discussions with experts improve your results.

You should reach out to manufacturers like YLS for tailored ribbon cable solutions.

FAQ

What is the difference between ribbon cable and round cable?

Ribbon cable has flat, parallel wires. Round cable bundles wires in a circular shape. You use ribbon cable for space-saving and easy organization. Round cable works well for flexible routing in larger spaces.

How do you choose the right pitch for your ribbon cable?

You match the pitch to your connector and device requirements. Smaller pitch fits compact electronics. Larger pitch supports higher current. Always check your connector specifications before you order.

Can ribbon cables handle high temperatures or moisture?

You select ribbon cables with special insulation for harsh environments. High-temperature cables use materials like polyimide. Waterproof cables have sealed jackets. YLS offers options for both conditions.

What termination options are available for ribbon cables?

You can choose IDC connectors, tinned ends, or gold fingers. IDC connectors allow quick mass termination. Tinned ends work for soldering. Gold fingers fit into card-edge connectors.