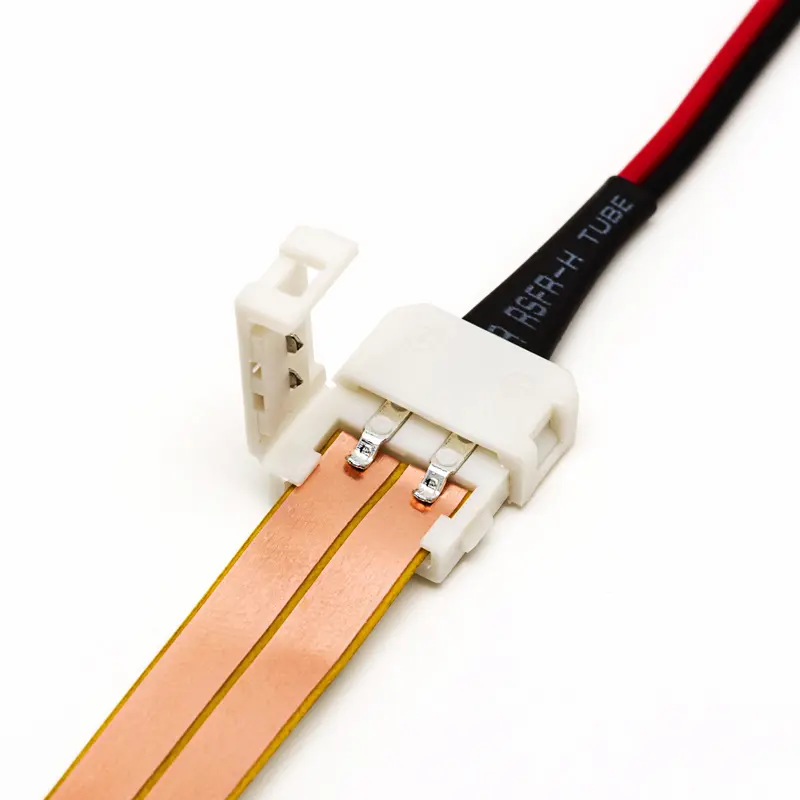

Custom Smart Home FFC Cable Solutions for Lighting & Sensors

YLS provides compact, flexible FFC cables tailored for smart home applications—from touch panels to lighting modules. We help you achieve stable performance in limited space with cost-effective, customizable solutions.

Introduction to Smart Home FFC Cable Applications

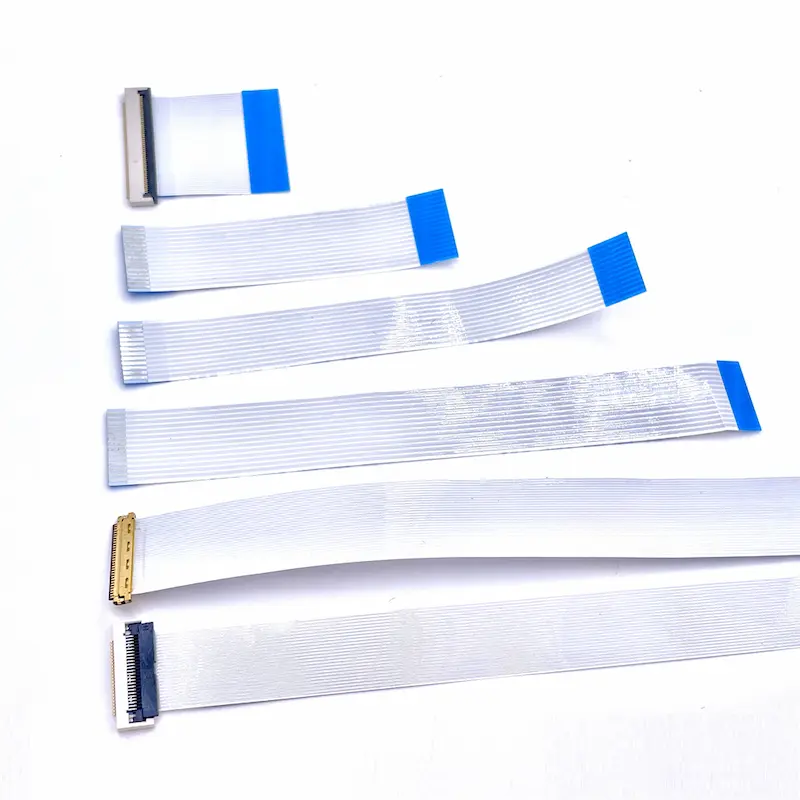

Modern smart homes rely on sleek design and embedded electronics. From wall-mounted control panels to IoT sensors and smart lighting systems, flat flexible cables (FFCs) are essential for connecting modules where space and aesthetics matter. YLS specializes in supplying ultra-thin, foldable, and high-pin-count FFCs that support your layout and performance needs without compromise.

Where Smart Home Devices Use FFC Cables

Smart home devices require compact, reliable connections—especially for touch panels, lighting modules, and embedded sensors. YLS provides ultra-thin, foldable, and EMI-protected FFC cables designed for tight spaces, high pin counts, and seamless integration into smart home electronics.

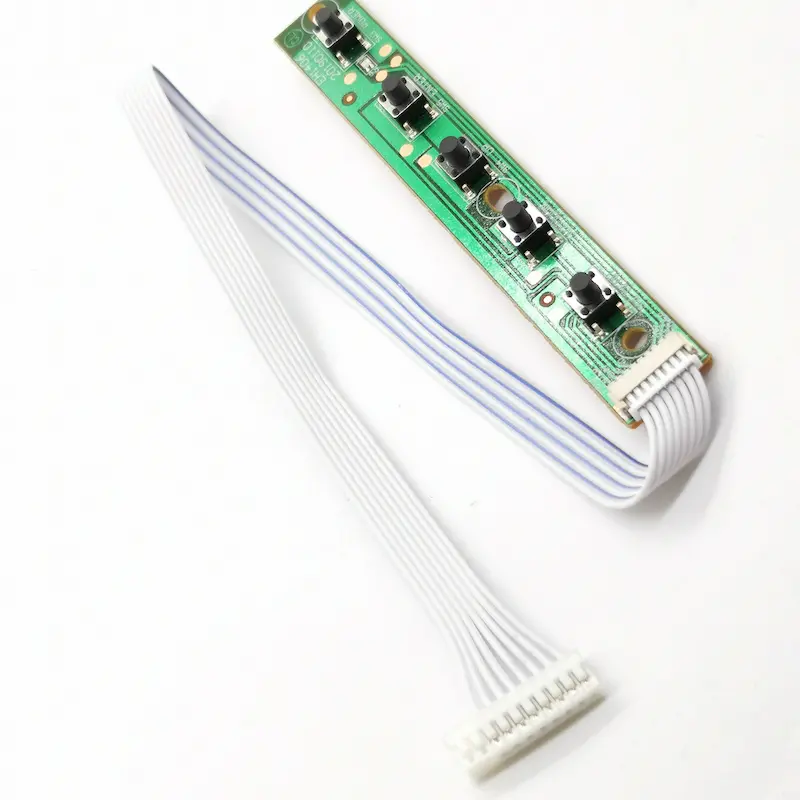

Touch Switches & Wall Panels

Ultra-thin FFCs for seamless integration behind glass or plastic smart panels.

LED Lighting Systems

Flexible FFCs for connecting LED strips, drivers, or panel backlights in smart lighting.

Smart Thermostats & HVAC Panels

Multi-pin FFCs used to link displays, temperature sensors, and control relays.

Window Automation Units

Compact and durable FFCs for motorized blinds, smart curtain tracks, or ventilator modules.

PIR & Motion Detection Sensors

Low-pin-count FFCs connect sensor heads to main control boards in occupancy and motion detection modules.

Smart Audio / Video Interfaces

Shielded FFCs designed for smart speakers, intercoms, or AV hubs.

Common Wiring Challenges in Smart Home —Solved with FFC

Struggling to fit wiring in a sleek product enclosure?

Our ultra-thin, pre-folded FFCs route cleanly around tight corners and components where round wires won't.

Getting signal noise in a dense Wi-Fi/Bluetooth environment?

We offer shielded, impedance-controlled FFCs to protect sensitive data streams for displays, sensors, and cameras.

Production line complaining about assembly time and errors?

We add features like alignment notches, connector labels, and reinforced stiffeners to make installation fast and foolproof.

Worried about heat and safety in a sealed, always-on device?

Our cables use UL-rated, high-temperature materials designed for thermal stability and safety in enclosed electronics.

Chat with us now for your Custom needs. Chat on WhatsApp Now

Technical Capabilities

FFC Cable Specs for Smart Home

- Supports complex routing between multiple smart modules

- Tailored bend radius and fold tolerance to fit narrow wall panels

- EMI-aware designs for clean signals in sensor and audio circuits

- Color-coded tails and notching improve assembly speed and accuracy

- Surface-printing for easier installation tracking

- Assistance in connector matching & PCB interface alignment

- Cross-functional support from design through to pilot production

- Experience in smart switches, lighting, HVAC, and security systems

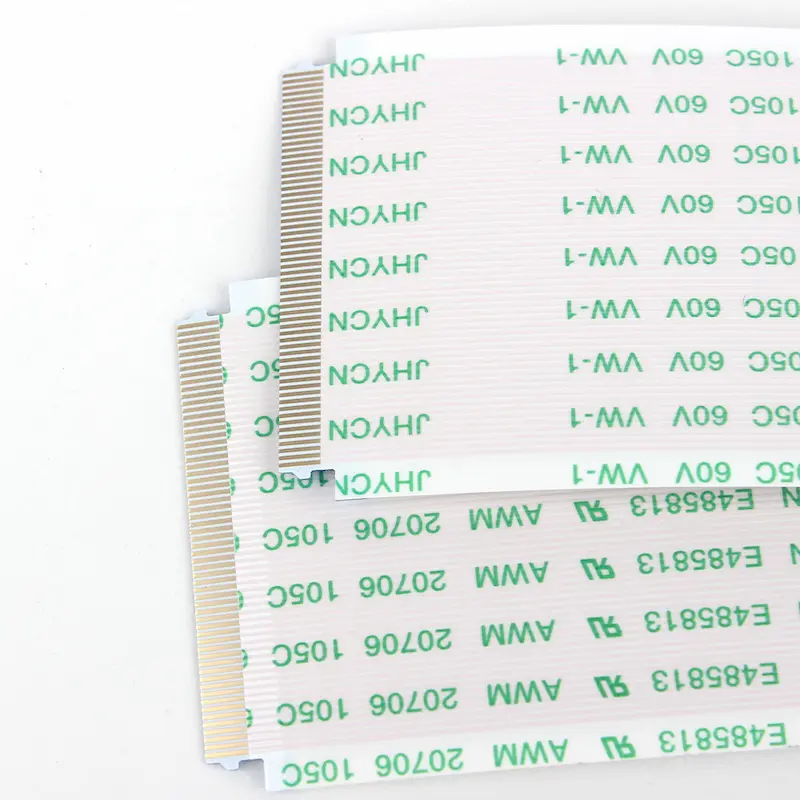

Quick Spec Summary:

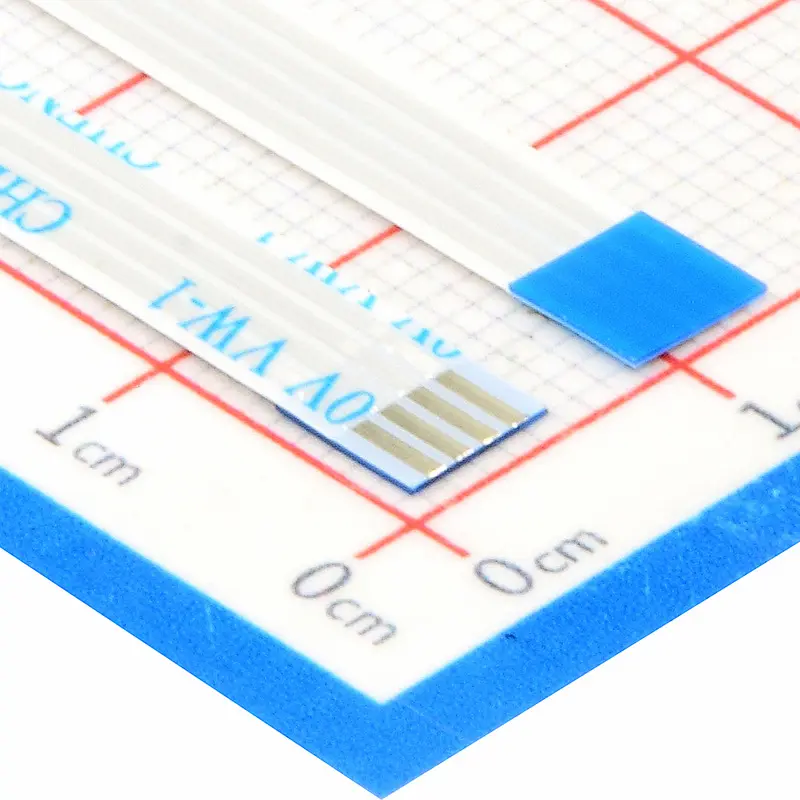

| Parameter | Specification Range | Remarks |

|---|---|---|

| Pitch | 0.4mm / 0.5mm / 1.0mm / 1.25mm | For compact layout of control panels and sensor boards |

| Conductor Count | 6–64 pins | Supports multiple device connections |

| Cable Thickness | 0.12–0.25mm | Ultra-thin for flush-mounted smart modules |

| Folding Configuration | Z-shape, U-shape, side entry | Customized per housing depth and orientation |

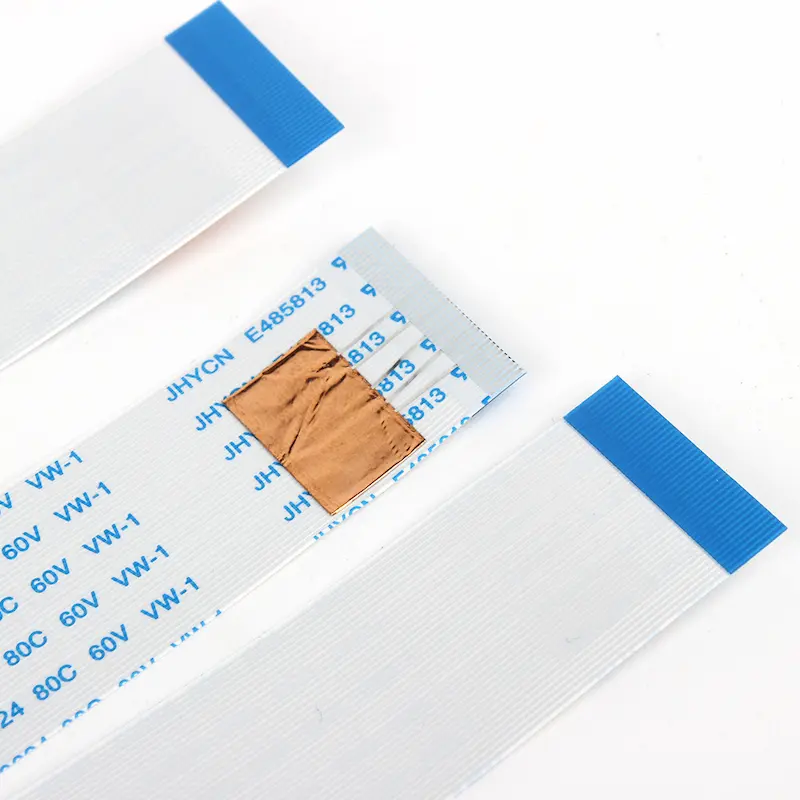

| Shielding Type | Foil or dual-sided aluminum layer | Applied for audio, display, or signal integrity modules |

| Connector Compatibility | ZIF, LIF, custom pad tail | Works with Molex, TE, Hirose, and others |

| Flex Rating | 50,000–150,000 cycles | For frequent-touch devices and smart blinds |

| Operating Temp. | -20°C to +85°C | For indoor residential environments |

| Certification | UL / RoHS / Reach | Optional flame-retardant materials available |

| MOQ & Lead Time | MOQ: 500 pcs; Prototypes: 5–7 days | Design assistance included |

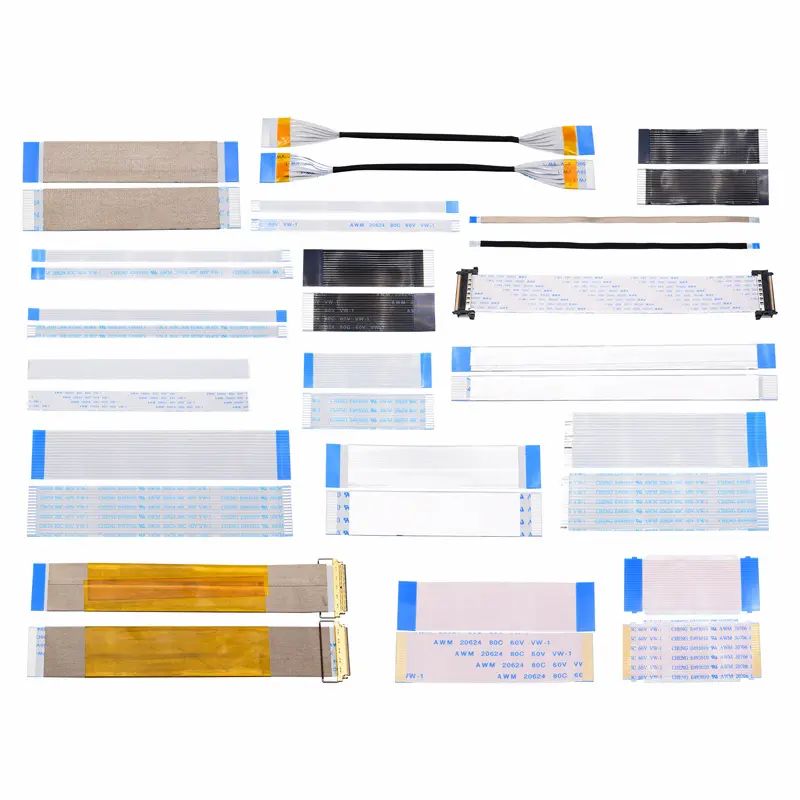

Custom Ribbon Cable Capabilities — Built to Your Specs

Your application may require more than just a standard pitch or length. That’s why we offer complete customization on all critical parameters — so your ribbon cable fits perfectly, functions reliably, and installs easily.

Whether you need just 50 pieces for a prototype or 50,000 for production, we can deliver with speed and precision.

1. Pitch & Conductor Configuration

Design the spacing and layout that fit your device’s constraints.

- Available pitches: 0.4mm / 0.5mm / 0.8mm / 1.0mm / 1.25mm

- 4 to 96 conductors

- Symmetrical or custom pin-out

2. Cable Length & Shape

Adapt the cable to your layout without compromising space.

- Lengths from 30mm to 1000mm+

- Straight, L-shape, Z-fold, or multi-branch

- Fold lines pre-creased for easy routing

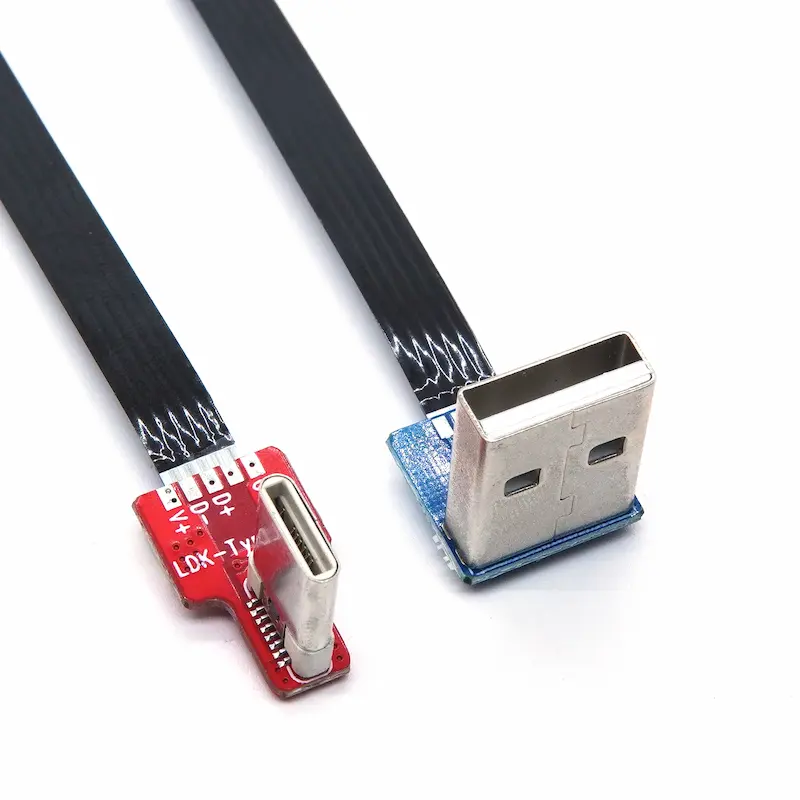

3. End Termination Options

Seamless integration with your connectors or boards.

- Tinned or gold-flashed bare ends

- PET/PI stiffeners for ZIF sockets

- Solder tail, FPC-style, or custom header connector

4. Shielding & EMI Control

Protect signal integrity in sensitive environments.

- Aluminum foil or mesh shielding

- Ground tail or drain wire

- Optional double-shielded design

5. Surface & Insulation Customization

Improve durability, appearance, and signal performance.

- PET or PI insulation

- Conductor surface: tin-plated, bare copper, or gold

- Optional heat-resistant or flame-retardant materials

6. Punching & Mechanical Modifications

Built to fit into housings and tight enclosures.

- Punch holes, slots, notches for mounting

- Fold lines for compact 3D routing

- Peel tabs or extended tails

7. Labeling & Traceability

Simplify installation, QC, and inventory tracking.

- QR code / barcode / serial ID

- Printed position marks, logos, or terminal IDs

- Laser or ink marking options

8. Packaging Options

Fit your assembly line or ESD protocol.

- Bulk bag, tray, coil, or tape & reel

- Anti-static or moisture-proof packaging

- Custom labels or part numbers

Not sure which specs to choose? Our engineering team is ready to help. Ask an Engineer

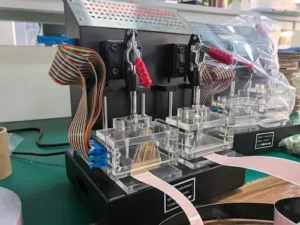

Custom FFC Cable Workflow

At YLS, we simplify the path from idea to production. Whether you’re upgrading a product or building something new, our six-step process ensures speed, accuracy, and full customization for your flat flexible cable solution.

🧩 Step 1: Project Kick-off

Tell us about your needs: cable pitch, pin count, length, connectors, UL specs, shielding, fold lines—our team starts with the details that matter.

📐 Step 2: Engineering Proposal

We translate your specs into manufacturable designs. Expect drawing files and connector matching within 24–48 hours.

🧪 Step 3: Sample Fabrication

Once drawings are approved, we build samples in 3–5 working days, including precision cutting, labeling, and insulation options.

🧷 Step 4: Testing & Validation

You verify the sample in your device. We assist with adjustments, feedback loops, or connector matching as needed.

🔁 Step 5: Final Sign-off

Once the prototype is approved, we lock the design, confirm packaging and delivery terms, and prepare for production.

🚛 Step 6: Mass Production & Global Delivery

We initiate volume production and ship on time via express, air, or sea—wherever your facility is.

✨ Optional Add-ons:

Fold lines or pre-bent shaping

Custom labels or barcodes

Hole punching, notching, peel-tab finishing

Shielding and grounding features

Special packing and reel packaging options

Technical support for connector sourcing

ABOUT YLS

Reliable FFC cables factory integrated services

Yulian is a direct manufacturer of flat flexible cables (FFC), delivering precision wiring solutions trusted by global OEMs. With in-house tooling, rapid prototyping, and full customization capabilities, we help you go from concept to cable—fast, reliable, and to your spec.

We offer pitch options from 0.4mm to 1.25mm and core counts up to 96, with full support for folding, shielding, notching, punching, labeling, and custom assembly.

- Ultra-Fine Pitch, High Pin Count

- 48-Hour Custom Sample Delivery

- Foldable & Shielded Cable Options

- Expert Support for Complex Wiring

- ISO/IATF Certified Manufacturing

- 100% Electrical QC Before Shipment

- Low MOQ, Fast Turnaround

- 10+ Years Across Key Industries

Frequently Asked Questions

What type of FFC cable is best for smart touch switches or control panels?

For smart touch switches and wall-mounted control panels, ultra-thin FFC cables with 0.5mm or 1.0mm pitch are commonly used. These provide reliable signal transmission while maintaining a slim profile that fits into compact panel enclosures.

Can FFC cables be pre-folded to match my housing layout?

Yes. At YLS, we offer Z-fold, U-fold, and side-entry pre-bending options based on your device structure. Each cable is folded during production to ±0.2mm accuracy, eliminating the need for manual shaping during assembly.

How do you ensure EMI protection in smart home devices?

We use foil or dual-sided shielding on FFC cables used in audio, video, or RF-connected modules. For higher integrity, we also offer impedance-controlled designs to reduce signal crosstalk in dense device layouts.

Are FFCs reliable for moving or flexible parts, like blinds or thermostat flaps?

Yes. We offer high-flex cycle FFCs rated for 50,000 to over 100,000 bends, suitable for motorized HVAC panels, window blinds, or other devices that require repeated movement over time.

What connector types are typically used in smart home applications?

ZIF (Zero Insertion Force) and LIF (Low Insertion Force) connectors are the most common. We support compatibility with leading brands like Molex, Hirose, TE, and also offer custom pad tails or double-ended designs.

Do you support labeling or custom markings for installation teams?

Absolutely. We can apply UL numbers, color-coded tails, notch tabs, or printed markers to assist installers in identifying direction, position, and cable matching during final assembly.

What's the typical lead time for smart home FFC prototypes?

We can produce samples within 5–7 business days once the drawings are confirmed. Small-batch production is also available with short lead times and no mold fee in many cases.

Can you help me select the right cable if I only have basic specs or a sample?

Yes. Our engineers can reverse-engineer from a physical sample or basic description (pitch, pins, length, connector type) to recreate or improve the design. We also support drawing confirmation and rapid prototype validation.

Chat with us now for your Custom needs. Chat on WhatsApp Now

More Solutions

Let’s Build Your Ideal FFC Cable — Fast Response Guaranteed

Whether it’s for foldable drones, camera gimbals, or onboard computing—our FFC solutions are designed to fly. Tell us what you need—we’ll build it.