When you put together a cable with ribbon cable and IDC connectors, you first pick the right ribbon cable and IDC connector for your job. You cut the ribbon cable to the length you need. Next, you line up the connector with the cable. Then, you use a crimping tool to push the IDC pins into the cable. This makes a strong and dependable cable. Many industries use ribbon cable assembly. Factory automation, automotive electronics, and consumer devices all use it. IDC connectors help stop shaking and give steady electrical connections. Always check that everything lines up and crimp tightly for the best results. For more help, use tips for ribbon cable assembly so you do not make common mistakes.

Key Takeaways

- Pick a ribbon cable and IDC connector that fit together in size and pitch. This helps make a strong connection. Cut the ribbon cable straight and neat. This stops damage and helps the contacts work well. Line up the red wire (pin 1) on the cable with the pin 1 mark on the connector before you crimp. Use the right crimping tool to press the connector down evenly and tightly onto the cable. Test your finished cable with a multimeter. This checks if the electrical connections are good and strong.

Parts and Tools

Ribbon Cable Types

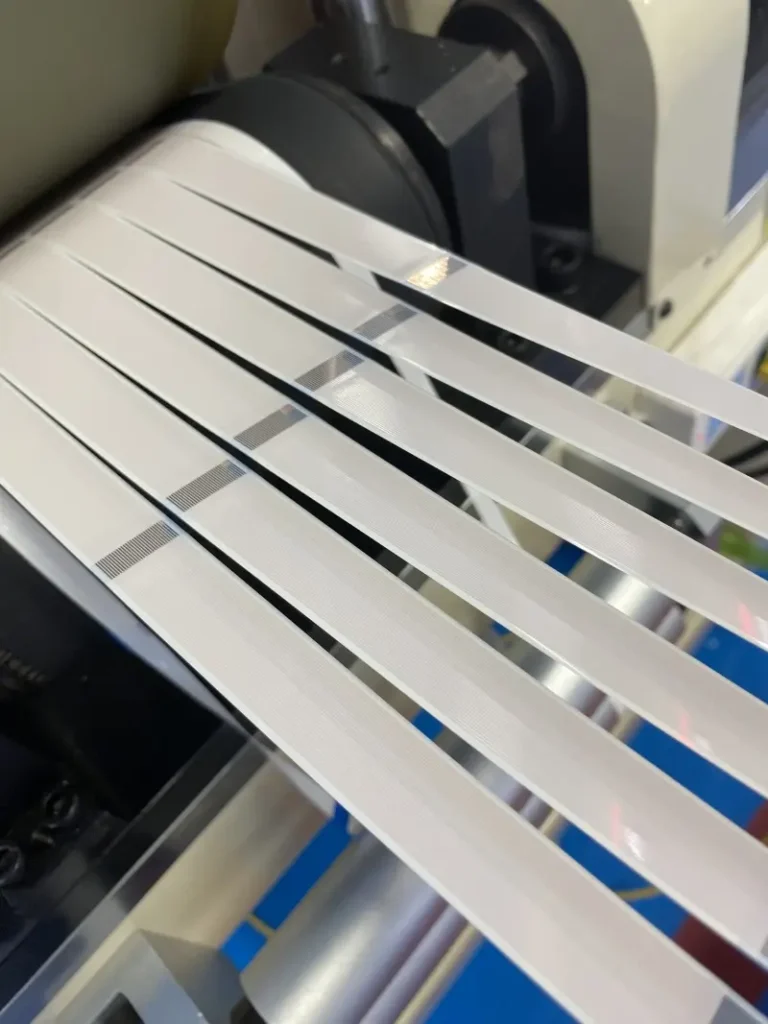

There are many ribbon cable types for different uses. Standard ribbon cable is good for wiring and mass termination. Rainbow ribbon cable uses colors to help you find wires fast. Twisted flat ribbon cable has twisted wire pairs. This helps lower noise and works with IDC connectors. Round-to-flat ribbon cable starts round and becomes flat. It fits well in small spaces. Bonded ribbon cable has wires stuck together. This keeps things neat but makes the cable less bendable.

Flexible flat cables (FFC) are also used. These cables have a thin plastic layer and flat conductors. FFCs are found in printers, scanners, and LCD screens. They are light and bend easily. Ribbon cable and FFCs have different uses. Ribbon cable is best for neat wiring and mass termination. FFCs are better for small places that need bending.

| Ribbon Cable Type | Description | Key Features |

|---|---|---|

| Standard | Gray, for mass termination | Flexible, common pitches |

| Rainbow | Color-coded for easy identification | Same as standard, visual aid |

| Twisted Flat | Twisted pairs for noise reduction | IDC compatible, moderate flexibility |

| Round-to-Flat | Round bundle flattens for tight spaces | Space-saving, flexible |

| Bonded | Wires bonded for neatness | Less flexible, organized wiring |

| FFC | Thin film, surface conductors | High flex, compact, lightweight |

Check the pitch size, wire count, and color before picking a ribbon cable or idc flat ribbon cable. Some cables have special covers for heat or water.

IDC Connectors Overview

IDC connectors let you join ribbon cable without soldering. You press the connector onto the cable. Sharp contacts poke through the cover to touch the wires. IDC connectors come in many shapes. Some are low-profile or right-angle to fit tight spots. Some have bumps to stop the latch from locking too soon. Some have pull tabs to unplug easily. IDC female connectors are used for wire-to-board jobs.

IDC connectors follow safety rules like RoHS. You can buy them in bulk for big jobs or preassembled for quick use. Double-recessed covers let you finish cable from either side. This saves time.

Tip: Always match the connector pitch to your ribbon cable pitch for a tight fit.

Tools for Ribbon Cable Assembly

You need some tools to put ribbon cable and IDC connectors together:

- Crimping tool or vise: This tool presses the IDC connector onto the ribbon cable.

- Wire cutters: Use these to cut the flat ribbon cable to the right length.

- Tweezers or alignment tools: These help you line up the cable and connector pins.

- Multimeter: Use this to test the connection after you finish.

When you pick a ribbon cable and IDC connector, check that the wire size matches the connector rating. Make sure the connector fits your space and works with your wire type. If you work in tough places, pick waterproof or heat-safe ribbon cable and sealed IDC connectors. For jobs with lots of shaking, use connectors with extra strength.

Note: Mixing wire sizes in one IDC connector can make weak connections. Always use the right size for each job.

Assembly Steps

Cutting Ribbon Cable

Start the ribbon cable assembly by measuring the length you need for your project. Use a ruler or tape measure to mark the spot where you want to cut. Always use a specialist ribbon cable cutter if you have one. This tool has a long, sharp blade and a built-in guide. It helps you make a straight, 90-degree cut. A clean, square cut is important. If you cut the ribbon cable at an angle or crush the wires, you can cause problems later. Crooked cuts may lead to shorts or weak connections. Damaged ends can cause the connector pins to pierce the wrong part of the wire, which can make your device fail or reset unexpectedly.

Tip: If you do not have a ribbon cable cutter, use sharp scissors and a steady hand. Make sure the cut is as straight as possible.

Never try to fix a bad cut by wedging plastic or using makeshift repairs. If you damage the end, cut off the bad part and start again. This step keeps your cable assembly reliable and safe.

Aligning IDC Connectors

Next, you need to align the idc connectors with the ribbon cable. Find pin 1 on the ribbon cable. Usually, the red wire marks pin 1. Look for the pin 1 mark on the idc connector. This mark is often a triangle or arrow. Make sure the red wire lines up with this mark. Insert the cable into the idc connector so it sits flush with the edge. The cable should fit naturally into the guide grooves of the connector.

Check that the pitch of the ribbon cable matches the pitch of the idc connector. If the pitch does not match, you can get misalignment. This can cause short circuits or unreliable contacts. For right-angle connectors, pay extra attention. Sometimes you need to rotate the connector or adjust the cable to keep pin 1 in the correct spot.

Before you crimp, double-check the alignment. Make sure the cable is not twisted and that all wires line up with the connector pins. This step prevents common mistakes in ribbon cable assembly.

Crimping Process

Now you are ready to crimp the connector onto the ribbon cable. Start by pressing the top clip of the idc connector down by hand. This holds the cable in place. Use a crimping tool, bench vise, or even a heavy book to press straight down at a 90-degree angle. Apply even pressure across the whole connector. If you use a vise, place a flat piece of cardboard or plastic on top to spread the force. This helps prevent damage to the connector.

Professional crimp tools give the best results, but you can use a vise or pliers if you are careful. Make sure all pins stay straight and the connector does not shift. After crimping, check that the pins are all the same length and none have bent out of place. If your connector has a strain relief clip, fold the cable over the top and snap the clip in place. This adds strength to your cable assembly.

A good crimp shows a slight wire extension beyond the connector and visible tooth marks on uninsulated connectors. If you see stray wires or the wires pull out easily, the crimp has failed. Always use the right wire gauge for your idc connector. Manual tools can work, but ratcheting crimpers give more even pressure and better results for insulated connectors.

Securing and Testing

After you finish crimping, you need to test your ribbon cable assembly. First, power down your circuit to stay safe. Use a multimeter to check for electrical continuity. Place the black lead in the ‘COM’ port and the red lead in the continuity port. Touch the leads to the two points you want to test. If you hear a beep or see low resistance, the connection is good. If not, you may have an open circuit or a short.

You can also do a pull test. Gently tug on the cable and connector to make sure they stay together. If the connector comes off or the wires move, the crimp did not work. For extra safety, some companies use high voltage tests or bend tests to check insulation and durability.

| Test Method | Purpose/Description | How to Conduct |

|---|---|---|

| Continuity Testing | Verifies unbroken electrical paths, detects open circuits and shorts. | Use a multimeter on continuity mode; place leads on test points; audible beep or low resistance indicates continuity. |

| Resistance Measurement (Milliohm Test) | Checks connection quality and wire gauge suitability by measuring low resistance. | Use a milliohm meter with four-terminal method; measure voltage and current; resistance should be low (e.g., ≤2.5 ohms). |

| High Voltage (Hipot) Test | Tests insulation integrity under high voltage stress to detect insulation breakdown or leakage. | Apply ~10 kV between conductors; verify insulation withstands voltage without failure. |

| Pull Test | Assesses mechanical security of crimps, connectors, and wires by applying force to ensure secure attachment. | Use a motorized pull tester; apply specified force; check for damage or failure; methods include pull and hold, pull and break. |

| Bend/Flex Test | Evaluates durability under repeated bending and flexing to simulate real-world mechanical stress. | Secure cable end to flex testing machine; simulate bending cycles; check for damage or performance degradation. |

If you find a problem, check your assembly steps. Sometimes you need to cut off the connector and repeat the whole procedure of assembling the cable. Always make sure you insert the cable correctly and use the right tools. This careful approach helps you assemble a cable that works well and lasts a long time.

Note: Following these assembly steps helps you avoid common errors and ensures your ribbon cable assembly meets industry standards for quality and safety.

Tips & Troubleshooting

Tips for Ribbon Cable Assembly

You can make your ribbon cable assembly strong and reliable by following some simple steps. Always use the correct crimping tool for your ribbon cable and connector. This tool helps you apply even pressure and avoid damage. Strip the cable insulation carefully so you expose just enough conductor for a good connection. Align the cable and connector so the wires stay straight and do not twist. When you press the connector, use steady, even pressure across the whole surface. After crimping, check your work. Look for straight wires, tight connections, and no gaps. Use strain relief parts like clamps or heat-shrink tubing to protect the cable where it enters the connector. These parts help prevent the cable from breaking if it bends or pulls.

Remember: Good strain relief keeps your ribbon cable safe from stress and helps your assembly last longer.

If you want more tips for ribbon cable assembly, always inspect your work before moving to the next step. This habit saves time and prevents mistakes.

Common Mistakes

Many people make the same errors when working with ribbon cable and IDC connectors. Here are some mistakes to watch out for:

- Placing the ribbon cable at the wrong angle or upside down in the connector.

- Not using enough pressure to snap the connector shell into place.

- Ignoring the pin 1 mark, which can cause wiring errors.

- Using the wrong wire gauge or mismatched pitch, leading to loose connections or damage.

- Forgetting to add strain relief or overtightening clamps, which can crush the cable.

- Passing the ribbon cable through a strain relief part after adding a connector, which can be tricky and lead to assembly errors.

You can avoid these problems by planning your assembly steps and checking each part before you move on.

Troubleshooting IDC Connectors

If your ribbon cable assembly does not work, you can use these steps to find and fix the problem:

- Look at the cable and connectors. Check for wear, bent pins, or loose wires.

- Use a multimeter to test for voltage, current, and resistance. This helps you find bad connections or broken wires.

- Test for continuity. If you find a break, you can cut out the bad section and splice in a new piece.

- Clean any dirty or corroded contacts with a wire brush or contact cleaner. Make sure everything is dry before you reconnect.

- Replace any frayed or damaged ribbon cable. Always use proper insulation and strain relief.

- Secure all connections with zip ties or clamps to stop movement and prevent future problems.

Tip: Always align the connector carefully and press straight down until it snaps into place. Never force the connector, as this can cause damage.

If you follow these steps, you can fix most issues with ribbon cable and IDC connectors. Careful assembly and regular checks help you avoid costly mistakes and keep your projects running smoothly.

You can make strong ribbon cables with IDC connectors if you follow some simple steps:

- Pick the right cable and connector size for your job.

- Cut the cable straight and match pin 1 by using the colored wire.

- Press the connector on tightly so the connection is strong and sealed.

- Check each connection to make sure it works and stays in place.

Lining things up right and pressing the connector on well helps you avoid mistakes. Try practicing with extra ribbon cable and connectors to get better and feel more sure. Ribbon cables and IDC connectors are fast, save money, and last a long time in many electronics projects.

FAQ

What does IDC stand for?

IDC means Insulation Displacement Connector. You use it to connect ribbon cables without stripping the wires. The connector pushes sharp contacts through the insulation to touch the wire.

How do you know which side is pin 1 on a ribbon cable?

You find pin 1 by looking for the red stripe on the ribbon cable. The red wire always marks pin 1. Match this wire with the pin 1 mark on your connector.

Can you reuse IDC connectors after crimping?

You should not reuse IDC connectors. Once you crimp them, the contacts may not grip the wire well again. Always use a new connector for reliable results.

What tools do you need for ribbon cable assembly?

You need these tools:

- Crimping tool or vise

- Wire cutters

- Tweezers for alignment

- Multimeter for testing

Tip: Using the right tools helps you make strong and safe connections.

How do you test if your ribbon cable assembly works?

You test your cable with a multimeter. Set it to continuity mode. Touch the leads to both ends of the wire. If you hear a beep, your connection works.