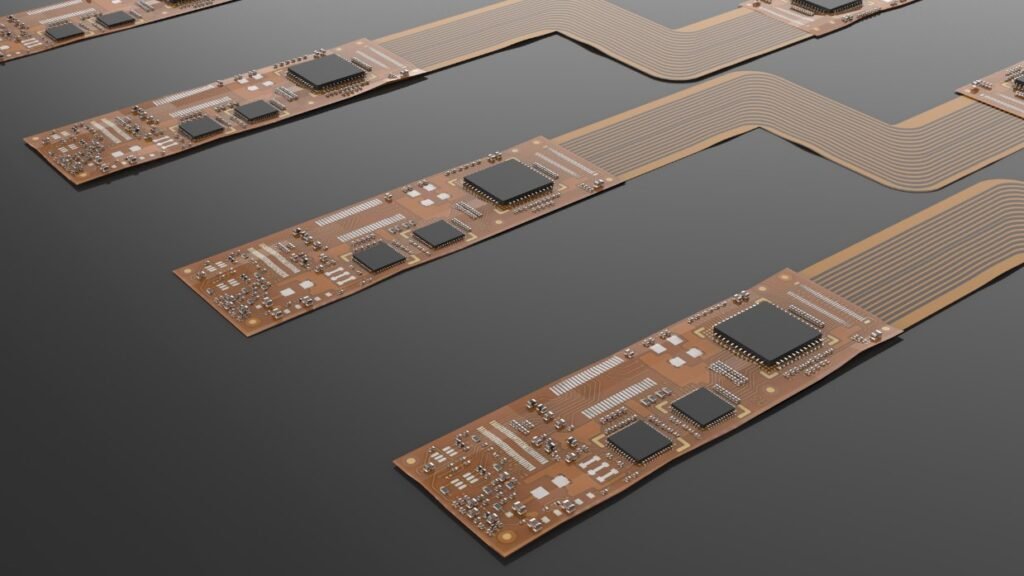

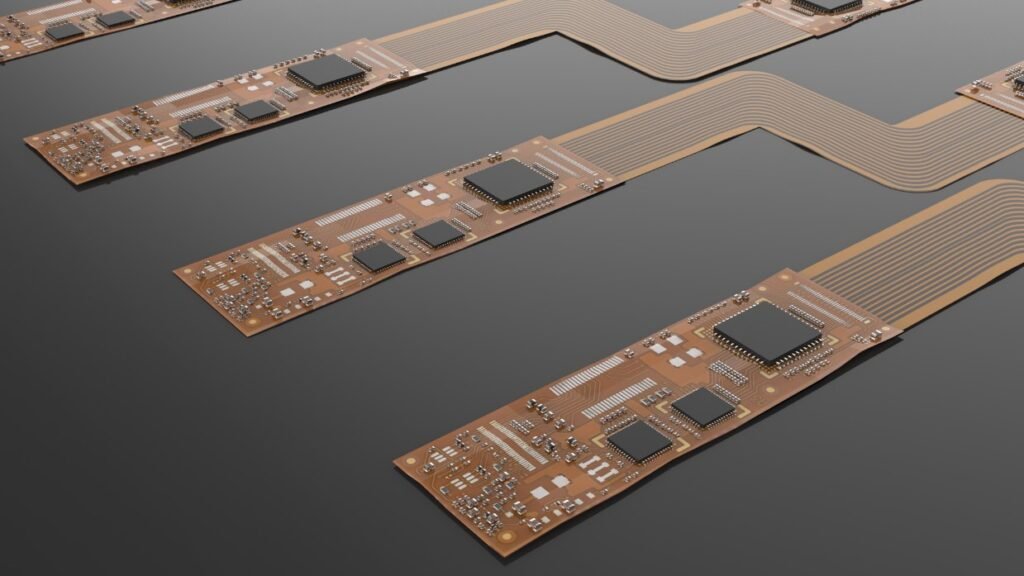

Why do new gadgets seem lighter and smarter each year? Flexible printed circuits help make this happen. They fit into small spaces. Devices can bend or fold because of them. Many companies use flexible printed circuits in wearables. They are also used in foldable screens and medical tools.

- These circuits give mechanical flexibility and lower the weight.

- Better materials and ways to make them help circuits get thinner and work better.

People want electronics that are thin, light, and strong. Flexible printed circuits are now a popular choice for new designs.

Key Takeaways

- Flexible printed circuits help make devices small and light. They use thin and bendable materials. This makes devices easier to carry.

- These circuits can bend and twist. They can also fold. Engineers can design gadgets with new shapes. Gadgets can have moving parts.

- Flexible printed circuits last a long time. They handle shocks well. This makes devices work better and last longer.

- They make device assembly easier. There are fewer wires and connectors. This saves time. It also lowers costs.

- Flexible printed circuits are used in many things. You can find them in wearables and foldable phones. They are in medical devices, cars, and robots. They help these devices work better and be easier to use.

Flexible Printed Circuits Overview

What Is a Flexible Printed Circuit?

A flexible printed circuit is a thin board that bends easily. It connects parts and sends signals, like a regular pcb. It uses special materials so it can twist or fold. It can also wrap around different shapes. This helps it fit in small devices and tight spaces.

| Material Type | Examples | Contribution to Flexibility and Functionality |

|---|---|---|

| Substrate | Polyimide, Polyester (PET), Liquid Crystal Polymer (LCP) | Makes the base flexible so it can bend and twist. It is strong and can handle heat. |

| Conductive Layer | Copper foil (including annealed copper) | Lets electricity flow. Annealed copper foil bends well and does not break easily. |

| Coverlay Film | Polyimide or polyester film coated with thermoset adhesive | Keeps the circuits safe from damage and rust. It stays flexible. |

| Adhesives and Stiffeners | Various adhesives and stiffening materials | These help balance bending and keep parts steady, especially where things connect. |

Manufacturers pick these materials to make flexible printed circuits tough and dependable. Polyimide and copper foil let the pcb bend without snapping. Coverlay films shield the circuits from harm. Stiffeners give extra support when needed. Using these materials lets flex pcbs fit in small places and move without breaking.

How Flexible Printed Circuits Differ from Rigid Boards

Flexible printed circuits are different from rigid boards in many ways.

- Flexible pcbs use polyimide film for the base. Rigid pcbs use glass-reinforced epoxy.

- The copper in flexible pcbs is annealed, so it bends easily. Rigid pcbs use electrodeposited copper, which can crack.

- Flexible pcbs have a coverlay film for safety. Rigid boards use a hard resin mask.

- Stiffeners are added to flexible pcbs for more support. Rigid boards do not need stiffeners.

- Designers must think about how much the pcb bends and how the lines run. Rigid boards do not have this problem.

- Flexible printed circuits can fit more circuits in small spaces. Rigid boards work best in big, flat devices.

- Flexible pcbs cost more but make small, light designs possible. Rigid boards are cheaper and easier for simple circuits.

Flexible printed circuits also get rid of heat better and work well. Their design helps engineers control how electricity moves and avoid mistakes. Flex pcbs are great for things that bend or fold, like wearables and foldable phones. Rigid boards are good for devices that stay the same shape and need to be strong.

Tip: Flexible printed circuits help make devices with more circuits and cool shapes. They let engineers build smarter and lighter products.

Benefits of Flexible Printed Circuit Boards

Space and Weight Efficiency

Flexible printed circuit boards help make devices smaller and lighter. They use thin materials that weigh much less than regular boards. This lets engineers design products that fit in small spaces. Devices are easier to carry or wear.

| Comparison Context | Weight Reduction Achieved |

|---|---|

| Flex-rigid PCBs vs. Traditional Rigid PCBs | 20-30% lighter |

| Wearable Fitness Trackers using Flex-rigid PCBs | 25% device weight reduction |

| Flexible PCBs vs. Rigid PCBs (general) | 50-80% lighter |

Flexible pcb technology can cut the weight of electronics by up to 80%. This happens because they use light materials and do not need heavy wires. Smartwatches, fitness trackers, and foldable phones all use this benefit. Lighter and smaller devices are easier to use every day.

Flexible pcbs also save space inside products. They can bend and fold, so more circuits fit in a small area. This helps make thin laptops, small cameras, and medical tools that fit in a pocket.

Flexibility and Adaptability

Flexibility is the main reason flexible pcb designs are popular. These boards can bend, twist, and fold to fit many shapes. This lets engineers make products with cool shapes and moving parts.

- Flexible pcbs use polyimide and polyester films. These materials let the board bend and twist without breaking.

- Rigid-flex designs let many parts go in one spot. Flexible sections connect them and help fold circuits into small cases.

- Flexible pcbs can handle both single bends and many bends. This is important for wearables and foldable gadgets.

| Industry Sector | Product Examples |

|---|---|

| Medical Devices | Pacemakers, insulin pumps, cochlear implants, surgical robots |

| Consumer Electronics | Foldable smartphones, smartwatches, fitness trackers, thin and light laptops, cameras with movable parts |

| Automotive | Airbags, dashboards, lighting systems |

| Aerospace | Heads-up displays, satellite navigation devices |

| Industrial | Robots, automation equipment, sensors |

Flexible pcb designs help products fit tricky shapes and curves. A smartwatch wraps around your wrist. A foldable phone bends in half. Medical devices like pacemakers use flexible pcbs to fit inside the body. This makes devices more comfortable and useful.

Reliability and Durability

Flexible printed circuit boards are strong and last a long time. They use fewer connectors and wires, so there are fewer things that can break. Flexible pcbs also handle shaking and bumps better than rigid boards.

| PCB Type | Vibration Resistance | Failure Rate Impact in High-Vibration Environments |

|---|---|---|

| Flexible PCBs | Up to 20G | 35% reduction in failure rates vs. rigid boards in ADAS cameras; excels in reducing connector-related failures |

| Rigid PCBs | Moderate (5-10G) | More prone to connector and wiring harness failures under vibration |

| Rigid-Flex PCBs | High (15-20G) | Lower failure rates due to integrated flexible layers reducing solder joints and connectors |

Flexible pcbs made with polyimide can handle heat and chemicals. They keep working even when bent or twisted many times. This is great for wearables, portable electronics, and tough environments. Rigid-flex pcbs mix strong and flexible parts to absorb shocks and protect the device.

Note: Devices like fitness trackers and medical implants last longer and work better because flexible pcbs are tough and flexible.

Efficiency in Assembly

Flexible printed circuit boards make building devices faster and easier. They cut down the number of parts that need to be joined. This means workers spend less time putting things together and make fewer mistakes.

- Flexible pcbs replace lots of wires and connectors with one flexible layer.

- Plug-and-play connectors make setup quick and easy.

- Fewer parts and connections mean less testing and lower costs.

Flexible pcbs also help by letting circuits go straight where they need to. This removes big wire bundles and keeps the inside neat. Companies can build products faster and with fewer mistakes. This means better quality and more reliable electronics.

Tip: Flexible pcbs help companies make lighter, smaller, and stronger devices. They also save time and money when putting devices together.

Real-World Applications

Wearables and Medical Devices

Flexible printed circuits make wearables comfy and helpful. Fitness trackers and smartwatches use them to fit on your wrist. They help track health and movement. Smart clothes use flexible sensors to check heart rate and steps. Medical devices like pacemakers and insulin pumps use these circuits. They are small and work well inside the body. These circuits help devices survive tough places. Continuous glucose monitors and smart patches use flexible printed circuits. They stay close to the skin and give good readings. Flexible printed circuits also help smart bandages and tiny cameras. Doctors use them to watch patients and give better care. Flexible printed circuits often replace wires and parts. This makes devices lighter and easier to wear.

Note: Flexible printed circuits make medical devices safer, smaller, and more comfy for people.

Foldable Phones and Displays

Foldable phones and screens need circuits that bend and move. Flexible printed circuits connect the screen, battery, and camera. They go through the folding part of the phone. These circuits keep signals strong when the phone folds a lot. Polyimide and copper foil help the circuits bend and last longer. Rigid-flex designs hold some parts still and let others move. Flexible printed circuits link sensors, fingerprint readers, and antennas. They fit in small spaces and help phones get thinner. Tests show flexible printed circuits can handle lots of folds. This lets engineers make phones and tablets that change shape and do new things.

- Flexible printed circuits connect screens and motherboards.

- They link batteries, cameras, and other parts for smooth use.

- These circuits keep power and data steady when folding.

Automotive and Robotics

Cars and robots use flexible printed circuits to save weight and work better. Thin materials help make cars lighter. This helps cars use less fuel and makes electric cars go farther. Flexible printed circuits can handle shaking and heat. They are good for engines and safety systems. They soak up shocks and lower the chance of broken joints. Flexible printed circuits also work in hot and cold places. They fit into tight spots. In cars, they replace wires and parts. This makes fixing and building cars easier and cheaper. Robots use flexible printed circuits to connect moving parts and sensors. This helps robots move well and last longer.

| Aspect | How FPCBs Improve Automotive Electronics Reliability and Reduce Weight |

|---|---|

| Lightweight Nature | FPCBs use thin, bendy materials that make cars lighter and help them use less energy and go farther. |

| Vibration Resistance | Flexibility soaks up shakes and stress, so parts break less and last longer in tough driving. |

| Temperature Stability | Materials work well in hot and cold, so devices stay safe in all weather. |

| Wiring Harness Reduction | Fewer wires and simpler paths mean fewer problems and lower costs. |

| Spatial Optimization | Flexible circuits fit tricky shapes, save space, and make building easier. |

| Ease of Assembly & Maintenance | Custom designs and simple parts make fixing and upgrading easier, so systems work better. |

Tip: Flexible printed circuits help cars and robots work better, last longer, and use less energy.

Why Manufacturers Choose Flexible Printed Circuits

Performance and Efficiency

Manufacturers want products to work well and last longer. Flexible printed circuit boards help them do this. These boards make devices lighter, thinner, and more reliable. The table below shows how flexible boards are different from rigid ones:

| Performance Aspect | Rigid PCBs | Flexible PCBs |

|---|---|---|

| Weight | Heavier | Lighter |

| Thickness | Thicker | Thinner |

| Design Freedom | Limited, fixed shape | Increased, adaptable |

| Reliability in Use | Static environments | Enhanced in dynamic use |

| Assembly Complexity | Requires wiring harnesses | Simplified, integrated harness |

| Application Flexibility | Static applications | Suitable for dynamic and irregular shapes |

Switching to flexible boards helps companies save money on parts and building. These boards let devices be smaller and more compact. Companies can make more products at once. For example, one company fixed a problem product with flexible boards and now has over 1,200 working products.

Flexible boards also help save energy. Smaller and lighter devices use less power. Making these boards creates less waste and uses fewer materials. This helps companies make products that are better for the planet.

Space and Weight Efficiency

Space and weight are important in today’s electronics. Flexible boards let engineers use all the space inside a device. They can bend and fit into small places. This makes products smaller and easier to carry. Thin and light materials help lower the total weight.

Manufacturers also save money over time. Even though flexible boards cost more at first, they save money later. Fewer parts mean less time building and fixing things. Strong designs mean fewer repairs and less time when devices do not work.

Tip: Flexible boards help companies make products that are light, small, and simple to use.

User Experience

Flexible boards change how people use their devices. Designers can make products with new shapes and cool features. Devices can have curved edges, foldable screens, or fit into clothes. This makes gadgets more comfortable and fun.

People want devices that are smaller, lighter, and stronger. Flexible boards help make this possible. They also help products last longer and work better, even when bent or moved. Wearables, foldable phones, and smart home gadgets use these boards to give people a better experience.

Flexible printed circuits make devices smarter and lighter. They help devices work better and use less energy. Engineers can design products that bend and stretch. These circuits fit into small and tight spaces. They help with new ideas like making things smaller and wearable technology. They also help companies make products in ways that are better for the planet. Companies pick flexible printed circuits because they save space and cut down on waste. They let designers create new shapes for devices. Flexible printed circuits help the market grow as technology gets better. They often take the place of other parts and cable harnesses. This makes building and using devices easier. In the future, these circuits will help bring even more new ideas to electronics.

FAQ

What makes flexible printed circuits different from regular circuit boards?

Flexible printed circuits can bend and twist. Regular circuit boards are flat and stiff. Flexible designs fit into small and odd spaces. This helps engineers make thinner and lighter devices.

How do flexible printed circuits help wearable devices?

Flexible printed circuits let wearables wrap around wrists or fit in clothes. They make devices more comfy and tough. These circuits also help track movement and health.

Why do manufacturers use flexible printed circuits in foldable phones?

Manufacturers pick flexible printed circuits because they bend without breaking. Foldable phones need circuits that move with the screen. Flexible printed circuits keep signals strong and help phones last longer.

Can flexible printed circuits replace other parts in electronics?

Flexible printed circuits often take the place of other parts and cable harnesses. This makes devices lighter and easier to put together. Fewer parts mean fewer problems and faster building.

Are flexible printed circuits safe for medical devices?

Flexible printed circuits work well in medical devices. They handle heat and movement. Doctors trust them in pacemakers and insulin pumps. These circuits help devices fit inside the body and last longer.