You can find many ribbon cable types for different jobs:

- Flat ribbon cables have wires side by side. This makes them easy to connect in groups.

- Twisted pair ribbon cables twist wires together. This helps stop signal problems.

- Shielded ribbon cables have a cover. This cover blocks outside noise.

- Rainbow ribbon cables use colors. This makes it easy to tell wires apart.

- Bonded ribbon cables stick wires together. This makes them stronger.

- Coaxial ribbon cables work well with fast signals.

- Round-to-flat ribbon cables bend easily. They also have flat ends for connecting.

Manufacturers use pitch and wire count to name ribbon cables. The right connector is important when picking a cable. In home electronics, copper wires with 1mm pitch and 10-20 wires are common. Factories may need gold wires and bigger pitches.

Key Takeaways

- Learn about the types of ribbon cables. Some types are flat, twisted pair, and shielded. Pick the best type for your project.

- Think about the pitch and conductor count. This helps your ribbon cable fit your devices. It also stops connection problems.

- Use rainbow ribbon cables with colors. This makes wires easy to spot. It helps a lot when you test or build things.

- Check if ribbon cables can handle outdoor use. Find cables that resist weather. This makes them last longer outside.

- Always use the right connector for your ribbon cable. This keeps connections safe. It also makes everything work better.

Ribbon Cable Types

Flat Ribbon Cable

Flat ribbon cables have wires lined up next to each other. You can see these in printers and scanners. They are also in other electronics. The wires stay straight and do not cross. This makes it easy to connect many pins at once. Most flat ribbon cables use colors to help you tell the wires apart fast.

Tip: Flat ribbon cables are good for keeping wires neat in small spaces.

Here is a table that shows how flat ribbon cables compare to other ribbon cable types:

| Feature | Flat Ribbon Cables | Other Ribbon Cable Types |

|---|---|---|

| Conductor Arrangement | Parallel conductors molded together | Varies (e.g., twisted, split) |

| Color Coding | Typically color-coded for pin identification | May or may not be color-coded |

| Number of Conductors | Ranges from 2 to 154 | Varies by type |

| Pitch | Ranges from 0.017” to 0.394” | Varies by type |

Flat ribbon cables come in different pitches like 1.00 mm, 1.25 mm, and 1.27 mm. You can find these cables in many things. They are used in cars and military gear too.

| Specification/Application | Details |

|---|---|

| Pitch | 1.00 mm, 1.25 mm, 1.27 mm, etc. |

| Conductor Size | Measured by width and thickness |

| Use Cases | Printers, scanners, copiers, automotive, military equipment, consumer electronics, etc. |

Twisted Pair Ribbon Cable

Twisted pair ribbon cables twist two wires together inside the cable. This helps stop noise and keeps signals clear. You might use these when you need better sound or data signals. These cables help signals stay strong in busy places.

Shielded Ribbon Cable

Shielded ribbon cables have a cover around the wires. This cover blocks outside noise like electromagnetic and radio waves. You should use shielded ribbon cables where there is lots of electrical stuff or strong signals.

- Shielded ribbon cables keep out electromagnetic and radio noise.

- The shield helps keep your data safe from outside problems.

- Engineers use shielded ribbon cables in tough places to keep signals working well.

Rainbow Ribbon Cable

Rainbow ribbon cables use a different color for each wire. This makes it easy to match wires to the right pins. You often see rainbow ribbon cables when testing or building things. These cables work like normal ribbon cables but are easier to trace.

Bonded Ribbon Cable

Bonded ribbon cables use a special way to stick wires together. This makes the cable stronger and stops it from splitting. You can bend bonded ribbon cables without the wires coming apart. These cables are good when you need them to last longer.

Coaxial Ribbon Cable

Coaxial ribbon cables mix the flat shape of ribbon cables with the shield of coaxial cables. Each wire has its own shield. This helps carry fast signals without problems. You might use coaxial ribbon cables for video or data that need strong signal protection.

Round-to-Flat Ribbon Cable

Round-to-flat ribbon cables start round and get flat at the ends. This lets you fit the cable in tight spots. You can still connect it easily to flat connectors. You get the bendy part of a round cable and the easy connection of a flat ribbon.

Note: When picking a ribbon cable, think about space, signal needs, and how easy it is to connect.

There are many ribbon cable types for different jobs. Each type has special features like colors, shields, or extra strength. If you know what each type does, you can pick the best cable for your project.

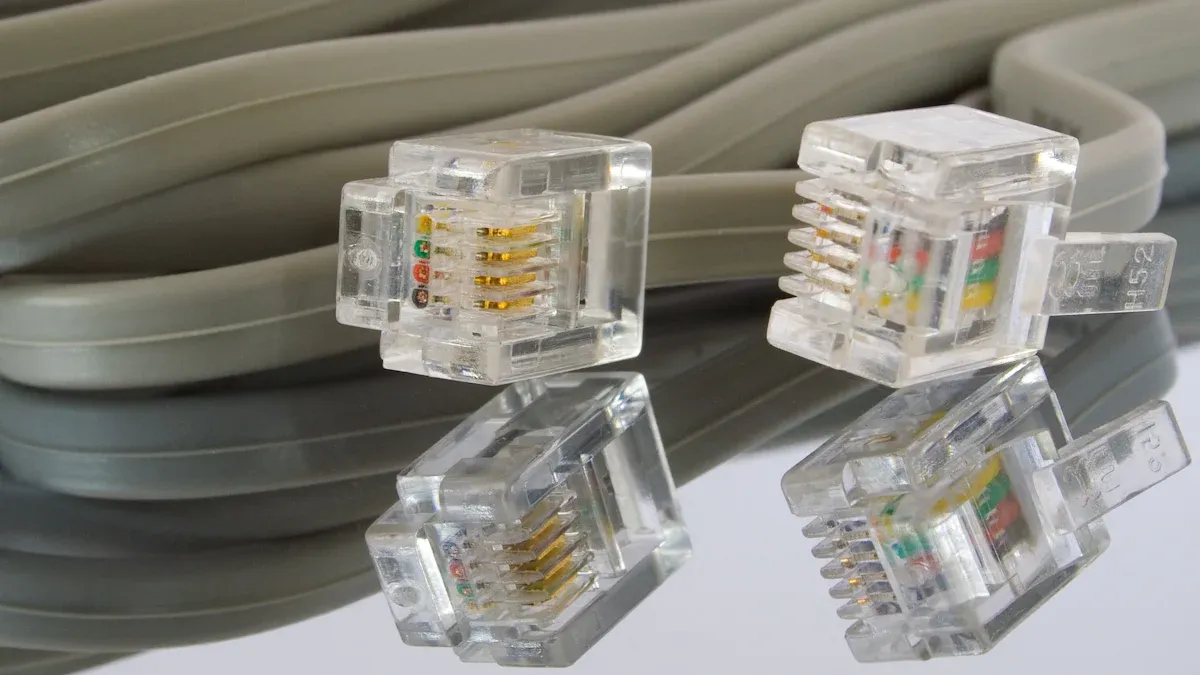

Types of Ribbon Cable Connectors

You need the right connector for your ribbon cable. Connectors help cables fit with devices. Each connector style works best with certain cables. Here are the main connector choices.

ZIF Connectors

ZIF means “Zero Insertion Force.” You do not need to push hard to connect. You slide the ribbon cable in and lock it with a lever. ZIF connectors work well with flat ribbon cables and flexible cables. You see ZIF connectors in laptops, printers, and small electronics.

Tip: ZIF connectors help keep thin cables safe when you install them.

Features of ZIF Connectors:

- Simple to use

- Good for thin or fragile cables

- Makes a strong connection

Locking Tab Connectors

Locking tab connectors use a small tab to hold the cable. You press the tab to let the cable go. This keeps the cable safe, even if you move the device. Locking tab connectors fit many ribbon cable types like shielded and bonded cables.

Advantages:

- Holds tight

- Stops cables from coming loose

- Works with cables in moving machines

| Connector Type | Best Cable Match | Security Level |

|---|---|---|

| Locking Tab | Shielded, Bonded, Flat | High |

Flat-Topped Connectors

Flat-topped connectors have a smooth, flat top. You can stack them or fit them in small spaces. These connectors work with flat ribbon cables and rainbow cables. You see flat-topped connectors in computers, control panels, and test equipment.

Note: Flat-topped connectors help save space when you connect many cables side by side.

Quick Comparison Table:

| Connector Type | Main Use | Compatible Cable Types |

|---|---|---|

| ZIF | Easy install/removal | Flat, Flexible |

| Locking Tab | Secure connection | Shielded, Bonded, Flat |

| Flat-Topped | Space-saving | Flat, Rainbow |

Always check the connector type before you buy a ribbon cable. The right connector makes installing easier and helps your system work well.

Selection Guide

Pitch and Conductors

When you pick a ribbon cable, look at pitch and conductor count. Pitch is the space between each wire. There are different pitch sizes for different jobs. Each size works with certain devices.

| Pitch Size | Typical Applications |

|---|---|

| 0.5mm | Board-to-Board Interface |

| 1mm | Instrumentation and Measurement |

| 1.25mm | Medical Equipment |

| 2mm | Aerospace Devices, Defense Equipment, Robotics |

Count the conductors to match your device’s needs. More conductors let you send more signals. Always check pitch and conductor count before buying.

Tip: Make sure pitch and conductor count match your needs. This helps you avoid problems when connecting.

Flexibility and Durability

You want your ribbon cable to bend and last a long time. Flexible cables can twist and stretch without breaking. This is important if your cable moves or fits in tight spots.

- Flexible cables work well in places that move a lot.

- Durable cables do not break easily and last longer.

- Indoor ribbon fiber optic cables are light and bendy. They do not work well in tough places.

- Outdoor ribbon fiber optic cables are strong and handle harsh conditions better.

Manufacturers test cables to make sure they are strong. They use visual checks, electrical tests, mechanical tests, and flame tests.

| Testing Method | Description |

|---|---|

| Visual Inspection | Looks for problems in the insulation and wires. |

| Electrical Tests | Checks how well the insulation and wires work. |

| Mechanical Tests | Tests how strong, flexible, and tough the cable is. |

| Flame Resistance Test | Checks how well the cable handles heat. |

Environmental Resistance

Think about where you will use your ribbon cable. Some cables work well inside, but others need to survive outside. Outdoor cables protect against water, heat, and chemicals. Manufacturers make these cables tough and test them for hard places.

| Feature | Description |

|---|---|

| Testing | Products are checked for military and industrial use. |

| Design | Tough packaging and careful alignment make cables last longer. |

| Compliance | Cables meet rules for good performance and long life. |

Note: Always check if your cable meets the rules for your environment. This helps you avoid problems and keeps your system safe.

Applications

Computers and Electronics

Ribbon cables are used inside computers and electronics. They connect drives, circuit boards, and other parts. You must pick the right cable to avoid problems. Signal loss or interference can happen if you choose wrong. The table below shows how ribbon cables are used and what you need for each:

| Applications | Performance Requirements |

|---|---|

| Mainframe computer devices | Short-distance, low-speed communication tasks |

| Internal drives in early consumer PCs | Can have EMI and crosstalk if not shielded |

| Industrial, automotive, embedded systems | Strong cables work in tough places |

| NASA aerospace applications | Made to stop signal problems in harsh conditions |

Tip: Check if your cable needs shielding. Shielding helps block electromagnetic interference (EMI).

Industrial Equipment

Factories and robots use ribbon cables. Heavy machines need cables that last and stay safe. When you pick a ribbon cable for machines, think about these things:

- Pitch means how far wires are spaced apart.

- Use silicon jackets for very hot or cold places.

- Flexible cables fit in tight or moving spots.

- Long-lasting cables help stop machine downtime.

- Fire-resistant cables meet safety rules.

Ribbon cables are found in control panels and sensors. They help machines work well and stay safe.

Consumer Devices

Ribbon cables make gadgets smaller and better. You see them in phones, cameras, and smart home devices. These cables let you add more features in small spaces. Here is how ribbon cables help in electronics:

- They help make small device designs.

- They give flexible, packed connections for better use.

- They help send data well in smart and automated products.

More people want ribbon cables as smart devices become popular at home and work.

You now know about the main ribbon cable types and connector choices. Picking the right cable helps you avoid errors and saves money. The table below explains why these choices are important:

| Selection Criteria | Importance |

|---|---|

| Pitch | Shows how far wires are spaced for your device. |

| Extreme Temperatures | Helps cables work in very hot or cold places. |

| Flexibility | Makes it easier to put cables in small spaces. |

| Long Life | Means you do not have to buy new cables often. |

| Fire Resistance | Keeps people and equipment safe by following safety rules. |

For special projects, you can use these tools:

- Custom cable help with engineering support

- Special advice for your technical needs

- Free expert help for your project

Tip: Always read datasheets and talk to experts before buying cables for important jobs.

FAQ

What is the difference between flat and twisted pair ribbon cables?

Flat ribbon cables keep wires side by side. Twisted pair ribbon cables twist wires together. Twisted pairs help reduce noise and signal problems. You should use twisted pair cables when you need better signal quality.

How do I choose the right pitch for my ribbon cable?

You need to match the pitch to your device’s connector. Pitch is the space between each wire. Check your device’s manual or datasheet for the correct pitch size before you buy a cable.

Can I use ribbon cables outdoors?

You can use ribbon cables outdoors if they have special jackets. Look for cables marked as weather-resistant or outdoor-rated. These cables protect against water, heat, and chemicals.

Why do some ribbon cables have different colors?

Manufacturers use color coding to help you identify each wire quickly. Rainbow ribbon cables make it easy to match wires to the right pins. This helps prevent wiring mistakes.

Do all ribbon cables work with ZIF connectors?

Not all ribbon cables fit ZIF connectors. ZIF connectors work best with flat and flexible cables. Always check the connector type and cable compatibility before you connect them.