You use a cable zif when you need a reliable and gentle connection for electronic components. This cable uses zif technology, which lets you insert or remove it without applying force. The special design helps prevent damage and extends the life of delicate parts.

| Feature/Functionality | Description |

|---|---|

| Zero Insertion Force | Easy insertion and removal without force, reducing wear and tear. |

| Reliability | Offers a stable connection, lowering the risk of physical damage. |

| Versatility | Comes in many sizes and fits different devices. |

Key Takeaways

- ZIF cables allow easy insertion and removal without force, reducing wear and tear on delicate electronic components.

- Choose the right ZIF cable by matching the number of pins and pitch to your device to ensure reliable connections.

- Regularly inspect and maintain ZIF connectors to catch wear or corrosion early, extending their lifespan.

- ZIF connectors are ideal for tight spaces in devices like smartphones and laptops, providing reliable connections without damaging components.

- Consider environmental factors like temperature and humidity when using ZIF connectors to prevent performance issues.

ZIF Connector Basics

What is a ZIF Connector

You encounter a zif connector when you work with sensitive electronics that need gentle handling. This connector uses a special design to connect components without applying pressure. You often see zif connectors in devices that use cable zif, such as laptops, cameras, and smartphones. The main purpose of a zif connector is to protect fragile parts from damage during installation or removal.

Tip: ZIF stands for “zero insertion force.” This means you do not need to push or force the connector into place. You simply align the parts and secure them with a small actuator.

Here is a table showing the main components and materials used in zif connectors:

| Component Type | Description |

|---|---|

| Actuator Types | Flip-lock and slider actuators are the main types used in ZIF connectors. |

| Common Materials | Tin and gold are the primary materials used in ZIF connectors. |

| Corrosion Consideration | Tin can corrode and cause issues when mixed with gold, affecting reliability. |

How ZIF Connectors Work

You use a zif connector to make connections without mechanical stress. The zero insertion force mechanism lets you insert or remove integrated circuits easily. You do not need to apply pressure, which helps prevent damage and increases reliability.

- The zero insertion force mechanism enables easy insertion and removal of integrated circuits (ICs) without mechanical pressure.

- This design minimizes wear and tear on electronic components, enhancing their longevity and reliability.

- The ease of use reduces the risk of incorrect insertion, which can lead to connection failures and potential damage.

You find two main actuator mechanisms in zif connectors. Flip-lock actuators use a small lever that you flip to secure the connection. Slider actuators use a sliding part that locks the cable in place. Both types allow you to connect flexible printed circuits (FPC) or flat flexible cables without force.

- ZIF connectors utilize flipping or sliding actuator mechanisms.

- These mechanisms secure the connection after the flexible printed circuit (FPC) is inserted.

- The design allows for zero insertion force, reducing mechanical stress and enhancing durability.

When you use a zif connector, you protect your device from physical damage. You also make the installation process faster and safer. This technology helps you maintain the quality and performance of your electronics.

Cable ZIF Types

FFC and FPC Cables

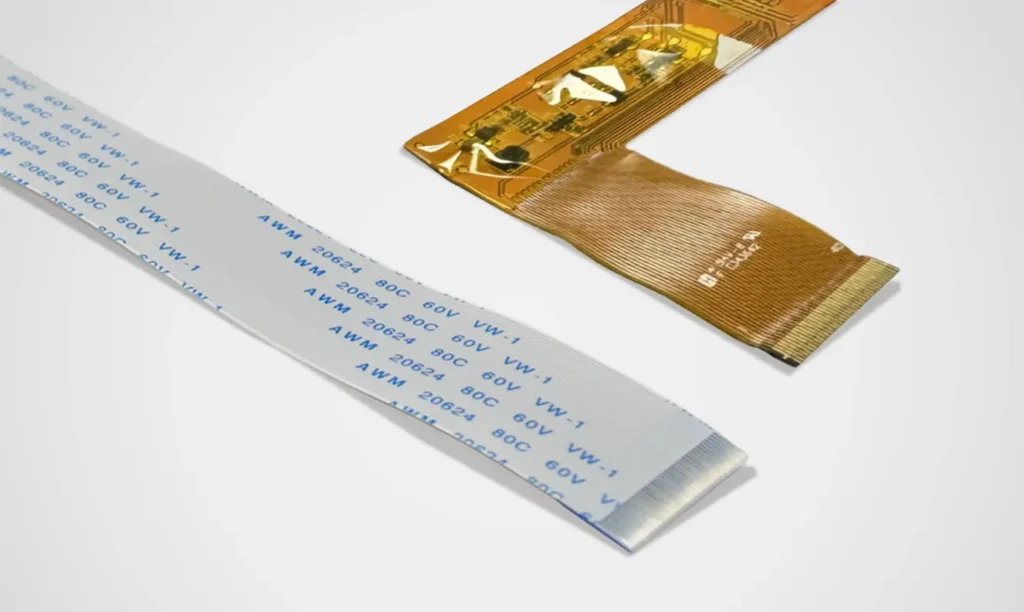

You often see two main types of cable zif in electronics: FFC and FPC cables. Each type serves a different purpose and fits specific needs in device design.

- FFC cables work best for simple connections. You find them in devices where the wiring path is straightforward.

- FPC cables handle complex tasks in tight spaces. You use them when you need flexible routing and compact layouts.

| Feature | FFC Cables | FPC Cables |

|---|---|---|

| Structure | Flat cables with simple linear wiring | Flexible printed circuits with complex routing |

| Cost | Lower cost, reusable | More expensive, designed for complex tasks |

| Application | Simple connections | Tight spaces, harsh environments |

You notice that FFC cables are made by stamping or laminating flat metal conductors between PET layers. This process creates a flexible flat cable that is easy to install and replace. FPC cables use light-based printing and chemical etching. This method allows you to create intricate circuit layouts for advanced electronics.

Tip: Choose FFC cables for basic connections. Select FPC cables when you need flexibility and reliability in small spaces.

ZIF Cable Structure

You rely on the structure of cable zif to ensure both flexibility and reliability. The design of these cables affects how well they perform in your devices.

- Long FFC cables can become loose during shipping. You should fasten the cable along its length to reduce movement and improve reliability.

- Short FFC cables, such as those only one inch long, often show greater reliability. You can tape FFC cables to the board for extra mechanical support.

| Connector Type | Pitch Range | Contact Count | Operating Temperature | Current Rating |

|---|---|---|---|---|

| ZIF FFC/FPC | 0.3-2.54mm | 2-250 contacts | -40°C to +125°C | 0.5-2.0A |

| LIF FFC/FPC | 0.5-2.0mm | 2-120 contacts | -40°C to +125°C | 0.5-3.0A |

| High-temp variants | 0.5-1.0mm | 10-68 contacts | -40°C to +125°C | 0.5A |

You see that cable zif comes in many sizes and configurations. You can use them in small devices or large systems. The tail structure varies, including straight, folded, reverse-conductor, or dual-ended options. This variety helps you match the cable to different board connectors. You also find that cable zif fits standard 0.5mm or 1.0mm pitch connectors from manufacturers like Hirose, JAE, or Molex.

Note: Pre-folding the cable reduces stress and makes installation easier. You avoid sharp bends and ensure reliable contact.

You use cable zif for its compatibility and performance. The structure supports a wide range of operating temperatures and current ratings. You can trust these cables to work in harsh environments and demanding applications.

ZIF Connectors in Devices

Consumer Electronics

You see zif connectors in many popular consumer electronics. Their design lets you connect and disconnect parts easily, which helps when you need to upgrade or repair your device. This feature is especially useful in products that often get new components. You find zif connectors in tablets and smartphones because these devices have very little space inside. The low profile of zif connectors fits well in tight spots.

- Tablets and smartphones use zif connectors for their screens and buttons.

- Laptops rely on zif connectors for touchpads and keyboards.

- Cameras and gaming consoles also use these connectors for internal parts.

ZIF connectors help your devices last longer. The zero insertion force design reduces wear and tear, so you do not damage the connector or the cable during use. A secure locking mechanism keeps the connection stable, which means your device works reliably over time.

Integrated Circuits

You use zif connectors when you need to connect integrated circuits in a compact and efficient way. These connectors support high-density connections, which is important for modern electronics. In automotive systems, such as infotainment and advanced driver assistance systems, zif connectors help manage complex wiring. You also find them in laptops, smartphones, and LED lighting systems.

- Rigid-flex printed circuit boards with zif connectors let you update single components without changing the whole board.

- This setup makes upgrades easier and saves time.

- Wearable devices use zif connectors to attach sensor modules to the main board, which helps with repairs and replacements.

Industrial and Medical Uses

You depend on zif connectors in industrial and medical equipment because they offer reliable and safe connections. Medical devices need connectors that can handle many pins, shield against interference, and work in extreme temperatures. Industrial machines benefit from zif connectors because they are cost-effective and easy to assemble. These connectors can last through at least 10,000 connection cycles.

| Application/Market | Features |

|---|---|

| Medical | High pin count: 60-440 layouts, EMI/RFI shielding, Operating temp: -40°C to +105°C |

| Industrial | Cost-effective, Fast and easy assembly, Min. 10,000 mating cycles |

Medical devices require connectors that deliver steady power, signal, and data. You must use connectors that meet strict standards for durability, biocompatibility, and resistance to sterilization. Organizations like the FDA and ISO set rules to make sure connectors are safe and reliable. You also need to follow regulations for labeling, quality, and materials to get approval for medical equipment.

ZIF Benefits and Drawbacks

Advantages

You gain several important benefits when you choose zif connectors for your electronic projects. The zero insertion force design helps you avoid mechanical stress during installation and removal. This feature reduces wear and tear, so your connectors and components last longer. You can connect and disconnect parts quickly, which is useful if you need to make frequent adjustments or repairs.

- You minimize the risk of incorrect insertion, which protects your device from connection failures.

- You experience less physical damage because the connector does not require force.

- You enjoy a longer lifespan for both the connector and the cable.

ZIF connectors can endure over 20,000 mating cycles. You can rely on them for repeated use in devices that need regular maintenance.

You also benefit from a low-profile design. This makes it easier to fit flat flexible cables into tight spaces on printed circuit boards. You simply open the connector, insert the cable, and close it to secure a reliable connection.

| Feature | Benefit |

|---|---|

| Zero Insertion Force | Less wear, longer lifespan |

| Quick Operation | Fast connection and disconnection |

| Low Profile | Fits in compact electronic assemblies |

| Reliable Locking | Reduces risk of connection failure |

Limitations

You should consider some challenges before using zif connectors. Signal degradation can occur over time, which may affect electrical performance and data integrity. Precise alignment is necessary, and misalignment can lead to unreliable connections. Environmental factors such as temperature and humidity also impact performance. High temperatures may increase electrical resistance and risk connector failure. Humidity can cause moisture intrusion, which leads to corrosion.

| Test Condition | Value |

|---|---|

| Relative Humidity | 90% – 95% (up to 98%) |

| Temperature | +40±20℃ |

| Test Duration | Less than 96 hours |

You may face limited compatibility with certain flexible printed circuit designs. Maintenance can be complex and time-consuming, which increases operational costs. The connectors are delicate, so you must handle them carefully to avoid damage.

- Signal degradation affects data quality.

- Alignment issues can cause unreliable connections.

- Environmental factors may shorten connector lifespan.

- Maintenance requires extra care and time.

Note: Always check the compatibility and environmental requirements before choosing zif for your application.

Using ZIF Cables

Choosing the Right ZIF Cable

You need to select the right cable for your project to get the best results from zif technology. Start by checking the number of pins. The pins on the cable must match the pins on your device. Next, look at the pitch, which is the distance between each pin. If the pitch does not match, you risk short circuits or poor connections. Pay attention to the connection side. The contacts on the cable must line up with the contacts on your device and the printed circuit board. The type of metal used in the connector also matters. Gold lasts longer than tin and works better for high-speed data transmission.

| Criteria | Description |

|---|---|

| Pins | The number of pins on the ZIF connector must match the number of pins on the tail of the display. |

| Pitch | The distance between individual pins must match the tail’s pitch to avoid short circuits. |

| Connection Side | The orientation of the connector’s contacts must align with the tail’s contacts and PCB design. |

| Metal | The type of metal used in the connector affects durability and compatibility; tin is less durable than gold. |

Tip: Always double-check the datasheet for your device before choosing a cable. This helps you avoid mistakes and ensures a reliable zif connection.

Installation Tips

You can make the most of zif technology by following a few simple steps during installation. Handle the cable gently to avoid bending or creasing it. Use the low insertion force feature to slide the cable into the connector without pushing hard. Make sure the cable sits flat and straight before you lock it in place. If your device supports high-speed data transmission, keep the cable away from sources of interference like motors or power lines. This helps you maintain signal quality.

- Align the cable with the connector before inserting.

- Use the actuator to lock the cable securely.

- Avoid touching the metal contacts with your fingers.

Note: A clean work area reduces the risk of dust or debris affecting the zif connectors.

Maintenance

You keep your devices running smoothly by caring for your cables and connectors. Inspect the cable and connector for signs of wear or corrosion. Clean the contacts with a soft, dry cloth if you see dirt or residue. If you notice any damage, replace the cable right away. Zif technology allows for easy removal and replacement, so you can swap out cables without damaging your device. For high-speed data transmission, check the connection regularly to prevent signal loss. The low insertion force design makes maintenance quick and safe.

Regular checks help you catch problems early and extend the life of your zif cable.

You see that ZIF cables offer reliable, cost-effective connections for sensitive electronics. Their zero insertion force design protects components and extends lifespan.

| Aspect | ZIF Connectors | Other Connectors |

|---|---|---|

| Cost-Effectiveness | Competitive pricing | Higher costs |

| Reliability | High durability | Often less durable |

| Lifespan | Extended | Shorter |

Industry experts recommend these steps for new designs:

- Test signal integrity after assembly.

- Select connectors with suitable temperature ratings and vibration resistance.

- Match connector pitch and current rating to your circuit.

- Avoid sharp bends near the connector entry.

You can trust ZIF solutions for high-precision and delicate electronic connections.

FAQ

What does ZIF stand for?

ZIF stands for “Zero Insertion Force.” You use this technology to connect cables or components without applying pressure. This design helps you avoid damage to delicate parts.

How do you install a ZIF cable?

You align the cable with the connector. Slide it in gently. Lock it using the actuator.

Tip: Do not force the cable. The connector holds it securely once you close the lock.

Where do you find ZIF connectors most often?

You see ZIF connectors in laptops, smartphones, cameras, and medical devices.

- They connect screens, keyboards, and sensors.

- You also find them in industrial machines.

Can you reuse ZIF cables?

Yes, you can reuse ZIF cables many times. The zero insertion force design lets you disconnect and reconnect without damaging the cable or connector.

What problems can happen with ZIF connectors?

You may face issues like poor alignment, signal loss, or corrosion.