Shielded Cables for EMI-Sensitive Applications

All uploads are secure and confidential

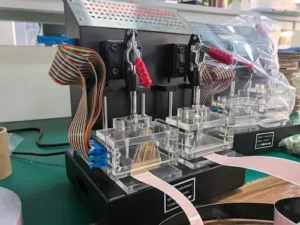

Shielded FFC Cable

Shielded FFC cables offer essential EMI protection for high-speed and noise-sensitive applications. We provide flat flexible cables with foil, braid, or dual-sided shielding—designed to maintain signal integrity for USB, HDMI, CAN, and LVDS lines. Ideal for automotive, medical, and industrial electronics with strict EMI compliance needs.

| FFC Flat Cable | Specification |

|---|---|

| Pitch | 0.5mm, 0.8mm, 1.0mm, 1.25mm, 1.27mm, 2.0mm, 2.54mm |

| Conductor | 0.035×0.3, 0.05×0.5, 0.1×0.65, 0.05×0.5 |

| Insulation | 0.043, 0.06, 0.1, 0.08 |

| Reinforcing Tape | 0.16, 0.225, 0.25 |

| Blue Stiffener | 4–8mm & 3–5mm |

| Contact Sides | Same side & opposite side contact |

| Pin Count | 4 to 96 pins (customizable) |

| Cable Length | 20mm – 10,000mm (customizable) |

| Cable Type | Type A, B~H, I (custom options) |

| Service | OEM / ODM available |

| Certification | ISO9001:2008, RoHS compliant |

| MOQ | 50 pcs |

Ask us about sample support.

Product Categories &

Engineering Solutions

Our Shielded FFC Cables are designed for EMI-sensitive applications where signal integrity matters. From foil and mesh shielding to twisted-pair and impedance-controlled options, we provide custom solutions for USB, LVDS, and high-speed data lines—perfect for medical, industrial, and automotive systems.

Top-Foil Shielded FFC

- 0.5mm / 1.0mm pitch available

- Available in 8 to 60 pins

- Flame-retardant PET + foil laminated surface

This FFC uses a single aluminum foil layer on the top side to reduce external electromagnetic noise. It’s ideal for standard-speed signal transmission in LED lighting, office equipment, and touchscreen modules.

Double-Sided Shielded FFC

- Up to 80 dB EMI suppression (with grounding tab)

- 1.0mm pitch standard; other options available

- Optional stiffeners and folded ends

Foil shielding is applied on both top and bottom surfaces, providing 360° EMI coverage. This is a practical choice for control boards in medical equipment, power modules, and dense industrial assemblies.

Mesh-Braided Shielded FFC

- 100K dynamic bend cycles

- 90–120Ω impedance options available

- Supports twisted signal layout inside

Instead of foil, this FFC features a copper mesh braided layer, allowing excellent shielding and durability under motion. Suitable for robotics, automotive displays, and test rigs that involve continuous movement.

Shielded Twisted Pair FFC(STP-FFC)

- Supports up to 2 Gbps per pair

- 2–8 pair configurations, customizable

- Impedance-matched and EMI tested

This FFC embeds twisted pairs within the flat cable and applies external shielding (foil or mesh). It ensures signal symmetry and minimal crosstalk — a must for camera modules, ADAS, and embedded computing.

Impedance-Controlled Shielded FFC

- 90Ω (LVDS), 100Ω (USB), or custom

- ±10% impedance tolerance

- Length from 50mm to 1000mm; folded options

Designed with precise conductor layout and spacing to control characteristic impedance. When combined with shielding, this type guarantees signal clarity across long runs or temperature variations.

Connector-Integrated Shielded FFC

- Fully tested for insertion force and signal continuity

- Ground tab routing pre-integrated

- Available in tray, bundled or taped packaging

This cable comes with shielding and high-reliability connectors (Molex, Hirose, JAE, etc.) installed on one or both ends. Ideal for high-volume assembly lines where speed and consistency matter.

Contact our engineer for drawing review and sample proposal.

Custom Capabilities — Built to Your Specs

Not all EMI problems are the same — and neither are your cable needs. At YLS, we help you configure the shielding structure, grounding layout, bend direction, and connector type that match your specific electronic environment. Whether you’re routing MIPI over 300mm or suppressing noise near a motor driver, we build cables that work — in your real-world conditions.

1. Shielding Structure Options

Aluminum foil / copper foil / braided mesh / dual-layer shield

With or without ground tails or integrated drain wire

2. Pitch & Pin Customization

0.4mm, 0.5mm, 1.0mm, and 1.25mm pitch available

Pin count from 4 to 96; both sides or one-side contact

3. Fold & Routing Design

Z-shape / L-shape / reverse bend / crease marking

Engineered to fit inside compact housings or hinge systems

4. Connector Compatibility

Support for ZIF, LIF, soldered ends, or fully assembled with:

Molex | JAE | Hirose | TE | JST | Foxconn | customized terminals

5. Impedance & Signal Control

Target impedance: 90Ω / 100Ω / 120Ω depending on protocol

Shielded FFC can support LVDS, eDP, HDMI, USB, and MIPI signals

6. Test & Packaging Services

100% continuity tested before shipment

Packaged in trays, tape-and-reel, or anti-static bundles with barcode labeling

Faster assembly time

Better fit and fewer errors

Ready for production line

Custom-made to your specs

Send Us your drawing or photo — we’ll make a sample that fits.

Where Our FFC Cables Are Used

Standard Ribbon Cables are ideal for compact, high-performance electronic assemblies across diverse industries. Whether you’re designing wearable tech, medical devices, or automation equipment, our cables provide reliable, space-efficient signal transmission with full customization support.

Drone Interconnect Solutions

Internal wiring in UAVs often faces extremely limited space, vibration, twisting, and weight sensitivity.

We offer lightweight, flexible, and shielded FFC (Flexible Flat Cable) solutions for flight control boards, gimbal control modules, power management modules, and more. We can provide pre-bent and multi-fold designs to improve assembly efficiency and stability.

- Folded ribbon cables optimized for 3D routing

- Low-weight, low-profile design reduces UAV payload

- Tin-plated or EMI-shielded options for signal integrity

Energy Storage Systems

Energy storage battery systems (e.g., lithium batteries, home energy storage) require multi-core cable connections between the BMS (Battery Management System) and battery cells, often encountering EMI and space constraints.

YLS provides custom-length, custom-pitch, and multi-core FFC cables with shielding, flame retardancy, and numbering labels, facilitating efficient integration and long-term stable operation.

- Up to 96 conductors per cable, for dense battery arrays

- Shielded cable variants reduce EMI near switching circuits

- Folded layouts improve space usage in battery trays

Smart Home Devices

Smart home modules, such as LED light strips, access controls, and display controllers, require miniature wiring solutions, along with UL safety certification and long-term stability.

We support small-pitch (0.5mm) and multi-fold designs, suitable for LED strip controllers and touch modules. We offer UL-certifiable materials and support terminal assembly and bulk packaging.

- Flame-retardant materials for in-wall or indoor applications

- Labels & barcodes for easy batch traceability

- Ready-to-connect ends with pre-installed connectors

Robotics & Motion Systems

Internal wiring in robotic arms, linear stages, and collaborative robots often involves continuous movement, bending, and vibration, making it challenging for standard wire harnesses to meet lifespan requirements.

We offer FFC wiring solutions with high flex life (>1 million cycles), multi-fold points, and enhanced flexibility designs, suitable for embedding within mechanical motion areas.

- High-flex life cable construction

- Folded flat cable for articulated joints

- Compact routing inside confined enclosures

Medical Devices

Medical devices (portable diagnostic instruments, surgical robots) demand miniaturization, high signal integrity, and material safety.

We can provide small-sized, high-density flat cables for medical equipment, supporting PI insulation, high-temperature resistance, RoHS/UL materials, and printable traceability markers.

- Medical-grade PET/PI insulation options

- Gold-finished ends for corrosion-free signal transfer

- Serial ID/QR traceability for compliance and QC

Automotive Systems

In-vehicle systems, such as dashboards and in-car display modules, require wiring that can withstand high temperatures and vibration, and integrate with connectors.

YLS offers FFC cables with rigid stiffeners, UL certification, and a temperature range of –40°C to +105°C, compatible with ZIF sockets, crimp terminals, and other connection methods.

- Vibration-resistant reinforced ends

- Temperature range: –40°C to +105°C

- Fully tested & labeled for assembly line traceability

Telecom & RF Devices

Communication terminals and antenna modules are often compact, with extremely demanding cable space requirements, and are prone to RF interference.

We offer shielded, impedance-matched flat cables for MIMO and dual-antenna configurations, with custom lengths and pin assignments to optimize layout and signal integrity.

- EMI-shielded versions with drain wire

- Impedance-tuned for RF or antenna use

- Fits ultra-thin housings & tight routing paths

Consumer Electronics

Consumer electronic devices (printers, cameras, tablets) predominantly use FFCs for inter-module connections, requiring high cost-effectiveness and consistency.

YLS can support FFC deliveries up to millions of units, providing labeling and assembly services to meet the automated production line needs of consumer electronics.

- Competitive pricing with factory-direct supply

- Pre-labeled and reel-packaged for automation

- Available from 50 pcs for pilot production

Not sure which configuration suits your device?

Talk to our technical engineer and get tailored recommendations based on your industry.

Why Choose YLS

More than a cable supplier — we’re your engineering and production partner.

At YLS, every project begins with understanding your technical needs. Whether you require a custom pitch, folded layout, or labeled packaging, we support your project from concept to mass production — with speed, flexibility, and trust.

Over 10 Years of Flat Cable Manufacturing

We specialize in FFC cables and know the industry inside and out.

Factory-Direct Supply with Fast Turnaround

Support complex, high-density signal layouts.

Fully Customizable from Pitch to Packaging

Choose your pitch, pin count, length, termination, folding, and more.

Samples in as Fast as 5–7 Days

Once drawings are confirmed, samples can be ready within a week.

100% Electrical Testing Before Shipment

Each cable is electrically tested to ensure performance and reliability.

Engineering Support at Every Step

Our team helps you match specs, connectors, and optimize routing.

Low Minimum Order Quantity

Start from as few as 50 pieces — perfect for prototyping and pilot runs.

Compliant with UL, RoHS, and REACH

All materials can meet major compliance standards, with full documentation.

Frequently Asked Questions

What is a shield cable?

A shield cable refers to any electrical cable with a conductive barrier (foil, mesh, or braid) that encases the inner conductors. This barrier acts as a Faraday cage to absorb or deflect incoming noise and reduce emissions. In flat cables, shielding may be laminated on one or both sides, or embedded within the cable core.

What is shielded cable used for?

Shielded cables are used to prevent electromagnetic interference (EMI) from affecting signal integrity. They’re essential in environments where high-frequency signals run near noisy power sources or RF components. In FFCs, shielding protects display, sensor, and data lines in automotive dashboards, medical imaging devices, and industrial controllers. Sources: IPC-2141A; IEC 61000-4-3.

When should I use shielded cable?

Shielded cables are recommended when signal degradation could result from EMI, crosstalk, or transient voltages. If you’re transmitting high-speed data (e.g. MIPI, LVDS, CAN, USB) or placing FFCs near motors, wireless modules, or switching power supplies, shielding is strongly advised. In FFCs, shielding is critical in high-density layouts or long signal runs.

What types of shielding are available in FFC cables?

FFC shielding options include:

Single-sided aluminum foil (lightweight, cost-effective)

Double-sided foil (for bidirectional EMI exposure)

Braided copper mesh (for dynamic environments)

Shielded twisted pair (for differential signals)

Each type offers varying levels of EMI suppression, bendability, and cost.

Does shielding affect FFC cable flexibility?

Yes, but the impact depends on the shielding structure. Foil-based shielding adds minimal thickness and remains flexible. Mesh braid offers superior EMI performance but reduces flexibility. Hybrid designs (foil + mesh) strike a balance. For frequent movement (e.g. robotic arms), choose reinforced foldable FFCs with dynamic shield layouts.

Can shielded FFC cables support impedance-controlled signals?

Absolutely. Many shielded FFCs are designed for 90Ω–120Ω impedance control, making them suitable for LVDS, eDP, HDMI, and MIPI DSI/CSI signals. Impedance stability is achieved through precise conductor spacing, dielectric selection, and symmetrical layout — shielding helps maintain signal quality under thermal or mechanical stress.

Chat with us now for your Custom needs. Chat on WhatsApp Now

Let’s Build Your Ideal FFC Cable — Fast Response Guaranteed

Need a quote, sample, or technical consultation? Our team responds within 8 hours. Send us your requirements and we’ll help you build the right cable — no delays, no guesswork.

- 6 specialized cable types for different electronic modules

- Fully customizable specs, connectors, folds, lengths

- Factory-direct pricing & low MOQ starting from 50 pcs

- Fast sample turnaround (5–7 days) and delivery in 2 weeks

- RoHS, UL, and REACH-compliant materials

- Worldwide shipping available (EXW/FOB/CIF terms)

- Engineering support for part matching and customization

- Factory-direct pricing, no middlemen