A cable zif lets you connect delicate electronic parts without using much force. You simply slide the flat cable into a zif connector, and it locks into place. This zero insertion force design protects tiny pins and keeps your devices working longer. You find these connections in slim gadgets like tablets, cameras, and laptops where space matters most.

Key Takeaways

- ZIF cables allow easy connections without force, protecting delicate electronic parts and extending device life.

- The flat ribbon design of ZIF cables fits easily into tight spaces, making them ideal for compact devices like smartphones and tablets.

- ZIF connectors use a locking mechanism that prevents damage during installation, ensuring reliable connections for frequent use.

- Choosing the right ZIF cable involves matching pins, pitch, and connection type to your device for optimal performance.

- Regular maintenance and proper installation of ZIF connectors can significantly enhance their lifespan and reliability.

Cable ZIF Basics

ZIF Cable Structure

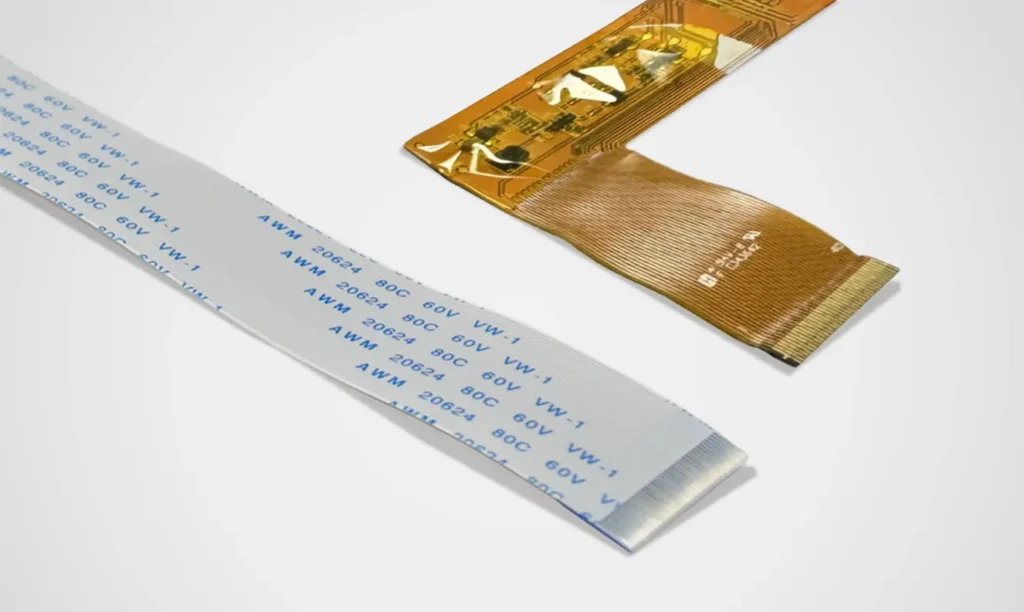

When you look at a cable zif, you notice its flat ribbon shape. This design makes it easy to fit into tight spaces inside electronic devices. The YLS ZIF FFC Cable uses a flexible, flat ribbon that bends and twists without breaking. You can install it in compact gadgets like tablets or cameras where every millimeter counts.

- The flat ribbon design lets you insert the cable gently, which helps prevent damage to delicate flex cables or PCB pads.

- You get high-density connections, so you can connect many signals in a small area.

- You can choose the pitch, length, and pin count to match your project, making it adaptable for different layouts.

- If you need to remove or replace the cable, you can do it easily, which helps during repairs or upgrades.

Tip: The flexibility of the YLS ZIF FFC Cable means you can route it around corners or fold it to save even more space.

ZIF Connector Mechanism

The zif connector uses a special clamping mechanism. You do not need to push hard or use tools to connect the cable. Instead, you slide the cable zif into the connector, and a locking flap holds it in place. This zero insertion force method protects fragile copper traces and prevents mechanical stress on your components.

- You avoid damaging circuits because there is no abrasion or pressure during installation.

- Assembly becomes faster and cleaner, which saves you time on the production line.

- You do not need a mating connector; the flex tail fits directly into the board-side connector.

- Zif connectors work well in devices that need to be opened and closed many times, like wearables or foldable electronics.

Note: The tool-free connection of zif connectors reduces installation time and lowers the risk of errors during assembly.

ZIF Connectors & Sockets

ZIF Connector Types

When you work with modern electronics, you find several types of zif connectors. Each type fits different needs and device designs. You can see the main types and their common uses in the table below:

| Type of ZIF Connector | Applications |

|---|---|

| Flat Flexible Cable (FFC) | Used in digital cameras, laptops, and compact devices due to flexibility and small size. |

| Land Grid Array (LGA) | Found in high-speed applications like servers and networking equipment. |

| Low Profile | Ideal for slim devices such as tablets and smartphones. |

| Through-Hole | Provides a robust connection, suitable for harsh conditions. |

You often choose the type based on the space available and the level of flexibility you need. For example, the cable zif works well in tight spaces because it bends easily and fits into small connectors. Low profile types help you save even more space in ultra-thin devices.

Zif connectors also come in many sizes and configurations. You can select the pitch, which is the distance between each contact. Common pitches include 1.27 mm, 2.00 mm, and 2.54 mm. The number of contacts can range from just a few up to 240, so you can match the connector to your project’s complexity.

ZIF Socket Features

A zif socket uses a special locking flap mechanism. This design lets you insert or remove the cable without using force. The zero insertion force technology protects the delicate contacts and prevents damage during installation or removal. Here is how the locking mechanism works:

- You slide the cable into the socket with almost no resistance.

- A lever, slider, or latch secures the cable in place.

- The locking flap holds the cable steady, so the contacts stay safe.

- You can open and close the mechanism many times without wearing out the socket.

Tip: Always make sure the lever or slider is in the correct position before inserting or removing the cable. This step helps you avoid damaging the contacts.

Zif connectors use different locking styles, such as levers, sliders, latches, or hinges. These features ensure a solid connection and make assembly easy. You do not need special tools, which saves you time and reduces the risk of mistakes.

You can customize zif sockets to fit your needs. YLS offers options for pitch, pin count, and length. You can also request special layouts or reinforced structures for unique projects. The table below shows some of the features and benefits you get with YLS zif sockets:

| Feature | Benefit |

|---|---|

| Flexible routing | Faster, simpler assembly |

| Temperature resistance | Reliable in demanding environments |

| Up to 96-pin configurations | Supports complex electronic systems |

If you need a custom solution, YLS can help you design a socket that matches your exact requirements. You get flexibility, durability, and reliable performance for any application.

ZIF Cable Applications

Consumer Electronics

You see zif technology everywhere in modern consumer electronics. Manufacturers use cable zif to connect parts inside slim devices. You find these cables in:

- Smartphones

- Tablets

- Laptops

These devices need reliable and compact connections. Zif connectors make assembly easy and safe. You can connect and disconnect display modules or touch panels without damaging the parts. This feature helps during repairs or upgrades.

Here is how zif cables improve reliability in touch panels and display modules:

- The zero insertion force design lets you connect and disconnect parts quickly, which reduces mechanical stress.

- You lower the risk of incorrect insertion, so connection failures happen less often.

- The easy-to-use design makes zif connectors perfect for devices that need frequent adjustments.

You also benefit from secure and long-lasting connections. Zif connectors use a locking mechanism that keeps the cable in place. This design minimizes cable wear and extends the life of your device. The compact size fits well in space-limited gadgets, which boosts performance.

YLS offers OEM and ODM services for consumer electronics. You can customize pitch, length, and pin count to fit your project. YLS engineers help you design the right solution for your device.

Medical & Industrial Devices

Zif cables play a key role in medical and industrial equipment. You need precise and safe connections in these fields. The table below shows how zif features help in medical devices:

| Feature | Benefit |

|---|---|

| Zero Insertion Force (ZIF) | Allows precise connections in laparoscopic tools |

| Sterilizable, IP-rated connectors | Withstand repeated autoclaving and fluid exposure |

You use zif technology in surgical tools, diagnostic machines, and industrial robots. The reliable connection keeps your equipment running safely. YLS adapts cable designs for harsh environments and strict safety standards. You can work with YLS to create custom cables for any application.

ZIF Cable Advantages

Benefits

When you use zif cables in your projects, you gain several important benefits. The low insertion force design lets you connect delicate components without risking damage. You do not need to apply pressure, so you protect sensitive pads and traces on your circuit boards. This feature helps you extend the lifespan of your devices.

You also get flexibility. The flat ribbon style bends and folds easily, which makes routing simple in tight spaces. You can fit these cables into compact assemblies, such as smartphones or medical devices, without trouble. The locking mechanism keeps connections secure, even if you need to open and close the device many times.

Take a look at how zif technology compares to other connection methods:

| Feature | ZIF Connectors | Flexible Test Fixtures |

|---|---|---|

| Cycle Life | Low; not for repeated use | High; withstand many cycles |

| Signal Integrity | May degrade over time | Consistent transmission |

| Alignment | Needs precise alignment | Easy alignment |

| Environmental Resilience | Sensitive to temperature/humidity | Resistant to environmental factors |

| Device Protection | Risk of damaging FPC pads | Gentle connection, protects device |

| Maintenance Complexity | Complex and time-consuming | Easy to maintain |

Tip: You can choose gold-plated contacts for better conductivity and corrosion resistance, which further improves reliability.

Limitations

You should also know about some common challenges when working with zif cables. Mechanical stresses, such as bending, twisting, or pulling, can cause connector degradation. Corrosion may develop if the cable faces harsh environments, which affects electrical performance. If the contacts deform, you might lose a reliable connection, especially in areas with strong vibrations.

Here are some typical failure modes:

| Failure Mode | Description |

|---|---|

| Mechanical Stresses | Bending or pulling can degrade connectors |

| Corrosion | Environmental factors may affect performance |

| Loss of Positive Force | Deformed contacts reduce connection reliability |

| Debris Generation | Wear can create particles that contaminate contacts |

| Wear of Electrical Contacts | Frequent use wears down contact surfaces |

When you install zif connectors in compact assemblies, you may face these challenges:

- A one-time bend of 45° usually causes only minor visual stress.

- Bends of 90° or more can cause cracks, especially in ENIG-plated circuits.

- Cracks may not break the circuit right away, but they increase the risk of future failure.

Note: Always handle zif cables gently and avoid sharp bends to maintain long-term performance.

ZIF Cable Selection & Installation

Choosing ZIF Cables

Selecting the right zif cable for your project helps you achieve reliable performance and long device life. You need to match several key criteria to your application. The table below shows what you should check before making a choice:

| Criteria | Description |

|---|---|

| Pins | Match the number of pins on the cable and connector. |

| Pitch | Make sure the distance between pins fits your connector to avoid damage. |

| Connection Side | Align the connector’s contacts with the cable for a proper zif connection. |

| Metal | Choose gold-plated contacts for better durability and high-speed data transmission. |

YLS offers a wide range of options, including custom pin counts, pitches, and lengths. All YLS cables meet UL, RoHS, and REACH standards, so you can trust their safety and quality.

Installing ZIF Connectors

Proper installation of zif connectors protects your device and ensures a low insertion force connection. Follow these steps for best results:

- Confirm that the connector matches the cable in pins, pitch, connection side, and metal type.

- Open the connector fully before inserting or removing the cable.

- Insert the cable gently, making sure it sits straight and flat.

- Close the locking flap or lever to secure the cable.

- Clean the connector with a soft, dry cloth to prevent dust buildup.

- Store unused connectors in a cool, dry place away from sunlight.

Tip: Always check the lever or slider position before handling the connector. This step helps you avoid accidental damage.

Maintenance Tips

You can extend the life of your zif technology by following a few simple maintenance practices:

- Use zif connectors in applications with frequent connections to reduce wear.

- Align the cable and connector precisely during assembly to maintain signal quality.

- Add strain relief features to protect against mechanical stress and increase lifespan.

- Choose gold-plated contacts for excellent corrosion resistance and reliable electrical performance.

YLS provides gold plating options for enhanced durability. Their cables undergo strict quality checks and come with full documentation, so you can install and maintain them with confidence.

You now know that ZIF cables offer flexibility, easy installation, and strong reliability for modern electronics. When you choose a solution like the YLS ZIF FFC Cable, you get customizable options that fit many applications.

- ZIF connectors save time and reduce errors with their zero insertion force design.

- Their compact build supports smaller, more efficient devices.

- The market for ZIF technology continues to grow, showing its value in the industry.

ZIF cables make your electronic projects easier, safer, and more efficient.

FAQ

What is the main advantage of a ZIF cable?

You get easy, tool-free connections with a ZIF cable. The zero insertion force design protects delicate parts and helps you avoid damage during installation or removal.

Can I use ZIF cables in high-speed applications?

Yes, you can use ZIF cables in high-speed applications. These cables support fast data transfer and maintain signal quality, making them suitable for advanced electronics.

How do I choose the right ZIF cable for my device?

Tip: Check the number of pins, pitch, length, and connector type. Make sure the cable matches your device’s requirements for a secure and reliable fit.

Are ZIF cables reusable?

You can reuse ZIF cables many times. The locking mechanism allows you to insert and remove the cable without wearing out the contacts quickly.