Imagine assembling a medical device where a small mismatch in standard pitches causes a connection failure. You need to select the correct standard pitches for flexible flat cables to ensure perfect device compatibility and reliable performance. Standard pitches define the distance between conductors in a cable, making them critical for your application. Choosing the right standard pitches and standard cable length can speed up assembly and reduce errors in automotive, medical, or consumer electronics. YLS delivers both standard and custom Zif cable solutions, supporting your need for precise standard pitches in every project.

Key Takeaways

Understand standard pitches as the distance between conductors. This knowledge ensures proper cable compatibility and reliable device performance.

Select the right pitch size based on your application. Smaller pitches suit compact electronics, while larger pitches are better for high-power needs.

Always check the pitch and connector type before assembly. This step prevents costly errors and ensures a secure fit.

Consider custom cable solutions when standard options do not meet your needs. Customization allows for flexibility in design and application.

Follow industry standards for pitch and length to enhance compatibility and reduce costs. Adhering to these standards improves overall device reliability.

Standard Pitches and Roof Pitch Fundamentals

What Are Standard Pitches?

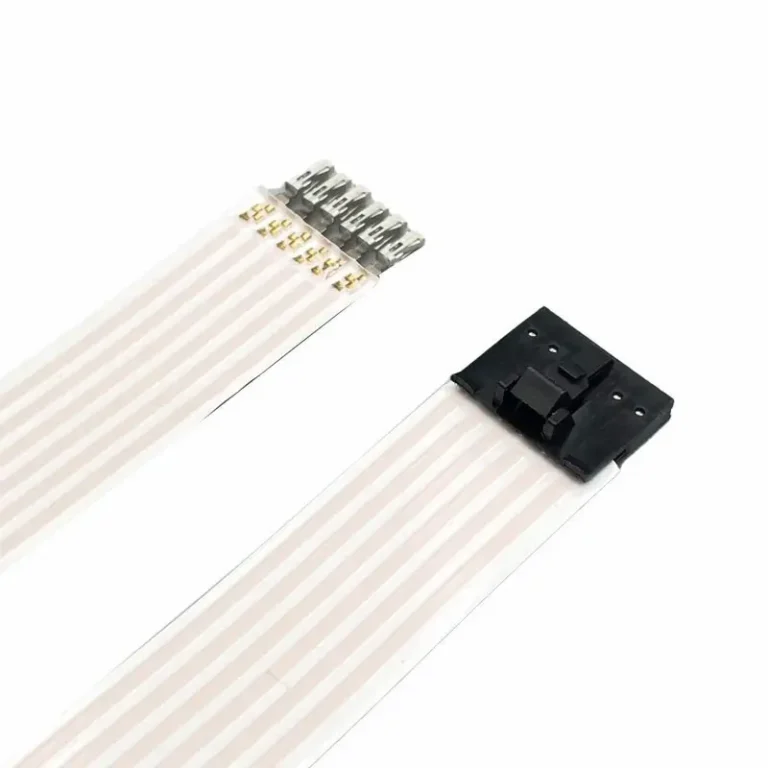

You often hear the term pitch when working with flexible flat cables. Pitch is the distance from the center of one conductor to the center of the next. This measurement determines how many conductors fit into a cable and how the cable connects to devices. Standard pitches help you match cables with connectors from different manufacturers. If you choose the wrong pitch, your cable may not fit, or it could cause electrical problems.

Over the past five years, you have seen a growing demand for different pitch sizes. Many industries now prefer smaller pitches for compact electronics. Larger pitches still play a role in applications that need higher power. You can see this trend in the table below:

Pitch Size | Application Area | Trend Description |

|---|---|---|

0.500 mm | Compact Electronics | Increasing demand for smaller sizes in compact designs |

1.000 mm | General Applications | Balanced use across various sectors |

1.250 mm | Higher Power Transmission | Preferred for applications requiring more power |

You should always check the pitch before selecting a cable. This step ensures your assembly works smoothly and reliably.

Roof Pitch Fundamentals in Cable Design

You might wonder why roof pitch fundamentals matter in cable design. In construction, roof pitch describes the steepness or angle of a roof. In cable design, you use similar ideas to describe the angle or bend of a cable as it routes through a device. Essential roof pitch definitions help you understand how much a cable can bend without damage. Standard roof pitch categories guide you in choosing the right cable for your application.

The most common roof pitch in cable assemblies allows for easy installation and safe operation. Roof pitch selection factors include the space inside your device, the flexibility of the cable, and the need for reliable connections. If you work in areas with heavy snow, you know the minimum roof pitch for snow shedding is important for buildings. In cable design, you use similar thinking to prevent stress and damage in tight spaces.

Tip: Always consider the angle and bend radius when routing cables. This practice helps you avoid sharp bends that could damage the cable or reduce its lifespan.

YLS Zif Cable Pitch Options

YLS offers a wide range of Zif cable pitch options to meet your needs. You can choose from several standard sizes that match industry norms. The table below shows the available pitch options and how they compare to what you find in the market:

Pitch Options | Industry Norms |

|---|---|

0.5mm | Commonly used |

0.8mm | Commonly used |

1.0mm | Commonly used |

1.25mm | Commonly used |

1.27mm | Commonly used |

2.0mm | Commonly used |

2.54mm | Commonly used |

You can select the pitch that fits your device and connector. YLS supports both standard and custom pitches, so you always find the right solution for your project. If you need a special size, YLS can create a custom cable for you. This flexibility helps you keep up with new trends and changing requirements in electronics.

Growing demand for various pitch sizes tailored to specific applications.

Preference for smaller pitch sizes in compact electronic designs.

Larger pitches used in applications needing higher power transmission.

Shift towards sustainable materials and enhanced durability in FFC products.

When you choose YLS, you get cables that meet global standards and fit your exact needs.

Common Pitch Sizes and Applications

Popular Standard Pitches (0.3mm–2.54mm)

You will find that flexible flat cables come in a variety of pitch sizes. Each pitch size serves a different purpose in electronics. The most common pitch sizes range from 0.3mm to 2.54mm. These sizes help you match cables to specific devices and connectors. The table below shows the most popular pitch sizes and where you might use them:

Pitch Size | Typical Applications |

|---|---|

0.3mm | Signal transmission lines in various electronic devices |

0.5mm | Connecting lines in printers, scanners, and copiers |

0.8mm | Used in audio devices and plotters |

1.0mm | Common in televisions and other electrical equipment |

1.25mm | Suitable for PCB board connections |

1.27mm | Versatile for various electronic applications |

2.54mm | Often used in motherboards and moving parts of devices |

You can see that each pitch size fits a unique role. Smaller pitches work well in compact devices. Larger pitches handle higher power or moving parts. When you select a pitch, you improve device reliability and assembly speed.

Application Examples for Zif Cable

Zif cables support many practical applications and calculations in modern electronics. You will see them in consumer electronics, medical devices, and automotive systems. The table below highlights some common uses:

Application Area | Specific Uses |

|---|---|

Consumer Electronics | Used in devices like smartphones for display connections, laptops for linking internal parts, and cameras for display connections. |

Medical Devices | Support for various display interfaces, ensuring reliable connections in devices. |

Automotive Systems | Used in systems requiring frequent connection and disconnection, enhancing efficiency. |

You benefit from Zif cables because they offer easy installation and reliable connections. In consumer electronics, you often use them for displays and cameras. In medical devices, they ensure stable performance. Automotive systems rely on them for quick and secure connections.

Compatibility with Major Connectors

You need to match the pitch of your cable with the connector. Major brands design connectors to fit standard pitch sizes. This compatibility makes assembly easier and reduces errors. Here are some examples:

Brand | Model | Pitch | Description |

|---|---|---|---|

3M | Ribbon Cable Wiremount Socket 451 Series | 1.27 mm | Allows for higher connection density in less board space, integrates easily into standard designs. |

Kyocera | 6893 Series FPC/FFC Connectors | N/A | Utilizes a proprietary structure for quick, stable connections, improving foreign matter removal. |

You will notice that connector brands like 3M and Kyocera support a range of pitch sizes. This flexibility helps you choose the right cable for your project. In automotive and consumer electronics, you often need thin, flexible cables. Automotive connectors must handle vibration and heat, while consumer devices focus on compactness and easy installation.

Tip: Always check the pitch and connector type before starting your project. This step ensures your cable fits and works as expected.

Standard Cable Lengths and How to Measure Roof Pitch Angles

Typical Length Ranges for Flexible Flat Cables

You need to select the right cable length for your application to ensure installation success and safety. Flexible flat cables come in a wide range of lengths. The table below shows typical length ranges for different industries:

Application Type | Typical Length Range |

|---|---|

General Use | 50 cm – 2 meters |

Home Appliances | 5 cm – 50 cm |

Industrial Devices | 10 cm – 200 cm |

Military Applications | 5 cm – 150 cm |

Marine Devices | 10 cm – 100 cm |

Medical Devices | 2 cm – 100 cm |

You can request custom lengths for specialized needs. Customization helps you meet installation requirements, manage cost, and maintain safety. Always consider the angle and installation space when specifying cable length. Proper length selection reduces installation errors and supports safety thresholds.

How to Measure Roof Pitch Angles in Cable Assemblies

You must know how to measure roof pitch angles to ensure correct cable routing and installation. Follow these steps for accurate measurement:

Position the level on the cable path, keeping it horizontal.

Mark the 12-inch point from where the level touches the surface.

Measure the vertical rise from the 12-inch mark down to the cable surface.

Express the angle as a ratio, such as “X:12,” based on the rise.

Verify your results by repeating the measurement at different locations.

You should always check the angle during installation to avoid sharp bends. This practice improves safety and extends cable life. Safety considerations during measurement include using proper tools and maintaining a clear workspace. Accurate measurement of roof pitch angles helps you achieve reliable installation and meet safety standards.

Tip: Always double-check your angle measurements to avoid costly installation mistakes and ensure safety.

YLS Custom Length Solutions

YLS offers custom cable lengths to fit your unique installation needs. The process includes several steps:

Project kick-off: You discuss cable pitch, pin count, length, connectors, and installation requirements.

Engineering proposal: YLS converts your specifications into a manufacturable design.

Sample fabrication: YLS creates samples quickly for your review.

Testing and validation: You test the sample in your device, checking angle and installation fit.

Final sign-off: You confirm the design meets your safety and installation needs.

Mass production and global delivery: YLS produces and ships your cables on time.

Custom solutions from YLS help you manage cost, improve installation efficiency, and meet safety thresholds. You gain flexibility in design, reduce cost implications, and ensure your cables fit perfectly, even in tight spaces with challenging roof pitch angles.

Full Metric Thread Size Chart and Technical Specifications

Metric Thread Size Chart for Connector Compatibility

You need to understand how the full metric thread size chart helps you select the right connector for your flexible flat cable. The chart shows the relationship between thread diameter, pitch, and code. You use this information to match cable ends with connector threads. Each thread type has a specific code that identifies its size and material. You see thread codes like M2, M2.5, and M3 in electronics. These codes help you avoid mistakes during assembly. The chart below gives you a quick reference for common thread sizes:

Thread Code | Thread Diameter (mm) | Pitch (mm) | Material Type |

|---|---|---|---|

M2 | 2.0 | 0.4 | Steel, Brass |

M2.5 | 2.5 | 0.45 | Copper, Alloy |

M3 | 3.0 | 0.5 | Stainless Steel |

M4 | 4.0 | 0.7 | Aluminum, Plastic |

M5 | 5.0 | 0.8 | Composite Material |

You use the full metric thread size chart to check if your connector matches the cable thread. This step ensures a secure fit and reliable performance.

Tip: Always verify the thread code and material before finalizing your cable assembly.

Zif Cable Technical Specifications

You need to know the technical specifications for Zif cables to ensure safe and efficient operation. Zif cables use specific thread codes and materials to meet industry requirements. The table below summarizes the key specifications:

Specification | Value |

|---|---|

1200 Vac RMS (crimp & square post contacts), 1000 Vac RMS (PC/RC round PCB contacts), 750 Vac RMS (DL4) | |

Current Rating | 5 Amps max (crimp & square post contacts), 4 Amps max (PC/RC contact), 10 Amps up to 60 Amps max (buss contacts) |

Operating Temperature | -55°C to 105°C; DL4: -55°C to 71°C |

You see that each thread code and material type affects voltage and current ratings. Zif cables use high-quality material to withstand harsh environments. You select the right thread and material to match your device’s needs. You also check the code for compatibility with your connector.

Zif cables support a wide range of thread codes and material types.

You choose the cable based on voltage, current, and temperature requirements.

You ensure the thread matches the connector for reliable assembly.

Industry Standards and Compliance

You must follow industry standards to guarantee safety and reliability. Flexible flat cables and Zif cable products meet strict thread and material requirements. You check the code and material for compliance with global standards. The table below lists important standards:

Standard | Description |

|---|---|

Classifies material based on flammability with ratings V-0, V-1, and V-2. | |

IEC 60332 | Specifies flame propagation tests for cables to ensure fire safety. |

You look for cables with the right thread code and material certification. These standards help you choose cables that resist fire and meet safety codes. You also confirm that the cable material passes all required tests.

Note: Always select cables with certified thread codes and material to meet your industry’s safety standards.

Selecting the Right Pitch and Length for Your Application

Device Compatibility and Performance

You need to choose the right pitch and length to make sure your device works as expected. The pitch affects how many connections you can fit in a small space. Smaller pitches let you pack more connections into compact devices, which is important for smartphones, tablets, and other electronics. However, smaller pitches can also increase the risk of signal interference, like crosstalk, especially in high-speed designs. You must balance connection density with signal quality.

When you select the correct pitch, you also improve the mechanical strength of the connection. Finer pitches give you more precise control, which is important for devices that need accurate positioning. Coarser pitches allow for faster movement and can handle higher loads, which helps in applications that need more power. The pitch selection impacts not only the speed and accuracy but also the durability of your device.

Thread pitch influences speed and travel distance.

Finer pitches provide greater precision and load-bearing ability.

Smaller pitches allow higher connection density but may affect signal integrity.

Finer pitch connectors may have less mechanical engagement, which can impact durability.

Tip: Always match the pitch to your device’s needs for both electrical performance and mechanical reliability.

YLS Customization Process

YLS helps you get the exact cable you need by following a detailed customization process. This process ensures your cable matches your device’s requirements for pitch, length, and performance.

Material Preparation: YLS selects the best materials for your flexible flat cable.

Circuit Patterning: Engineers define the electrical paths with high accuracy.

Drilling: Precise holes are made for electrical connections.

Electroplating: A thin copper layer is added for better conductivity.

Layer Alignment: Multiple layers are aligned for reliable performance.

Lamination: Layers are bonded together under controlled conditions.

Cutting: The cable is shaped to the final size for easy integration.

You can request a custom cable that fits your unique application. YLS works with you at every step, from design to delivery, making sure your cable meets all your requirements for pitch and length.

Practical Selection Tips

You can follow these practical tips to make the best pitch selection and length choice for your project:

Identify the devices you want to connect. Different devices need different pitches.

Check your data transmission needs. Smaller pitches can support faster speeds but may cost more.

Think about how flexible the cable needs to be. The pitch affects how well the cable bends and handles stress.

Make sure the cable pitch matches your connector type. This step prevents assembly errors.

Balance the cost with the benefits. Smaller pitches can improve performance but may increase expenses.

Follow industry standards for pitch and length. Standardization helps with compatibility and reduces costs.

Note: Always test your cable in the real device before final production. This step helps you catch any issues with pitch or length early.

You can improve device reliability and assembly efficiency by following these tips. Careful pitch selection and length planning help you avoid costly mistakes and ensure your product performs well.

When Custom Solutions Are Needed

Unique Device Constraints

You may encounter devices with tight spaces, unusual shapes, or demanding environments. These constraints often require you to look beyond standard cable designs. Flexible flat cables with a flat, rectangular shape allow you to route connections efficiently, even in compact electronics, automotive systems, IoT devices, and robotics. You benefit from high-density connections and exceptional flexibility, which help you fit cables into limited spaces. If your project needs durability or must withstand repeated movement, custom cable assemblies can provide the right solution.

Flat, rectangular cables enhance flexibility and space efficiency.

FFCs fit into tight spaces in modern devices.

High-density connections support devices with space limitations.

Specialized Performance Requirements

Some applications demand more than just a standard cable. You may need cables that offer advanced features for specific environments or tasks. The table below shows common requirements and where you might use them:

Requirement | Application Area | Description |

|---|---|---|

EMI Shielding | Aerospace and Military | Protects against electromagnetic interference for mission-critical systems. |

Flexibility | Medical and Industrial | Supports movement and adaptability in tight spaces. |

Shielded Twisted Pairs | Medical Equipment | Reduces interference in sensitive imaging and monitoring devices. |

Low-Noise Grounding | Industrial Equipment | Minimizes EMI from heavy machinery. |

Combination Shielding | High-Speed Signal Applications | Ensures broad protection for high-performance needs. |

Medical devices often require biocompatibility, sterilization, and regulatory compliance. You may also need cables that resist wear and maintain electrical performance over time. Custom solutions help you meet these specialized needs.

How to Order Custom Zif Cables from YLS

Ordering custom Zif cables from YLS is a straightforward process. You start by gathering key specifications for your project. The table below lists the information you need to provide:

Specification | Description |

|---|---|

Pitch Size | Measure the distance between the centers of two adjacent contacts. |

Length | Tailor the cable length to your project’s layout. |

Pin Count | Count the number of pins in the connector to ensure compatibility. |

YLS offers rapid prototyping, delivering samples in as little as 48 hours, while the industry average is 3–7 days. You can request additional features such as EMI shielding, biocompatibility, or custom layouts. YLS supports OEM and ODM projects, helping you move from concept to production quickly.

Tip: Always confirm your pitch, length, and pin count before placing an order. This step ensures your cable fits and performs as expected.

You improve product reliability and assembly efficiency when you understand standard pitches and cable lengths. YLS and Zif cable products give you space-saving designs, flexibility, and rapid customization for any industry.

Advantage | Description |

|---|---|

Space-saving characteristics | Maximizes space inside devices, allowing for higher density of conductors. |

Flexibility | Can be bent, twisted, and folded to fit design needs. |

Ease of installation | Many flex cables come with connectors for quick and simple assembly. |

Durability | Designed to withstand repeated flexing and bending. |

Production efficiency | Reduces assembly time and material costs, speeding up manufacturing. |

Cost savings | Lowers expenses by using fewer materials and streamlining assembly. |

Rapid prototyping and customization | Allows adjustments in length, width, and conductor count to match applications. |

Checklist for Choosing Standard vs. Custom Cables:

Define your application requirements.

Select conductor type and count.

Choose insulation and jacket materials.

Determine shielding needs.

Add wraps or fillers if needed.

Include strength members or breather tube.

Pick connector and termination options.

Assess environmental and mechanical factors.

Ensure compliance with standards.

Specify customization needs.

Contact YLS for expert guidance or a quote. You get support for both standard and custom cable solutions.

FAQ

What is a standard pitch in flexible flat cables?

You measure standard pitch as the distance from the center of one conductor to the next. This measurement helps you match cables with connectors and ensures reliable electrical performance in your devices.

How do I select the right pitch for my application?

You should check your device’s connector specifications and space requirements. Smaller pitches fit compact electronics. Larger pitches handle higher power. Always test the cable in your device before finalizing your choice.

Can I customize cable length and pin count with YLS?

Yes, you can request custom cable lengths and pin counts from YLS. You provide your requirements, and YLS engineers design a solution that fits your project. This flexibility helps you manage total project costs.

Are Zif cables compatible with most connector brands?

You can use Zif cables with many major connector brands, such as Hirose, Molex, and JAE. Always confirm the pitch and contact type to ensure a secure fit.

Do I need to consider anything else besides pitch and length?

You should also think about insulation, shielding, and choosing masking caps for your assembly. These factors help protect your cable and improve device reliability.