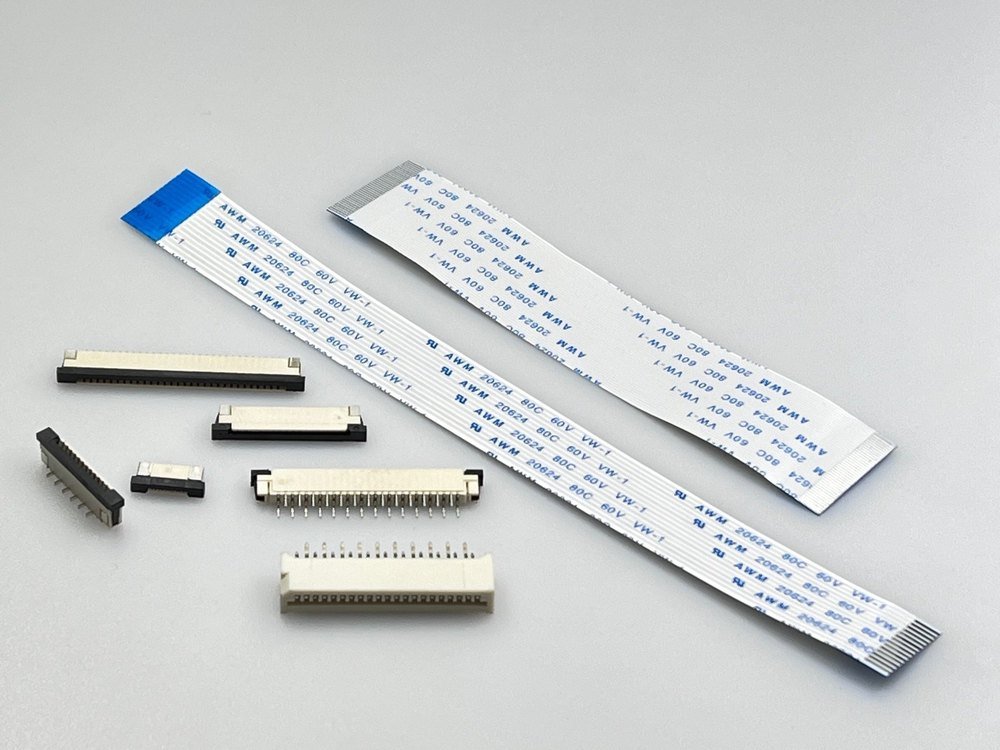

If you want reliable connections in your electronics, robotics, or automotive projects, choosing the right flat wire connector is crucial. YLS Flexible Flat Cable (FFC) stands out for cost savings, space efficiency, and easy use. You get high flexibility for frequent movement and quick setup.

- Designed for robotics joints, sensors, and camera systems

- Supports multi-axis control and clean signal delivery

- Handles over 5 million dynamic cycles without failure

Always focus on safety when installing these connectors to protect your devices and ensure lasting performance.

Key Takeaways

- Choose the right tools for installation. Use wire strippers, precision screwdrivers, and a multimeter to ensure secure connections.

- Prioritize safety before starting. Always turn off power, wear protective gear, and inspect cables to prevent accidents.

- Follow a step-by-step process for installation. Strip the cable, attach the connector, and test the connection for reliability.

- Avoid common mistakes like using the wrong size connectors or stripping too much insulation. These errors can lead to connection failures.

- Regularly inspect and maintain your connections. This helps prevent issues and ensures long-term performance.

Tools for Wire Connectors

Before you start installing flat wire connectors, you need the right tools and materials. Using the correct equipment helps you achieve a secure and reliable connection with YLS Flexible Flat Cable (FFC). You also reduce the risk of damaging your cables or connectors.

Essential Tools

You should gather these tools before you begin:

- Wire Strippers: Use these to remove insulation from the ends of your FFC without damaging the conductors.

- Precision Screwdrivers: These help you open connector housings and secure locking tabs.

- Tweezers: Use tweezers to handle delicate FFCs and small connectors, especially in tight spaces.

- Crimping Tool: If your connector requires crimping, this tool ensures a firm and even connection.

- Multimeter: Always test your connections for continuity and correct polarity.

- Cutting Tool: Use a sharp cutter or scissors to trim the FFC to the required length.

- ESD Wrist Strap: Wear this to prevent static discharge, which can damage sensitive electronics.

Tip: Keep your workspace clean and organized. This reduces the chance of losing small parts or making mistakes during installation.

Materials Checklist

You need to select the right materials for a successful installation. YLS FFCs use high-quality components to ensure durability and performance. Here is a quick overview:

| Component | Common Materials |

|---|---|

| Conductors | Copper, Aluminum |

| Insulation | Polyester (PET), Polyimide (PI), PVC, Teflon (PTFE) |

For insulation, you may encounter several options:

- PVC: Offers high flexibility and resists heat, chemicals, and moisture.

- XLPE: Provides excellent durability and handles heat well.

- Silicone Rubber: Bends easily and works in extreme temperatures.

- TPE: Maintains strength and resists scratches and chemicals.

Choose materials that match your application. For example, use silicone rubber for environments with high temperature changes. Select PET or PVC for general electronics. Always check the cable and connector specifications before installation.

Preparation for Flat Wire Connector Installation

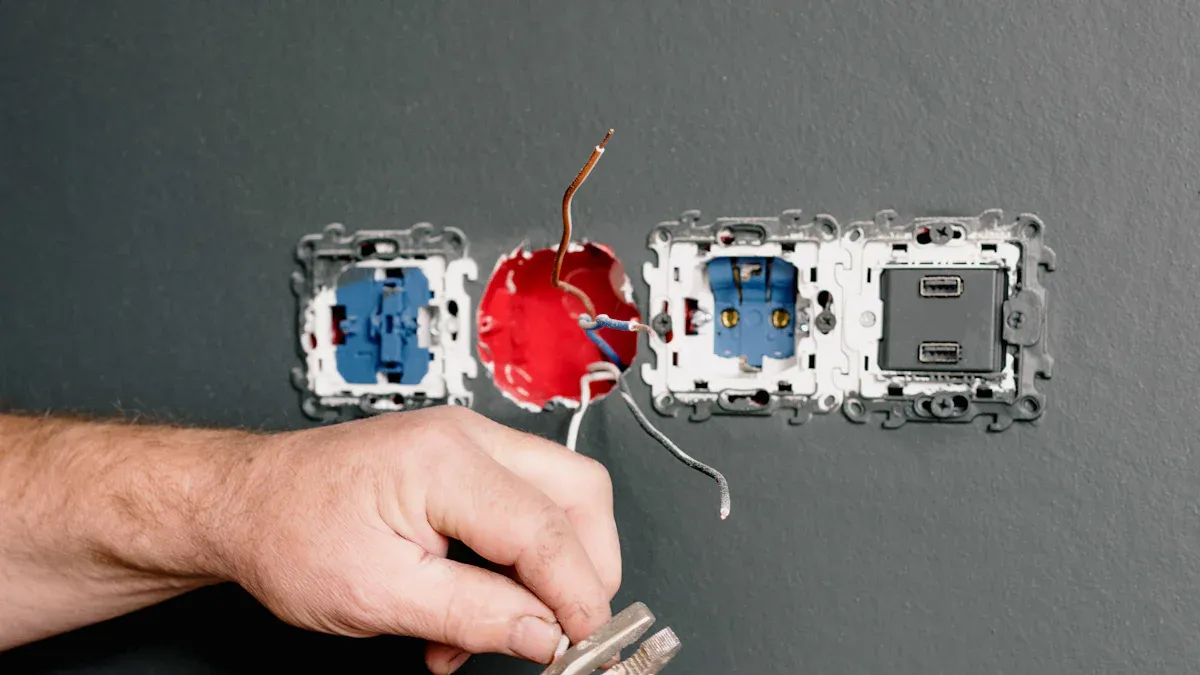

Safety Steps

Before you start working with flat wire connectors, you must focus on safety. You protect yourself and your equipment when you follow the right steps. Many accidents happen because people skip basic safety checks. Take a few minutes to prepare and you can avoid most hazards.

- Shut off the power at the circuit breaker before you touch any wires.

- Wear rubber gloves and safety glasses to guard against electrical hazards.

- Use a non-contact voltage tester to make sure no electricity flows through the wires.

- Gather all your tools, such as wire strippers and voltage testers, before you begin.

- Keep your workspace clean and organized to prevent accidents.

Tip: Always double-check that the power is off. Even a small mistake can lead to serious injury.

You should also wear protective clothing to shield your body from sparks or debris. Always test wires before you handle them. If you skip these steps, you risk injury or damage to your project. Safety must come first every time you work with electrical systems.

Cable Inspection

Careful inspection of your YLS Flexible Flat Cable (FFC) ensures a reliable connection. You want to catch any problems before installation. Follow these steps to prepare your cable:

- Check the ends of the FFC for straightness and cleanliness. If you see damage or fraying, trim the cable.

- Strip the insulation to the correct length. This step helps you make good contact with the connector.

- Align the cable with the connector slot. Make sure the metal lines match the contacts inside.

- Slide the cable gently into the connector. Avoid using too much force, which can damage the wires.

- Inspect the connection. The cable should sit straight and fit snugly in the connector.

Note: Replace any cable that shows signs of wear or damage. Damaged cables can cause poor connections or even create safety risks.

You should also measure and cut the cable to the right length, leaving enough slack for routing. A clean and organized work area helps you avoid mistakes. When you follow these steps, you set the stage for a safe and successful installation.

Flat Wire Connector Installation Steps

Installing a flat wire connector with YLS Flexible Flat Cable (FFC) requires careful attention to detail. You want to ensure a secure connection that will last. Follow these steps for a smooth installation process and reliable performance.

Strip the Cable

Start the installation by preparing the cable ends. Proper installation begins with clean, undamaged conductors. Use these steps to strip your YLS FFC safely:

- Place the FFC on a flat, stable surface.

- Remove insulation from only one side. YLS FFCs have two layers held together by adhesive.

- Use a sharp scalpel to cut away the insulation. Peel it gently from the other side, taking care not to damage the copper conductors.

- Clean any adhesive residue from the exposed copper with white spirit. Do not remove the adhesive that holds the copper to the insulation.

- Attach a layer of Kapton tape or similar tape to the insulated side. This helps the cable fit snugly in the connector slot.

- Inspect the stripped end. The copper should look clean and flat, with no fraying or lifted traces.

Tip: Avoid sharp bends or twists during this step. Bending the cable sharply can break the conductors or weaken the insulation.

Attach the Connector

Now you can attach the flat wire connector. This part of the installation process requires precision and patience. Follow these guidelines for best results:

- Align the stripped end of the FFC with the connector slot. Make sure the copper lines match the contacts inside the connector.

- Insert the cable gently. Do not force it. The copper conductors should slide in smoothly without crumpling or peeling away.

- Engage the locking mechanism. Many connectors use a locking bar or tang. Push or flip the lock into place to secure the cable.

- If your connector uses a Zero Insertion Force (ZIF) socket, insert the cable fully, then close the locking bar to hold it.

- For extra protection, you can apply acid-free RTV to reinforce the mechanical fixing between the cable and connector.

Always check the insertion direction. The copper contacts must face the correct way to ensure a good electrical connection.

Handle the connectors with care. Avoid overtightening screws or clamps. Too much force can damage the cable or the connector housing. Store unused connectors in a dry, cool place to maintain their quality.

Secure and Test

Securing and testing your flat wire connector ensures long-term reliability. You want to confirm that your installation process created a strong, safe connection.

- Use the locking mechanism on the connector. This prevents accidental unplugging and keeps the cable stable.

- Perform a tug test. Gently pull on the cable to check if it stays in place. If the cable comes loose, reattach it and check the lock.

- Limit unnecessary plugging and unplugging. Frequent use can wear out connectors not rated for high mating cycles.

- Use protective ribs or cable guides if available. These features add support and reduce strain on the cable.

After securing the connector, test the connection:

- Connect the cable to a test fixture for electrical checks.

- Use a multimeter to verify each conductor for continuity and correct polarity.

- Perform a high-pot test to check insulation integrity.

- Measure contact resistance to find any weak spots.

- Check the pitch consistency along the cable.

Note: High-quality connectors and careful installation improve system performance and reduce the risk of failure.

By following these steps, you achieve ease of installation and ensure your flat wire connector works reliably in your application. Always double-check your work for safety and performance.

Wire Connectors: Mistakes & Fixes

Common Errors

When you install wire connectors, you may run into some common mistakes. These errors can cause connection failures or even damage your equipment. Knowing what to avoid helps you create safe and reliable connections every time.

Here is a table showing frequent mistakes and their possible consequences:

| Mistake | Consequence |

|---|---|

| Stripping With a Knife or Boxcutter | May accidentally cut through both insulation and inner conductor, leading to connection failure. |

| Using the Wrong Size Connectors | Too big may fail to create a complete circuit; too small may not fit, causing connection issues. |

| Overtwisting Winged Connectors | Can damage the wires, leading to potential connection failures. |

| Stripping Away Too Much Insulation | Exposed conductor outside the connector may lead to safety hazards and connection failures. |

You should also watch for issues like insulation degradation or conductor fatigue. High temperatures or repeated bending can weaken the insulation on your wire connectors. If you route cables with sharp bends, you may stress the copper wires, causing them to break over time. Fatigue in the transmission wires can lead to signal problems, especially if the shielding layer breaks down.

Tip: Always use the correct size and type of wire connectors for your project. Plan your cable routing to avoid sharp bends and reduce stress on the connectors.

Troubleshooting

If your wire connectors do not work after installation, you can follow a step-by-step process to find and fix the problem. Start by checking the orientation of the cable. Make sure the pink stripe and label face the correct direction. The connector’s tongue should also point the right way.

Follow these troubleshooting steps:

- Ensure the pink stripe and label are correctly oriented on the cable.

- Verify the connector’s tongue faces the correct direction during installation.

- Check that the cable is securely inserted into the connector and that the connector is crimped properly.

- Confirm the cable is wrapped and secured correctly at the back of the connector.

- Perform a final check to ensure all wire connectors are secure before powering on the device.

If you still have issues, inspect the connections for loose wires. Use a multimeter to check for voltage and continuity. Label each wire clearly to avoid confusion. Follow standard color codes to prevent polarity errors. Always perform a final inspection before turning on the power.

You can also fix common problems by planning your cable routing, using cable ties to keep wire connectors organized, and choosing only compatible connectors. Avoid overloading outputs and keep your connectors clean by removing debris with canned air.

Note: Secure connections and regular inspections help prevent most failures in wire connectors. Take your time and double-check your work for the best results.

You can achieve reliable flat wire connector installations by following each step with care. Always focus on safety, use the right tools, and double-check your connections for proper orientation. This helps prevent misalignment and connection failures.

- Proper orientation ensures strong connections.

- Misalignment may cause incomplete crimps.

- Using quality tools improves results.

YLS offers support and customization to help you succeed:

| Service Type | Description |

|---|---|

| Technical Consultations | Get expert advice for your flat wire connector needs. |

| Custom Flat Flexible Cables | Request cables tailored to your specifications. |

| Flexible Flat Cable Configurator | Use a tool to design cables for your requirements. |

For complex projects, consider professional help to ensure safety and performance.

FAQ

What are the most common types of wire connectors for flat cables?

You will find several types of wire connectors for flat cables. These include IDC, ZIF, and crimp connectors. Each type supports different wire sizes and applications. You should choose based on your project’s electrical needs and the number of wire conductors.

How do I ensure proper insulation and safety standards during installation?

You must check that each wire has full insulation. Always follow insulation and safety standards. Inspect the cable for damage. Use only approved electrical connectors. Test each wire connection before powering your device. This keeps your electrical system safe.

Can I reuse flat wire connectors after removal?

You can reuse some wire connectors if they remain undamaged. Always inspect each wire and connector for wear. Replace any connector that shows signs of stress or electrical failure. Reusing damaged connectors can cause electrical problems or wire faults.

Why does my wire connection fail after installation?

Wire connection failure often happens due to poor contact, incorrect insertion, or damaged insulation. You should check each wire for proper alignment. Test the electrical connection with a multimeter. Replace any wire or connector that does not meet electrical standards.

How do I test the electrical performance of my wire connectors?

You can use a multimeter to check each wire for continuity. Test for correct voltage and polarity. Inspect the insulation for any damage. Always verify that each wire meets electrical requirements. This ensures your wire connectors work safely and reliably.