A ZIF connector gives you a way to join delicate electronic parts without using force. Zero insertion force helps you avoid damaging fragile components during installation. You often use ZIF connectors in devices with thin, flexible cables, like displays or cameras. When you choose a connector for sensitive electronics, you reduce the risk of pin breakage and contact wear.

- Common issues include alignment problems, incomplete connections, and wear from repeated cycles.

These risks make ZIF connectors important for modern electronics that need gentle handling.

Key Takeaways

- ZIF connectors allow you to connect delicate electronic parts without applying force, reducing the risk of damage.

- The zero insertion force mechanism simplifies installation, making it easy to connect and disconnect components without tools.

- Choosing the right ZIF connector involves checking the pin count, pitch, and material to ensure a reliable connection.

- ZIF connectors are ideal for high-cycle environments, supporting frequent assembly and maintenance without wear.

- These connectors are widely used in consumer electronics, medical devices, and automotive systems, enhancing device reliability and performance.

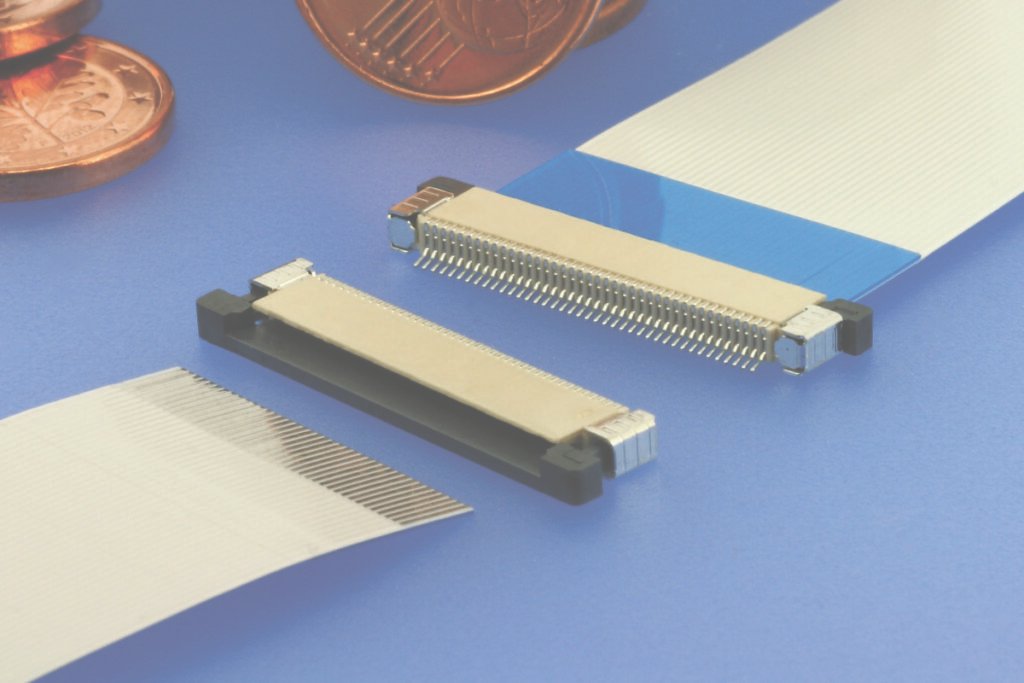

ZIF Connector Basics

What is a ZIF Connector

You often see a ZIF connector in modern electronics when you need to connect delicate parts like displays or flexible cables. ZIF stands for zero insertion force. This means you can insert or remove a cable or component without applying pressure. You avoid damaging fragile pins or contacts, which is important for devices that require frequent assembly or maintenance.

- ZIF connectors use a special technology that lets you insert and remove integrated circuits (ICs) or cables easily.

- You will notice a lever or slider on most ZIF connectors. This part secures or releases the cable or IC, making the process simple and safe.

- The design reduces mechanical stress on the parts you connect, which helps your devices last longer.

You can find ZIF connectors in many forms. Some have a single row of pins, while others use a dual-row layout for higher connection density. The main parts of a typical ZIF connector include pins, pitch, connection side, and metal contacts. The table below shows these components and their roles:

| Component | Description |

|---|---|

| Pins | The number of pins must match the tail of the display to ensure proper fit and function. |

| Pitch | The distance between individual pins; must match the tail’s pitch to avoid short circuits. |

| Connection Side | Refers to which side of the connector has contacts; important for orientation with the PCB. |

| Metal | Common metals include tin and gold; choice affects durability and performance of the connection. |

Materials also play a big role in how well a ZIF connector works. Manufacturers use polyimide, polyester, and FR-4 for flexibility, strength, and electrical performance. The thickness and alignment of these materials help prevent damage during use.

Tip: When you choose a ZIF connector, always check the pin count, pitch, and material. This ensures a reliable and long-lasting connection.

Recent advances in ZIF connectors include micro and nano designs for smaller devices. Manufacturers now focus on recyclable materials and high-speed data transmission to meet the needs of IoT and Industry 4.0.

Zero Insertion Force Mechanism

The zero insertion force mechanism sets ZIF connectors apart from other types. You do not need to push or force the cable or IC into place. Instead, you follow a simple process:

| Step | Description |

|---|---|

| 1 | You open the connector using a hinged or sliding mechanism. This step requires no force. |

| 2 | You gently place the component or cable into the socket. There is no pressure on the pins or contacts. |

| 3 | You close the connector, which clamps the leads or pins securely in place. |

For example, when you connect a display tail, you slide it into the ZIF connector. A movable piece, such as a lever or slider, locks the tail in place. This method ensures a secure fit without stressing the cable or the connector.

ZIF connectors offer a clear advantage over other connectors that use low insertion force. With ZIF connectors, you reduce the risk of bent pins, incomplete connections, and wear from repeated use. However, newer dual-row ZIF connectors can sometimes face reliability issues due to their smaller trace widths. If you do not need high connection density, a single-row ZIF connector often provides better long-term reliability.

You see ZIF connectors in many growing markets. The global market for ZIF connectors is expanding, with a projected value of over $117 billion by 2032 and a steady growth rate. This trend shows how important these connectors have become for electronics, especially as devices get smaller and more complex.

Features and Types of ZIF Connectors

Key Features

When you look at a zif connector, you notice several features that set it apart from other connector types. The zero insertion force design lets you connect and disconnect cables or components without applying pressure. This feature helps you avoid damaging fragile contacts. You get high reliability, especially in devices that need frequent assembly or maintenance. ZIF connectors offer flexibility and versatility, so you can use them in many different applications. Their compact size makes them ideal for small devices and tight spaces.

- Zero insertion force design makes connections easy and safe.

- High reliability supports frequent changes and long-term use.

- Flexibility and versatility allow you to choose the right connector for your project.

- Compact size fits well in modern electronics.

You often use ZIF connectors in high-vibration or high-cycle environments. The table below shows how these connectors maintain reliable connections:

| Key Aspect | Description |

|---|---|

| Stiffeners | Enhance mechanical stability and reduce stress. |

| Material Overlap | Improves durability and prevents material fatigue. |

| Simplified Assembly | Reduces potential points of failure by eliminating the need for a mating connector. |

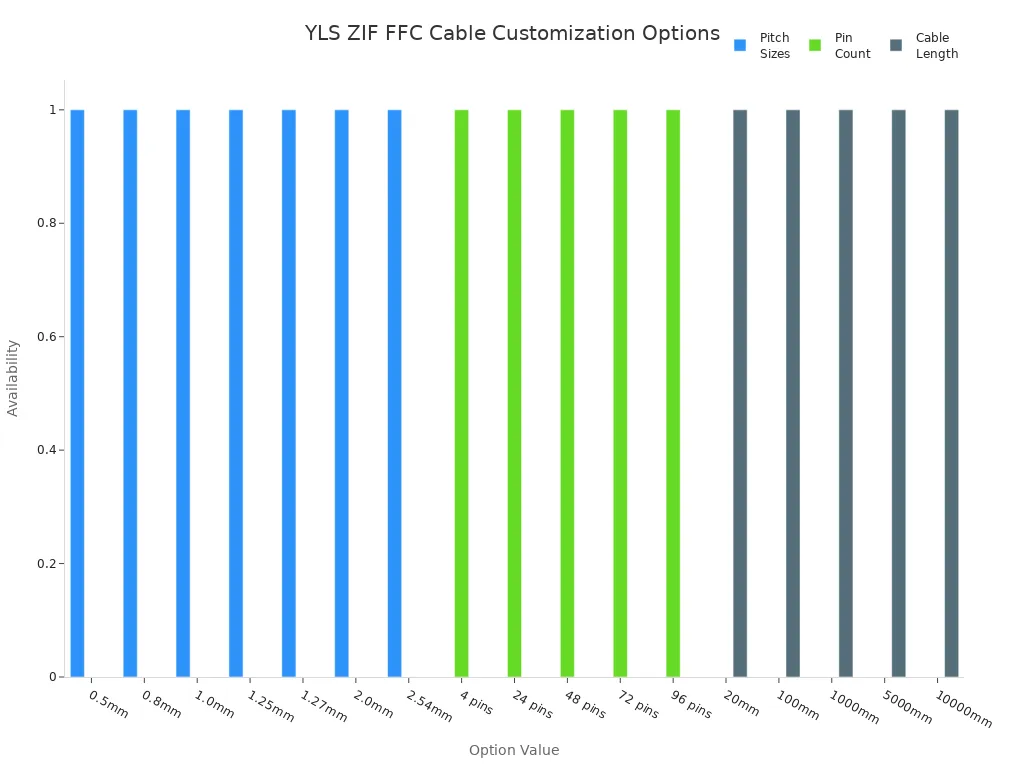

If you need a cable for your project, the YLS ZIF FFC Cable gives you many customizable options. You can select the layout, contact type, pitch, pin count, cable length, and tail structure. The cable works with Hirose, Molex, and JAE connectors, so you get broad compatibility. Gold plating and reinforced structures add durability for high-cycle use. The chart below shows the range of pitch sizes, pin counts, and cable lengths available:

Tip: Choose a ZIF FFC cable with the right pitch and pin count to match your device and ensure a secure fit.

Common Types

You find different types of zif connectors in the electronics industry. Each type suits specific needs and applications. The table below lists the most widely used types:

| Connector Type | Description | Pin Count Range |

|---|---|---|

| DL | Plastic shell | 60 to 408 |

| DLM | Metal shell | 60 to 408 |

| DLP | Enhanced shielded | 60 to 408 |

| QLC | Miniaturized | 60 to 408 |

You see these different types of zif connectors in devices like displays, cameras, and PCBs. ZIF FFC cables work with these connectors to provide tool-free, reliable connections. You insert the flat flexible cable into the connector housing without tools. The design ensures a secure and removable connection, which is important for printed circuit boards and other sensitive electronics.

You can select from different types of zif connectors based on your project’s requirements. The YLS ZIF FFC Cable supports many layouts and tail structures, so you get a perfect fit for your application. You benefit from easy assembly, strong durability, and broad compatibility.

Applications of ZIF Connectors

Consumer Electronics

You see zif connectors everywhere in modern consumer electronics. These connectors help you build devices that are smaller, lighter, and more reliable. In smartphones, you use them to connect displays, making assembly quick and reducing the risk of damage. Laptops rely on zif connectors to link internal parts, such as touchpads and keyboards, to the main board. Cameras use them for display connections, which makes repairs and upgrades easier.

- ZIF connectors allow you to design compact devices because you can connect and disconnect cables without force.

- The zero insertion force mechanism reduces wear on the connector, so your device lasts longer.

- Micro and nano versions support high-speed connections in small gadgets like wearables.

The YLS ZIF FFC Cable supports many of these applications. You can use ultra-thin FFCs for displays behind glass panels, flexible cables for touch panels, and multi-pin cables for smart home devices. For example, you might connect a temperature sensor or a smart speaker using a shielded FFC. This flexibility helps you create advanced products for the smart home market.

Note: ZIF connectors make assembly and disassembly easy, which is important for devices that need frequent servicing.

Medical and Automotive Uses

You also find zif connectors in medical devices and automotive systems. In medical equipment, you use them to support display interfaces and ensure reliable connections. Automotive systems benefit from quick and easy connections, especially in areas where you need to swap parts often.

| Application Area | Specific Uses |

|---|---|

| Medical Devices | Support for various display interfaces, ensuring reliable connections in devices. |

| Automotive Systems | Used in systems requiring frequent connection and disconnection, enhancing efficiency. |

You reduce the risk of incorrect insertion, which helps prevent connection failures in critical systems. ZIF connectors also work well in high-cycle environments, such as automotive dashboards or medical monitors.

When you use YLS ZIF FFC cables, you get compact and durable solutions for displays, sensors, and control modules. These cables fit into tight spaces and withstand repeated use, making them ideal for both medical and automotive applications. You also maintain reliable signal integrity, which is essential for safety and performance.

Advantages and Limitations

Benefits

You gain several important benefits when you use a ZIF connector in your electronic projects. The zero insertion force design makes installation and maintenance much easier. You do not need to push or force cables into place, so you avoid damaging fragile contacts. This technology helps you create reliable connections and reduces the chance of physical damage. Your devices last longer because you minimize wear and tear during assembly and servicing.

You also enjoy quick and easy connections. You can connect and disconnect components without tools, which saves you time and lowers the risk of mistakes. The design of ZIF connectors makes it less likely for you to insert cables incorrectly, so you prevent failures that could affect your device. You find these connectors especially useful in applications that require frequent changes, such as displays, touch panels, and PCBs.

- You reduce mechanical stress during insertion and removal.

- You experience less wear and tear on both connectors and components.

- You lower the risk of incorrect insertion, which helps prevent connection failures.

- You benefit from high reliability and quality connections.

- You save time with efficient, user-friendly assembly.

Tip: If you work with sensitive electronics or need to swap parts often, ZIF connectors offer a smart solution for long-lasting performance.

Drawbacks

You should also consider some limitations when choosing ZIF connectors for your project. ZIF connectors may cost more than traditional connectors, especially in specialized designs. You might need to pay attention to compatibility with certain cable types or layouts. Some ZIF connectors require precise alignment during installation, so you must handle them carefully to avoid connection issues.

You may find that ZIF connectors are not always suitable for high-power applications or environments with extreme vibration. The compact design works best for low-voltage signals and delicate components. If you need a connector for rugged or outdoor use, you should check the specifications to make sure it fits your needs.

Note: Always review your project requirements and connector specifications before making a final choice. This helps you avoid problems and ensures a reliable connection.

Practical Tips for ZIF Connectors

Choosing the Right Connector

Selecting the right connector for your project helps you achieve reliable performance and easy assembly. You should consider several factors before making a choice. The pitch, pin count, and length must match your device’s requirements. The orientation of contacts and the type of metal used also affect durability and compatibility. The table below highlights important factors to review:

| Factor | Description |

|---|---|

| Pitch | The distance between individual pins on the connector tail, crucial for compatibility with the display. |

| Connection Side | The orientation of contacts on the connector, which affects how it connects to the PCB. |

| Metal Used | The type of metal (tin or gold) impacts durability and performance, especially in fine pitches. |

You should also check compatibility with leading brands such as Hirose, Molex, JAE, and Amphenol. Each brand offers unique connector series with different pitch sizes and profiles. The table below shows examples:

| Brand | Connector Series | Pitch (mm) | Height (mm) | Pin Count | Description |

|---|---|---|---|---|---|

| Hirose | FH34SRJ | 0.5 | 1.0 | N/A | Low-profile, compatible with 0.3 mm thick fpc/ffc. |

| JAE | FA10 | 0.5 | 0.9 | N/A | One-action LIF connector, space-saving design. |

| Amphenol | F31L | 0.5 | 2.55 | 4 to 80 | Right angle ZIF flex connector, ideal for various applications. |

| KYOCERA | 6824 | 0.4 | 0.93 | N/A | Designed for mobile equipment, low-profile features. |

If you need a custom solution, YLS offers ZIF FFC cables with options for pitch, pin count, and length. You can request special layouts or reinforced structures to fit your specific needs. This flexibility supports projects with unique requirements, including those involving ics or sensitive displays.

Tip: Always match the connector’s specifications to your device to ensure smooth component insertion and removal.

Installation and Maintenance

Proper installation and maintenance help you extend the life of your connector and prevent failures. Follow these best practices:

- Open the connector fully before inserting or removing the cable to avoid damage.

- Handle the connector gently to prevent harm from excessive force.

- Clean the connector regularly with a soft, dry cloth to keep dust away.

- Store connectors in a cool, dry place, away from sunlight and heat.

You should use the correct ffc or fpc for your application. This ensures a secure fit and reliable signal transmission. YLS provides support for installation and can help you choose the right cable for your project.

Note: Careful handling and regular cleaning keep your connector working well, especially in high-cycle environments.

You gain many advantages when you choose the right ZIF connector for your project.

- ZIF connectors give you secure, low-stress connections that last longer.

- You enjoy quick, easy assembly and fewer connection errors.

- The design helps prevent damage and supports frequent changes.

Customizable options like the YLS ZIF FFC Cable let you match your exact needs.

| Feature | Benefit |

|---|---|

| Flexible routing | Faster, simpler assembly |

| Temperature resistance | Reliable in demanding environments |

| Up to 96-pin configurations | Supports complex electronic systems |

Explore tailored solutions to boost your device’s performance and reliability.

FAQ

What makes ZIF connectors different from other connectors?

You use ZIF connectors when you want to avoid damaging delicate parts. These connectors let you insert cables or components without force. Most connectors need pressure, but ZIF connectors use a lever or slider. This design helps you protect sensitive electronics and ensures reliable connections.

How do you install a cable into ZIF connectors?

You open the lever or slider on ZIF connectors. You gently place the cable into the slot. You close the lever to lock the cable. This process keeps connectors safe from damage. You do not need tools. ZIF connectors make installation quick and easy.

Where do you commonly find ZIF connectors in electronics?

You find ZIF connectors in laptops, smartphones, cameras, and medical devices. These connectors work well in tight spaces. You use ZIF connectors for displays, touch panels, and sensors. Many modern devices rely on these connectors for secure, tool-free connections.

Can ZIF connectors handle frequent connections and disconnections?

Yes, ZIF connectors are built for high-cycle use. You can connect and disconnect cables many times without wearing out the connectors. These connectors use durable materials. You often see ZIF connectors in devices that need regular maintenance or upgrades.

Are ZIF connectors compatible with flexible flat cables (FFC)?

You can use ZIF connectors with flexible flat cables. These connectors support FFCs in many applications. You choose the right pitch and pin count for your connectors. ZIF connectors and FFCs give you reliable, compact, and easy-to-install connections in modern electronics.