You will find several flexible wire types and cables in modern electrical systems. These include flat flexible cable (FFC), stranded wire, power cables, control cables, and flexible electrical conduit. Each type meets specific needs across industries like automotive, electronics, and medical devices.

Here is a quick look at how leading cable types are used worldwide:

| Type of Cable | Market Share/Usage Statistics | Applications |

|---|---|---|

| Flexible Cords | N/A | Automotive, Aerospace, Medical, Electrical Systems |

| Flat Flexible Cables | 55% (Shielded) | Consumer Electronics, Automotive, Industrial, Medical |

You can match each cable type to your unique environment, from robotics to consumer electronics.

Key Takeaways

- Flexible wires and cables come in various types, each designed for specific applications in industries like automotive, electronics, and medical devices.

- Stranded wire offers greater flexibility and durability, making it ideal for dynamic environments where movement occurs frequently.

- Multi-core flexible cables simplify wiring by combining multiple conductors, which is essential for managing complex connections in automation and robotics.

- Choosing the right flexible cable material, such as PVC or rubber, ensures optimal performance and safety in different environments.

- Flexible electrical conduits protect cables from moisture and mechanical damage, with options like flexible metal conduit for dry areas and liquidtight non-metallic conduit for wet environments.

Flexible Wire Types Overview

Flexible wire types play a crucial role in modern electrical systems. You will find that each type offers unique features for different environments and applications. Understanding the structure and uses of these wires helps you select the right solution for your project.

Stranded Wire

Stranded wire stands out as one of the most common flexible wire types. Manufacturers create it by twisting together many small wires to form a single conductor. This design gives you greater flexibility and durability, especially in places where wires must bend or move often.

Tip: Stranded wire works best in dynamic environments where movement and vibration occur frequently.

Here is a comparison between stranded wire and solid wire:

| Attribute | Stranded Wire | Solid Wire |

|---|---|---|

| Flexibility | Greater flexibility, ideal for frequent movement | Less flexible, better for fixed installations |

| Durability | Resists fatigue better in dynamic environments | More durable in fixed installations |

| Conductivity | Slightly less due to multi-strand design | Better conductivity due to uninterrupted structure |

| Ease of Installation | May require ferrules or crimping for connections | Easier to insert into terminal blocks |

| Cost | Typically more expensive due to complex manufacturing | More affordable due to simpler processes |

You will often use stranded wire in these situations:

- Electrical wiring in buildings for flexibility and durability.

- Automotive and marine wiring to handle vibrations.

- Power distribution and transmission for medium- to high-voltage needs.

- Telecommunications and data transmission where cables move often.

- Robotics and machinery for complex movements.

- Audio and video systems to reduce signal loss.

- Renewable energy systems for connecting solar and wind components.

Stranded wire offers more pliability than solid wire, making it easier to route around obstacles. You can use it for shorter distances and in places where frequent movement is expected.

Multi-Core Flexible Cables

Multi-core flexible cables contain several conductors within a single sheath. This structure allows you to save space and carry multiple signals at once. These types of flexible cables are essential in complex wiring systems where you need to manage many connections efficiently.

Note: Multi-core flexible cables help you simplify wiring and reduce clutter in control panels and devices.

Here are some industries and applications where you will find multi-core flexible cables:

| Industry | Application Description |

|---|---|

| Automotive | Connecting lighting, infotainment, and engine control units. |

| Robotics | Wiring for robotic arms and automated machinery. |

| Consumer Electronics | Internal wiring for computers, smartphones, and audio equipment. |

You will also see these cables in:

- Industrial automation, such as powered arms and conveyors.

- Telecommunications, where maintaining signal integrity is vital.

- Renewable energy installations, like solar panels and wind turbines.

- Healthcare devices, including diagnostic imaging equipment.

Multi-core flexible cables offer several advantages:

- They save space by combining multiple conductors in one cable.

- You can transmit several signals at once, which is ideal for complex systems.

- These cables support low-voltage control, communications, and data transmission.

- Manufacturers classify them into various types of flexible cables for different uses, increasing their versatility.

Flexible Power and Control Cables

Flexible power and control cables deliver electricity and transmit control signals in many commercial and industrial settings. You will find these cables in automation systems, machinery, and building wiring.

Here is a table showing standard voltage ratings for flexible power and control cables:

| Voltage Rating Category | Voltage Range | Application Description |

|---|---|---|

| Low Voltage (LV) | Up to 1 kV | Power distribution and lighting in homes, offices, and factories. |

| Medium Voltage (MV) | 1 kV to 35 kV | Power distribution in industrial facilities and utility networks. |

| High Voltage (HV) | Above 35 kV | Power transmission networks. |

Flexible power and control cables contribute to safety and efficiency in several ways:

- They reduce power loss, making your system more reliable and energy-efficient.

- These cables support eco-friendly construction by minimizing waste and improving sustainability.

- You can rely on them for safe and consistent signal transmission, which is critical in automation.

- They simplify wiring, saving space and making installation easier.

- Flexible control cables connect sensors, actuators, and controllers, allowing precise control of machines and processes.

- Multi-conductor flexible control cables withstand motion and interference, making them essential in dynamic environments.

You will also encounter other types of flexible cables, such as coaxial cables and fiber optic cables, which serve specialized roles in data transmission and communication.

Choosing the right flexible wire types ensures your system operates safely, efficiently, and reliably. By understanding the differences between stranded wire, multi-core flexible cables, and flexible power and control cables, you can make informed decisions for your next project.

Different Types of Flexible Cables

Flexible cables come in many forms to meet the demands of modern technology. You will find that each type offers unique features for specific environments and applications. Understanding the different types of flexible cables helps you select the right solution for your project.

Motion-Rated Flexible Cables

Motion-rated flexible cables are designed to handle constant movement without breaking down. You will see these cables in robotics, conveyor systems, and automated machinery. These cables must withstand rolling, bending, torsional, and variable or random motion.

- Rolling motion cables move back and forth along a track. You often use them in cable carriers or drag chains.

- Bending motion cables flex repeatedly in one direction. These are common in robotic arms and moving equipment.

- Torsional motion cables twist along their length. You will find them in rotating machines and turntables.

- Variable or random motion cables handle unpredictable movements. These are essential in complex automation systems.

Tip: Choose motion-rated flexible cables if your application involves frequent or complex movement. This will help prevent cable failure and reduce downtime.

You can improve the lifespan of these cables by selecting the right insulation material. For example, rubber flexible cables and silicone flexible cables offer excellent flexibility and durability. These materials help the cable resist cracking and wear, even after thousands of cycles.

Specialty Flexible Cables

Specialty flexible cables serve unique roles in demanding environments. You may need these cables for high temperatures, chemical exposure, or heavy mechanical stress.

Some common types include:

- High-temperature cables: Silicone flexible cables and teflon flexible cables can withstand extreme heat. Silicone flexible cables remain elastic from -60°C to +180°C. Teflon flexible cables handle temperatures up to 260°C and resist chemicals.

- Shielded cables: These cables block electromagnetic interference. You will use them in data centers, medical devices, and sensitive electronics.

- Armored cables: These cables have a protective metal layer. You will find them in mining, oil and gas, and outdoor installations where mechanical damage is a risk.

- Low smoke zero halogen (LSZH) cables: These cables release minimal smoke and toxic gases during a fire. They are ideal for public buildings and transport systems.

Note: Specialty flexible cables often combine several features, such as shielding and high-temperature resistance, to meet strict safety and performance standards.

Rubber flexible cables are popular in mining and marine applications because they resist abrasion and moisture. Silicone flexible cables are common in aerospace and industrial automation due to their flexibility and thermal stability.

Material Options for Flexible Cables

The choice of insulation and jacketing material affects the flexibility, safety, and lifespan of your flexible cables. You should consider the environment, temperature, and mechanical stress when selecting a material.

Here is a comparison of the most widely used materials:

| Material | Advantages | Disadvantages | Typical Applications |

|---|---|---|---|

| Polyvinyl Chloride (PVC) | Affordable, flame retardant | Brittle in cold, toxic smoke | Indoor wiring, telecom |

| Polyethylene (PE) | Moisture/UV resistant | Rigid, less flame-resistant | Outdoor, direct burial |

| Polyurethane (PUR) | Flexible, abrasion resistant | Costlier | Robotics, automation |

| Chlorinated Polyethylene (CPE) | Chemical/flame resistant | Higher cost | Industrial, utility |

| Rubber-Based Jackets | Flexible, durable, temp. proof | Heavy, costly | Mining, oil & gas, marine, outdoor heavy-duty cables |

| Fluoropolymers (FEP, PTFE/Teflon) | Extreme temp./chemical proof | Expensive | Aerospace, military |

| Cross-Linked Polyolefins (XLPE) | Safe, non-halogenated | Lower flame resistance | LSZH, transport, buildings |

You will often use pvc flexible cables for household wiring because they are cost-effective and flame retardant. Rubber flexible cables provide better flexibility and durability, making them suitable for environments with frequent bending or vibration. Silicone flexible cables stand out for their exceptional flexibility and ability to handle high and low temperatures. Teflon flexible cables offer outstanding chemical resistance and minimal signal loss, which is important in electronics and high-frequency communication.

- PVC flexible cables are ideal for indoor use and telecom systems.

- Rubber flexible cables work well in dynamic and harsh environments.

- Silicone flexible cables are perfect for industrial and aerospace applications.

- Teflon flexible cables excel in harsh chemical and high-frequency settings.

Choosing the right material ensures your flexible cables perform reliably and safely in any environment.

You can see that different types of flexible cables use a variety of materials to achieve the right balance of flexibility, strength, and resistance. By understanding these options, you can make informed decisions for your next project.

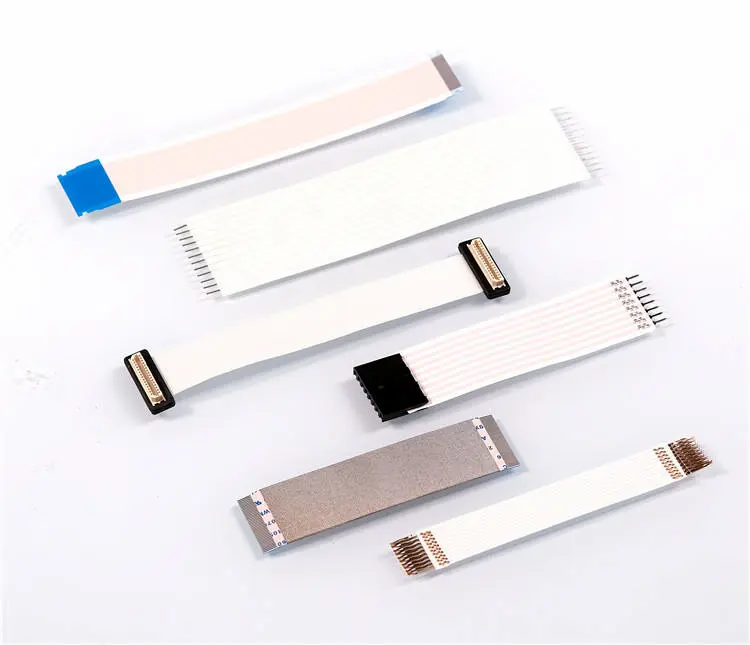

Flexible Flat Cable (FFC) Solutions

What Is Flexible Flat Cable?

You will find flexible flat cable (FFC) as one of the most popular types of flex cable in electronics today. FFC stands out because it uses parallel conductive strips, which makes it simple and cost-effective compared to other flexible cables. You can see how FFC compares to flexible printed circuits (FPC) in the table below:

| Characteristic | Flexible Flat Cable (FFC) | Flexible Printed Circuits (FPC) |

|---|---|---|

| Structure | Parallel conductive strips | Reinforced, complex designs |

| Applications | Printers, TVs, simple devices | High-performance electronics |

| Flexibility | Good, but less than FPC | Superior flexibility |

| Data Performance | Best for low-demand signals | High-frequency signals |

| Cost Implications | Lower cost | Higher cost |

You will often use FFC in devices that need compact and reliable connections, such as printers, LCD monitors, and consumer electronics.

YLS FFC Features and Applications

YLS offers flexible cables designed for high-density wiring and dynamic environments. You can choose from a wide range of pitch options, from 0.4mm to 1.25mm, and up to 96 conductors. YLS flexible flat cable uses hot-pressed copper wire on a PET film, which makes it lightweight and easy to install in tight spaces.

You will find YLS FFC in many applications:

- LCD monitors

- Computers and tablets

- Cameras and video equipment

- Printers and scanners

- Industrial automation systems

- Medical devices

YLS provides features such as shielding for noise-sensitive environments and foldable designs for intricate installations. You can rely on YLS for fast sample turnaround, usually within 48 hours, and ISO-certified quality.

Tip: If you need a flexible cable for a project with limited space or frequent movement, YLS FFC offers a reliable solution.

Customization and Industry Uses

You can customize YLS flexible cables to fit your exact needs. Options include folding, shielding, and labeling. This flexibility helps you meet the demands of industries like automotive, robotics, and healthcare, where standard types of flex cable may not work.

Industries that require custom FFC solutions include:

- Aerospace

- Automotive

- Healthcare

- Industrial automation

YLS supports rapid prototyping and small batch production, so you can test and refine your designs quickly. You will benefit from expert support and fast response times, which help you stay on schedule.

Note: Custom flexible cables from YLS allow you to solve unique connectivity challenges in your industry.

Flexible Electrical Conduit Types

Flexible electrical conduit protects and organizes cables in many environments. You will find several types of flexible wire conduits, each designed for specific needs. These conduits help you route flexible cables safely through buildings, factories, and outdoor spaces.

Flexible Metal Conduit (FMC)

Flexible metal conduit uses helically wound metal, such as galvanized steel or aluminum, to provide strength and flexibility. You can install flexible metallic conduit in commercial, industrial, and residential settings. It works well for wiring appliances, lighting systems, and office equipment.

Here is a table showing how flexible electrical conduit types compare:

| Type of Conduit | Construction Details | Common Applications |

|---|---|---|

| Flexible Metal Conduit (FMC) | Helically wound metal for strength and flexibility | Wiring appliances, lighting, office equipment |

| Liquid Tight Flexible Metal Conduit (LFMC) | Metal core with thermoplastic cover for moisture protection | Outdoor, underground, hazardous locations |

| Liquid Tight Flexible Non-Metallic Conduit (LNFC) | PVC extruded as liquid tight conduit | Wet, corrosive, and outdoor environments |

Flexible metallic conduit resists vibration and adapts to tight spaces. You will see it in machinery wiring and HVAC systems.

Liquidtight Flexible Non-Metallic Conduit (LNFC)

Liquidtight flexible non-metallic conduit uses PVC or similar materials to protect cables from moisture and corrosion. You can install liquidtight flexible non-metallic conduit in wet or corrosive environments, such as car washes, food processing plants, and water management facilities.

This conduit offers high flexibility and superior protection against chemicals and water. You will find it easy to bend around obstacles and tight corners. Liquidtight flexible non-metallic conduit requires little maintenance and provides long-term savings.

Here is a table comparing FMC and LNFC:

| Feature | Flexible Metal Conduit (FMC) | Liquidtight Flexible Non-Metallic Conduit (LNFC) |

|---|---|---|

| Material Composition | Metal | Non-metallic (PVC, TPE, neoprene) |

| Protection Level | Good mechanical protection | Superior moisture and corrosion protection |

| Flexibility | Moderate | High |

| Typical Uses | Dry locations | Wet and corrosive environments |

Tip: Use flexible metal conduit in dry areas. Choose liquidtight flexible non-metallic conduit for wet or corrosive spaces.

Applications and Selection Tips

You will see flexible electrical conduit in many places:

- Office buildings and retail spaces for lighting and equipment wiring

- Industrial facilities for machinery and HVAC systems

- Outdoor installations and agricultural sites with liquid tight flexible metal conduit or liquidtight flexible metal conduit

- Car washes, food plants, and chemical facilities with liquidtight flexible non-metallic conduit

When you select between flexible metal conduit and liquidtight flexible non-metallic conduit, consider these factors:

- Application requirements: Check if your environment is dry, wet, or exposed to chemicals.

- Material compatibility: Match the conduit material to your cables and armoured cables.

- Flexibility and bend radius: Decide if you need to bend around obstacles.

- Conduit sizing: Make sure the conduit fits all your flexible cables and armoured cables.

- Code compliance: Follow local electrical codes for flexible electrical conduit.

- Durability and protection: Look for impact and corrosion resistance.

- Installation considerations: Choose conduits with easy-to-use fittings.

- Budget: Balance quality and cost for your project.

Note: Flexible electrical conduit helps you protect flexible cables and armoured cables in any environment. By understanding the differences between flexible metallic conduit and liquidtight flexible non-metallic conduit, you can make the best choice for your installation.

You have explored the main types of flexible wire, cable, FFC, and electrical conduit. Each solution fits specific needs in industries like robotics, medical equipment, and automation. Matching the right cable or conduit to your application helps you avoid overheating, failure, and costly downtime.

When choosing a flexible solution, consider these criteria:

- Moisture levels and UV exposure

- Temperature extremes and chemical resistance

- Vibration absorption and EMI shielding

- Compliance with local codes

Follow these practical tips:

- Define your environment and application.

- Select materials for durability and safety.

- Size cables and conduits accurately.

- Use proper fittings and strain relief.

- Test thoroughly before installation.

The flexible cable market continues to grow, driven by new technology and rising demand for reliable connections.

FAQ

What makes flexible cables different from standard cables?

Flexible cables use stranded conductors and special insulation. You can bend and move them without damage. Standard cables use solid conductors and work best in fixed positions.

Can you use flexible cables outdoors?

Yes, you can use flexible cables outdoors. Choose cables with weather-resistant jackets like rubber or polyurethane. Always check the cable’s rating for UV and moisture resistance.

How do you select the right flexible cable for your project?

Start by listing your application’s needs. Consider voltage, temperature, movement, and environment. Use manufacturer datasheets and ask for expert advice if you have questions.

What is the main advantage of using FFC in electronics?

FFC saves space and weight. You can use it in tight spaces where round cables do not fit. It also supports high-density connections in devices like printers and displays.

Do flexible conduits protect against water and chemicals?

Yes, some flexible conduits protect against water and chemicals. Look for liquidtight flexible non-metallic conduit (LNFC) or liquidtight flexible metal conduit (LFMC) for the best protection.