A high speed ffc cable has copper wires that run side by side. These wires are inside a thin, flat plastic strip. Flex cables move digital signals fast and well. Engineers pick flex cables because they are small and can bend easily. Flex cables do not break when bent. Many new devices use ffc to link parts in small spaces. Flat flexible cables and flex cables make electronics less crowded. They help air move better inside devices. Flex cables can send lots of data quickly. This makes them important for modern technology. A flat flexible cable often takes the place of old wires. It works best where bending and speed are needed.

- Flex cables help save space and make devices work better.

- High speed ffc cable gives steady and quick links between parts.

Key Takeaways

- High speed FFC cables have flat copper wires inside soft plastic. They send data quickly and stay strong when bent. Shielding and good spacing between wires keep signals clear. This also stops outside noise from causing problems. Flex cables can bend many times and do not break. This makes them good for devices that move or shake. These cables save space inside devices and make connections simple. They help electronics stay small and work fast. Flex cables cost less than other cables and are easy to put in. This makes them a smart pick for many uses.

High Speed FFC Cable

Structure and Materials

A high speed ffc cable is flat and looks like a ribbon. Inside, copper conductors run next to each other. These conductors are between layers of flexible plastic, like polyimide or polyester. This design lets flex cables bend and twist without breaking.

- Copper or gold-plated contacts let electricity move easily. This keeps resistance low and helps data move fast.

- Heat-resistant plastics keep the cable safe in hot places.

- Materials that do not rust help flex cables last longer, even in tough spots.

- The way the conductors are lined up keeps them spaced out. This is important for keeping signals strong.

Flat flexible cables sometimes have extra layers for shielding. These layers stop outside signals from messing up the cable. Flex cables can bend, fold, and twist many times. This makes them great for small devices that need strong connections.

Tip: New high speed flex cables use special materials like polyimide. This helps them handle heat and last longer. It also keeps signals from getting weak and lets data move fast.

Signal Integrity

Signal integrity means the signal stays strong and clear in the cable. Flex cables must keep signals from getting lost or noisy. Many things can hurt signal integrity in a high speed ffc cable:

- Resistance in the wires can turn signal energy into heat. This makes the signal weaker over time.

- At high speeds, current moves to the outside of the wire. This is called the skin effect. It makes resistance and signal loss worse.

- Wires close together can cause unwanted effects. These effects can change the signal.

- If the cable’s impedance is not right, signals can bounce back. This makes the signal weaker.

- Other electronics can cause electromagnetic interference (EMI). This adds noise and hurts the signal.

Flex cables use shielding, like metal foil or mesh, to block EMI. Good grounding at connectors and in the system helps keep signals strong. Tough cable jackets protect against scratches, chemicals, and heat. Careful testing checks for impedance, signal loss, and shielding. This makes sure high speed flex cables work well in real life.

Note: Bending the cable many times can stress the copper and shields. Good flex cables use strong materials and smart design. This stops breaks and keeps signals strong.

Pitch and Shielding

Pitch is the space between each conductor in the cable. In ffc, pitch is usually from 0.5 mm to 2.0 mm. The pitch changes the cable’s size and how it works.

| Aspect | Explanation |

|---|---|

| Pitch Definition | Space between conductors, usually 0.5mm to 2.00mm in ffc cables |

| Wider Pitch | Lets each wire have its own shield, cuts EMI, and helps heat escape |

| Smaller Pitch | Fits more wires in a small space, but needs good EMI control |

| EMI Shielding | Built into connectors and cables for fast data |

| Connector Examples | I-PEX EVAFLEX and Molex connectors have tight pitches and EMI shielding |

| Limitations | For speeds over 10 Gbps, micro-coaxial cables may work better |

A smaller pitch lets engineers put more wires in a tiny space. This is good for new electronics that need lots of connections. But a smaller pitch makes it harder to stop EMI and keep signals strong. Shielding gets more important as pitch gets smaller. Some connectors, like I-PEX EVAFLEX, have built-in EMI shielding. This helps flex cables send fast signals without problems.

Flex cables with wider pitch can shield each wire by itself. This lowers EMI and keeps the cable working well, even at high speeds. For very fast data, like over 10 Gbps, engineers might pick micro-coaxial cables. These cables give even better shielding and signal strength.

Tip: Picking the right pitch and shielding is important for high speed ffc cable. Engineers must choose the best size, flexibility, and signal strength for each job.

How FFCs Work

Data Transmission

Flat flexible cables use copper conductors that run side by side. These conductors sit inside a thin, flat strip. This design keeps the electrical path smooth. Signals move quickly and clearly along these paths. There is little resistance or loss. The flat shape helps control impedance. This means signals do not bounce or get weak. Keeping data clean and fast is very important.

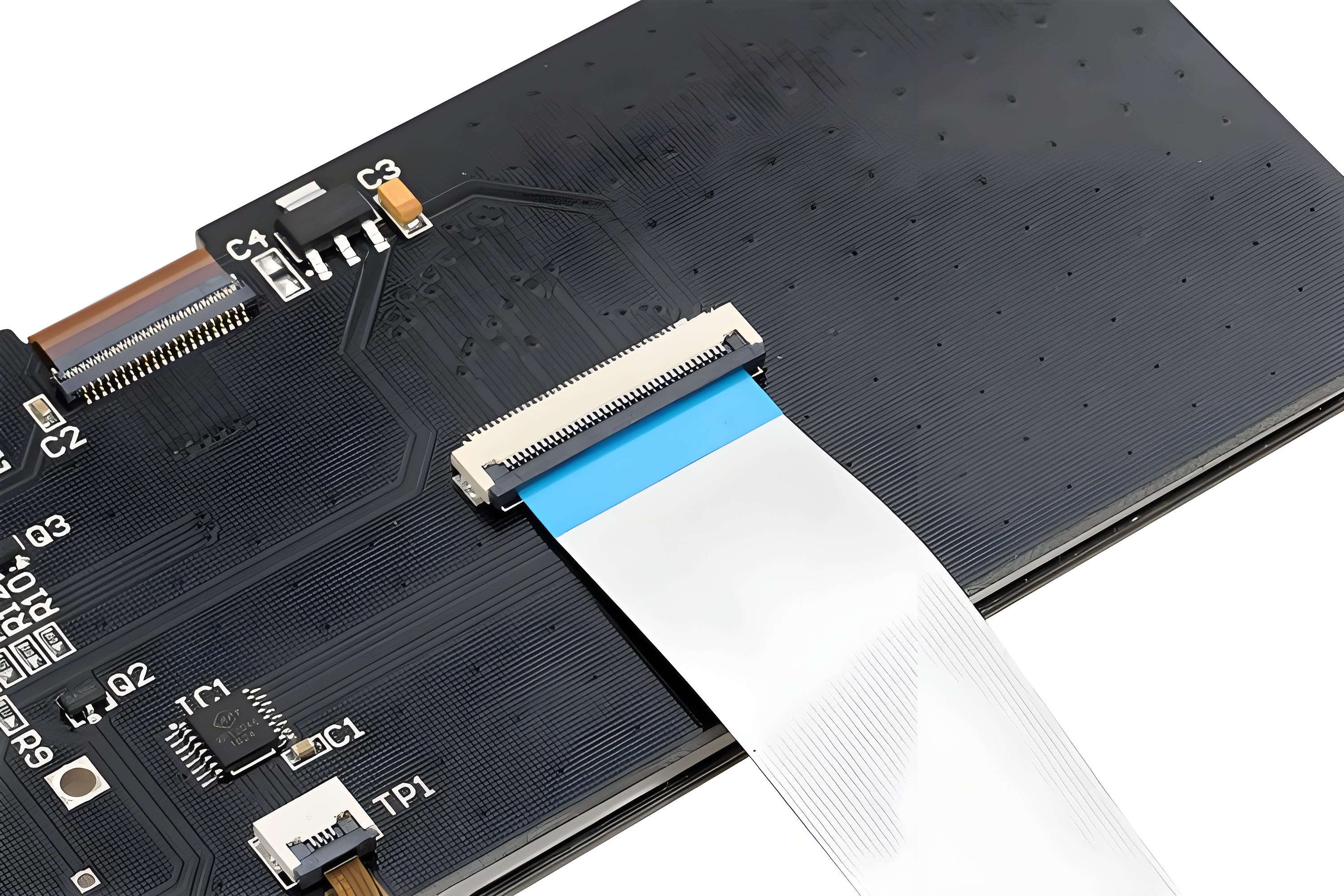

Special connectors, like Zero Insertion Force or Low Insertion Force, attach flex cables to circuit boards. These connectors hold the cable tight but do not hurt it. Shielding, like metal foil or mesh, wraps around the conductors. This blocks outside noise and keeps the signal strong. Even in busy systems, the signal stays clear.

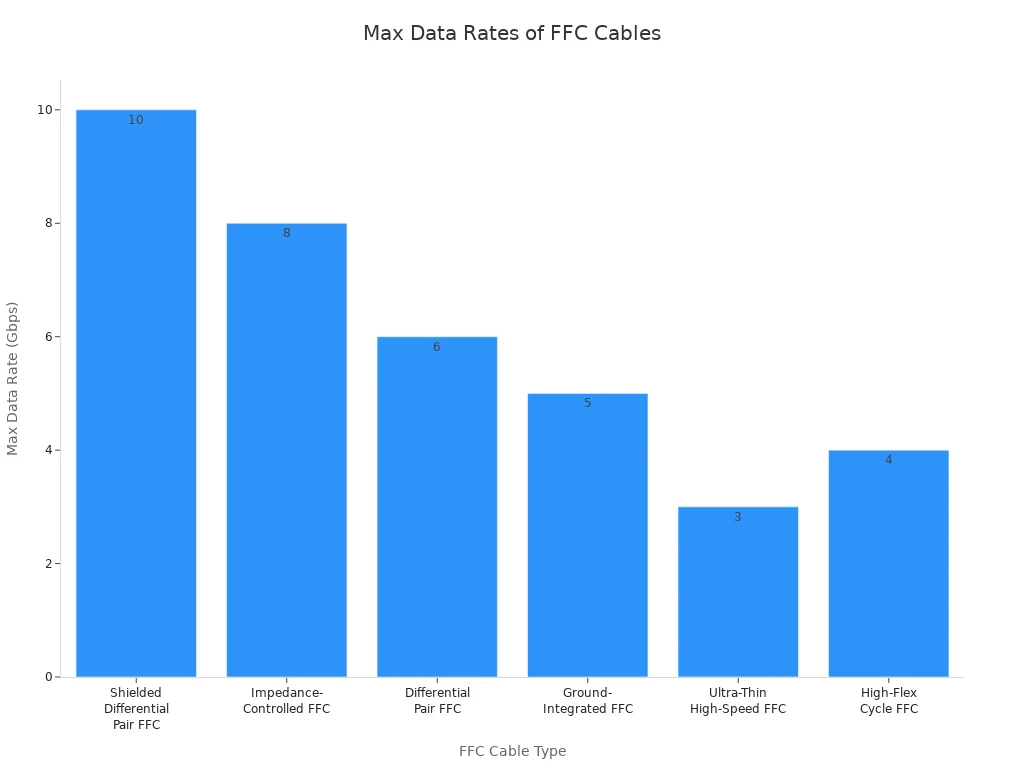

The table below shows how different flex cables support high-speed data rates for many uses:

| Cable Type | Max Data Rate | Key Use Case |

|---|---|---|

| Shielded Differential Pair FFC | Up to 10 Gbps | Medical, automotive, USB 3.0, HDMI |

| Impedance-Controlled FFC | Up to 8 Gbps | Display, camera, board-to-board |

| Differential Pair FFC | Up to 6 Gbps | LVDS, eDP, MIPI, CAN |

| Ground-Integrated FFC | 3–5 Gbps | Sensor interface, industrial control |

| Ultra-Thin High-Speed FFC | Up to 3 Gbps | Foldable displays, wearables |

| High-Flex Cycle FFC | Up to 4 Gbps | Robotics, diagnostic equipment |

Flex cables keep the signal path short and direct. This helps devices send and get information fast. Fine pitch means small space between conductors. More signals fit in a small area. Flex cables are great for small electronics that need to move lots of data.

Tip: Using flex cables with controlled impedance and good shielding helps stop signal loss and keeps high-speed data moving smoothly.

Flexibility and Reliability

Flex cables bend, fold, and twist without breaking. This lets engineers fit them into tight spaces. The flat, ribbon-like shape makes routing easy. Flex cables can handle movement and vibration. This is common in cars, robots, and machines.

Reliability is important when flex cables move many times. Makers test these cables for millions of flex cycles at different temperatures. The table below lists some key reliability facts for flex cables:

| Reliability Metric | Description/Requirement |

|---|---|

| Mechanical Protection | Impact and crush resistance tested per UL 1277; example rating MP-02 includes 10/50 lbs impact, 1,000/2,000 lbf crush, tensile strength 1,700 psi, elongation 175% |

| Oil Resistance | UL Oil Resistance Level I: 4 days at 100°C, retain ≥50% tensile strength and elongation |

| UL Oil Resistance Level II: 60 days at 75°C, retain ≥65% tensile strength and elongation | |

| Flame Resistance | UL VW-1 (UL 1581) Vertical Flame Test; cable must not emit flame or glowing particles during test |

| Endurance to Flexing | Withstand over 8 million cycles of continuous flexing at temperatures from -40°C to +90°C |

Flex cables also resist oil, heat, and flames. This makes them safe and strong for many jobs. Their light weight puts less stress on connectors. This helps keep connections tight over time.

- Flexibility lets flex cables bend or fold without damage. This is important for routing in small spaces.

- Their low profile and high flexibility help install them in tight or odd spaces.

- Flex cables can handle vibrations and temperature changes. This helps them last longer.

- Securing the cable with tape or fasteners reduces stress and improves reliability.

- The light weight of flex cables lowers force on connectors. This helps prevent loose connections.

Proper handling and installation help flex cables last longer. Shorter cables have fewer problems. Longer cables may need extra support to stay in place. Matching the cable thickness to the connector and avoiding sharp bends keeps the connection strong.

Note: Flex cables are made to survive bending and flexing many times. Their materials resist wear and tear. This makes them reliable for high-speed data in devices that move or vibrate.

High Speed Features

Design Factors

Engineers make flex cables work fast by thinking about a few things. The size of each conductor is important. The space between conductors matters too. The materials used in the cable help signals move quickly. When conductors are close together, it is called pitch. Smaller pitch means more signals can travel next to each other. Common pitches are 0.5mm, 0.8mm, and 1.0mm. Smaller pitch can make data move faster. But it can also make the cable harder to build and cost more. The size of the conductor also affects how it works. Thin conductors fit in small spaces. But they can lose more signal at high frequencies. This happens because of the skin effect. The skin effect makes current flow on the surface of the conductor. This raises resistance and can make the signal weaker.

Engineers need to match the cable’s pitch with the connector. This keeps the connection strong and steady.

The table below shows some common sizes and spacing for flex cables:

| Parameter | Common Values |

|---|---|

| Conductor Sizes | 0.035×0.3mm, 0.05×0.5mm, 0.1×0.8mm |

| Spacing (Pitch) | 0.5mm, 0.8mm, 1.0mm, 1.25mm |

| Number of Pins | 20 to 100 |

Other choices in design help too. Using materials with a low dielectric constant helps signals move faster. Shielding, like metal foil, blocks outside noise. This keeps the signal clear. Strong cable jackets stop movement that could change the signal path.

Performance Optimization

Engineers use smart ways to make flex cables work their best:

- They design the cable to control impedance. This matches the system and stops signal reflections.

- They pick materials like polyimide with low dielectric loss. This keeps signals strong.

- Shielding and grounding protect the cable from interference.

- Strong ends and strain reliefs stop stress from hurting the cable.

- Engineers avoid sharp bends and keep the bend radius right. This stops copper traces from breaking.

- They use connectors with fine pitch to help high-speed signals.

- Simulation tools and testing find and fix problems before using the cable.

Flex cables with these features can send data fast in small devices. These steps help keep signals quick and clear in modern electronics. High speed flex cables must be strong, reliable, and keep signals safe to work well in tough jobs.

Applications of Flexible Flat Cable Assemblies

Consumer Electronics

Many electronics use flex cables for quick connections. Smartphones and tablets link screens, cameras, batteries, and boards with these cables. Flex cables help keep devices thin. They let parts fit close together. Laptops and computers use flex cables for keyboards, touchpads, and screens. The flat shape works well in foldable devices. It saves space inside each product.

Some common uses of ffcs in electronics are:

- Connecting LCD screens in TVs and monitors

- Linking printers and gaming consoles to main boards

- Helping fast data move between inside parts

Flex cables cost less than old ribbon cables. Their thin and light build is better for small devices. The flat shape lets connectors fit close together. This means more connections in a tiny space. Flex cables also block EMI and RFI. This keeps signals clear and fast.

Industrial Uses

Flex cables are important in many factories and machines. Cars use flex cables in dashboards, radios, steering, and engine sensors. Medical tools use flex cables for imaging, surgery, and patient monitors. Robots and machine tools need flex cables for moving parts and controls.

Common uses of ffcs in industry are:

- Connecting sensors and controls in assembly lines

- Linking parts in planes and defense systems

- Helping data move in telecom and data centers

Flex cables help machines fit in small spaces. Their flat shape helps heat escape. This is good for strong electronics. The side-by-side wires lower crosstalk and EMI. This keeps signals strong. Flex cables can bend millions of times. This makes them great for places that move a lot. Their tough and bendy build saves time and work.

Benefits

Flex cables give many good things for electronics and machines. They make devices work better with strong, small, and safe connections. Their bendy build lets them fold easily. This lowers stress and makes them last longer. EMI shields and tight connectors keep connections strong, even when things shake.

A table below shows the main benefits of flex cables:

| Benefit | Description |

|---|---|

| Signal Integrity | Differential signaling and controlled impedance reduce noise |

| Durability | Flexible design resists bending and vibration |

| Easy Installation | Flat, lightweight cables simplify handling |

| Cost Savings | Lower maintenance and faster assembly |

| Compact Design | Supports miniaturized and ergonomic devices |

Flex cables help save money on repairs. Getting jumpers and connectors from one place makes design easier. It also means the parts are tested to work well. Their flat and bendy shape lowers the chance of damage. This helps devices last longer and work well.

Tip: Flex cables send data fast and stay strong. They are a smart pick for new electronics and machines.

FFC vs. FPC and Round Cables

Cost and Complexity

Flex cables, flexible printed circuits, and round cables all cost different amounts. They also have different levels of difficulty. The way ffcs and fpcs are made is not the same. Flex cables have a flat shape with copper lines inside. They do not always need shielding. Machines make these cables fast, so they are cheap. Flexible printed circuits are more complicated. They can have one layer or many layers. This makes them cost more than flex cables. Making flexible printed circuits is like making a printed circuit board. This adds to the price.

Round cables cost the most. They use more materials and need more work by hand. Shielding is almost always needed to stop interference. People often put these cables together by hand. This takes more time and money. The table below shows how they compare:

| Cable Type | Construction Complexity | Shielding Requirement | Manufacturing Process | Cost Implication |

|---|---|---|---|---|

| FFC | Simple laminated flat structure | Usually unshielded | Automated | Most cost-effective |

| FPC | Single or multilayer, more complex | May include shielding | PCB-like fabrication | Moderate cost |

| Round | Bulky, manual assembly | Usually shielded | Manual assembly | Highest cost |

Flex cables are the easiest to install and fix. They use simple connectors and are easy to move around. Flexible printed circuits take longer to put in because they are more complex. Round cables are big and hard to fit in small places.

Tip: Using flex cables can help save money and time. They are good for projects with lots of connections.

Use Cases

Flex cables are best for devices that need simple and cheap connections. They are used in electronics, robots, car sensors, and medical tools. These cables fit in small spaces and can bend many times.

Flexible printed circuits are used when the design is more complex. They are found in wearables, airplanes, and advanced cars. These circuits can handle tough places and fit odd shapes. The differences between ffcs and fpcs show up in these uses. FPCs last longer and work better in hard spots.

Round cables are strong and last a long time. They are used in factories and power systems. These cables are not as bendy as flex cables or fpcs. They take up more room and are harder to put in small devices.

A list of common uses of fpcs and flex cables: – Smartphones, laptops, and tablets – Automotive sensors and controls – Medical diagnostic equipment – Robotics and automation – Consumer appliances like printers and microwaves

Knowing how fpcs work helps engineers pick the right cable. Flex cables are best for simple and bendy jobs. FPCs are better for hard circuits and tough places. Knowing how fpcs work and where they are used helps make the right choice.

Flex cables are special in fast systems because they are small, bendy, and keep signals strong. Engineers pick flex cables since they fit in tight spots. They can bend many times and still work well. These cables use shielding and controlled impedance to keep signals clear. This helps even when data moves as fast as USB 3.0. Flex cables do not get damaged by heat. They last through lots of bending and make building devices easier. Their light weight and custom wires are good for new electronics. Flex cables are a smart and cheap way to connect parts in devices that need speed and strength.

- Flex cables help move fast data in small, moving spaces.

- Flex cables are tough, simple to put in, and keep signals strong.

- Flex cables are what engineers need for new, advanced devices.

| Feature | Flex Cables Benefit |

|---|---|

| Flexibility | Can bend millions of times |

| Signal Integrity | Uses shielding and keeps impedance steady |

| Compact Design | Fits in small places and tiny devices |

| Durability | Handles heat and does not wear out fast |

| Assembly | Easy to use with surface mount connectors |

Flex cables are the answer for quick and steady links in fast systems.

FAQ

What are flex cables used for in electronics?

Flex cables connect parts inside devices like phones, laptops, and cameras. They help move signals quickly between screens, batteries, and circuit boards. Their flat shape saves space and allows for easy bending in tight spots.

How do flex cables improve device reliability?

Flex cables resist bending and vibration. They last through millions of flex cycles. Their strong materials and careful design prevent breaks. This makes them a reliable choice for devices that move or shake during use.

Can flex cables handle high-speed data?

Flex cables support high-speed data transfer. Engineers use them for USB 3.0, HDMI, and camera signals. Shielding and controlled impedance help flex cables keep signals clear, even at fast speeds.

Are flex cables easy to install?

Flex cables have a flat, lightweight design. This makes them simple to route and connect. Many connectors use a push-in or slide-in method. Installers can fit flex cables into small spaces without special tools.

What makes flex cables different from round cables?

Flex cables have a flat, ribbon-like shape. Round cables are thicker and less flexible. Flex cables fit better in small devices. They bend more easily and help keep signals strong in compact electronics.