A flexible flat cable, or FFC, connects electronic components inside devices using thin, flat strips of metal embedded in a flexible plastic film. You often see FFCs in cell phones, laptops, cameras, and flat screen TVs. These cables link printed circuit boards to displays, help parts move or fold, and serve as wiring in many consumer electronics. FFCs make devices slimmer, lighter, and more reliable for everyday use.

Key Takeaways

- Flexible flat cables (FFCs) are thin, lightweight cables that connect electronic components in devices like laptops and cameras. They save space and improve device reliability.

- FFCs consist of copper traces embedded in a flexible plastic film, allowing them to bend and flex without breaking. This makes them ideal for devices with moving parts.

- When choosing an FFC, consider factors like the operating environment, durability, and space constraints. Matching the cable to your device’s needs ensures reliable performance.

- FFCs are cost-effective and easy to install, making them a popular choice in consumer electronics and automotive applications. They help create slimmer, more efficient devices.

Flexible Flat Cable Basics

What Is an FFC

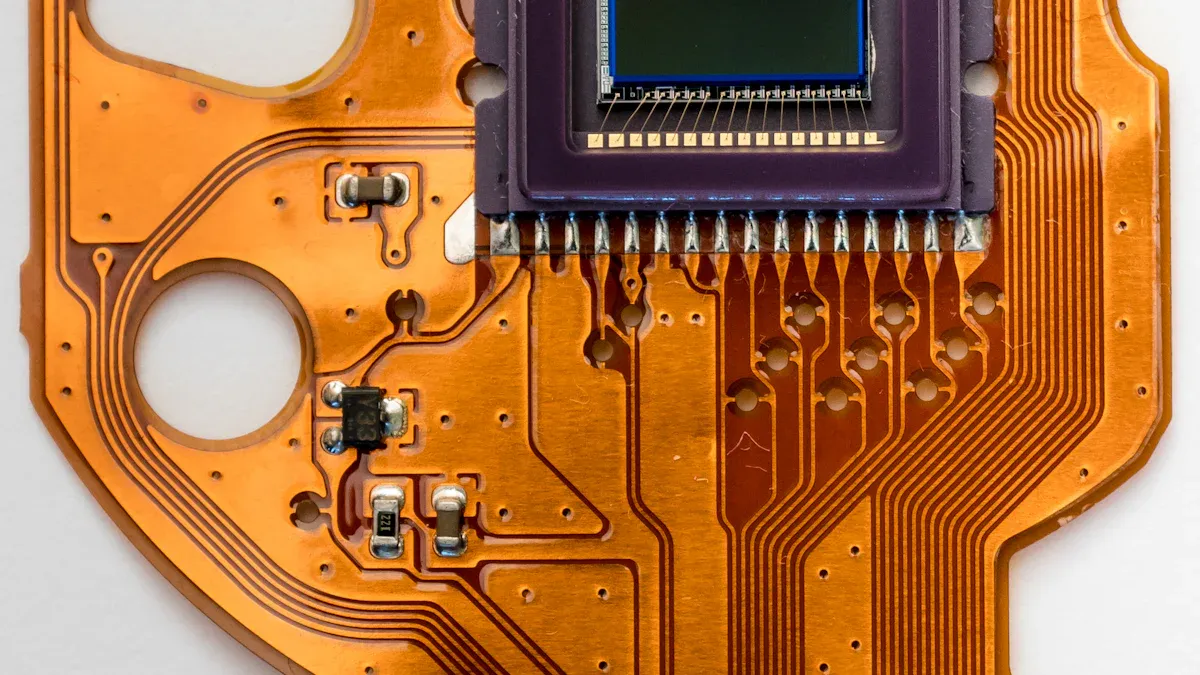

When you look inside many electronic devices, you will find flat flexible cables, also known as FFCs. These cables use thin, flat strips of metal that run parallel to each other. The strips sit inside a flexible plastic film. This design makes FFCs different from round or bulky cables. You often see FFCs in places where space is tight, such as inside laptops, printers, and cameras.

Here is a quick comparison to help you see what sets a flexible flat cable apart from other cable types:

| Characteristic | Flexible Flat Cable | Other Cable Types |

|---|---|---|

| Design | Thin, flexible, and flat | Varies (e.g., round, rigid) |

| Space Efficiency | Fits into tight spaces | Often bulkier |

| Conductor Arrangement | Parallel conductors | Varies (e.g., twisted pairs) |

| Weight | Lightweight | Can be heavier |

| Cost | Low cost | Varies (often higher) |

| Shielding | No external shield | Some have shielding |

| Application | Laptops, printers, etc. | Varies |

You can see that flat flex cables offer a unique combination of flexibility, light weight, and cost savings. These features make them a popular choice for connecting parts inside modern electronics.

Structure and Materials

The structure of an FFC gives it both flexibility and strength. You will find three main parts in most flat flexible cables:

| Component | Material/Description |

|---|---|

| Base Material | Polyimide plastic film, known for durability, electrical insulation, and high temperature tolerance. |

| Conductive Traces | Copper, chosen for its cost-effectiveness and conductivity, can be etched thin without losing resistivity. |

| Protective Layer | Polyimide coverlay, which protects copper traces from environmental damage while allowing selective connections. |

| Adhesives | Acrylic, epoxy, or polyimide adhesives that bond flex layers reliably without cracking under flexing. |

You may also find special materials in some flat flexible cables:

- Flexx-Sil: A silicone rubber polymer that gives high flexibility, shields against electromagnetic interference (EMI), and resists heat.

- PTFE: Used for its excellent electrical insulation and ability to handle high temperatures, often in cleanroom settings.

These materials work together to create a cable that bends and flexes without breaking. The copper traces carry signals or power, while the plastic layers protect and insulate the conductors.

How FFCs Work

Flat flex cables work by providing a reliable path for electrical signals between different parts of a device. The parallel arrangement of conductors helps reduce interference and keeps signals clear. You can bend or fold these cables many times without damaging them, which is important in devices with moving parts, like printers or folding phones.

The structure of a flexible flat cable gives you several performance benefits:

| Feature | Contribution to Flexibility and Performance |

|---|---|

| Compact Design | Makes routing easy and reduces device weight. |

| Arrangement of Conductors | Lowers crosstalk and EMI, improving signal quality. |

| Material Properties | Allows repeated bending without losing function. |

| Increased Surface Area | Helps release heat, preventing overheating in high-power devices. |

You will often choose flat flexible cables for internal connections because they fit into tight spaces and handle movement well. Their design supports both flexibility and durability, making them ideal for modern electronics. When you need a cable that can bend, twist, and still deliver strong performance, flex cables are the answer.

Types and Specifications of Flat Flex Cables

Common Types

You will find several types of flat flex cables designed for different needs. Each type offers unique features that suit specific applications. The table below shows the most common types of flat flex cables, their characteristics, and where you might use them:

| Cable Type | Characteristics | Common Applications |

|---|---|---|

| Round Conductor Flat Cables | Flexible, ideal for tight bending radii | Aerospace, automotive, industrial |

| Shielded Flat Cables | Reduces EMI and RFI, has a metallic shield | High-speed data transmission, networking |

| High-Temperature Flat Cables | Made from heat-resistant materials, withstands extreme temperatures | Industrial, automotive |

| Low-Voltage Flat Cables | Designed for low voltage and current, lightweight and flexible | Electronics, telecommunications, control |

| Ribbon Cables | Multiple conductors, high density of connections | Computers, printers, televisions |

You can choose the right type based on your device’s requirements. For example, shielded flat cables work best in environments with lots of electrical noise, while ribbon cables help when you need many connections in a small space.

Pitch, Size, and Length

When you select an ffc, you need to consider the pitch, which is the distance between the centers of two conductors. The pitch affects both compatibility and performance. Here are the standard pitch sizes you will see:

| Standard Pitch Sizes (mm) | Commonly Used |

|---|---|

| 0.5 | Yes |

| 0.8 | Yes |

| 1.0 | Yes |

| 0.625 | No |

| 0.635 | No |

| 1.25 | No |

| 1.27 | No |

| 1.5 | No |

| 2.00 | No |

| 2.54 | No |

Tip: Always match the pitch of your ffc to the connector in your device. This ensures a secure and reliable connection.

The size of flexible flat cable also includes its length and width. You will find that the size of flexible flat cable varies by application:

| Application Context | Typical Length Range |

|---|---|

| Home Appliances | 5cm – 50cm |

| Industrial Devices | 10cm – 200cm |

| Military Applications | 5cm – 150cm |

| Marine Devices | 10cm – 100cm |

| Medical Devices | 2cm – 100cm |

You should always check the size of flexible flat cable to make sure it fits your project.

Key Specifications

When you choose between different types of flat flex cables, you need to look at key specifications. These details help you find the best cable for your needs:

- Flexibility: Lets you use the cable in devices that bend or move often.

- Pitch: Determines how many signals you can send in a small space.

- Reinforcement: Oversized and anchored pads give extra support at the ends.

- Strain Relief: Extra slack near the ends prevents damage from pulling.

- Customizability: You can order cables with different lengths, widths, and numbers of conductors.

Note: Always review these specifications before you buy or install a cable. This helps you avoid problems and ensures your device works as expected.

FFC vs. Other Cable Types

FFC vs. FPC

When you compare an ffc to an fpc, you notice several important differences. Both connect electronic components, but they serve different needs. You often choose an ffc for basic tasks, such as linking a printer head or display. These cables cost less and work well for simple connections. On the other hand, flexible printed circuits offer greater adaptability and handle more complex jobs. You see fpc used in medical devices, aerospace systems, and advanced consumer electronics.

Here is a table that highlights the main differences:

| Attribute | FFC (Flexible Flat Cable) | FPC (Flexible Printed Circuits) |

|---|---|---|

| Cost | More cost-effective | Higher production costs |

| Flexibility | Limited flexibility | Greater flexibility and adaptability |

| Application Suitability | Basic applications | High-tech applications |

You can rely on an ffc for straightforward tasks. If you need a flex cable that endures vibration or extreme temperatures, flexible printed circuits perform better. FPCs cost more because their manufacturing process is complex. Manufacturers etch flexible copper clad laminate to create fpc, while ffc uses flat copper wires coated with PET. FPCs are usually thinner, which helps in tight spaces.

Tip: Choose ffc for budget-friendly projects. Pick fpc when you need advanced performance and durability.

FFC vs. Round Cables

You may wonder how a flex cable compares to round cables. The shape and structure make a big difference in installation and reliability. Flat cables have a slim profile, so you can run them along edges or under carpets. This design saves space and keeps your setup neat, especially in data centers or small devices.

Flat cables bend easily and fit into tight spots. You find them easier to manage during installation because they do not tangle as much. Round cables, however, can suffer from repetitive flex failure. Their jackets and conductors wear out faster when bent often. Both types can experience insulation degradation and conductor fatigue, but the flat design helps reduce these risks in the flex area.

- Repetitive flex failure affects round cables more.

- Both cable types can face insulation wear and conductor fatigue.

- Flat cables offer better space management and installation flexibility.

Note: If you need a cable for a mobile device or a setup with limited space, a flex cable gives you the best results.

Applications and Benefits of Flexible Flat Cable

Where FFCs Are Used

You see flexible flat cable in many industries because it offers unmatched flexibility and space efficiency. When you open a laptop or cellphone, you often find flex cables connecting the display to the main board. Printers use these cables to link moving parts, and cameras rely on them for compact internal wiring. You also find ffc cables used for connecting sensors and control panels in industrial automation systems.

Here is a table showing where you find flex cables in different industries:

| Industry | Application Examples |

|---|---|

| Consumer Electronics | Gaming consoles, LCD monitors, cameras, printers, home appliances |

| Automotive | GPS systems, built-in LCD displays, engine wiring harnesses |

| Medical Devices | Display monitors, imaging systems (MRI, CT scanners), hand-held devices |

| Industrial Automation | Machinery, automation systems, sensors, control panels |

| Aerospace and Defense | Avionics systems, satellites, specialized harnesses, rugged environments |

You notice that flex cables play a key role in devices where space is limited and movement is frequent. Their flexibility allows you to design slimmer products and fit more components into tight spaces.

Tip: If you work with consumer electronics or automotive systems, you will likely use ffc cables for compact and reliable connections.

Benefits of Flexible Flat Cable

You gain several benefits when you choose flexible flat cable for your projects. The flat design saves space and lets you route cables through narrow gaps. You can bend and fold flex cables without damaging them, which is essential in devices with moving parts. The benefits of flexible flat cable include:

- Space-saving characteristics: You maximize space inside devices, allowing for higher density of conductors.

- Flexibility: You can bend, twist, and fold the cable to fit your design needs.

- Ease of installation: Many flex cables come with connectors that make assembly quick and simple.

- Durability: You rely on these cables to withstand repeated flexing and bending.

- Production efficiency: You reduce assembly time and material costs, which helps speed up manufacturing.

- Cost savings: You lower expenses by using fewer materials and streamlining the assembly process.

You also benefit from rapid prototyping and customization. Flex cables let you adjust length, width, and conductor count to match your application. You save on shipping costs because the cables are lightweight.

Note: The benefits of flexible flat cable extend beyond just saving space. You improve reliability, reduce costs, and make your devices easier to assemble.

Reliability and Durability

You depend on flex cables for reliable performance in demanding environments. Flexible flat cable resists wear from repeated bending, which is important in devices that move or fold. Cables designed for continuous flex applications can last from 1 to 20 million flex cycles, depending on their materials and construction. You avoid common problems like conductor breakage and jacket erosion by choosing cables built for durability.

You also need to consider certifications when you select flex cables for critical applications. Here is a table of common reliability standards:

| Certification | Description |

|---|---|

| UL | Ensures safety and performance |

| CPR | Complies with EU construction product regulations |

| REACH | Regulates hazardous substances |

| RoHS | Restricts hazardous substances in electronics |

| ISO | International standards for quality and safety |

You see these certifications on cables used in medical devices, aerospace systems, and automotive electronics. They guarantee that your flexible flat cable meets strict safety and quality requirements.

Block Quote: You improve device reliability and safety by choosing flex cables with recognized certifications.

You should remember that the lifespan of flex cables depends on how often you bend them and the environment they operate in. Heat, friction, and cold hardening can shorten cable life, but high-quality flexible flat cable withstands millions of cycles in the right conditions.

Choosing the Right FFC

Selection Factors

When you design a new device, you need to consider several factors before you choose ffc cables. Start by thinking about the operating environment. High temperatures can soften materials like PVC, causing insulation problems. Low temperatures make cables brittle, which affects performance. Humidity can corrode metal parts and reduce insulation strength, leading to electrical failures. You should always match the cable’s material to the conditions it will face.

Here are the most important factors to review when you select a flexible flat cable:

- Operating Environment: Check for temperature extremes and humidity.

- Durability: Pick cables that handle wear and tear.

- Space Constraints: Make sure the cable fits tight spaces.

- Shielding: Prevent electromagnetic interference for clear signals.

- Maintenance and Replacement: Design for easy cable swaps.

- Future-Proofing: Select cables that allow upgrades.

- Real-World Testing: Test cables in actual conditions.

- Supplier Collaboration: Work with trusted suppliers for custom options.

- Bending Radius: Respect the cable’s bend limits.

- Material and Construction: Use quality materials like polyimide and copper.

Tip: Ignoring bend radius or choosing the wrong material can lead to cable failure. Always check these details before you choose ffc cables.

Matching FFC to Application

You need to match the cable’s features to your device’s electrical and mechanical needs. Follow these best practices to avoid common mistakes:

- Leave slack for movement so the cable does not stretch or tear.

- Consider fatigue life and never exceed bend radius limits.

- Position cables so they bend in the right direction and avoid twist stresses.

- Spread dynamic areas to reduce stress and avoid sharp bends.

- Reinforce terminals to prevent ripping and allow flex relief.

- Protect copper traces from nicks and cuts, especially at edges.

- Manage layer stacks so traces cross safely inside the cable.

Engineers sometimes ignore bend radius or pick materials based only on cost. Sharp corners in trace routing can cause damage. If you overlook manufacturability, you may face higher costs and production delays. When you choose ffc cables, always match the cable’s design to your application for reliable performance.

You can rely on flexible flat cable for compact, durable connections in electronics. The table below shows key facts:

| Aspect | Description |

|---|---|

| Definition | Thin copper traces on flexible plastic film |

| Structure | Unshielded, lightweight, single or multi-layered |

| Key Features | Low-profile connectors, millions of flex cycles |

You gain flexibility, space efficiency, and easy installation. When you choose cables, consider jacketing, environmental resistance, and movement needs. Use this knowledge to improve your device design and reliability.

FAQ

What is the main difference between FFC and FPC?

You see FFC as a simple cable with parallel copper wires. FPC uses a printed circuit on a flexible substrate. FPC offers more design options and handles complex circuits. FFC works best for basic connections.

Tip: Choose FFC for cost savings. Pick FPC for advanced flexibility.

Can you cut or modify an FFC to fit your device?

You should not cut or modify an FFC. The cable may lose its electrical properties or break. Always order the correct length and pitch for your device. Custom cables are available from suppliers.

How do you connect an FFC to a circuit board?

You use a Zero Insertion Force (ZIF) connector. Slide the FFC into the connector slot. Lock the tab to secure the cable. This method prevents damage and ensures a reliable connection.

| Step | Action |

|---|---|

| 1 | Insert FFC into slot |

| 2 | Lock connector tab |

Are FFC cables safe for high-temperature environments?

You need to check the cable’s material. Polyimide FFCs handle high temperatures well. PVC-based cables may soften or fail. Always match the cable type to your device’s operating conditions.

What causes FFC cables to fail?

You may see failure from excessive bending, sharp folds, or exposure to moisture. Poor installation and incorrect pitch also lead to problems. Always follow manufacturer guidelines for best results.

Note: Proper handling extends cable life and improves device reliability.