You often see flat wire cables in modern electronics and industry. A cable flat wire features a flat, oval cross-section with several insulated conductors—usually solid copper—inside a flexible, flame-retardant jacket. This design saves space and improves heat dissipation.

The global market for flat wire continues to grow, with values projected to reach over $3 million by 2030.

YLS, a trusted leader, offers Flexible Flat Cable (FFC) solutions that help you achieve reliable, compact, and efficient connections for your projects.

| Characteristic | Description |

|---|---|

| Space-saving design | Flat cables use less space than round cables. |

| Flexibility | They bend easily for tight installations. |

Key Takeaways

- Flat wire cables save space and fit easily into tight areas, making them ideal for modern electronics and compact installations.

- The flexibility of flat wire allows for easy bending and routing, perfect for applications that require frequent movement or tight bends.

- Durability is a key feature of flat wire, as it resists abrasion, cold, and high temperatures, ensuring reliable performance in tough environments.

- Customization options for flat wire cables include length, pitch, and shielding, allowing you to tailor solutions for specific project needs.

- Flat wire cables enhance heat dissipation and reduce weight, making them a smart choice for automotive, medical, and aerospace applications.

Cable Flat Wire Overview

What Is Flat Wire?

You encounter flat wire in many modern devices. This type of wire has a rectangular cross-section, which helps it fit into small spaces and maintain consistent electrical qualities. You see flat wire used in electronics, automotive systems, medical devices, construction, and aerospace. The design makes it ideal for applications where space and reliability matter most.

Here is a quick comparison of how flat wire is defined and used across industries:

| Definition/Application | Description |

|---|---|

| Definition | Flat wire is characterized by its rectangular cross-section, offering advantages over round wire, such as fitting into small spaces and providing consistent electrical qualities. |

| Electronics | Used in transformers and inductors for efficient power flow and heat dissipation. |

| Automotive | Employed in electrical systems for flexibility and durability. |

| Medical Devices | Utilized in devices requiring precision and reliability, like catheters and stents. |

| Construction | Important for reinforcing structures and connections. |

| Aerospace | Used where weight and space are critical. |

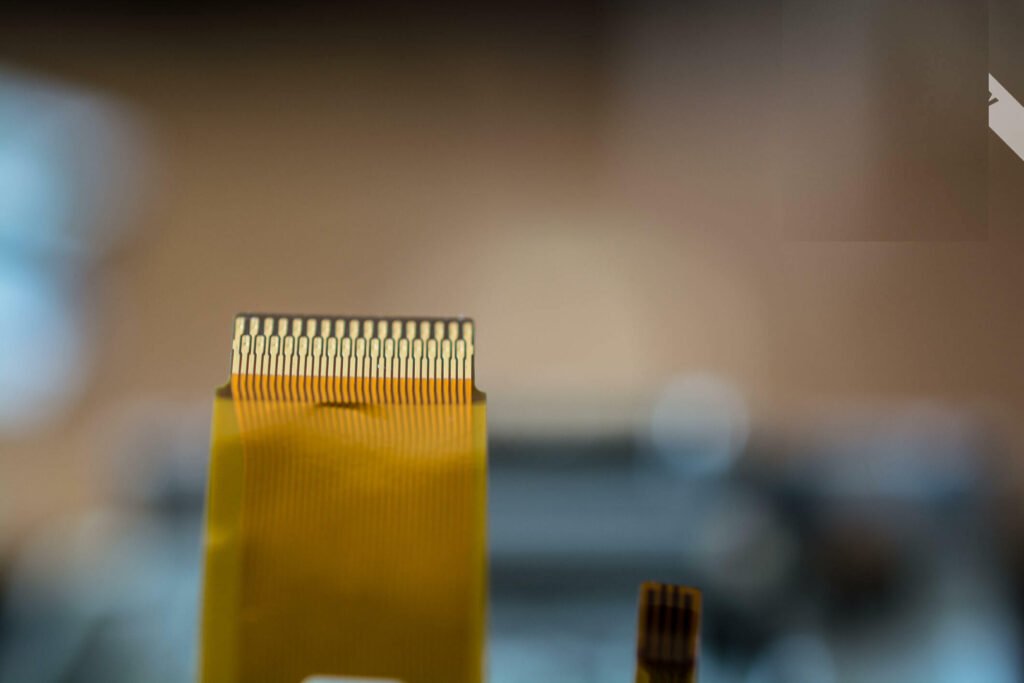

YLS’s Flexible Flat Cable (FFC) stands out as a prime example. You can use it for basic tasks like linking printer heads or displays. The thin, flat strips of metal in a flexible plastic film make it easy to install and manage.

Structure and Materials

You notice that cable flat wire features conductors arranged in a flat, parallel configuration. Manufacturers use materials like hot-pressed copper for the conductors and PET film for insulation. This structure gives you a thin, flexible cable that works well in tight spaces or high-density wiring setups.

Common materials in flat cable assemblies include:

| Material Type | Description |

|---|---|

| Hot-pressed copper | Used for conductors, provides excellent electrical performance. |

| PET film | Durable and flexible insulation, resists heat and chemicals. |

| PVC | Common insulation material used in flat cables. |

| Shielding | Reduces signal interference, important for sensitive applications. |

You benefit from this design because it allows for easy stacking and efficient use of space. Flat cable assemblies often include features like shielding and folding, which help you customize the cable for your specific needs.

Key Features

Flat wire offers several unique characteristics that make it popular for high-density wiring. You get a lightweight cable with strong toughness and resistance to heat, cold, acid, and alkali. The wires inside are arranged in rows, which helps with organization and reliability.

Here are some key features you should know:

- Reliability: Parallel conductor geometry reduces wiring errors and ensures proper contact assignment.

- Weight Reduction: Eliminates redundant insulating materials, making the cable lighter.

- Space Efficiency: Low profile and rectangular shape allow for efficient stacking and minimal wasted space.

- Flexibility: Extremely flexible, suitable for continuous bending in dynamic applications.

- Strength: Conductors and insulation share tensile loads, enhancing durability.

- Consistent Electrical Characteristics: Fixed conductor spacing ensures stable electrical properties.

- Current Carrying Capacity: Improved heat dissipation allows for higher current levels.

- Reduced Skewing Effects: Exact physical and electrical lengths minimize signal delays.

- High-Density Interconnections: Superior cabling density compared to conventional cables.

- Ease of Handling: Easy to handle and install, conforms to mounting areas.

You see these features in YLS’s FFC products. The slim profile and flexible design make cable flat wire perfect for high-density routing. You can use flat cable assemblies in portable devices, display connections, and compact installations. The lightweight nature and adaptability of flat wire help you achieve reliable and efficient connections in your projects.

Tip: When you need a cable that bends easily and fits into tight spaces, choose flat cable assembly for your next design.

Flat wire gives you the flexibility and compactness that traditional round cables cannot match. You save space, reduce weight, and simplify installation with flat cable assemblies.

Flat Wire Applications

Electronics and Robotics

You see flat wire used everywhere in electronics and robotics. This type of cable helps you connect components in tight spaces and supports high-density wiring. In modern electronics, you often rely on flat cable assemblies for display connections, printer heads, and internal device wiring. Robotics systems use flat wire to handle repetitive motion and tight bends, especially in robotic arms and joints.

Here are some of the most common uses for flat wire in these fields:

- Automotive dashboards use flat cable assemblies to route wiring through confined spaces, supporting screens, controls, and sensors.

- Robotics joints depend on flat wire for high cycles of bending and movement.

- Aerospace panels benefit from flat cable assemblies to reduce weight and maximize reliability.

- Medical devices use flat wire for connecting imaging equipment and surgical tools.

- Telecommunications centers use flat wire to streamline wiring and improve signal performance.

YLS Flexible Flat Cable (FFC) stands out in these applications. You can customize the cable for your specific robot design or electronic device. The table below shows how YLS FFC adapts to different needs in electronics and robotics:

| Feature | Description |

|---|---|

| Custom Solutions | You can order FFC cables with exact specifications for your robot or device. |

| High Durability | Rated for up to 5 million bending cycles, perfect for moving parts. |

| Flexibility in Design | Ultra-thin and flexible, ideal for tight bends and dynamic joints. |

| EMI Shielding | Options for single or double-sided shielding to protect data signals. |

| Application Versatility | Suitable for industrial robots, cobots, and medical robotics. |

Tip: When you need a cable that bends and flexes without breaking, choose a flat cable assembly for your next robotics or electronics project.

Automotive and Medical

You find flat wire in many automotive and medical devices. In cars, cable flat wire connects electronic components quickly and saves space. This design reduces running noise and allows for smooth movement of parts. You see ribbon wire in infotainment systems, sensor connections, and advanced driver assistance systems (ADAS). These cables help you route wiring flexibly and keep the vehicle interior organized.

In the medical field, flat wire plays a vital role in devices that require both support and flexibility. You see it in stents, catheters, and neurovascular devices. Medical imaging equipment and surgical tools also use ribbon wire for precise and reliable connections. Flat wire supports portable diagnostics and enhances the reliability of compact medical devices like pacemakers.

Here are some real-world examples:

- Flat wire is used in compact, flexible medical devices such as pacemakers and imaging equipment.

- It supports portable diagnostics, improving biocompatibility and reliability.

- Flexible flat cables are found in automotive infotainment systems and sensor connections.

- They are critical for ADAS, allowing flexible routing and reducing wiring clutter.

| Industry | Primary Uses |

|---|---|

| Automotive | Fast, space-saving connections for electronic components, reducing noise. |

| Medical | Used in stents, catheters, and neurovascular devices for support and flexibility. |

Note: You can rely on ribbon wire for both safety and performance in demanding automotive and medical environments.

Home and Office

You also use flat wire in home and office settings. Cable flat wire is perfect for in-wall, under-floor, and ceiling installations. You often see it in lighting circuits, power outlets, and small appliances. In offices, ribbon wire powers lighting systems, computers, and other equipment. The slim profile of ribbon wire makes it easy to route under carpets or along walls, creating a clean and organized workspace.

Flat cable assemblies offer several advantages in these environments:

- Flexibility: You can bend and adapt the cable around corners and tight spaces.

- Ease of Installation: The slim design allows for simple routing and a tidy setup.

- Visual Appeal: Flat wire helps you maintain a neat and professional look in your home or office.

| Application Type | Typical Uses |

|---|---|

| Residential Wiring | In-wall, under-floor, and ceiling installations for lighting and outlets. |

| Commercial Applications | Internal wiring in offices and retail spaces, enhancing safety. |

| Light Industrial Projects | Wiring for small-scale industrial equipment, ensuring reliable performance. |

Callout: Choose ribbon wire when you want a safe, flexible, and visually appealing solution for your home or office wiring needs.

You can see how flat wire, cable flat wire, and ribbon wire provide solutions across many industries. Whether you work in electronics, robotics, automotive, medical, or manage a home or office, you benefit from the flexibility, reliability, and space-saving features of flat cable assemblies.

Flat Wire Advantages

Space Saving

You often choose flat wire because it saves space where every millimeter counts. The flat shape lets you fit cables into tight areas, making them perfect for home and office setups. You can run lines parallel to each other without tangling or wasting room. This design helps you manage cables more easily, especially in crowded panels or compact devices.

- Flat cables save space and fit easily in tight areas, making them ideal for home and office setups.

- Flat cables can be easier to manage in scenarios where space is limited or when lines need to run parallel to each other.

You also gain measurable benefits from this space-saving feature. The table below shows how flat wire can help you work faster and save money during installation:

| Benefit | Description |

|---|---|

| Time Savings | 86% time savings over screw clamp technology during installation. |

| Installation Efficiency | Tool-free and one-handed operation minimizes human error and speeds up the installation process. |

| Cost Savings | Faster connections lead to reduced labor costs in panel building and installation processes. |

Flexibility

Flat wire stands out for its flexibility. You can bend it around corners, fold it for tight routing, and use it in dynamic applications where movement happens often. The flat design spreads out mechanical stress, so the cable lasts longer even when you bend it many times. You can meet tighter bending radius requirements, which is important for complex cable routing.

- The flat design enhances space efficiency, allowing you to fit cables where round ones cannot.

- Flat cables have superior bending characteristics, distributing stress evenly and reducing the risk of fatigue.

- This design allows for tighter bends, ensuring both electrical continuity and mechanical strength.

YLS Flexible Flat Cable (FFC) offers you even more flexibility. You can customize the length, pitch, and even add pre-folded designs for your specific needs. Shielding options protect your signals from noise, and custom labels make installation easier.

Durability

You rely on flat wire for its strength and durability, especially in tough environments. Industrial tests show that high-quality flat cable assemblies resist abrasion, cold, crushing, and high temperatures better than many commercial-grade cables. The chart below compares commercial and industrial grade flat wire cable durability in several tests:

The table below highlights some of these results:

| Test Type | Commercial Grade Result | Industrial Grade Result |

|---|---|---|

| Abrasion | Conductors visible through breaks in the jacket | No compromise in conductor pairs |

| Cold Bend | Visible cracks at -80°C, -60°C, and -40°C | No visible damage at all temperatures |

| Crushing | Failed at 400 lbs | Failed at 2,250 lbs |

| High Temperature | Attenuation increased at +60°C | Supported maximum run distance even at +60°C |

YLS FFC gives you more options to boost durability. You can select vibration-resistant and EMI-shielded cables for noisy environments, ISO-grade materials for medical safety, and heat-resistant designs for high-temperature use. Fast prototyping lets you test new flat cable assembly formats quickly, so you always get the right fit for your project.

Tip: When you need a cable that saves space, bends easily, and stands up to tough conditions, flat cable assemblies give you the edge.

Flat Wire vs. Ribbon Cable

Key Differences

You often see flat wire and ribbon wire used in similar environments, but they have important differences. Flat wire usually means a single flattened conductor, while ribbon wire contains multiple parallel conductors arranged side by side. You use flat conductor cable when you need high flexibility and a small bending radius. Ribbon wire works best when you want organized connections in compact spaces.

Here is a table that highlights the main differences:

| Feature | Flat Wire | Ribbon Wire |

|---|---|---|

| Physical Structure | Single flattened conductor | Multiple parallel conductors |

| Applications | High flexibility applications | Organized connections in compact spaces |

| Flexibility and Bending | Greater flexibility, tight bends | Less flexible, keeps connections neat |

| Space and Efficiency | Fits in narrow spaces, ideal for winding | Keeps multiple connections in order |

You also compare flat cable assemblies to round cables. Flat cable assemblies offer easier installation and better thermal efficiency. Round cables provide more durability in harsh environments and superior electrical performance for some uses.

| Feature | Flat Cables | Round Cables |

|---|---|---|

| Electrical Performance | Designed for mass termination | Superior, more protective |

| Current Carrying Capacity | Better thermal efficiency | Lower than flat cables |

| Flexibility | Adapts to various shapes | Less flexible, bends in multiple directions |

| Installation | Easier, mass termination | More complex, needs precision |

| Maintenance | Needs precision construction | Easier in harsh environments |

Tip: You should choose flat cable assemblies when you need space-saving routing and flexibility. Ribbon wire is best for keeping multiple connections organized.

Choosing the Right Type

You need to consider several factors before selecting the right cable for your project. Flexibility is important if your installation requires tight bends or movement. Pitch, or the spacing between conductors, affects how well the cable fits your system. Temperature tolerance matters for environments with extreme heat or cold. Customizability lets you tailor cables for specific needs, such as adding shielding or choosing connector types. Application suitability ensures you get the best performance for your intended use.

| Factor | Description |

|---|---|

| Flexibility | Ability to bend and fit into tight spaces |

| Pitch | Spacing of conductors, varies by requirement |

| Temperature Tolerance | Operation under extreme temperatures |

| Customizability | Tailoring cables for project needs |

| Application Suitability | Matching cable type to intended use |

YLS gives you many customization options for flat cable assemblies. You can select exact lengths, pitches, and connector types for a tailored fit. You may choose enhanced durability features like overmolding or shielding for tough environments. YLS also optimizes cables for signal integrity and EMI protection. You can request cables built for medical, aerospace, industrial, or automotive compliance.

- Tailored fit and function: Exact lengths, pitches, and connector types

- Enhanced durability: Overmolding, shielding, or reinforcement

- Improved performance: Signal integrity, EMI protection, space-saving routing

- Application-specific compliance: Meets industry requirements

Note: When you plan your next project, review your needs for flexibility, organization, and durability. YLS can help you design the perfect flat cable assemblies or ribbon wire for your application.

You have seen how flat wire cables offer flexibility, space efficiency, and reliable performance across many industries. YLS Flexible Flat Cable (FFC) stands out with its thin, lightweight, and customizable design. You can use these cables in automotive, aerospace, industrial, and medical devices.

- Flat wire cables fit tight spaces and handle frequent motion.

- They reduce weight and improve heat dissipation.

- You can customize pitch, length, and durability for your project.

For the best results, consult with YLS experts. They provide technical support and tailored solutions to match your needs.

FAQ

What is the main advantage of using flat wire cables?

You save space with flat wire cables. Their slim design lets you fit them into tight spots. You also get better heat dissipation and easier cable management compared to round cables.

Can you customize YLS Flexible Flat Cable (FFC) for your project?

Yes! You can choose the length, pitch, number of conductors, and even add shielding or folding. YLS offers fast prototyping and custom solutions for many industries.

Where do you commonly use flat wire cables?

You find flat wire cables in electronics, robotics, automotive systems, and medical devices. They work well in display connections, printer heads, dashboards, and compact medical equipment.

How do flat wire cables improve reliability?

Flat wire cables have parallel conductors. This design reduces wiring errors and ensures stable electrical performance. You get consistent results, especially in high-density or critical applications.

What should you consider when choosing a flat wire cable?

Tip: Check the cable’s flexibility, pitch, temperature rating, and compatibility with your connectors. You should also consider if you need extra features like shielding or folding for your application.