Telecom & RF FFC Cable Solutions for Reliable Signal Transmission

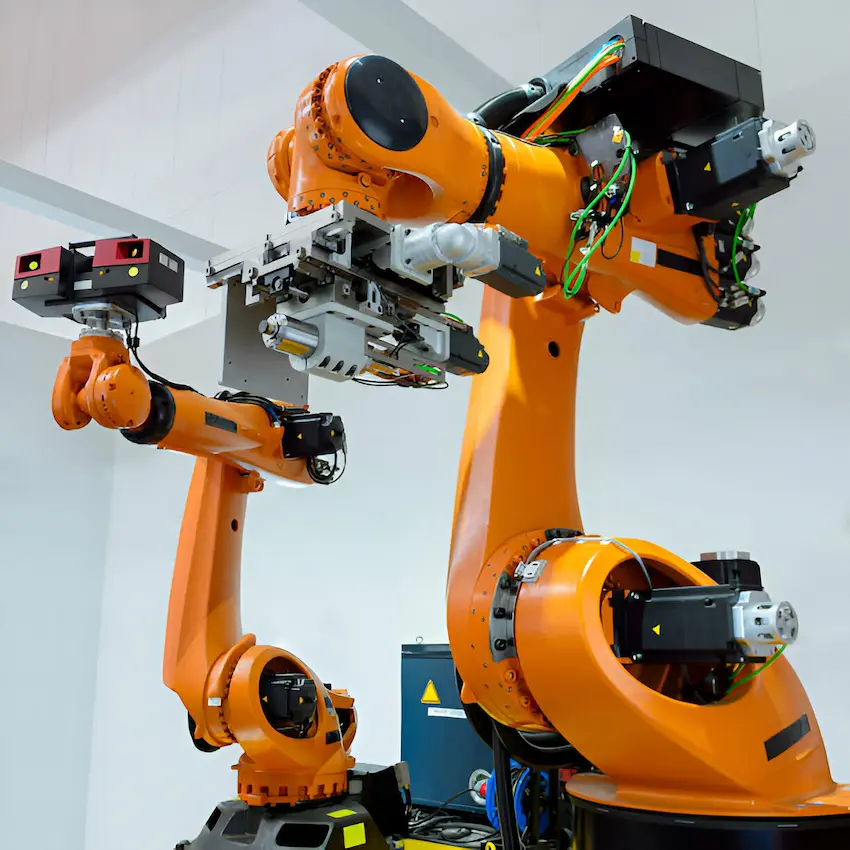

From 5G antennas and routers to fiber transceivers and base station interconnects, YLS provides telecom-grade flat flexible cables with proven signal reliability. Our shielded and impedance-optimized FFC solutions are designed for high-density, low-noise communication systems that demand performance and precision.

Telecom & RF Industry Overview

Modern telecom infrastructure—whether fiber, wireless, or satellite—relies on precise, low-loss interconnects between modules. From compact 5G radio units to optical transceivers and RF boards, FFC cables play a critical role in enabling high-speed signal routing within tight spaces. Their flexibility, EMI resistance, and impedance consistency make them ideal for antenna signal chains, small-form-factor devices, and high-density PCBs.

Where Our FFC Cables Fit in Your Telecom & RF Architecture

Telecom & RF FFC cables are essential for high-speed, low-interference data transmission across tightly packed electronic systems. These cables are commonly used in base stations, 5G antenna units, fiber optic modules, RF transceivers, and satellite communication boards—where controlled impedance, compact design, and EMI shielding are critical.

RF Board Interconnect FFC

For signal links between TX/RX module, baseband, RF transceiver.

5G Antenna Unit FFC

Used inside AAUs for beamforming, clock signal and digital I/O transmission.

SFP / QSFP Module Wiring

EMI-optimized FFC for LVDS, SerDes, and signal integrity between optical transceivers and boards.

Router & Gateway Internal Links

Connect SoC, RF switch, and Wi-Fi module in compact network gear.

SATCOM & Microwave Systems

Low-noise FFC with foldable routing for RF to baseband interfaces.

Filter & Duplexer Module FFC

Used inside shielding enclosures, with tight bend and space control.

Common Wiring Challenges in Telecom & RF —Solved with FFC

Struggling to fit wiring in a sleek product enclosure?

Our ultra-thin, pre-folded FFCs route cleanly around tight corners and components where round wires won't.

Getting signal noise in a dense Wi-Fi/Bluetooth environment?

We offer shielded, impedance-controlled FFCs to protect sensitive data streams for displays, sensors, and cameras.

Production line complaining about assembly time and errors?

We add features like alignment notches, connector labels, and reinforced stiffeners to make installation fast and foolproof.

Worried about heat and safety in a sealed, always-on device?

Our cables use UL-rated, high-temperature materials designed for thermal stability and safety in enclosed electronics.

Chat with us now for your Custom needs. Chat on WhatsApp Now

Technical Capabilities

FFC Cable Specs for Smart Home

- Optimized Differential Layout — Precisely routed signal-ground pairs minimize skew in high-speed lines.

- TDR-Verified Integrity — All impedance designs are validated by TDR for signal reliability.

- High-Frequency Ready — Supports USB 3.1, MIPI, SerDes, and RF lines without signal loss.

- Connector-Compatible Ends — Cable ends tailored for SFP+, RF sockets, and board-to-board links.

- RF-Tuned Conductors — Use of RA copper or silver-coated wires ensures GHz-level performance.

- Rugged for Telecom Use — Reinforced structures resist vibration and outdoor environmental stress.

Quick Spec Summary:

| Capability | Specification / Description |

|---|---|

| Differential Impedance Tolerance | 85Ω / 100Ω ±8%, tested with TDR for high-speed signal lines |

| Signal Transmission Speed | Up to 12 Gbps per pair (depends on cable design & structure) |

| Shielding Options | Multi-layer shielding: aluminum foil + braided mesh + drain wire |

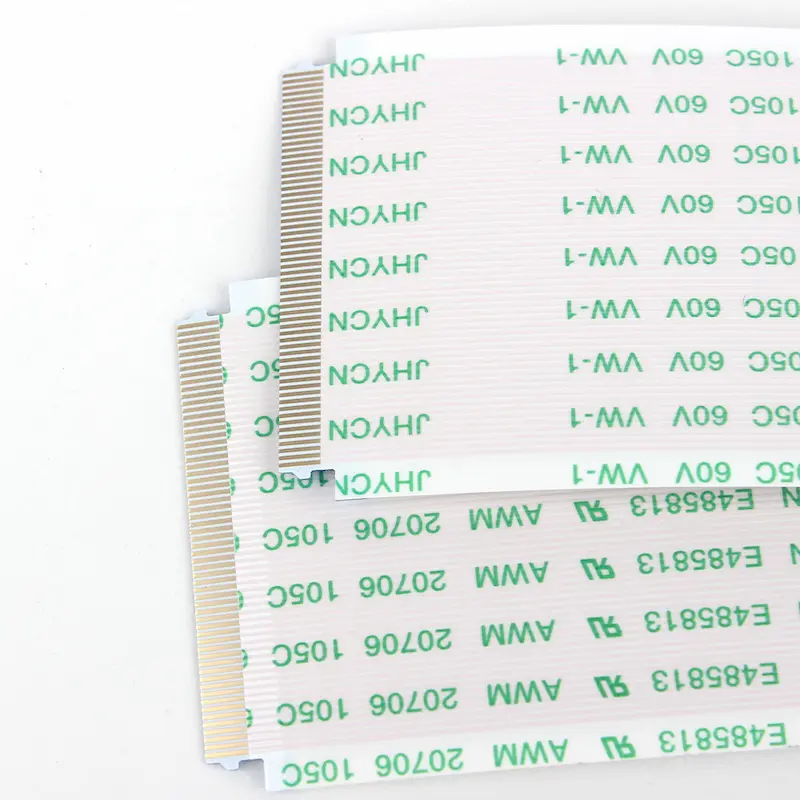

| Conductor Type | Rolled annealed copper or silver-plated copper for RF lines |

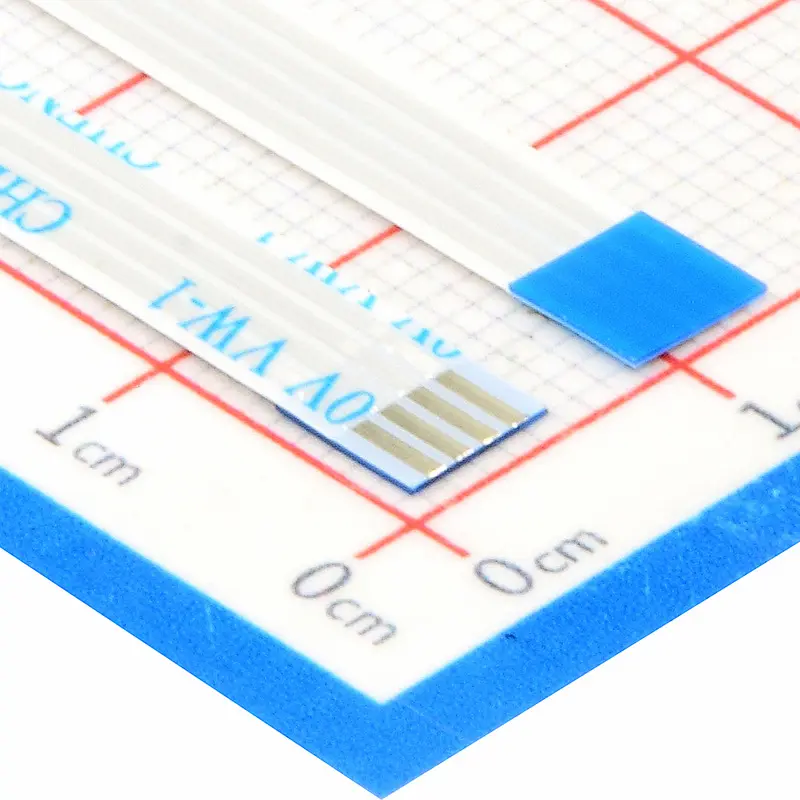

| Pitch Range | 0.3 mm / 0.5 mm / 0.8 mm / 1.0 mm (customizable for impedance control) |

| Cable Thickness | 0.08 mm – 0.25 mm (including shielded variants) |

| Contact Plating | Tin, nickel, or gold plating; optional pre-tinned end for better soldering performance |

| Connector Compatibility | Supports ZIF / LIF, SFP+, QSFP, high-frequency board-to-board sockets |

| End Folding / Shield Return | Shield fold-back or EMI tab folding supported for noise return path |

| Operating Temperature Range | -30°C to +105°C for telecom outdoor/indoor routing |

| Length & Tolerance | Custom length with ±0.5 mm tolerance; exposed length ±0.15 mm |

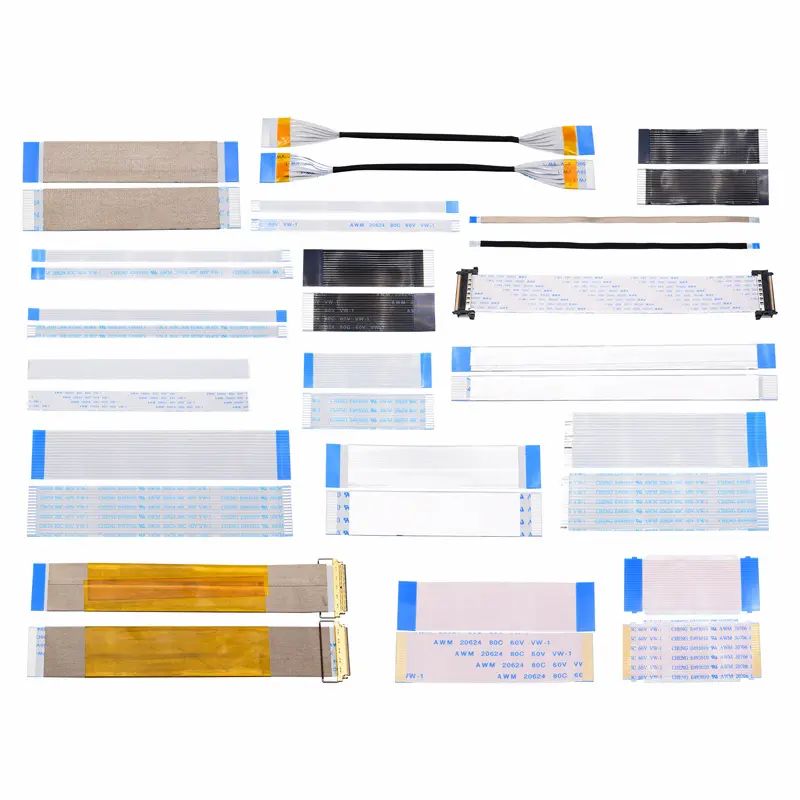

Custom Ribbon Cable Capabilities — Built to Your Specs

Your application may require more than just a standard pitch or length. That’s why we offer complete customization on all critical parameters — so your ribbon cable fits perfectly, functions reliably, and installs easily.

Whether you need just 50 pieces for a prototype or 50,000 for production, we can deliver with speed and precision.

1. Pitch & Conductor Configuration

Design the spacing and layout that fit your device’s constraints.

- Available pitches: 0.4mm / 0.5mm / 0.8mm / 1.0mm / 1.25mm

- 4 to 96 conductors

- Symmetrical or custom pin-out

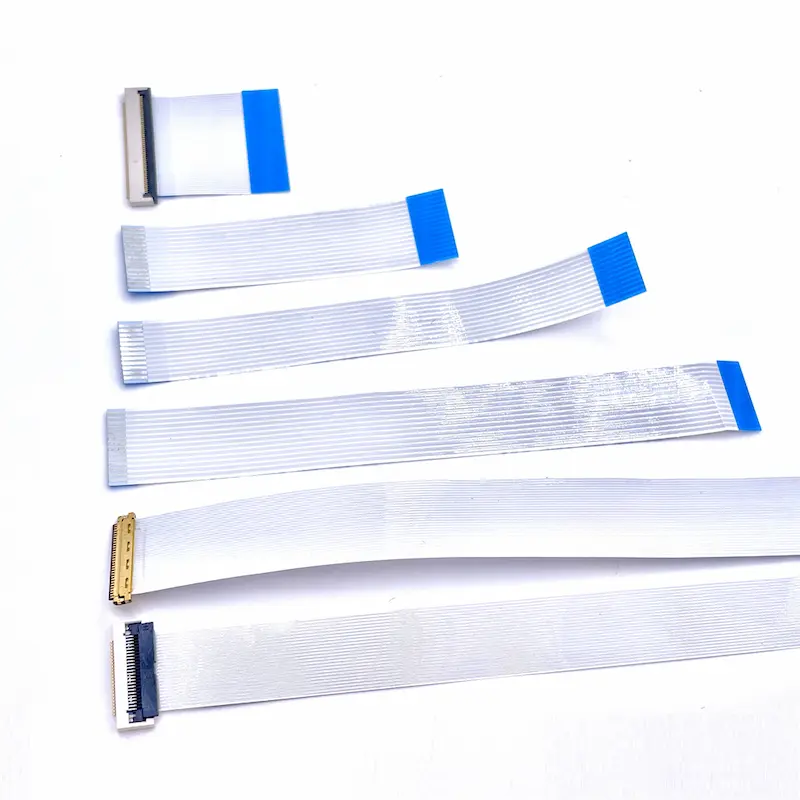

2. Cable Length & Shape

Adapt the cable to your layout without compromising space.

- Lengths from 30mm to 1000mm+

- Straight, L-shape, Z-fold, or multi-branch

- Fold lines pre-creased for easy routing

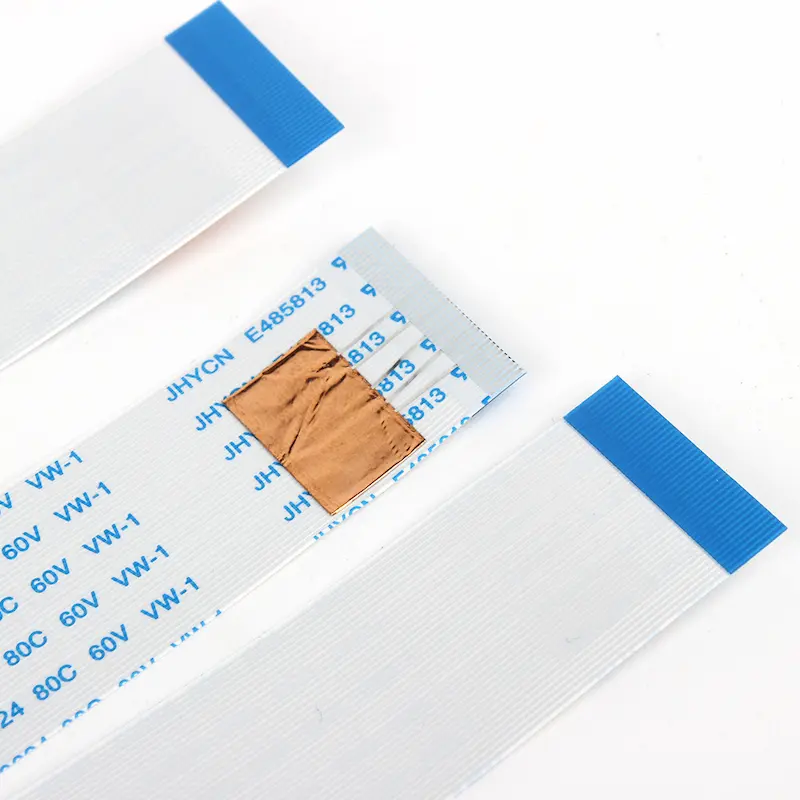

3. End Termination Options

Seamless integration with your connectors or boards.

- Tinned or gold-flashed bare ends

- PET/PI stiffeners for ZIF sockets

- Solder tail, FPC-style, or custom header connector

4. Shielding & EMI Control

Protect signal integrity in sensitive environments.

- Aluminum foil or mesh shielding

- Ground tail or drain wire

- Optional double-shielded design

5. Surface & Insulation Customization

Improve durability, appearance, and signal performance.

- PET or PI insulation

- Conductor surface: tin-plated, bare copper, or gold

- Optional heat-resistant or flame-retardant materials

6. Punching & Mechanical Modifications

Built to fit into housings and tight enclosures.

- Punch holes, slots, notches for mounting

- Fold lines for compact 3D routing

- Peel tabs or extended tails

7. Labeling & Traceability

Simplify installation, QC, and inventory tracking.

- QR code / barcode / serial ID

- Printed position marks, logos, or terminal IDs

- Laser or ink marking options

8. Packaging Options

Fit your assembly line or ESD protocol.

- Bulk bag, tray, coil, or tape & reel

- Anti-static or moisture-proof packaging

- Custom labels or part numbers

Not sure which specs to choose? Our engineering team is ready to help. Ask an Engineer

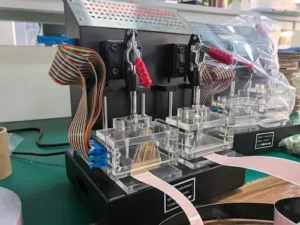

Custom FFC Cable Workflow

At YLS, we simplify the path from idea to production. Whether you’re upgrading a product or building something new, our six-step process ensures speed, accuracy, and full customization for your flat flexible cable solution.

🧩 Step 1: Project Kick-off

Tell us about your needs: cable pitch, pin count, length, connectors, UL specs, shielding, fold lines—our team starts with the details that matter.

📐 Step 2: Engineering Proposal

We translate your specs into manufacturable designs. Expect drawing files and connector matching within 24–48 hours.

🧪 Step 3: Sample Fabrication

Once drawings are approved, we build samples in 3–5 working days, including precision cutting, labeling, and insulation options.

🧷 Step 4: Testing & Validation

You verify the sample in your device. We assist with adjustments, feedback loops, or connector matching as needed.

🔁 Step 5: Final Sign-off

Once the prototype is approved, we lock the design, confirm packaging and delivery terms, and prepare for production.

🚛 Step 6: Mass Production & Global Delivery

We initiate volume production and ship on time via express, air, or sea—wherever your facility is.

✨ Optional Add-ons:

Fold lines or pre-bent shaping

Custom labels or barcodes

Hole punching, notching, peel-tab finishing

Shielding and grounding features

Special packing and reel packaging options

Technical support for connector sourcing

ABOUT YLS

Reliable FFC cables factory integrated services

Yulian is a direct manufacturer of flat flexible cables (FFC), delivering precision wiring solutions trusted by global OEMs. With in-house tooling, rapid prototyping, and full customization capabilities, we help you go from concept to cable—fast, reliable, and to your spec.

We offer pitch options from 0.4mm to 1.25mm and core counts up to 96, with full support for folding, shielding, notching, punching, labeling, and custom assembly.

- Ultra-Fine Pitch, High Pin Count

- 48-Hour Custom Sample Delivery

- Foldable & Shielded Cable Options

- Expert Support for Complex Wiring

- ISO/IATF Certified Manufacturing

- 100% Electrical QC Before Shipment

- Low MOQ, Fast Turnaround

- 10+ Years Across Key Industries

Frequently Asked Questions

What makes your FFC cables suitable for high-frequency RF and telecom applications?

Our FFCs are engineered with precise impedance control, EMI shielding layers, and RF-compatible materials to ensure signal integrity at high frequencies.

Can you support customized impedance values for differential pairs?

Yes, we provide tailored impedance (e.g., 85Ω, 100Ω, 110Ω) based on your signal protocol requirements and validate each design using TDR testing.

What is the maximum data rate your RF/telecom FFCs can support?

Our high-speed FFCs can support data rates up to 10+ Gbps, compatible with USB 3.1, MIPI D-PHY/C-PHY, and SerDes interfaces.

Do your cables support both signal and power transmission in telecom modules?

Yes, we offer hybrid FFC designs that combine high-frequency signal pairs and power lines in a single flat cable structure.

What connectors can your RF & telecom FFCs be terminated with?

We support SFP/SFP+ sockets, micro coaxial connectors, and custom ZIF/FPC-compatible terminations to fit your module or board layout.

What’s your typical lead time for RF/telecom FFC prototypes and mass production?

Prototypes can be ready in 7–10 days, and standard production orders are shipped within 2–3 weeks depending on complexity and volume.

Chat with us now for your Custom needs. Chat on WhatsApp Now

More Solutions

Let’s Build Your Ideal FFC Cable — Fast Response Guaranteed

Whether it’s for foldable drones, camera gimbals, or onboard computing—our FFC solutions are designed to fly. Tell us what you need—we’ll build it.